1 Purpose of this method

1.1 This method provides sampling and analysis procedures to identify the presence of

organotin compounds and/or cybutryne in the anti-fouling systems on ships. The method is

designed such that the sampling and the first stage analysis could be carried out by

ship surveyors or port State control officers (PSCOs) on the survey/inspection site,

e.g. at a dry dock.

1.2 The method for organotin compounds is based on a two-stage analysis (case A under

paragraph 4.6 of the Guidelines). The first stage detects total tin as an indicator for

the presence of organotin and the second stage is necessary only in the case that the

first stage analysis providing a positive result to detect specific organotin

compounds.

1.3 The method for cybutryne analysis (case B under paragraph 4.6 of the Guidelines) is

based on a one-step analysis based on the gas chromatography/mass spectrophotometry

analytical method (GC/MS).

1.4 A simplified approach to detect organotin and cybutryne (case C under paragraph 4.6

of the Guidelines) is based on a one-step analysis using the gas chromatography/mass

spectrophotometry analytical method (GC/MS).

2

Sampling

2.1 The sampling is carried out by using abrasive paper rubbing on the surface of the

anti-fouling system. This results in collection of paint fragments of the anti-fouling

system from a thin area, less than several micrometres in depth from the surface, which

do not affect the coatings lying underneath such as sealers.

2.2 Abrasive paper is pasted on a disc of approximately 10 mm in diameter. Rubbing the

surface of the anti-fouling system with the disc collects several milligrams of the

sample on to the abrasive paper.

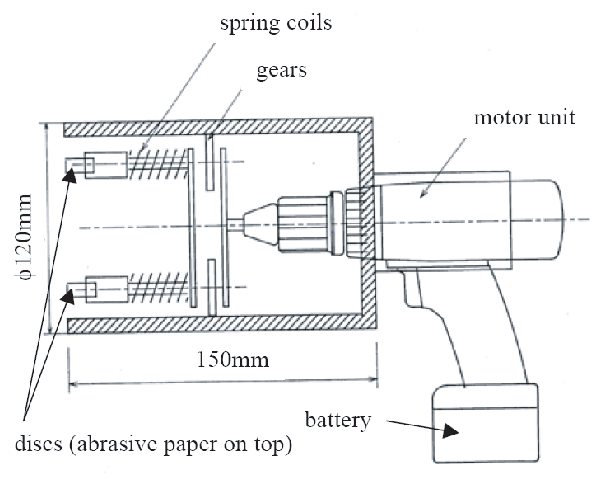

2.3 The sampling device consists of an electric motor, two (or three) rotating rods on

each of which a disc is attached, and a battery for electric power supply. The discs are

pressed on to the surface of the ship's hull by spring coils. The discs rotate

counter-clockwise while the rods turn clockwise around the centre of the device. A

schematic diagram is given in figure 1.

Figure 1. Schematic diagram of sampling device

2.4 A sampling point is selected such that the anti-fouling system is intact over an

area of approximately 50 cm x 50 cm or more.

2.5 Depending on the substances targeted as listed in Annex 1 of the AFS Convention:

-

Case A. For the analysis of organotin only, at each sampling point, three sets of

sampling, or more if necessary, should be carried out to obtain at least six

specimens.

-

Case B. For the analysis of cybutryne only, at each sampling point, three sets of

sampling, or more if necessary, should be carried out to obtain at least six

specimens.

-

Case C. For the analysis of organotin and cybutryne, at each sampling point, three

sets of sampling, or more if necessary, should be carried out to obtain at least

six specimens.

2.6 The device is pressed on the ship's hull where it is appropriate to be sampled and

held by hand. The electric motor is switched on to slide along the painted surface to

lightly scrape off the fragments of the paint onto the abrasive paper. After the sample

collection, each disc is removed from the device and stored in an inert container.

2.7 Sampling should normally be carried out with the sampling device. However, in the

case that accessibility to the sampling point is poor, it is acceptable to collect

samples with the discs by hand if necessary.

3

Analysis

Case A. Analysis of organotin only

3.1 The first-stage analysis

-

.1 The first-stage analysis is assumed to be carried out on the spot of the survey

or inspection, e.g. dry docks and sea ports. In order to accomplish the on-site

analysis, X-ray fluorescence analysis (XRF) is used in this method to detect total

tin content.

