By 2.1

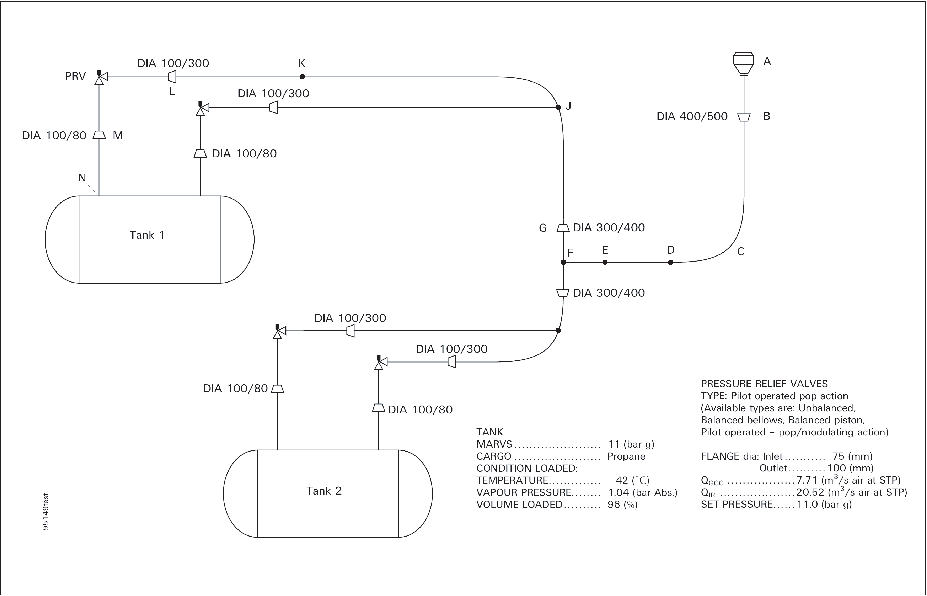

Figure 1 is a simplified flow sheet

of a cargo tank vent system with one vent stack connected to two tanks.

The system has been divided into sections between nodes, marked by

capital letters A to N, at changes in pipe diameter and at interconnections

with flows from other relief valves at F and J.

Table 1 lists the vent

pipe lengths and external surfaces areas, the fittings in the vent

system and their Friction Resistance Factors. Table 2 gives some typical values

for Friction Resistance Factors (N). N may vary with pipe diameter.

Figure 1 Simplified Flow Sheet of a Cargo Tank Vent System With One Vent Stack

Connected Two Tanks

Table 1 List of Vent Pipe Lengths

and Surface Areas, Fittings and Dynamic Loss Coefficients

| Pipe section

|

Length

(mm)

|

Pipe

Diameter (mm)

|

Surface

area (m2)

|

Fitting

|

Specification

|

Dynamic

loss coefficients N

|

Pipe

|

|

| A

|

1,080

|

500/750

|

2.04

|

A =

Cowl/Vent Exit

|

|

2.25

|

|

2.25

|

| A-B

|

1,565

|

500

|

2.46

|

|

|

|

0.063

|

0.063

|

| Section

total

|

|

|

4.50

|

|

|

|

|

2.313

|

| B-C

|

2,650

|

400

|

3.331

|

B = Conical

Expansion

|

d/D =

0.8

|

*

|

0.132

|

0.132

|

| C-D

|

2,546

|

400

|

3.20

|

C = Long

Radius Bend

|

90°

|

0.3

|

0.127

|

0.427

|

| D-E

|

14,880

|

400

|

18.701

|

D = Bend

|

45°

|

0.2

|

0.744

|

0.944

|

| E-F

|

2,093

|

400

|

2.63

|

E =

Bend

|

45°

|

0.2

|

0.105

|

0.305

|

| Section

total

|

|

|

27.86

|

|

|

|

|

2.008

|

| F-G

|

642

|

400

|

0.81

|

F =Hard

Tee

|

|

1.1

|

0.032

|

1.132

|

| G-J

|

1,066

|

300

|

1.00

|

G = Conical

Expansion

|

d/D =

0.75

|

*)

