3 Method of test

3.1 Principle

This test procedure enables the determination of the effectiveness

of different gaseous agent extinguishing systems against spray fires,

pool fires and class A fires.

3.2 Apparatus

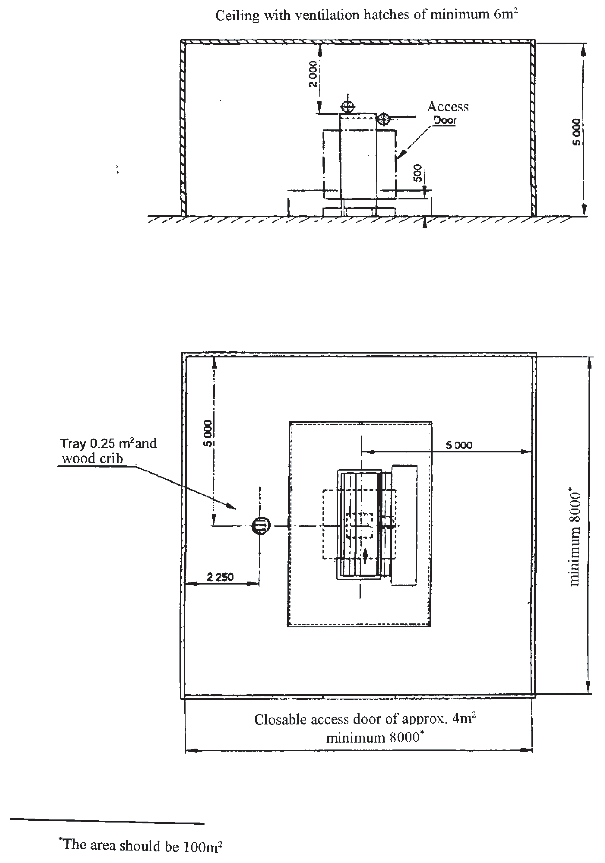

3.2.1 Test room

The tests should be performed in 100 m2 room, with

no horizontal dimension less than 8 m, with a ceiling height of 5

m. The test room should be provided with a closable access door measuring

approximately 4 m2 in area. In addition, closable ventilation

hatches measuring at least 6 m2 in total area should be

located in the ceiling.

3.2.2 Integrity of test enclosure

The test enclosure is to be nominally leak tight when doors

and hatches are closed. The integrity of seals on doors, hatches,

and other penetrations (e.g., instrumentation access ports) must be

verified before each test.

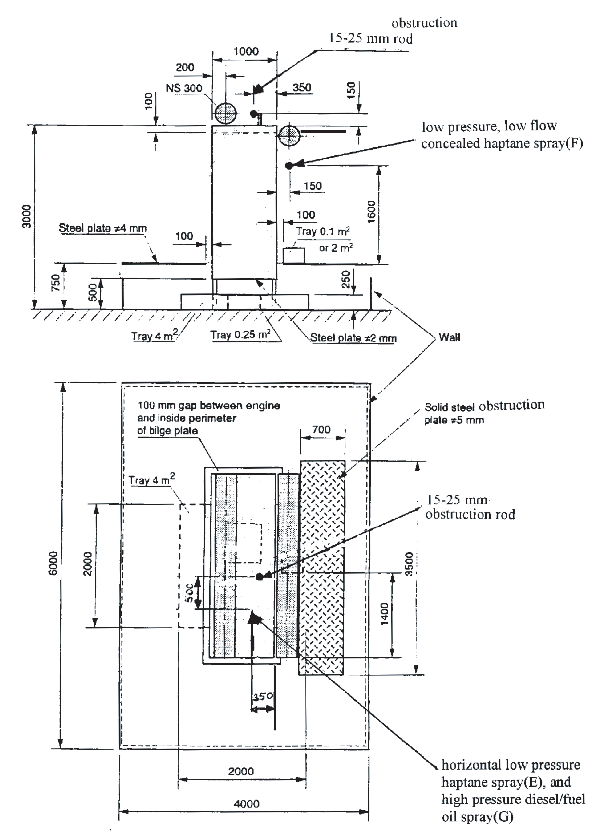

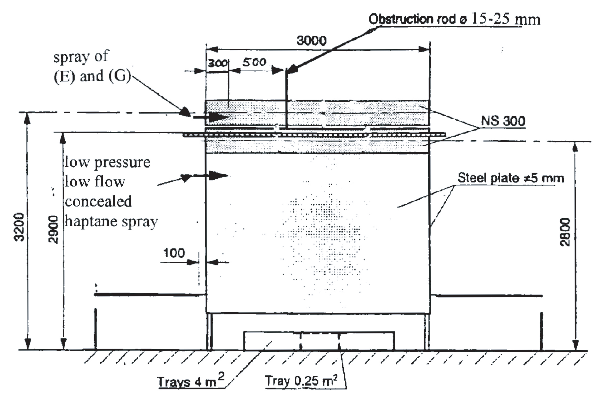

3.2.3 Engine mock-up

-

.1 An engine mock-up of size (width x length x

height) 1 m x 3 m x 3 m should be constructed of sheet steel with

a nominal thickness of 5 mm. The mock-up should be fitted with two

steel tubes diameter 0.3 m and 3 m length that simulate exhaust manifolds

and a solid steel plate. At the top of the mock-up a 3 m2 tray

should be arranged. See

figures

1, 2 and 3.

