1 SOLAS Regulation II-2/59.4 requires oil tankers constructed on or after 1 October 1994,

to be provided with suitable arrangements for gas freeing and ventilation

of double hull spaces. In addition, oil tankers fitted with inert

gas systems are required to have suitable arrangements for inerting

double hull spaces, when necessary.

2 The recommendations contained in this annex

are intended to provide an advice for alternative solutions available

and indicate acceptable arrangements.

Gas Freeing and Ventilation

3 The gas freeing and ventilation arrangements

must be capable of gasfreeing:

in order to maintain adequate ventilation continuously during

entry of personnel.

Alternative Methods of Ventilation

4 The following methods of ventilation are feasible:

-

.1 filling and subsequent emptying with water

ballast,

-

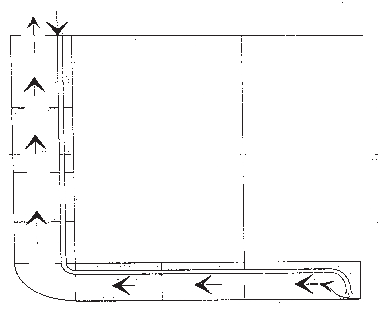

.2 using portable gas-freeing fan fitted to tank

openings with hose or pipe led to bottom of the tank. Discharge may

be through hatch or manhole (See

Fig. 1, 2 and 3). Pipes made of non-metallic material

may be accepted if documented to be of electrically conductive type

and suitably grounded. For acceptable results in larger L-shaped tanks,

the purge pipes should be led inboard to the centreline double bottom

girder. An alternative to portable fans is to use inert gas fans;

-

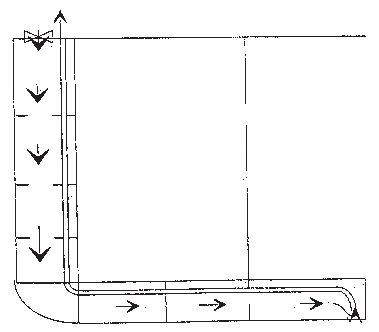

.3 same arrangement as paragraph 4.1.2, however,

extraction from bottom through purge pipe and fresh air supply from

deck (see

Fig.2.);

-

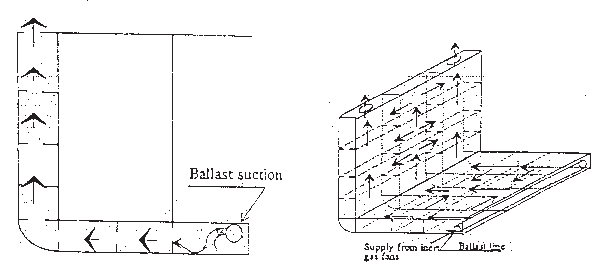

.4 connection between the inert gas line and the

water ballast line for fresh air supply through ballast suctions (see

Fig.3);

-

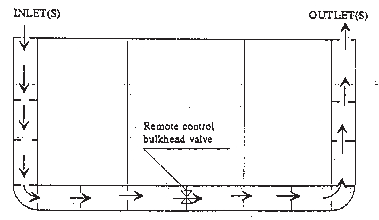

.5 cross-over ventilation (see

Fig.4);

-

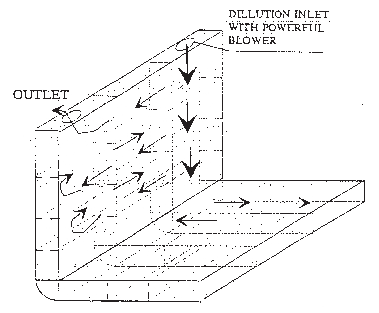

.6 an arrangement utilizing dilution method with

inlet and outlet at deck level (see

figure 5). This method will require

a powerful fan so that the jet will penetrate all the way down to

the tank bottom. The high inlet velocity causes turbulent mixing with

the tank atmosphere. The gas being exhausted from the tank is at any

time a mixture of the gas supplied and the tank atmosphere. For L-shaped

tanks this method alone is normally not considered sufficient, but

in combination with air supply through ballast suctions, it may be

acceptable; and

-

.7 combination of partly filling and ventilation,

e.g. filling of double bottom section of U-shaped tanks and ventilation

of side spaces.

Figure 1 Ventilation by means of portable fan/inert gas fan and purge pipe

Figure 2 Gas freeing by means of portable fan and purge pipe

Figure 3 Ventilation with supply from inert gas fan through ballast

suction

Figure 4 Cross-over ventilation through remote operated bulkhead valve(s)

Figure 5 Ventilation by dilution method

5 Methods listed in paragraphs 4.1 to 4.5 are

based on displacement of gas, which is considered to be the best solution

for deep tanks of cellular design.

6 Most hydrocarbon gases from crude oil, hydrogen

sulphide and inert gas are heavier than air. With requirements for

connections for inert gas supply to ballast tanks, inerting of ballast

tanks will probably be a normal procedure. A ventilation arrangement

extracting the heavier gases from bottom utilizing portable fans mounted

on purge pipes and with fresh air supply from open hatches in deck

will probably be an effective gas-freeing method.

7 However, filling of ballast tanks and subsequent

emptying is considered as the most efficient way of gas-freeing ballast

tanks. Hull strength limitations must be observed.

8 The arrangements for inerting of double hull

spaces may be through portable connections to the inert gas system

for cargo tanks or by fixed piping connections.

9 If fixed piping is used, the arrangement must

include a separate deck water seal and a non-return valve in order

to prevent communication between vapour spaces of cargo tanks and

the double hull spaces. The practices for inerting double hull spaces

may either be to keep these spaces inerted at all times when empty,

or to inert them only if hydrocarbon gases are detected indicating

leakage between cargo tank(s) and the double hull spaces. If the former

practice is utilized, a fixed piping system is considered necessary.

Methods and Arrangements for Inerting

10 As for gas freeing and ventilation the easiest

method for inerting is to supply inert gas to the space during deballasting.

For that purpose an inert gas inlet in the top of the space is needed.

However, arrangements must additionally, be provided to enable the

space to be purged with inert gas. For this purpose at least L-shaped

tanks must be provided with inert gas supply outlets near bottom far

ends. Alternative arrangements for inert gas purging will be the same

as for ventilation purposes detailed in paragraphs 4,5,6 and 7, replacing

portable fan with inert gas supply inlets.

11 Written procedures should be available onboard

giving details on how to carry out ventilation, inerting of cleaning

or double hull spaces.