1.4 Modified Proctor/Fagerberg test procedure for Iron Ore Fines

1.4.1

Scope

-

.1 The test procedure specified in this section (this

test) should only be used for determining transportable moisture limit (TML) of

iron ore fines. See individual schedule for iron ore fines.

-

.2 iron ore fines is iron ore containing both:

-

.1 10% or more of fine particles less than 1

mm; and

-

.2 50% or more of particles less than 10

mm.

-

.3 The TML of iron ore fines is taken as equal

to the critical moisture content at 80% degree of saturation according to

the modified Proctor/Fagerberg method test.

-

.4 The test procedure is applicable when the

degree of saturation corresponding to optimum moisture content (OMC) is 90%

or higher.

1.4.2

Modified Proctor/Fagerberg test equipment

-

.1 The Proctor apparatus (see figure 1.4.1) consists

of a cylindrical iron mould with a removable extension piece (the compaction

cylinder) and a compaction tool guided by a pipe open at its lower end (the

compaction hammer).

-

.2 Scales and weights (see 3.2) and suitable sample

containers.

-

.3 A drying oven with a controlled temperature

interval from 100°C to maximum 105°C.

-

.4 A container for hand mixing. Care should be taken

to ensure that the mixing process does not reduce the particle size by breakage or

increase the particle size by agglomeration or consistency of the test

material.

-

.5 A gas or water pycnometry equipment to determine

the density of the solid material as per a recognized standard (e.g. ASTM D5550,

AS1289, etc.)

1.4.3

Temperature and humidity

(see 1.1.3)

1.4.4

Procedure

-

.1

Establishment of a complete compaction curve

-

A representative sample according to a relevant standard (see

4.7 of this Code) of the test material is partially dried at a temperature

of approximately 60°C or less to reduce the sample's moisture to suitable

starting moisture, if needed. The representative sample for this test should

not be fully dried, except in case of moisture content measurement.

-

The total quantity of the test material should be at least three

times as big as required for the complete test sequence. Compaction tests

are executed for five to ten different moisture contents (5 to 10 separate

tests). The samples are adjusted in order that partially dry to almost

saturated samples are obtained. The required quantity per compaction test is

about 2,000 cm3.

-

At each compaction test a suitable amount of water is added to the sample of

the test material. The sample material is gently mixed before being allowed

to rest and equilibrate. Approximately one fifth of the mixed sample is

filled into the mould and levelled and then the increment is tamped

uniformly over the surface of the increment. Tamping is executed by dropping

a 150 g hammer 25 times through the guide pipe, 0.15 m each time. The

performance is repeated for all five layers. When the last layer has been

tamped, the extension piece is removed and the sample is levelled off along

the brim of the mould with care, ensuring to remove any large particles that

may hinder levelling of the sample, replacing them with material contained

in the extension piece and re-levelling.

-

When the weight of the cylinder with the tamped sample has been determined,

the cylinder is emptied, the sample is dried at 105ºC and the weight is

determined. Reference is made to ISO 3087:2011 "Iron ores – Determination of

the moisture content of a lot". The test then is repeated for the other

samples with different moisture contents.

-

Density of solid material should be measured using a gas or

water pycnometry equipment according to internationally or nationally

accepted standard, e.g. ASTM D5550 and AS 1289 (see 1.4.2.5).

-

.2

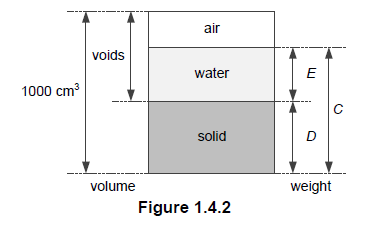

Definitions and data for calculations (see figure 1.4.2)

-

- empty cylinder, mass in grams: A

-

- cylinder with tamped sample, mass in grams: B

-

- wet sample, mass in grams: C

-

C = B - A

-

- dry sample, mass in grams: D

-

- water, mass in grams (equivalent to volume in cm3):

E

- E = C - D

- Volume of cylinder: 1,000 cm3

-

.3

Calculation of main characteristics

-

- density of solid material, g/cm3 (t/m3):

d

-

- dry bulk density, g/cm3 (t/m3):

-

-

- net water content, volume %: ev

-

- void ratio: e (volume of voids divided by volume of solids)

-

- degree of saturation, percentage by volume: S

-

- gross water content, percentage by mass: W1

-

- net water content, percentage by mass: W

-

.4 Presentation of the compaction

tests

-

.5 Compaction curve

-

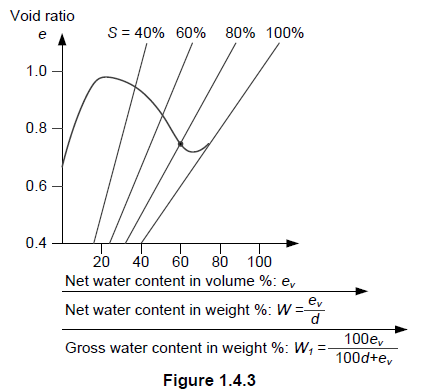

The test sequence results in a specific compaction curve (see figure 1.4.3).

-

The critical moisture content is indicated by the intersection of the

compaction curve and the line S = 80% degree of saturation. The

transportable moisture limit (TML) is the critical moisture content.

-

Optimum moisture content (OMC) is the moisture content

corresponding to the maximum compaction (maximum dry density) under the

specified compaction condition. To check the applicability of this test, the

relationship between moisture content and dry density should be evaluated,

during this test. Then the OMC and the corresponding degree of saturation

should be determined. This test procedure was developed based on the finding

that the degree of saturation corresponding to OMC of iron ore fines was 90

to 95%, while such degree of saturation of mineral concentrates was 70% to

75%. In the case that the degree of saturation corresponding to OMC is less

than 90%, the shipper should consult with an appropriate authority, for the

reason that this test may not be applicable for the material and the TML

determined by this test may be too high.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|