|

0.071

|

0.071

|

| Section

total

|

|

|

1.81

|

|

|

|

|

|

| J-K

|

1,340

|

300

|

1.263

|

J = Soft

Tee

|

|

0.3

|

0.089

|

0.389

|

| K-L

|

481

|

300

|

0.453

|

K =

Bend

|

45°

|

0.2

|

0.032

|

0.232

|

| Section

total

|

|

|

1.72

|

|

|

|

|

0.621

|

| L-PRV

|

216

|

300/100

|

|

L =

Conical Expansion

|

d/D =

0.33

|

*

|

0.043

|

0.043

|

| PRV-M

|

108

|

80

|

|

|

|

|

0.027

|

0.027

|

| M

|

108

|

80

|

|

M =

Conical Expansion

|

d/D =

0.8

|

0.1

|

|

0.1

|

| M-N

|

142

|

80

|

|

N =

Square Edged Inlet

|

|

0.5

|

0.028

|

0.528

|

Table 2 Typical values for Dynamic

Loss Coefficient (N) for vent system fittings, 'N' may vary with pipe

diameter

|

Fitting

|

Equivalent

|

|

Inlet pipe from tank to PRV:

|

|

| Square-edged

inlet

|

|

0.5

|

| Protruding

conical inlet

|

|

0.15

|

| Conical

reduction

|

|

0.1

|

|

Discharge piping from PRV to mast vent exit:

|

|

| 45°

|

|

0.2

|

| 45°

single-mitre elbow

|

|

0.45

|

| 90°

|

|

0.3

|

| 90°

|

|

0.5

|

| 90°

|

|

0.6

|

| Soft-Tee

|

|

0.3

|

| Hard-Tee

|

|

1.1

|

| Cowi mast

vent exit

|

|

2.25

|

| Top-Hat

mast vent exit

|

|

[4.5]

|

| Flame

screen for IGC Code 17.10

|

|

1.4

|

| References:

|

| Sizing Safety Valve Inlet Lines Chemical

Engineering Process, November 1980

|

| Engineering Data Book, Figure 174 Gas

processors Association, 10th Edition. 1987

|

| Guide for Pressure-Relieving and Depressurising

Systems Table 5, API RP 521 Third Edition, November 1990

|

By 2.2

The IGC Code minimum

tank relief capacity, QGCC

, is calculated

for the Case Study ship tank analysed in BCH 20/7, annexes 2 to 5

which has an external surface area 747 m2 MARVS 11.0 bar

g.

By IGC Code 8.5.2

for propane:

The QGCC

for actual case study ship

tank = 7.71 m3/s of Air at STP.

The installed rated capacity for two 75 mm

× 100 mm AGCo Type 95 POPRVs

QIR

= 20.52 m3/ s of

Air at standard conditions (STP) of 273 K and 1.013 bar a,

or 20.52/7.71 = 2.66 times the QGCC

By equation (1) for

all vapour mass flow rate

from tank for propane:

where hfg at

1.2 × MARVS=

308600 J/kg

or Code PRV all vapour mass flow rate per PRV = 5.22 kg/s

and Installed Rated all vapour mass flow rate per PRV =

5.22 × 2.66 = 13.89 kg/s

where hfg at MARVS =

322800 J/kg

or Installed Rated all vapour mass flow rate per PRV = 4.99

× 2.66 = 13.27 kg/s

By equation (2) for

two-phase mass flux

through PRV orifice for propane

At 1.2 MARVS where C = 2931 J/kg

At MARVS where C = 2750 J/kg

By equation (3) for

two-phase mass flow rate

through installed rated PRV orifice

area

Av

= 0.004032 m2;

Kw

= 0.72

W = 9727 × 0.72 × 0.004032 = 28.25 kg/s

w = 8959 × 0.72 ×0.004032 = 26.01 kg/s

By equation (4) for

two-phase mass flow rate

through Code PRV

By 2.3

The all

vapour capacity and two-phase pressure drops in the pipe from the

cargo tank to the PRV inlet are calculated as the difference in stagnation

pressures by suing the second term of equation

(5) for the pipe sections of constant diameter and by using equation (5.1) for conical reduction

fittings (contractions).

