As a means of assuring continued proper adjustment of the

apparatus, the following tests should be performed on a daily basis,

or more frequently if the nature of the specimens makes this necessary.

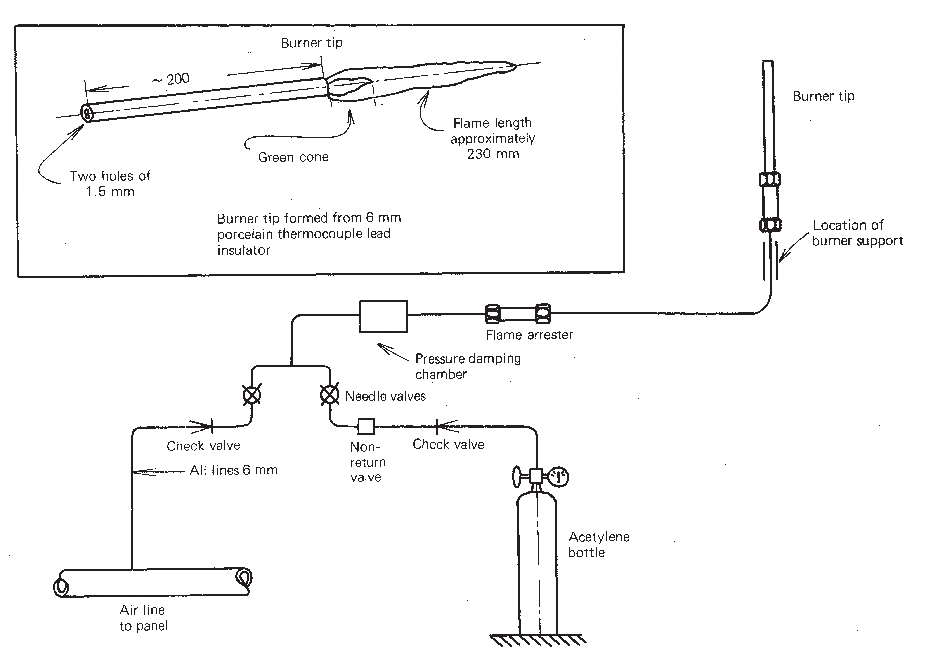

6.2.1 Adjustment of the Pilot Burner, the acetylene and

air supply should be adjusted to provide a flame length of about 230

mmfootnote. When this has been done, the

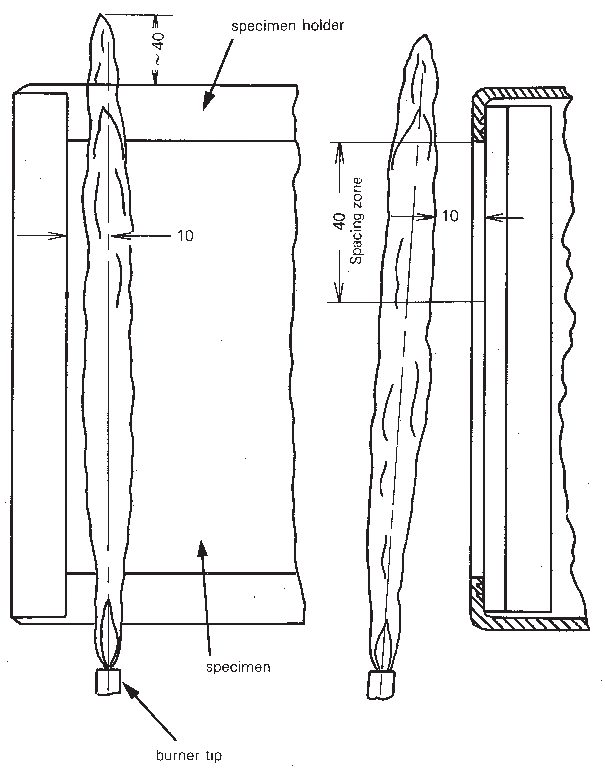

flame length as viewed in a darkened laboratory will be seen to extend

about 40 mm above the upper retaining flange of the specimen holder.

The burner spacing from the specimen is adjusted while the radiant

source is operating by the use of softwood splines of 3 mm thickness

and of 10 mm and 12 mm width. When these splines are moved during

a two second exposure along the flame length, between the pilot burner

flame and a dummy specimen surface, the 10 mm spline should not be

charred but the 12 mm spline should show char. With the specimen in

the vertical position, the charring of the 12 mm spline should occur

over a vertical distance of at least 40 mm from the upper exposed

edge of the specimen (see Figure

9).

Figure 8 Pilot burner details and connections

Figure 9 Position of pilot flame

6.2.2 The stack gas thermocouples should be cleaned

by light brushing at least daily. This cleaning may be required even

more frequently, in some instances before each test, when materials

producing heavy soot clouds are tested. These thermocouples should

also be individually checked for electrical continuity to ensure the

existence of a useful thermojunction. Following daily cleaning of

the parallel connected stack gas thermocouples, both they and the

compensating junction should be checked to verify that the resistance

between them and the stack is in excess of 106 ohms.