-

.2 A floor plate system 4 m x 6 m x 0.75 m high

shall surround the mock-up. Provision shall be made for placement

of the fuel trays, described in table 1, and located as described

in table 2.

Figure 1

Figure 2

Figure 3

3.2.4 Instrumentation

Instrumentation for the continuous measurement and recording

of test conditions should be employed. The following measurements

should be made:

-

.1 temperature at three vertical positions (e.g.,

1, 2.5, and 4.5 m)

-

.2 enclosure pressure

-

.3 gas sampling and analysis, at mid-room height,

for oxygen, carbon dioxide, carbon monoxide, and relevant halogen

acid products, e.g., hydrogen iodide, hydrofluoric acid, hydrochloric

acid

-

.4 means of determining flame-out indicators

-

.5 fuel nozzle pressure in the case of spray fire

-

.6 fuel flow rate in the case of spray fires

-

.7 discharge nozzle pressure

3.2.5 Nozzles

-

3.2.5.1 For test purposes, nozzles should be located

within 1 m of the ceiling.

-

3.2.5.2 If more than one nozzle is used they should

be symmetrically located.

3.2.6 Enclosure temperature

The ambient temperature of the test enclosure at the start of

the test should be noted and serve as the basis for calculating the

concentration that the agent would be expected to achieve at that

temperature and with that agent weight applied in the test volume.

3.3 Test fires and programme

3.3.1 Fire types

The test programme, as described in table

3, should employ test fires as described in table 1.

Achieve ignition of the crib by burning commercial grade

heptane in a square steel tray 0.25 m2 in area. During

the pre-burn period the crib should be placed centrally above the

top of the tray a distance of 300 to 600 mm.

Table 1 Parameters of Test

Fires

| Parameters of Test Fires

|

| Fire

|

Type

|

Fuel

|

Fire Size,

MW

|

Remarks

|

| A

|

76–100 mm ID

can

|

Heptane

|

0.0012

to 0.002

|

Tell

tale

|

| B

|

0.25 m²

Tray

|

Heptane

|

0.35

|

|

| C

|

2 m² Tray

|

Diesel/Fuel

Oil

|

3

|

|

| D

|

4 m² Tray

|

Diesel/Fuel

Oil

|

6

|

|

| E

|

Low pressure

spray

|

Heptane 0.16 ± 0.01

kg/s

|

5.8

|

|

| F

|

Low pressure, low

flow spray

|

Heptane 0.03 ±

0.005 kg/s

|

1.1

|

|

| G

|

High pressure

spray

|

Diesel/Fuel Oil 0.05

± 0.002 kg/s

|

1.8

|

|

| H

|

Wood crib

|

Spruce or

Fir

|

0.3

|

See Note 2

|

| I

|

0.10 m²

Tray

|

Heptane

|

0.14

|

|

| Notes to Table 1:

|

|

|

| 1

|

Diesel/Fuel Oil means light diesel or

commercial fuel oil.

|

| 2

|

The wood crib should be substantially the same as described in

ISO/TC21/SC 5/WG 8 ISO Draft International Standard, Gaseous fire

extinguishing systems, Part 1: General Requirements. The crib should

consist of six, trade size 50 mm x 50 mm by 450 mm long, kiln dried

spruce or fir lumber having a moisture content between 9% and 13%. The

members should be placed in 4 alternate layers at right angles to one

another. Members should be evenly spaced forming a square

structure.

|

|

|

|

|

3.3.2 Test programme

The fire test programme should employ test fires singly or in

combination, as outlined in table 3.

-

3.3.2.1 All applicable tests of table 3 should be conducted for every

new fire extinguishant gas, or mixture of gases.

-

3.3.2.2 Only Test 1 is required to evaluate new

nozzles and related distribution system equipment (hardware) for systems

employing fire extinguishants that have successfully completed the

requirements of 3.3.2.1. Test 1 should be conducted to establish and

verify the manufacturer's minimum nozzle design pressure.