For Code PRV all vapour capacity at 1.2 × MARVS

Conical reduction fitting M:

Section N to PRV total ΔP = 0.039

+ 0.018 + 0.005 = 0.06 bar

For installed rated all vapour capacity at MARVS

Conical reduction fitting M:

Section N to PRV total ΔP = 0.295

+ 0.137 + 0.037 = 0.47 bar

For Code PRV two-phase capacity at 1.2 × MARVS

Conical reduction fitting M

Section N to PRV total ΔP = 0.01

+ 0.005 + 0.001 = 0.016 bar

For Installed Rated two-phase capacity at MARVS

Conical reduction fitting M:

Section N to PRV total ΔP = 0.06

+ 0.028 + 0.008 = 0.10 bar:

By 2.4

Check system

compliance with requirements of General Section ref. 1.3

-

1.3.1

At

Code PRV all vapour capacity at 1.2 × MARVS

ΔP× 100/P

MARVS =

0.06 × 100/11.0 = 0.55%

Guideline 1.3 = 3% maximum

At Code PRV two-phase capacity at 1.2 × MARVS

= 0.016 × 100/11.0 = 0.15%

-

1.3.2

At

installed rated all vapour capacity at MARVS

= 0.47 × 100/11.0 = 4.27%*

At installed rated two-phase capacity at MARVS

= 0.10 × 100/11.0 = 0.91%

-

* Acceptable because pilot senses at a point that

is not affected by the inlet pipe pressure drop. If a protruding conical

inlet (N= 0.15) had been added to the square-edged inlet (N= 0.5),

the pressure drop would have been reduced, by 0.15/0.5 × 29500

= 8900 Pa to 3800 Pa which is 3.5% of set

pressure.

|

ΔPclose

|

= |

>

0.02 × PMARVS + ΔPinlet

|

|

|

= |

> 0.02 × 11.0 + 0.47 > 0.69 bar

|

For stable operation of the PRV, closing pressure

should be less than:

11.0 - 0.69 ≤ 10.31 bar g for a pop-action POPRV

By 2.5

The two-phase

critical exit choking pressure is estimated, using saturated propane

properties at 1.2 ×MARVS (14.2 bar a)

and where W' for Code discharge from four PRVs

Thus the exit flow is not choked and the vent pipe exit

pressure is 100000 Pa (1 bar a)

By 2.6

The exit

vapour fraction, xe

, assuming a fire exposure

heat flux of 108 kW/m2 into uninsulated vent discharge

piping at the Code rated two-phase flow rate, is estimated.

By equation (7) and

from Table 1:

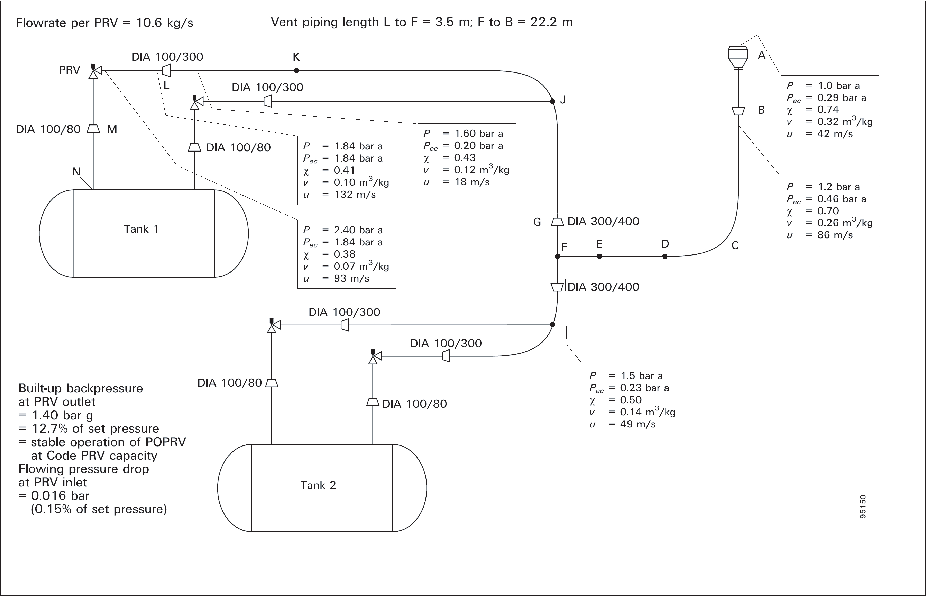

By 2.7

The pressure

drops between the vent discharge piping nodes are estimated by equation (5), with iteration until the

upstream node absolute pressure, vapour fraction and specific volume

are justified, and working section by section back up the pipe to

the PRV.

