1 Purpose of this method concerning brief sampling and

analysis of anti-fouling systems

1.1 This method has been developed in order to describe a rapid methodology appropriate

for the identification of anti-fouling systems on ship hulls containing organotin

compounds and/or cybutryne acting as biocide. This method has been designed such that

sealers should not be affected, and any underlying anti-fouling agent (or primer) is not

taken up in the sampling procedure. The method is not recommended for silicon-based

anti-fouling systems.

1.2 The method for organotin compounds (Case A under paragraph 4.6 of the Guidelines) is

based on a two-step analysis. The first step detects total tin as an indicator for

organotin; the second step, detecting specific organotin compounds, is only necessary in

the case of the first step proving positive.

1.3 The method for cybutryne (Case B under paragraph 4.6 of the Guidelines) is based on

a one-step analysis.

1.4 The simplified approach (Case C under paragraph 4.6 of the Guidelines) to detect

organotin compounds and cybutryne is based on a one-step analysis.

2 Sampling device and materials

2.1 The sampling device is constructed in a way that only the upper layer of paint is

removed, thereby it should leave any underlying paint (sealer, primer, etc.) intact.

This result is achieved through the use of a moving disk (eccentric rotation), which is

covered by an abrasive material like quartz or glass fibre fabric. This abrasive

material has to be suitable for its use as a supporting material for the removed

paint.

2.2 The device fulfils the following requirements:

-

.1 the device has to work independently from any

stationary power supply. The device may be driven by an electrical motor

(battery-driven) or may be mechanically driven by a clockwork-like spring,

provided it is able to sustain the movement over the required time period;

-

.2 the applied force has to be constant during the

operation, and the area for paint removal has to be defined;

-

.3 the abrasive material has to be inert against

chemical solvents and acids and must not contain more than trace amounts of tin or

tin compounds and/or cybutryne; and

-

.4 the amount of paint removed after a regular

operation of the device has to be shown to exceed 20 mg per sample.

2.3 The device as described in the following section has been shown to be suitable for

the brief sampling procedure. Any other device may be used however, provided such a

device has proven to meet all the above-mentioned requirements.

2.4 The sampling device described here consists of a polyethylene disk, on which fibre

glass fabric can be mounted by the use of an O-ring. The disk is moved on an

eccentrically rotating axis.

3

Sampling procedure

3.1 The sampling procedure should be performed in the following manner:

-

.1 control samples should be taken through the entire sampling and

analytical process to account for possible contamination;

-

.2 the mass of the fibreglass pads is weighed with a precision of at

least 1 mg. The weight should be documented for each sample;

-

.3 the fabric should be moistened thoroughly with isopropanol (0.7 mL

per sample) immediately before sampling;

-

.4 when a sample point on the hull has been selected, any fouling

present should be removed with water and a soft sponge/cloth before taking a

specimen of the anti-fouling system (to avoid contamination of the sample). Where

possible, if carried out in dry dock, sampling should be carried out after the

hull has been water-washed;

-

.5 the sampling device is then held against the surface to be sampled

for a period of five seconds, prior to the sampling device being switched on;

-

.6 the sampling device is switched on, thereby removing paint by the

circular motion of the fibre glass fabric against the surface of the ship;

-

.7 the sampling device should be applied to the surface of the hull

for a suitable period of time, such that at least 20 mg of paint is taken up by

the pad. As a general rule, if the pad colour after sampling matches the colour of

the hull coating a sufficient sample has been taken;

-

.8 the specimens should be taken as close to each other as possible, but without

overlap;

-

.9 upon completion of the sampling, the fibreglass fabric pads should be left to

dry and re-weighed;

-

.10 the number of samples will differ depending on the substances targeted as

listed in Annex 1 of the AFS Convention.

-

Case A. Analysis of organotin only, every sample should be taken in

triplicate.

-

Specimen 'A' – for Step 1

Specimen 'B' – for Step 2

Specimen 'X' – for storage/back-up

-

Case B. Analysis of cybutryne only, every sample should be taken in duplicate.

-

-

Case C. Simplified approach to detect organotin and cybutryne, every sample should

be taken in duplicate.

3.2 Samples should be stored in appropriate sealed packaging which will not

react with or contaminate the sample.

