When the craft enters service, safety assessment does not stop. It is

important that a management system is in place that ensures that all those aspects

identified in the safety assessment relating to operational procedures, regular checks

and maintenance tasks are implemented so that safety standards can be upheld. The

appropriate mechanism for this is provided by the International Safety Management (ISM)

Code, requiring the operator to implement a Safety Management System (SMS). The SMS

should incorporate results from the PSSA and SSA, in particular with reference to:

-

.1 crew operational procedures;

-

.2 emergency procedures and actions;

-

.3 procedures related to the control of hazardous

situations and accidents;

-

.4 maintenance procedures for equipment whose sudden

failure may have a hazardous or catastrophic effect;

-

.5 inspection intervals and methods; and

-

.6 control of documents and data relevant for the SMS

as well as the integrity and operation of the craft.

Table 1 – Correlation between levels of probability and categories of effect

| Probability(quantitative)

|

|

|

|

|

|

|

|

|

|

|

|

|

10-0

|

10-3

|

10-5

|

10-7

|

10-9

|

| Probability

(descriptive)

FAA

|

Probable

|

Improbable

|

Extremely

Improbable

|

| JAA

|

Frequent

|

Reasonably

Probable

|

Remote

|

Extremely

Remote

|

| Category

of Effect

|

Minor

|

Major

|

Hazardous

|

Catastrophic

|

| Effect on craft, occupants and

environment

|

- slight reduction in safety

margins or functional capabilities; or

- slight increase in

crew workload; or

- some inconvenience to

occupants

|

- significant reduction in

safety margins or functional capabilities; or

-

significant increase in crew workload; or

-

discomfort to occupants; or

- possibly injuries to

occupants; or

- localized structural damage; or

- moderate environmental pollution

|

- large reduction in safety

margins or functional capabilities; or

- large increase in

crew workload, so that the crew may not be able to perform tasks

accurately or completely; or

- serious or fatal

injuries to a relatively small number of occupants; or

- large structural damage; or

-

significant environment pollution

|

- loss of craft; or

- multiple fatalities;

or

- large environmental pollution with long-term

effects

|

Table 2 – SSA verification data sheet

| SSA

verification data sheet

|

Sheet____ of ____

Issue :

Date

:

|

| FHA/PSSA

requirement

|

Implemented

design

|

| No.

|

Failure condition

|

Objectives

|

Event

|

Probability

|

SSA/FTA reference

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 3 – Input function list

| List of

functions worksheet

|

Sheet____ of ____

Issue :

Date

:

|

| Function No.

|

Function

|

System

Subsystem

Equipment

|

Equipment- ID-No.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 4 – FHA worksheet

| Functional

hazard analysis worksheet

|

Sheet____ of ____

Issue :

Date

:

|

| System:

Subsystem:

|

Function:

|

| Item No.

|

Failure condition

|

Mission phase

|

Failure effects

|

Classification

|

Objectives

|

Remarks

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 5 – Component FMECA worksheet

| Component

FMECA worksheet

|

Sheet____ of ____

Issue :

Date :

|

| System:

Subsystem:

|

FTA reference:

|

| Item No.

|

Item

|

Item Failure mode

|

Mode Failure rate

|

Mission phase

|

Failure effects

|

Detection method

|

Classification

|

Remarks

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 6 – FMES worksheet

| FMES

worksheet

|

Sheet____ of ____

Issue :

Date

:

|

| System:

Subsystem:

|

| Item No.

|

Failure mode

|

Failure rate

|

Effects on system

|

Failure cause (FMECA

Ref.)

|

Detectability

|

Remarks

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 7 – Zonal Hazard Analysis data sheet

| ZHA: Hazard Identification data sheet

|

Sheet____ of ____

Issue :

Date

:

|

| System:

Zone:

Zone

number:

|

System:

Equipment:

|

Subsystem:

|

| ID

|

Hazardous element

|

Hazardous condition

|

Initiator event

|

Effects

|

Probability

|

Safety measures/ Means of

compliance

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

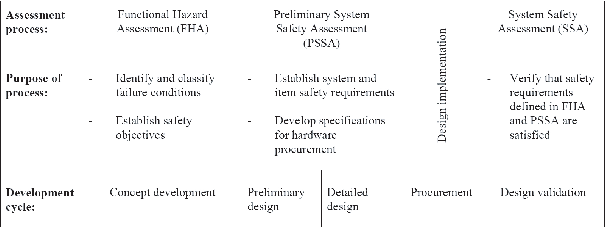

Figure 1 – Relationship between safety assessment processes and the different phases

of the development cycle