4.1

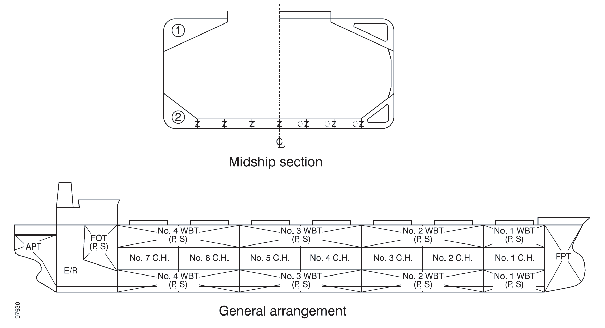

Bulk Carrier: a bulk carrier

is a cargo ship intended for carriage of dry bulk cargoes such as

grain, coal, ore, etc., provided with topside tanks at both shoulders

and bilge hoppers in both double bottom wings in the cargo space.

Below is a typical midship section

and general arrangement .

Figure 1 Typical midship section and general arrangement

4.2

Topside tank: tanks provided

in cargo spaces at both shoulders as the space (1) shown in the drawing

above.

4.3

Bilge hopper: a conventional

bulk carrier has hopper structures at the both bottom wings in cargo

holds. This part of cargo hold is called "bilge hopper". Double bottom

tanks in way of bilge hopper are often called "bilge hopper tank".

In the diagram, the space is shown as (2).

4.4

Girder and floor in double bottom: provided

in double bottom tanks, "girder" usually indicates a strong frame

usually with the full depth provided in ship's longitudinal direction.

The girder fitted on the center line is called "center girder", while

the others are called "side girders". "Floor" means strong framing

in ship's transverse direction provided in double bottom. In double

bottom beneath cargo holds, floor plates are usually solid ones with

full depth of the tank. In this regard, solid ones are called "solid

floors" distinctively from the others.

4.5

Transverse web in topside tanks: strong

framing provided in topside tanks in transverse direction, also called

"transverse ring". Of a transverse ring in a topside tank, the part

supporting the upper deck is called deck transverse, the part attached

to the side shell is called side transverse and the part attached

to the bottom is called (topside) bottom transverse.

4.6

Transverse web in bilge hopper tanks: strong

framing provided in the transverse direction in a bilge hopper tank.

Transverse webs are called "bilge hopper transverse", "side transverse"

and "bottom transverse" in accordance with the name of the hull members

to which they are attached.

4.7

Framing of various kinds: on

a typical bulk carrier, framing

is designed as a longitudinal system in topside and double bottom

tanks and as transverse system at cargo hold side shell. Framing fitted

in ship's longitudinal direction is called "longitudinals". To identify

them in detail, the name of the plate they are attached to is added

such as "deck longitudinals", "side longitudinals", "bottom longitudinals",

etc. Framing attached to the side shell in the cargo holds are called

"hold frames", "side frames", "main frames", "shell frames", etc.

Figure 2 Typical cross section of cargo ship (bulk carrier)