-

.2 Analytical characteristics, such as detection limit and accuracy, are highly

dependent on the type of the instrument, i.e. type of X-ray tube, spectrometer,

optical arrangement (filters or collimators), etc. Among several types of the XRF

instruments, an energy-dispersive spectrometer with a silicon drift detector

(SDD), which is compact in size and able to be operated without liquid nitrogen,

is preferable to the present analytical system for a field use, whereas

wave-length dispersion system or solid-state detector are also available if the

analysis is carried out at laboratories.

-

.3 Software customized for the tin analysis is prepared to assist the operator,

who is assumed to be a ship surveyor or PSCO, to detect total tin in the

specimens.

-

.4 The customized software may in advance need a calibration curve of the

characteristic X-ray intensity of tin in relation to the tin content particularly

in the range of 0.1 to 0.5%.

-

.5 After the preparation including the warming-up of the XRF instrument and

starting-up of the computer, a specimen (sampling disc) is placed on the sample

stage of the instrument. Afterwards, analysis is executed by the customized

software. A single batch of analysis for one specimen normally takes five minutes

and the result is shown on a display automatically.

-

6. Since the XRF analysis does not affect any properties of the specimens, all of

the collected specimens (six to nine specimens), including those for the second

analysis and storage, are able to be used for this analysis.

3.2 Interpretation of the result at the first-stage analysis

-

.1 Following the procedures above, XRF data of six, or nine, specimens are

obtained for each sampling point. Omitting the maximum and minimum values from the

data, an average of the tin content is calculated from the intermediate values for

the representing value of the sampling point.

-

.2 Compliance with the Convention is assumed when none of the tin contents

(average values) from the samples do not exceed the sum of the threshold (2,500 mg

per kg) and a tolerance (500 mg per kg).

-

.3 When one or more average values of samples from different sampling points do

not meet the above criteria, the samples should be sent to a laboratory for the

second stage analysis. Regardless of the results, it is also possible to undergo

the second stage analysis when the surveyor or PSCO considers that it is necessary

to do so.

3.3 Second-stage analysis

-

.1 Since the second-stage analysis provides the final and definitive results of

the samples, the method should be thoroughly reviewed by experts based on

scientific evidence. The following is a brief summary of a tentative methodology

for the second stage analysis.

-

.2 The collected paint specimens are removed from the abrasive paper and total

mass is measured with an electronic balance to an order of 0.1 mg. The specimens

are hydrolysed with sodium hydroxide aqueous solution, extracted with organic

solvent, and then derivatized with propylmagnesium bromide. After cleaning up the

extract, analysis using high resolution gas chromatography/mass spectrometry

(GC/MS) is carried out. For quantification analysis, tetrabutyl tin d36 is added

as the internal standard.

-

.3 These analyses provide the data of chemical species and their content (mg per

kg of the specimens). The content of organotin is obtained in a unit of mg per kg

of dry paint.

Case B. For the analysis of cybutryne only

3.4 The collected paint specimens are removed from the abrasive paper and total mass is

measured with an electronic balance to an order of 0.1 mg. The following procedure is

proposed for determining the concentration of cybutryne:

-

.1 sample extraction using ethyl acetate with added internal standard (ametryn)

using an ultrasonic bath for 15 minutes;

-

.2 centrifugation of the samples at 600 rcf for 5 minutes;

-

.3 analysis of the supernatant using high resolution capillary GC/MS, with the MS

operating in SIM mode;

-

.4 quantification using reference cybutryne solutions and an internal standard

normalization procedure; and

-

.5 modified GC/MS methods resulting in an expanded measurement uncertainty (k=2;

95% confidence) of 25% are acceptable.

Case C. Simplified approach to detect organotin and cybutryne

3.5 The collected paint specimens are removed from the abrasive paper and total mass is

measured with an electronic balance to an order of 0.1 mg. The following procedure is

proposed for determining the concentration of organotin and cybutryne:

-

.1 sample extraction using toluene with added internal standard (ametryn) using an

ultrasonic bath for 15 minutes;

-

.2 addition of sodium hydroxide aqueous solution to hydrolyse the sample and to

facilitate the extraction to the toluene;

-

.3 centrifugation of the samples at 600 rcf for 5 minutes;

-

.4 collection of the supernatant and derivatization with propylmagnesium bromide;

-

.5 clean-up of the extract;

-

.6 analysis of the toluene solution using high resolution capillary GC/MS, with

the MS operating in SIM mode;

-

.7 cybutryne quantification using reference cybutryne solutions and an internal

standard normalization procedure; organotin quantification using tetrabutyl tin

d36 is added as the internal standard; and

-

.8 modified GC/MS methods resulting in an expanded measurement uncertainty (k=2;

95% confidence) of 25% are acceptable.

