7.5 Positioning of Thermocouples

on the Specimen

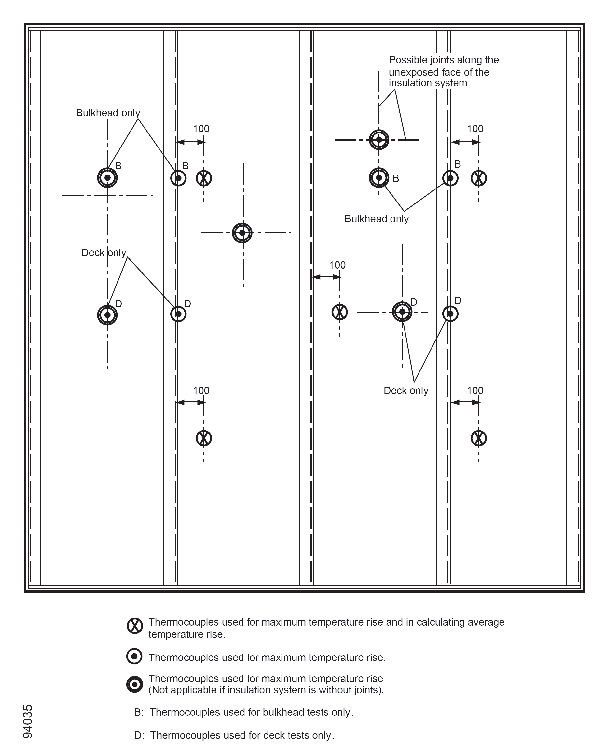

7.5.1 "A" class divisions, excluding doors

The surface temperatures on the unexposed face of the test

specimen should be measured by thermocouples located as shown in Figures 7 and 8:

-

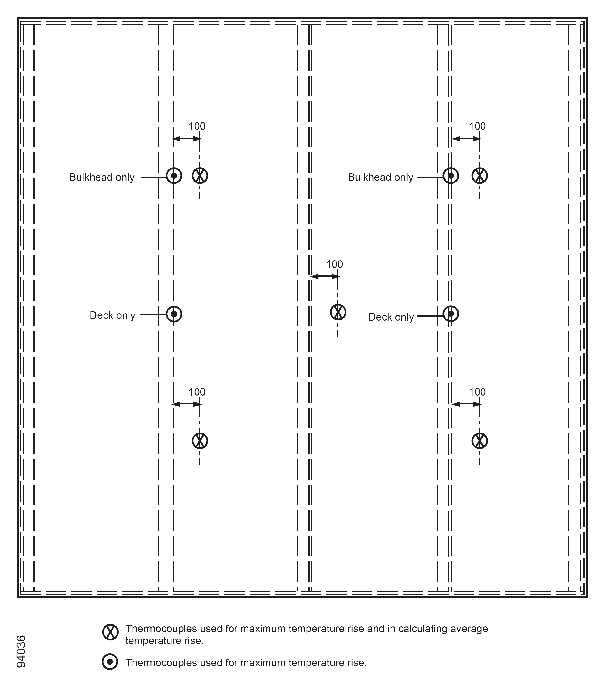

.1 five thermocouples, one at the centre of the

test specimen and one at the centre of each of the four quarters,

all positioned at least 100 mm away from the nearest part of any joints

and/or at least 100 mm away from the welds to any stiffeners;

-

.2 two thermocouples, one placed over each of

the central stiffeners and for a bulkhead at 0.75 height of the specimen

and for a deck at mid-length of the deck;

-

.3 two thermocouples, each placed over a vertical

(longitudinal) joint, if any, in the insulation system and positioned

for a bulkhead at 0.75 height of the specimen and for a deck at mid-length

of the deck;

-

.4 when a construction has two differently orientated

joint details, for example normal to each other, then two thermocouples

additional to those already described in 7.5.1.3 above should be used,

one on each of two intersections;

-

.5 when a construction has two different types

of joint detail, then two thermocouples should be used for each type

of joint;

-

.6 additional thermocouples, at the discretion

of the testing laboratory or Administration, may be fixed over special

features or specific construction details if it is considered that

temperatures higher than those measured by the thermocouples listed

above may result; and

-

.7 the thermocouples specified in 7.5.1.4 to 7.5.1.6

above for measurements on bulkheads, e.g. over different joint types

or over joint intersections, should, where possible, be positioned

in the upper half of the specimen.