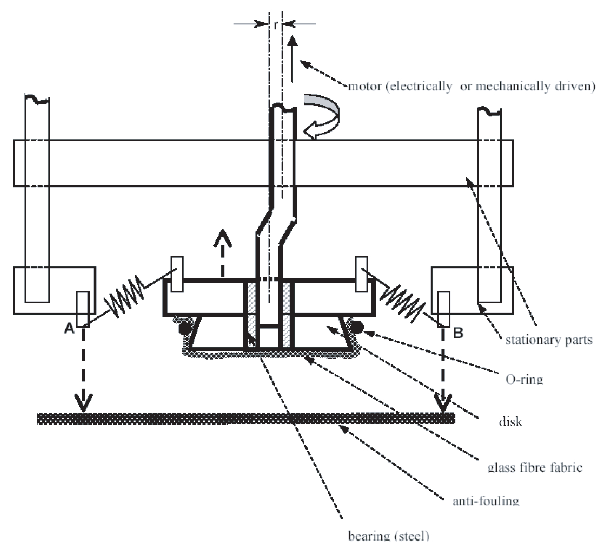

Diagram A: Schematic cross section of the sampling device

The indicated points A and B are to be pressed against the surface. The polyethylene

disk, covered with the glass fibre fabric, is moved with an amplitude of 2 r (r = 1.0

cm) on the surface.

|

|

Specific data:

|

|

|

|

|

Force

applied on the paint surface:

|

|

25 N

(Newton)

|

|

|

Effective diameter of the

disk:

|

|

5 cm

|

|

|

Frequency of rotation:

|

|

6

rotations/s

|

|

|

Solvent

used:

|

|

isopropanol (0.8 mL per sample).

|

4

Sampling strategy

4.1 Sampling should be conducted in accordance with paragraph 4 of the Guidelines.

4.2 For inspection purposes in most cases accessibility to all parts of the hull will

not be given. A minimum number of eight independent samples should be taken from

different accessible parts of the hull.

5

Analytical procedure

5.1 The analytical procedure will differ depending on the substances targeted as listed

in Annex 1

of the AFS Convention.

Case A. Analysis of organotin only

5.2 The two components comprising the analytical procedure are illustrated in the flow

diagram B. The two components, or steps, are as follows:

-

.1 (Step 1) - An analysis of Specimen 'A' for the

presence of total tin; and

-

.2 (Step 2) - A more cost- and time-consuming

analysis of Specimen 'B', that is applied only when Step 1 produces positive

results. This test involves organotin analysis by gas chromatography/mass

spectrophotometry (GC/MS) after derivatization and provides specific data on the

respective organotin species.

Step 1: Investigation of total tin content in Specimen 'A'

Analysis of Specimen 'A'

5.3 Specimen 'A' is analysed for mass of total tin per kilogram of dry paint (or mass of

tin per sample) by applying inductively coupled plasma/mass spectrometry (ICP/MS), once

the material had been solubilized by digestion using aqua regia. It should be noted that

any other scientifically recognized procedure for tin analysis (such as AAS, XRF and

ICP-OES) is acceptable.

Step 2: Characterization of organotin in Specimen 'B'

Analysis of Specimen 'B'

5.4 Should Specimen 'A' produce positive results, organotin compounds should be

identified and quantified in Specimen 'B'. Specimen 'B' may be analysed using the

following procedure:

-

.1 solvent extraction of Specimen 'B' as supported by sonication in an ultrasonic

bath;

-

.2 derivatization with ethylmagnesium bromide;

-

.3 clean-up of the extract;

-

.4 analysis using high resolution gas chromatography/mass spectrophotometry

(GC/MS); and

-

.5 quantifications using tripropyltin as a standard.

5.5 Any equally reliable method for the chemical identification and quantification of

organotin compounds is acceptable.

Case B. Analysis of cybutryne only

5.6 A one-step analysis of 'Specimen C' for determining the amount of cybutryne, using

gas chromatography/mass spectrophotometry (GC/MS).

