The following equipment and material are necessary for the

test:

-

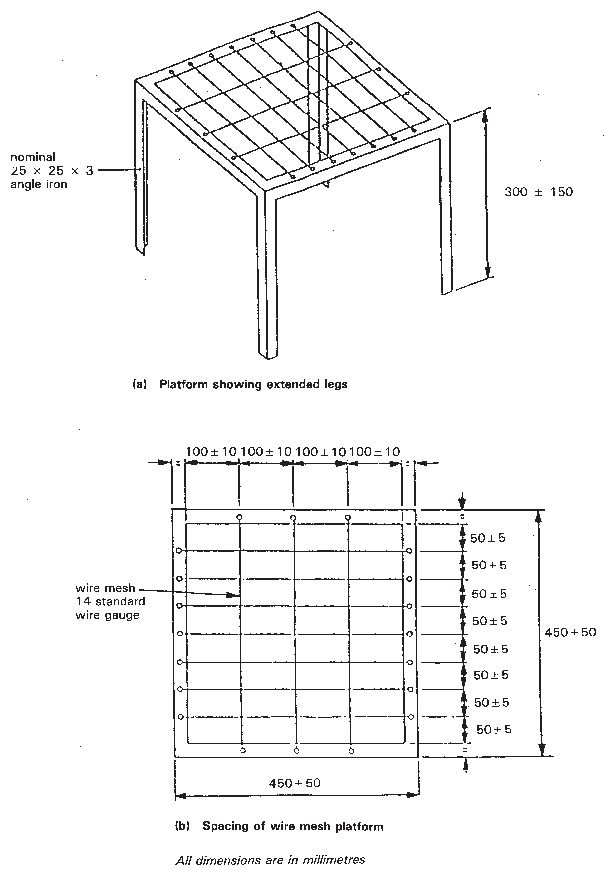

.1 The test rig for support of the specimen is

shown in Figure 1. The stand

is made of angle iron with nominal dimensions 25 mm x 25 mm x 3 mm.

On top of the stand is a platform of wire mesh with openings of nominal

dimensions 100 mm x 50 mm.

-

.2 Mineral wool with a nominal density of 60 kg/m3 and with dimensions 450 mm x 350 mm x 50 mm.

-

.3 Stop clock.

-

.4 Test enclosure, being either a room with a

volume greater than 20 m3 (which contains adequate oxygen

for testing), or a smaller enclosure with a through flow of air. Inlet

and extraction systems providing air speed of 0.02 m/s to 0.2 m/s

in the locality of the rig provide adequate oxygen without disturbing

the burning behaviour.

-

.5 Ignition sources. The sequent ignition sources

used are a smouldering cigarette covered with a cotton wool pad and

an open flame.

-

.6 Cigarettes. For the tests, cigarettes with

the following specifications should be used:

|

|

Length:

|

70 ± 4 mm

|

|

|

Diameter:

|

8 ± 0.5 mm

|

|

|

Weight:

|

1 ± 0.1 g

|

|

|

Smouldering rate:

|

12 ± 3 min/50

mm

|

Figure 1 Test Rig

-

The smouldering rate shall be verified for every carton

of 200 cigarettes as follows:

The cigarettes are conditioned as described below under 5.4.

One cigarette is marked at distances 5 mm and 55 mm from one end.

The cigarette is ignited at the end with the 5 mm distance marking,

and the air is drawn through the cigarette until a clear glow is observed,

but not further than on to the 5 mm marking, whereafter the cigarette

is impaled horizontally on a wire spike inserted not more than 13

mm into the unlit end. The time is recorded for the smouldering from

the 5 mm to the 55 mm marks.

-

.7 Cotton wool pad. The cigarette should be covered

with a pad of cotton wool of nominal dimensions 150 mm x 150 mm x

25 mm and of weight 20 ± 6.5 g. The cotton wool should consist

of new, undyed and soft fibres without any admixtures or artificial

fibres, and it should be free from thread, leaf and shell fibre dusts.

A suitable material for this purpose is packaged in the form of rolls

for surgical use. The piece should be unwrapped from the roll as a

single layer 25 mm to 30 mm thick, cut to plan size, then reduced

to the correct mass and thickness by removal of loose fibres from

the top.

-

.8 Flame. The burner is a tube of stainless steel

with internal diameter 6.5 ± 0.1 mm, outside diameter 8 ±

0.1 mm and length 200 mm. The fuel may be butane or propane gas. Fuel

supply rate: 6.38 ± O.25 g/h at 20°C.