4

Compliance with the Convention

Case A. Analysis of organotin only

4.1 Compliance with the Convention for organotin compounds is assumed when the results

from the second-stage analysis meet the following requirements at the same time:

-

.1 no more than 25% of the total number of samples yield results above 2,500

milligrams tin as organic form per kilogram dry paint (2,500 mg Sn/kg of dry

paint); and

-

.2 no sample of the total number of specimens shows a concentration of tin as

organic form higher than the sum of the threshold value plus the tolerance range,

i.e. no sample must exceed the concentration 3,000 mg Sn/kg dry paint.

4.2 When the result does not meet the above criteria, it is interpreted to mean that

organotin compounds are present in the anti-fouling system at a level where they would

act as a biocide.

Case B. Analysis of cybutryne only

4.3 Compliance with the Convention for cybutryne is assumed when the results from the

cybutryne analysis meet the following criterion:

4.4 When the result does not meet the above criterion, it is interpreted to mean that

cybutryne is present in the anti-fouling system at a level where it would act as a

biocide.

Case C. Simplified approach to detect organotin and cybutryne

4.5 Compliance with the Convention for organotin compounds and cybutryne is assumed when

the results from the cybutryne and organotin analysis meet the two conditions below:

-

.1 for organotin, the average value of the total number of specimens shows a

concentration below the threshold plus the tolerance range i.e. 3,000 mg Sn/kg of

dry paint; and

-

.2 for cybutryne, the average value of the total number of specimens shows a

concentration below the threshold plus the tolerance range, i.e. 1,250 mg of

cybutryne per kg of dry paint.

4.6 When the results do not meet one of the conditions above, it is interpreted to mean

that organotin compounds or cybutryne are present in the anti-fouling system at a level

where they would act as a biocide.

Appendix to Method 2

RECORD SHEET FOR THE SAMPLING AND ANALYSIS OF ANTI-FOULING SYSTEMS ON SHIP HULLS –

ORGANOTIN COMPOUNDS AND/OR CYBUTRYNE

|

|

|

Record number:

|

| Section 1:

Administration

|

| 1. Country

|

2. Location

|

| 3. Date

|

| 4. Reason for

survey/inspection

|

|

| 5. Details of the

ship

|

|

|

5.1 Name of ship

|

|

|

5.2 Distinctive number or

letters

|

|

|

5.3 Gross tonnage

|

5.4 Year of build

|

|

|

5.5 Owner or operator of

ship

|

|

|

5.6 Flag State

|

5.7 Class of ship

|

|

|

5.8 Authority of AFS

certificate

|

|

|

5.9 Date of issue

|

|

|

5.10 Date of last

endorsement

|

|

|

5.11 IMO number

|

|

|

5.12 Name of

shipmaster

|

|

|

5.13 Product name of

anti-fouling system

|

|

|

5.14 Name of

manufacturer

|

|

|

5.15 Name of shipyard where

applied

|

|

|

5.16 Comments

|

| 6. Inspecting official's

details

|

|

|

6.1 Name

|

|

|

6.2 Comments

|

Section 2: Sampling and analysis

Case A. Analysis of organotin only

|

|

|

|

|

|

|

|

|

|

Record number

|

|

|

|

Sampling and Stage 1 analysis (X-ray

fluorescence analysis)

|

|

|

|

Date:

|

Instrument I.D.

|

|

|

|

|

|

|

|

|

| Sample location

|

Specimen

I.D.