Figure 7 Position of unexposed-face thermocouples for `A' class division:

insulated face to the laboratory

Figure 8 Position of unexposed-face thermocouples for `A' class division: flat

face of structural steel core to the laboratory

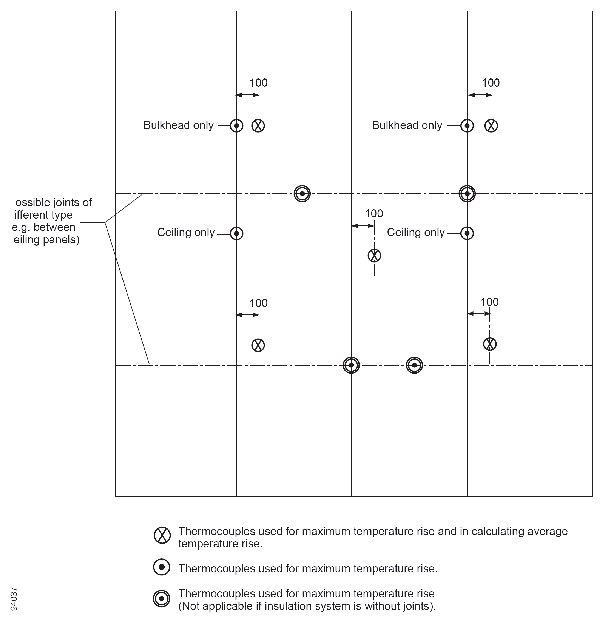

7.5.2 "B" and "F" class divisions, excluding doors

The surface temperatures on the unexposed face of the test

specimen should be measured by thermocouples located as shown in Figure 9:

-

.1 five thermocouples, one at the centre of the

test specimen and one at the centre of each of the four quarters,

all positioned at least 100 mm away from the nearest part of any joints;

-

.2 two thermocouples, each placed over a vertical

(longitudinal) joint, if any, in the division/insulation system and

positioned for a bulkhead at 0.75 height of the specimen and for a

deck/ceiling at mid-length of the deck/ceiling; and

-

.3 additional thermocouples, as required by 7.5.1.4

to 7.5.1.7 above.

Figure 9 Position of unexposed-face thermocouples for `B' and `F' class

divisions

7.5.3 "A", "B" and "F" class doors

The surface temperatures on the unexposed face of the test

specimen should be measured by:

-

.1 five thermocouples, one at the centre of the

door leaf and one at the centre of each of the four quarters of the

door leaf, all positioned at least 100 mm away from the edge of the

door leaf, from any stiffeners, from any door furniture and from any

special features or specific constructional details;

-

.2 if the door leaf incorporates stiffeners, two

additional thermocouples, one placed over each of two stiffeners in

the central portion of the door;

-

.3 additional thermocouples, at the discretion

of the testing laboratory or Administration, may be fixed over special

features or specific constructional details if it is considered that

temperatures higher than those measured by the thermocouples listed

above may result. Any additional thermocouples fixed to the door frame,

or to any part of the door leaf, which is closer than a distance of

100 mm from the gap between the edge of the door leaf and the frame

should not be used for the purpose of classification of the test specimen,

and if provided are for information only;

-

.4 the thermocouples specified in 7.5.3.2 and

7.5.3.3 above should, where possible, be positioned in the upper half

of the specimen; and

-

.5 when testing double-leaf door assemblies, the

requirements should be applied to each door leaf separately.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|