One-step analysis: Characterization of cybutryne in Specimen 'C'

Analysis of Specimen 'C'

5.7 Specimen 'C' should be analysed using the following procedure:

-

.1 sample extraction using ethyl acetate with added internal standard (ametryn)

using an ultrasonic bath for 15 minutes;

-

.2 ventrifugation of the samples at 600 rcf for 5 minutes;

-

.3 analysis of the supernatant using high resolution capillary GC/MS, with the MS

operating in SIM mode;

-

.4 quantification using reference cybutryne solutions and an internal standard

normalization procedure; and

-

.5 modified GC/MS methods resulting in an expanded measurement uncertainty (k=2;

95% confidence) of 25% are acceptable.

5.8 Other methods for the chemical identification and quantification of cybutryne, if

proven equally reliable, could be accepted by the Administration or the port State.

Case C. simplified approach to detect organotin and cybutryne

5.9 A one-step analysis of Specimen 'C' for determining the amount of organotin and

cybutryne using gas chromatography/mass spectrophotometry (GC/MS).

One-step analysis: Characterization of organotin and cybutryne in

Specimen 'C'

-

.1 sample extraction using toluene with added internal standard (ametryn) using an

ultrasonic bath for 15 minutes;

-

.2 derivatization with ethylmagnesium bromide;

-

.3 clean-up of the extract;

-

.4 centrifugation of the samples at 600 rcf for 5 minutes;

-

.5 analysis of the supernatant using high resolution capillary GC/MS, with the MS

operating in SIM mode;

-

.6 cybutryne quantification using reference cybutryne solutions and an internal

standard normalization procedure. Organotin quantification using tripropyltin as

the internal standard; and

-

.7 modified GC/MS methods resulting in an expanded measurement uncertainty (k=2;

95% confidence) of 25% are acceptable.

5.10 Other methods for the chemical identification and quantification of organotin and

cybutryne, if proven equally reliable, could be accepted by the Administration or the

port State.

6

Threshold and tolerance range

6.1 The threshold value for organotin compounds for the brief sampling method as

described here is:

6.2 The threshold value for cybutryne for the brief sampling method as described here

is:

Tolerance range

6.3 The tolerance range is 500 mg Sn / kg of dry paint (20%) in addition to the

threshold value.

6.4 The tolerance range is 250 mg cybutryne / kg of dry paint (25%) in addition to the

threshold value.

Organotin-containing compounds acting as biocides or catalysts

6.5 As stated in appendix I of resolution MEPC.358(78), for the purposes of defining compliance

with Annex 1

to the Convention, it should be noted that small quantities of organotin compounds,

acting as chemical catalysts (such as mono- and di-substituted organotin compounds), are

allowed, provided they are not acting as a biocide.

6.6 Inorganic impurities in the constituents of the paints should be considered.

6.7 At present neither organotin catalysts nor inorganic impurities are found at

concentrations which will be close to the threshold level (2,500 mg Sn/kg of dry paint)

or higher. However, organotin-containing compounds, when present in paint in order to

act as a biocide, were found in concentrations up to 50,000 mg Sn/kg of dry paint. Thus,

the discrimination between anti-fouling systems containing organotin compounds acting as

a biocide and anti-fouling systems not containing these compounds or not containing

these compounds at concentrations where they act as a biocide is reliably possible.

7

Definition of compliance

7.1 The analytical verification of the compliance will differ depending on the

substances targeted as listed in Annex 1 of the AFS Convention.

Case A. Analysis of organotin only

Two-step procedure

7.2 The analytical verification of the compliance with the Convention for organotin

compounds is performed in a two-step procedure according to the flow-diagram (diagram

B).

Diagram B: Flow diagram illustrating the two-step analysis procedure for organotin

compounds

Compliance with the criteria at the 'Step 1-level'

7.3 Compliance with the Convention is assumed when the results from the specimens 'A',

analysed in step 1, meet the following:

-

.1 no more than 25% of the total number of samples yield results above 2,500

milligrams total tin per kilogram dry paint (2,500 mg Sn/kg of dry paint); and

-

.2 no sample of the total number of at least eight samples shows a concentration

of total tin higher than the sum of threshold value plus the tolerance range, i.e.

no sample must exceed the concentration 3,000 mg Sn/kg of dry paint.

7.4 If the results in specimen 'A' indicate that no organotin acting as biocide is

present, then performing step 2 is not necessary.