|

Sample disc

|

Content of tin

|

max

|

min

|

Average

|

| (mg/kg)

|

|

A

|

A1

|

☐ abrasive

|

|

|

|

|

| A2

|

☐ metal

|

|

|

|

|

| A3

|

☐ others

|

|

|

|

Average

|

| A4

|

☐ abrasive

|

|

|

|

|

| A5

|

☐ metal

|

|

|

|

mg/kg

|

| A6

|

☐ others

|

|

|

|

☐ >

2,500 mg/kg

|

| A7

|

☐ abrasive

|

|

|

|

☐ >

3,000 mg/kg

|

| A8

|

☐ metal

|

|

|

|

|

| A9

|

☐ others

|

|

|

|

|

|

B

|

B1

|

☐ abrasive

|

|

|

|

|

| B2

|

☐ metal

|

|

|

|

|

| B3

|

☐ others

|

|

|

|

Average

|

| B4

|

☐ abrasive

|

|

|

|

|

| B5

|

☐ metal

|

|

|

|

mg/kg

|

| B6

|

☐ others

|

|

|

|

☐ >

2,500 mg/kg

|

| B7

|

☐ abrasive

|

|

|

|

☐ >

3,000 mg/kg

|

| B8

|

☐ metal

|

|

|

|

|

| B9

|

☐ others

|

|

|

|

|

|

C

|

C1

|

☐ abrasive

|

|

|

|

|

| C2

|

☐ metal

|

|

|

|

|

| C3

|

☐ others

|

|

|

|

Average

|

| C4

|

☐ abrasive

|

|

|

|

|

| C5

|

☐ metal

|

|

|

|

mg/kg

|

| C6

|

☐ others

|

|

|

|

☐ >

2,500 mg/kg

|

| C7

|

☐ abrasive

|

|

|

|

☐ >

3,000 mg/kg

|

| C8

|

☐ metal

|

|

|

|

|

| C9

|

☐ others

|

|

|

|

|

|

D

|

D1

|

☐ abrasive

|

|

|

|

|

| D2

|

☐ metal

|

|

|

|

|

| D3

|

☐ others

|

|

|

|

Average

|

| D4

|

☐ abrasives

|

|

|

|

|

| D5

|

☐ metal

|

|

|

|

mg/kg

|

| D6

|

☐ others

|

|

|

|

☐ >

2,500 mg/kg

|

| D7

|

☐ abrasive

|

|

|

|

☐ >

3,000 mg/kg

|

| D8

|

☐ metal

|

|

|

|

|

| D9

|

☐ others

|

|

|

|

|

|

|

| ☐ Stage 2 required

|

☐ ___ samples out of ___ are above 2,500 mg/kg

|

☐ Compliant

|

| ☐ sample(s) ___ is (are) above 3,000 mg/kg

|

| Sampled by

|

Analysed by

|

| Signature

|

Signature

|

|

|

Record number:

|

| Stage 2 analysis (Gas

chromatography/mass spectrometry)

|

| Date

|

|

|

|

|

| Instrument I.D.

|

| Comments on the method

|

| Sample I.D.

|

Specimen used

|

Content of tin (XFR analysis) (mg/kg)

|

Content of tin (as organotin) (mg/kg)

|

Compliance

|

| A

|

|

|

|

☐ > 2,500 mg/kg

|

| ☐ > 3,000 mg/kg

|

| B

|

|

|

|

☐ > 2,500 mg/kg

|

| ☐ > 3,000 mg/kg

|

| C

|

|

|

|

☐ > 2,500 mg/kg

|

| ☐ > 3,000 mg/kg

|

| D

|

|

|

|

☐ > 2,500 mg/kg

|

| ☐ > 3,000 mg/kg

|

| 4. Conclusion

|

|

|

☐Not compliant

|

___

samples out of ___ are above 2,500 mg/kg

|

|

|

sample(s) ___ is

(are) above 3,000 mg/kg

|

|

|

☐Compliant

|

|

|

|

| 5. Additional comments

|

| 6. Laboratory Name

|

| 7. Analysed by

|

8. Signature

|

Case B. Analysis of cybutryne only

|

|

Record number

|

| Sampling and

gas chromatography/mass spectrometry analysis

|

| Date:

|

Instrument

I.D.

|

|

|

|

| Sample location

|

Specimen I.D.