By 2.8

and Pec at

B

= 337.3 × 136.2 = 46000 Pa (0.46 bar

a) using mass flux at exit from section F to B

PF

= 1.18 + 0.26 = 1.44, Try 1.51 bar a

By equation (5)

-

ΔP = 337.32(0.256-0-0.145)

+ 0.5 × 337.32 (0.256 + 0.145)/2 × 1.808

-

= 12600 + 20600 = 33200 Pa (0.33 bar)

-

and PF

= 1.18 + 0.33 = 1.51 bar

a

By 2.8

and Pec at

F

= 168.7 × 136.2 = 23000 Pa(0.23 bar

a)

This pressure drop is too small to justify a more accurate

estimation. For the purposes of this calculation, we can assume the

specific volume remains constant from G to L.

Conical expansion fitting at L:

In accordance with Procedure

2.7 last paragraph, the static inlet pressure to this fitting

is assumed to be 1.55 bar a.

By 2.8

and Pec

at

exit of pipe section from PRV to L = 1349 × 136.2 = 184000 Pa (1.84 bar a)

Therefore, the exit of the 100 mm diameter pipe section

PRV to L is choked and the exit pressure at L is 1.84 bar a

P

PRV = 1.84 + 0.04 = 1.88 bar

a; Try 2.42 bar a

By 2.9

Back pressure

at Code PRV two-phase flow at 14.2 bar a is 1.40 × 100/11.0

= 12.7% of set pressure (gauge) which assures adequate relief capacity

for POPRVs.

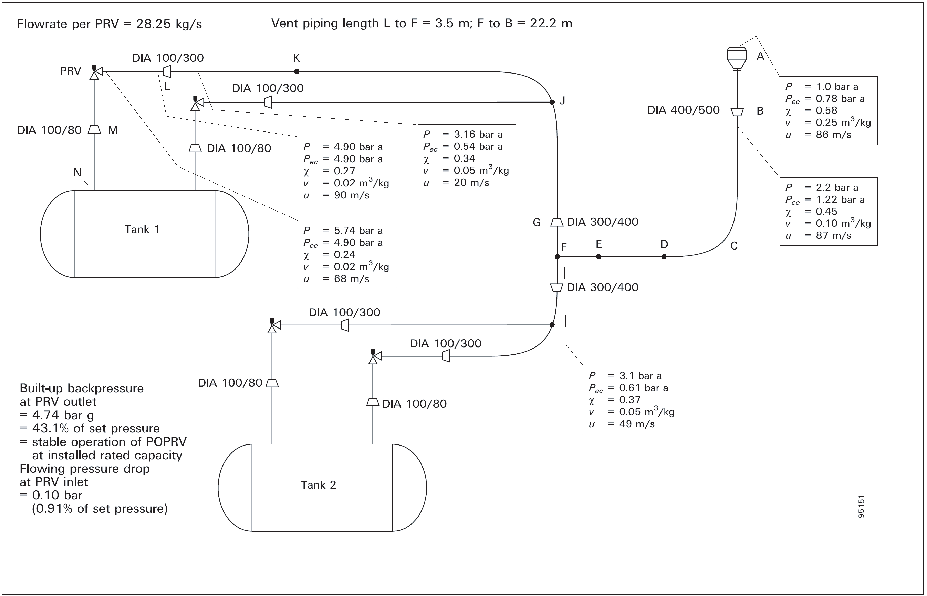

By 2.10

Procedure

for unbalanced PRVs only. The Procedures

2.5 to 2.8 are repeated in this worked example using the installed

rated mass flow for information only.

By 2.5

At the installed

rated two-phase mass flow W = 28.25 × 4 = 113.0 kg/s.

