This section contains guidance in determining the suitability

of a crude oil for use in crude oil washing.

In lieu of a list of crude oils unsuitable for carriage

and crude oil washing to be inserted in the Crude Oil Washing and

Equipment Manual the following standard text maybe used:

-

(1)

For a Tanker not fitted with heating

coils.

-

This tanker is not fitted with heating coils in the cargo

tanks and should not carry cargoes which will require to be heated

either to obtain pumpability criteria or to avoid excessive sludging

of both the designated clean ballast tanks and the vessel's tanks

to be washed for sludge control.

-

Notes and Definitions:

-

Pumpability Criterion is determined by the oil's Kinematic

Viscosity at the observed temperature of the cargo prior to its discharge.

In order to attain optimum efficiency for discharge this viscosity

should not exceed 250 centistokes and

never

in excess of 600 centistokes.

-

Excessive sludging criterion is determined primarily by

the crude oil's temperature throughout its transportation and storage.

If the cargo's temperature is likely to drop below the crude oil cargo's

cloud point temperature then sludging of cargo tanks is to be expected.

The cloud point temperature is the temperature at which the crude

oil's wax and associated oil phase separates from the bulk liquid

phase of the cargo.

-

(2)

For a Tanker fitted with heating coils

in Slop Tank(s)

-

This tanker is fitted with heating coils only in her Slop

Tank(s) and should not carry cargoes which will require to be heated

for pumpability.

-

Notes

-

If sludge deposition is suspected or determined in

the main cargo tanks then an alternative crude oil washing programme

should be utilised. Recommendations regarding this programme and procedure

are to be found in Section 11 of this

manual.

-

(3)

For a Tanker fitted with heating coils

-

This tanker is fitted with heating coils in all the cargo

tanks and, subject to the limitations of the cargo heating system,

can carry cargoes which require heating for either pumpability or

sludge deposition/control.

The approximate Cloud Point temperature of an oil may be

calculated by use of the following formula where the Pour Point temperature(x)

of the crude oil is known

The Cloud Point Temperature °C = 20.2 (10

0.00708 × - 0.1157714 ) + 8

Worked example:

Assume the Pour Point Temperature is + 1°C.

Then:

| = 20.2 x (10(0.00708 x 1) -

0.1157714) + 8

|

| = 20.2 x (100.00708 -

0.1157714) + 8

|

| = 20.2 x (10-0.1086914)

+ 8

|

| = (20.2 x 0.7785896) +8

|

| = 15.72 + 8

|

| Answer: Approx. Cloud Point °C =

24°C

|

-

OR

-

Consult the accompanying graph, (Fig

1) where if the Pour Point is known then the Cloud Point can

be extracted.

-

OR

-

If the Pour Point exceeds Approximately 25°C then the

Bondi test procedure could be used to determine this temperature.