Table 2 Spray fire test

parameters

| Spray fire test parameters

|

| Fire Type

|

Low Pressure

(E)

|

Low pressure, Low

flow (F)

|

High pressure

|

| Spray

nozzle

|

Wide spray angle (120

to 125°) full cone type

|

Wide

spray angle (80°) full cone type

|

Standard angle (at 6 Bar) full cone type

|

| Nominal fuel

pressure

|

8 Bar

|

8.5 Bar

|

150 Bar

|

| Fuel flow

|

0.16 ± 0.01

kg/s

|

0.03 ± 0.005

kg/s

|

0.050 ± 0.002 kg/s

|

| Fuel

temperature

|

20 ± 5°C

|

20 ± 5°C

|

20 ± 5°C

|

| Nominal heat release

rate

|

5.8 ± 0.6 MW

|

1.1 ± 0.1 MW

|

1.8 ± 0.2 MW

|

Table 3 Test Programme

| Test Programme

|

| Test No.

|

Fire Combinations (See Table 1)

|

| 1

|

A:

|

Tell tales, 8 corners.

See note 1.

|

| 2–a

|

B:

|

0.25 m² heptane tray

under engine mock up

|

|

|

E:

|

Horizontal LP spray directed at 15–25 mm rod 0.5 m away

|

| See

Note 2

|

G:

|

HP

diesel fuel oil spray on top of engine mock up

|

|

|

|

Total

Fire Load: 0.49 MW

|

| 2–b

|

B:

|

0.25

m² heptane tray under mock up

|

|

|

I:

|

0.10

m² heptane tray on deck plate located below sold steel

|

| See

Note 2

|

|

obstruction plate.

|

|

|

|

Total

Fire Load: 0.49 MW

|

| 3

|

C:

|

2 m²

diesel/fuel oil tray on deck plate located below sold steel obstruction

plate

|

|

|

H:

|

Wood

crib positioned as in Figure 1

|

|

|

F:

|

Low

pressure, low flow horizontal spray — concealed — with impingement on

inside of engine mock-up wall.

|

|

|

|

Total

Fire Load: 4.4 MW

|

| 4

|

D:

|

4 m²

Diesel tray under engine mock-up

|

|

|

|

Total

Fire Load: 6 MW

|

| Notes to table 3:

|

|

| 1

|

Tell-tale fire cans should be located as

follows:

|

|

|

(a) in upper corners of enclosure 150 mm

below ceiling and 50 nn from each wall;

|

|

|

(b) in corners on floors 50mm from

walls.

|

| 2

|

Test 2–a is for use in evaluating

extinguishing systems having discharge times of 10 seconds or

less.

|

|

|

Test 2–b is for use in evaluating

extinguishing systems having discharge times greater than 10

seconds.

|

3.4 Extinguishing system

3.4.1 System installation

The extinguishing system should be installed according to the

manufacturer's design and installation instructions. The maximum vertical

distance should be limited to 5 m.

3.4.2 Agent

-

3.4.2.1 Design concentration

The agent design concentration is that concentration (in volume

per cent) required by the system designer for the fire protection

application.

-

3.4.2.2 Test concentration

The concentration of agent to be used in the fire extinguishing

tests should be the design concentration specified by the extinguishing

system manufacturer, except for Test 1 which should be conducted at

77% of the manufacturer's recommended design concentration but in

no case at less than the cup burner extinguishing concentration.

-

3.4.2.3 Quantity of agent

The quantity of agent to be used should be determined as follows:

3.5 Procedure

3.5.1 Fuel levels in trays

The trays used in the test should be filled with at least 30

mm fuel on a water base. Freeboard should be 150 ± 10 mm.

3.5.2 Fuel flow and pressure measurements

For spray fires, the fuel flow and pressure should be measured

before and during each test.

3.5.3 Ventilation

-

3.5.3.1 Pre-burn period

During the pre-burn period the test enclosure should be well

ventilated. The oxygen concentration, as measured at mid-room height,

shall not be less than 20 volume per cent at the time of system discharge.

-

3.5.3.2 End of pre-burn period

Doors, ceiling hatches, and other ventilation openings should

be closed at the end of the pre-burn period.

3.5.5 Measurements and observations

-

3.5.5.1 Before test

-

.1 temperature of test enclosure, fuel and engine

mock-up

-

.2 initial weights of agent containers

-

.3 verification of integrity agent distribution

system and nozzles

-

.4 initial weight of wood crib.

-

3.5.5.2 During test

-

.1 start of the ignition procedure

-

.2 start of the test (ignition)

-

.3 time when ventilating openings are closed

-

.4 time when the extinguishing system is activated

-

.5 time from end of agent discharge

-

.6 time when the fuel flow for the spray fire

is shut off

-

.7 time when all fires are extinguished

-

.8 time of re-ignition, if any, during soak period

-

.9 time at end of soak period

-

.10 at the start of test initiate continuous monitoring

as per 3.2.4.

3.5.6 Tolerances

Unless otherwise stated, the following tolerances should apply:

| .1

|

length

|

±2 % of

value

|

| .2

|

volume

|

±5 % of

value

|

| .3

|

pressure

|

±3 % of

value

|

| .4

|

temperature

|

±5 % of

value

|

| .5

|

concentration

|

±5 % of

value.

|

These tolerances are in accordance with ISO standard 6182/1,

February 1994 edition [4].

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|