By equation (6)

Thus exit flow is not choked and vent pipe exit pressure

is 100000 Pa (1 bar a)

where

-

Gp

= 575 kg/m2-s; Σa/W = 0.339 m2-s/kg

-

xB

= 0.48; ρB = 10.31 kg/m3; vB

= 0.097 m3/kg

-

Δ

P

= 116900 Pa (1.17 bar)

-

PB

= 2.17 bar a

-

Pec

= 899 × 136.2 = 122000 Pa (1.22 bar a)

where

-

Gp

= 899 kg/m2-s; Σa/W = 0.0929 m2-s/kg

-

xF

= 0.37; ρF = 18.17 kg/m3; vF

= 0.055 m3/kg

-

Δ

P

= 89500 Pa (0.89 bar)

-

PF

= 2.17 + 0.89 = 3.06 bar a

-

Pec

= 449 × 136.2 = 61000 Pa (0.61 bar a)

where

-

G

p = 449 kg/m2-s

-

ΔP = 6300 Pa(0.06 bar)

where

-

G

p = 799 kg/m2-s

-

ΔP = 1200 Pa(0.01 bar)

where

-

G

p = 400 kg/m2-s

-

ΔP = 2600 Pa(0.03 bar)

-

PL

= 3.06 + 0.06 + 0.01 + 0.03 =

3.16 bar a

-

xL

= 0.34; ρ

L

=

20.44 kg/m3; vL

= 0.049 m3/kg

-

Pec

= 400 × 136.2 = 54000 Pa (4.9 bar a)

Conical Expansion Fitting at L:

By 2.9

Back pressure

at installed rated two-phase flow at 14.2 bar a is 4.7.4

× 100/11.0 = 43.1% of set pressure (gauge) which assures normal

full capacity operation of the POPRVs.

The predicted two-phase propane properties are shown at

five node points in the PRV discharge vent piping, in Figure 2 at the Code PRV flow-rate,

and in Figure 3 at the installed

rated flow-rate. The flowing pressure drop in the piping to the PRV

inlet is less than guideline1.3 requires.

The built-up back pressure at the PRV outlet is also less than guideline1.4 requires for the pilot-operated

PRVs installed.

The flowing pressure drop in the PRV inlet piping is well

within guideline1.3 of the Code

PRV all vapour flow-rate but exceeds the requirement for the installed

rated all vapour flow-rate. However, the pressure drop is acceptable

for reason * in footnote on page 9. The blowdown and closing pressure

should be set to assure stable operation when both PRVs are open.

These procedures are now applied to example case 3B in Dow

Chemical Company's report to CTAC using their RELief DESign program,

February 25, 1992 (BCH 22/INF.6). Per RELDES RESULTS on page 9, the

last two-phase flow of 106 lbs/sec (48.1 kg/s) occurs at a tank pressure

of 169 psig (12.66 bar a), Quality (percent vapour by mass) is stated

to be 0.10% and Vessel Inventory is 76.2% of liquid propane. The PRV

discharge vent pipe is assumed to be 10 ft long by 8 inches diameter

(3.04 m length × 0.203 m dia) and PRV Orifice Area is 12.3 sq.

in. (7.935 × 10-3

m2), Kd

=

0.953.

Figure 2 Two Phase Propane Properties at Code PRV Relief Flowrate - Simplified

Flow Sheet of a Cargo Tank Vent System With One Vent Stack Connected to Two

Tanks

Figure 3 Two Phase Propane Properties at Installed Rated Flowrate - Simplified

Flow Sheet of a Cargo Tank Vent System With One Vent Stack Connected to Two

Tanks

Thus equations (2) and (3) predict a flow rate 17% higher

than RELDES

12.66 bar a, Vapour Fraction by mass at PRV inlet.

|

Vapour Mass per cubic metre

|

=

|

0.238 ×

26.9

|

=

|

6.402

kg

|

|

Liquid Mass per cubic metre

|

=

|

9.762 ×

475.0

|

=

|

361.95

kg

|

|

Total Mass per cubic metre

|

|

|

=

|

368.35

kg

|

|

and Vapour Fraction = 6.3/368 = 0.017

|

or Quality = 1.7% compared to RELDES 0.10%

At vent piping exit back pressure = 1.70 bar a

say at inlet to vent discharge pipe back pressure = 3.31

bar a:

By equation (5),

where 4f L/D = 4 × 0.005 × 3.04/0.203 = 0.30

Thus Back Pressure at PRV discharge flange:

-

= 1.70 + 1.59 = 3.29 bar a or = 2.29 bar

g (33.2 psig) for comparison with RELDES prediction

32.8 psig

-

= Thus equations (6),

(7), (8),

(9) and (5) predict a Back

Pressure 1% higher than RELDES