Non-compliance with the criteria at the 'Step 1-level'

7.5 A positive result (non-compliance) is indicated if the provisions of paragraph 7.3

are not met.

7.6 A positive result at step 1 (specimen 'A') would indicate that step 2 should be

undertaken, and those samples labelled specimen 'B' should be analysed in order to

determine and characterize the organotin present (see diagram B).

Compliance with the criteria at the 'Step 2-level'

7.7 Compliance with the Convention is assumed when the results from the specimens 'B',

analysed in step 2, meet the following requirements at the same time:

-

.1 no more than 25% of the total number of samples yield results above 2,500

milligrams total tin per kilogram dry paint (2,500 mg Sn/kg of dry paint); and

-

.2 no sample of the total number of at least eight samples shows a concentration

of total tin higher than the sum of threshold value plus the tolerance range, i.e.

no sample must exceed the concentration 3,000 mg Sn/kg of dry paint.

Non-compliance at 'Step 2-level'

7.8 A positive result in step 2 indicates non-compliance if the provisions of paragraph

7.7 are not met. Such results should be interpreted to mean that organotin compounds are

present in the anti-fouling system at a level at which it would act as a biocide.

Case B. Analysis of cybutryne only

7.9 Compliance with the Convention is assumed when the results from specimen 'C',

analysed in a one-step analysis for cybutryne, meet the following requirement:

Non-compliance at the one-step analysis for cybutryne

7.10 An average value of the total number of specimens showing a concentration above the

threshold plus the tolerance range, i.e. 1,250 mg of cybutryne per kg of dry paint,

indicates non-compliance.

Case C. Simplified approach to detect organotin and cybutryne

7.11 Compliance with the Convention is assumed when the results from specimen 'C',

analysed in a one-step analysis for organotin and cybutryne, meet the two conditions

below:

-

.1 for organotin, the average value of the total number of specimens shows a

concentration below the threshold plus the tolerance range, i.e. 3,000 mg Sn/kg of

dry paint; and

-

.2 for cybutryne, the average value of the total number of specimens shows a

concentration below the threshold plus the tolerance range, i.e. 1,250 mg of

cybutryne per kg of dry paint.

Non-compliance at the one-step analysis for organotin and cybutryne

7.12 If one of the conditions set out in paragraph 7.11 above is not met, this indicates

non-compliance. Such results should be interpreted to mean that cybutryne or organotin

is present in the anti-fouling system at a level at which it would act as a biocide.

Appendix to Method 1

RECORD SHEET FOR THE BRIEF SAMPLING PROCEDURE FOR COMPLIANCE WITH THE CONVENTION IN

TERMS OF THE PRESENCE OF ORGANOTIN AND/OR CYBUTRYNE ACTING AS A BIOCIDE IN

ANTI-FOULING SYSTEMS ON SHIP HULLS

RECORD SHEET:

GUIDELINES FOR BRIEF SAMPLING OF ANTI-FOULING

SYSTEMS ON SHIPS - ORGANOTIN AND CYBUTRYNE

|

RECORD NUMBER:

|

| SECTION

1: Administration

|

| 1. Country

|

2. Name of port

|

3. Date

|

| 4.

Reason for sampling

|

| ☐ Port State control

|

☐ Survey & certification

|

☐ Other flag State compliance

inspection

|

| 5. Company details:

|

6. Inspecting official's

details

|

| 1. Name of ship:

|

1. Name:

|

| 2. Distinctive number or letters:

|

2. Comments:

|

| 3. Port of registry

|

|

| 4. Gross tonnage:

|

|

| 5. IMO

number:

|

|

| SECTION

2: Sampling

|

| 1. Time sampling

procedure initiated:

|

2. Description of

location from where samples were taken (frame number and distance from

boot topping, refer to paragraph

3.2):

|

| 3. Number of

samples taken (three or two specimens per sample):

|

| 4.

Photographs taken of the sample point prior to sampling?

|

|

|

☐ Yes

|

☐ No

|

5. Time sampling

procedure completed:

|

6. Additional

comments concerning sampling

procedure:

|

|

SECTION 3: Analysis and results

|

| Case A. Analysis of

organotin only

|

| 1.