|

Sample disc

|

Comments on the samples and sampling

|

Comments on the sample location

|

| procedure

|

|

A

|

A1

|

☐ abrasive

|

|

|

| A2

|

☐ metal

|

|

|

| A3

|

☐ others

|

|

|

| A4

|

☐ abrasive

|

|

|

| A5

|

☐ metal

|

|

|

| A6

|

☐ others

|

|

|

| A7

|

☐ abrasive

|

|

|

| A8

|

☐ metal

|

|

|

| A9

|

☐ others

|

|

|

|

B

|

B1

|

☐ abrasive

|

|

|

| B2

|

☐ metal

|

|

|

| B3

|

☐ others

|

|

|

| B4

|

☐ abrasive

|

|

|

| B5

|

☐ metal

|

|

|

| B6

|

☐ others

|

|

|

| B7

|

☐ abrasive

|

|

|

| B8

|

☐ metal

|

|

|

| B9

|

☐ others

|

|

|

|

C

|

C1

|

☐ abrasive

|

|

|

| C2

|

☐ metal

|

|

|

| C3

|

☐ others

|

|

|

| C4

|

☐ abrasive

|

|

|

| C5

|

☐ metal

|

|

|

| C6

|

☐ others

|

|

|

| C7

|

☐ abrasive

|

|

|

| C8

|

☐ metal

|

|

|

| C9

|

☐ others

|

|

|

|

D

|

D1

|

☐ abrasive

|

|

|

| D2

|

☐ metal

|

|

|

| D3

|

☐ others

|

|

|

| D4

|

☐ abrasive

|

|

|

| D5

|

☐ metal

|

|

|

| D6

|

☐ others

|

|

|

| D7

|

☐ abrasives

|

|

|

| D8

|

☐ metal

|

|

|

| D9

|

☐ others

|

|

|

|

|

|

| Average concentration of cybutryne (mg of cybutryne per kg of

dry paint)

|

|

| Sampled by

|

Analysed by

|

| Signature

|

Signature

|

Case C. Simplified approach to detect organotin and cybutryne

|

|

Record number

|

| Sampling and

gas chromatography/mass spectrometry analysis

|

| Date:

|

Instrument

I.D.

|

|

|

|

| Sample location

|

Specimen I.D.

|

Sample disc

|

Comments on the samples and sampling

|

Comments on the sample location

|

| procedure

|

|

A

|

A1

|

☐ abrasive

|

|

|

| A2

|

☐ metal

|

|

|

| A3

|

☐ others

|

|

|

| A4

|

☐ abrasive

|

|

|

| A5

|

☐ metal

|

|

|

| A6

|

☐ others

|

|

|

| A7

|

☐ abrasive

|

|

|

| A8

|

☐ metal

|

|

|

| A9

|

☐ others

|

|

|

|

B

|

B1

|

☐ abrasive

|

|

|

| B2

|

☐ metal

|

|

|

| B3

|

☐ others

|

|

|

| B4

|

☐ abrasive

|

|

|

| B5

|

☐ metal

|

|

|

| B6

|

☐ others

|

|

|

| B7

|

☐ abrasive

|

|

|

| B8

|

☐ metal

|

|

|

| B9

|

☐ others

|

|

|

|

C

|

C1

|

☐ abrasive

|

|

|

| C2

|

☐ metal

|

|

|

| C3

|

☐ others

|

|

|

| C4

|

☐ abrasive

|

|

|

| C5

|

☐ metal

|

|

|

| C6

|

☐ others

|

|

|

| C7

|

☐ abrasive

|

|

|

| C8

|

☐ metal

|

|

|

| C9

|

☐ others

|

|

|

|

D

|

D1

|

☐ abrasive

|

|

|

| D2

|

☐ metal

|

|

|

| D3

|

☐ others

|

|

|

| D4

|

☐ abrasives

|

|

|

| D5

|

☐ metal

|

|

|

| D6

|

☐ others

|

|

|

| D7

|

☐ abrasives

|

|

|

| D8

|

☐ metal

|

|

|

| D9

|

☐ others

|

|

|

|

|

| Average content of organotin (mg of organotin per kg of dry

paint)

|

|

| Average concentration of cybutryne (mg of cybutryne per kg of

dry paint)

|

|

| Sampled by

|

Analysed by

|

| Signature

|

Signature

|

| Section 3: Final

conclusion

|

| 1.

Conclusion

|

|

|

☐ Anti-fouling system is compliant with the

AFS Convention 2001.

|

|

|

☐ Anti-fouling system is NOT compliant with the AFS

Convention 2001.

|

| 2. Comments

|

|

| 3. Processed official

|

|

| 3.1 Name

|

3.2 Date

|

| 3.3 Signature

|

|

| 4. Authorized administrator

|

|

| 4.1 Name

|

4.2 Date

|

| 4.3 Signature

|

|