-

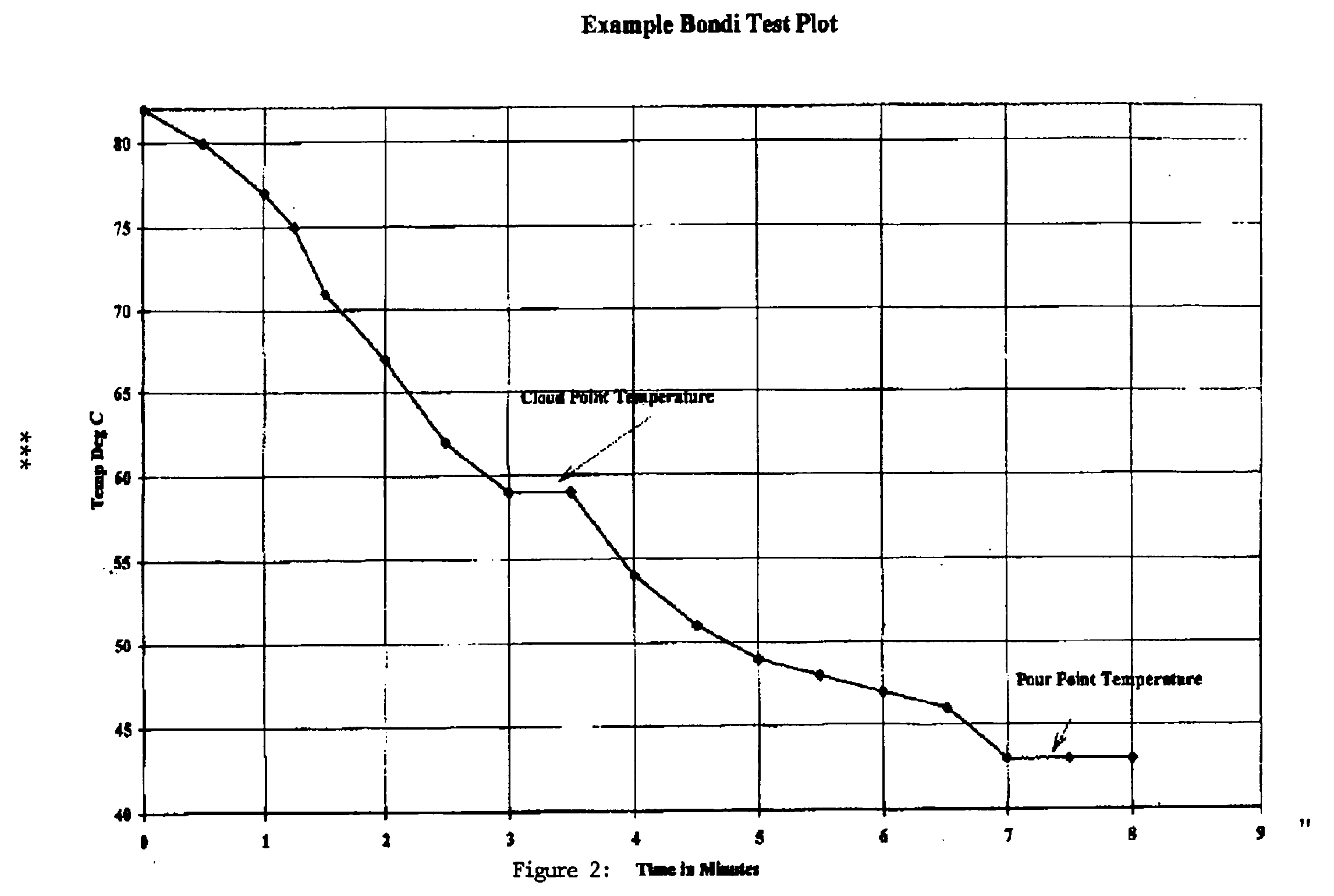

The Bondi Test Procedure (See Fig 2)

-

This method will obtain the cloud point temperature of high

pour point type crude oils.

Figure 1 A Graph to determine The

Cloud Point Temperature

Figure 2 Example Bondi Test

Pilot

Equipment and Procedure

-

(1) Obtain a representative sample of the cargo.

Do not allow the Cargo sample to cool before commencing the test procedure.

-

(2) Obtain a glass container (preferably nearly

spherical) that is made of heat/temperature resistant glass and fill

the container with the sample.

-

(3) Insert a thermometer into the centre of the

sample volume and heat the sample to a temperature of at least 30°C

above the pour point temperature of the crude oil in a hot water bath.

Do not tightly stopper the container during this process.

-

(4) Prepare an alternative bath with water whose

temperature is at least 15°C below the sample's pour point temperature.

Have a clock or watch available with a second hand.

-

(5) Immerse the heated sample contained into the

cold bath and record at very regular intervals (at least every 30

seconds) the temperature of the sample.

-

(6) Graphically plot the sample temperature against

time elapse from the start of the test. Determine the temperatures

at which there was no loss of temperature with time elapse. The first

such instance as detected will be the approximate Cloud Point temperature

and the second instance, if testing time is extended to the required

period, will be the approximate pour point temperature of the crude

oil.