Step 1 total tin analysis:

|

| Company name:

|

| Analyst

responsible:

|

Date :

|

| 2. Specimen

'A' results:

|

Total number of specimens

'A' analysed:

|

| No.

|

mg Sn / kg

|

No.

|

mg Sn / kg

|

No.

|

mg Sn / kg

|

No.

|

mg Sn / kg

|

| 1

|

|

5

|

|

9

|

|

13

|

|

| 2

|

|

6

|

|

10

|

|

14

|

|

| 3

|

|

7

|

|

11

|

|

15

|

|

| 4

|

|

8

|

|

12

|

|

16

|

|

| Number of

specimens exceeding 2,500 mg/kg:

|

| 1 or more

specimens exceeding 3,000 mg/kg:

|

☐

Yes

|

☐ No

|

| Conclusion:

|

Step 2

required

|

☐

|

| Compliance,

further analysis unnecessary:

|

☐

|

3.

Additional comments concerning analysis of results from Specimens

'A':

|

| 4.

Organotin analysis undertaken by:

|

| Company name:

|

| Analyst responsible:

|

Date :

|

| 5. Specimen

'B' results:

|

Total number of specimens

'B' analysed:

|

| No.

|

mg Sn / kg

|

No.

|

mg Sn / kg

|

No.

|

mg Sn / kg

|

No.

|

mg Sn / kg

|

| 1

|

|

5

|

|

9

|

|

13

|

|

| 2

|

|

6

|

|

10

|

|

14

|

|

| 3

|

|

7

|

|

11

|

|

15

|

|

| 4

|

|

8

|

|

12

|

|

16

|

|

| Number of

specimens exceeding 2,500 mg/kg:

|

| 1 or more

specimens exceeding 3,000 mg/kg:

|

☐

Yes

|

☐ No

|

| Conclusion:

|

Non-compliance

|

☐

|

| Compliance,

further analysis unnecessary:

|

☐

|

| 6.

Additional comments concerning analysis of results from Specimens

'B':

|

| Case B. Analysis of

cybutryne only

|

| 1.

A one-step analysis using gas chromatography/mass spectrophotometry

(GC/MS)

|

| Company name:

|

| Analyst

responsible:

|

Date :

|

| 2.

Specimen 'C' results:

|

|

| Total number of specimens 'C' analysed by GC-MS:

|

|

| Average concentration of cybutryne (mg of cybutryne per kg of dry

paint):

|

|

|

3. Conclusions:

|

| The

average concentration of cybutryne exceeds the threshold of 1,250 mg of

cybutryne per kg of dry paint

|

☐

Yes

|

☐ No

|

|

4. Additional comments concerning analysis of results from Specimens

'C':

|

| Case C. Simplified

approach to detect organotin and cybutryne

|

| 1.

A one-step analysis using gas chromatography/mass spectrophotometry

(GC/MS)

|

| Company name:

|

| Analyst

responsible:

|

Date :

|

| 2.

Specimen 'C' results:

|

|

| Total number of specimens 'C' analysed by GC-MS:

|

|

| Average concentration of organotin (mg Sn per kg of dry paint):

|

|

| Average concentration of cybutryne (mg of cybutryne per kg of dry

paint):

|

|

|

|

|

|

3. Conclusions:

|

| The

average concentration of organotin exceeds the threshold of 3,000 mg

Sn/kg of dry paint

|

☐

Yes

|

☐ No

|

| The

average concentration of cybutryne exceeds the threshold of 1,250 mg of

cybutryne/kg of dry paint

|

☐

Yes

|

☐ No

|

|

4. Additional comments concerning analysis of results from Specimens

'C':

|

| SECTION 4:

Final conclusion

|

| Summarized

conclusion:

|

|

|

Compliance with AFS Convention assumed

|

☐

|

|

|

Non-compliance with AFS Convention assumed

|

☐

|

|

THIS IS TO CERTIFY that this Record is correct in all respects.

|

| Issued

at

|

__________________________________________________

|

| (Place of issue of Record)

|

| _______________________________________________________________________________________________

|

| (Date

of issue)

|

(Printed name and signature of authorized official issuing the

Record)

|

|

|

(Seal

or stamp of the authority / organization)

|