3

Construction.

The construction and assembly of the device should be in accordance with tables A.2 to

A.5, figures A.1 to A.19 and figures A.21 to A.36. A tolerance of ± 6 mm is used

throughout for fabric cutting and stitching assembly. A tolerance of ± 6 mm is also used

for foam cutting, however, the buoyancy requirements of table A.3 should be met.

3.1 Seams

3.1.1 The seam allowances are 13 mm, unless otherwise specified. All structural seams

use a lock type stitch so that the seam will not unravel when a force is applied in the

direction of the seam on any of the threads forming the stitch. Stitching should have a

density of 7 to 12 stitches per 25 mm of stitch length. The box-X stitching on the

webbing is 15 mm x 18 mm, unless otherwise specified. The bar-tack stitching on the

webbing is 15 mm x 2 mm.

3.1.2 On the closing seam of the back section of the outer and inside cover, the cut

ends of the fabric are turned under and stitched so that the fabric will not ravel. The

cut ends of webbing should be heat-sealed.

3.1.3 Tabs on the ends of the waist belt are formed by turning under 40 mm of material

twice and stitching 19 mm from the end of the folds with box-X or bar tack stitching.

3.1.4 The zippers are set to the fabric by turning under the raw edge of the fabric 13

mm, aligning the fold with the centre of the closed zipper, and topstitching through

both layers of fabric and the zipper tape. The stitch line should be far enough from the

zipper teeth or coil so as not to interfere with the operation of the zipper.

3.2 Assembling the fabric cover

The fabric cover is assembled as described below, with the dimensions described in

figures A.31 through A.33 and table A.4.

3.2.1 Assembling the inside cover

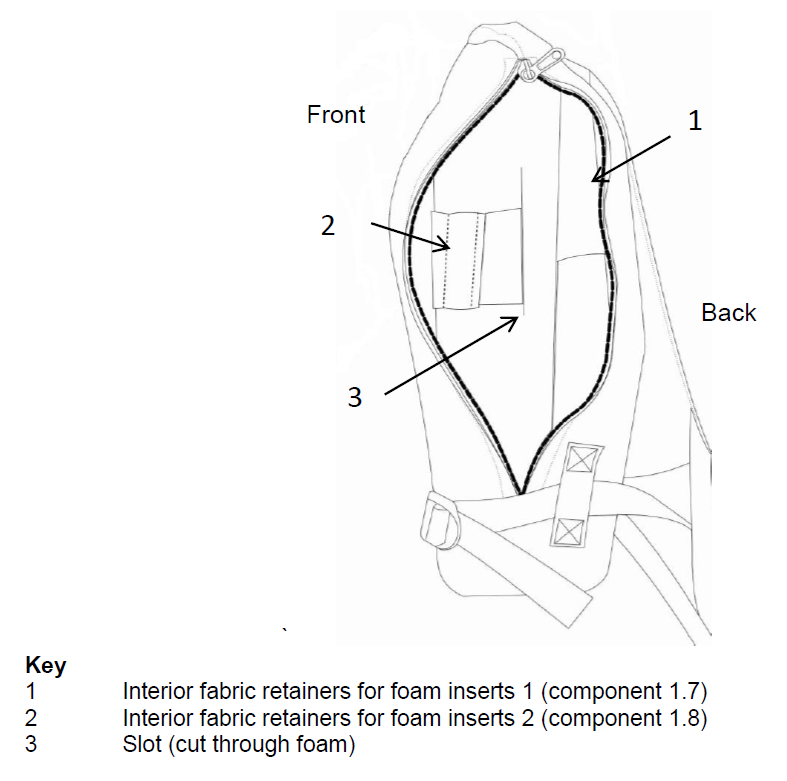

3.2.1.1 Attach the interior fabric retainers for foam inserts 1 (component 1.7) to the

"wrong" (interior) side on each lobe of the inside cover fabric (component 1.3).

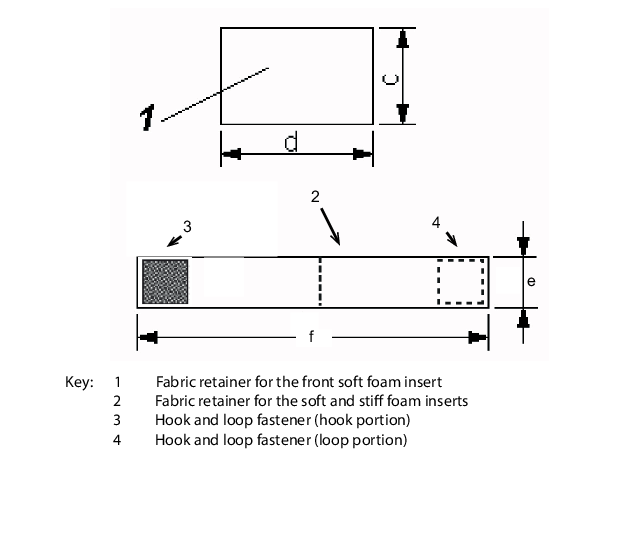

Figure A.1 – Location of Interior fabric retainers

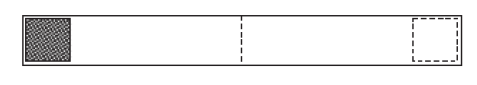

3.2.1.2 Sew the hook and loop fasteners (component 4) to opposing sides of

the interior fabric retainers for foam inserts 2 (component 1.8) as shown in figure

A.2.

Figure A.2 – Orientation of hook and loop fasteners

3.2.1.3 Fold the interior fabric retainers for foam inserts 2 (component 1.8) in half

and sew to the inside edge seam allowance of the "wrong" (interior) side of the inside

cover fabric (component 1.3). Sew one fabric retainer to each lobe of the front cover

fabric with the hook and loop fasteners (component 4) facing upward and oriented toward

the outer edge of the inside cover fabric. Turn the bottom edge of the back cover up 13

mm and topstitch.

Figure A.3 – Location of fabric retainers

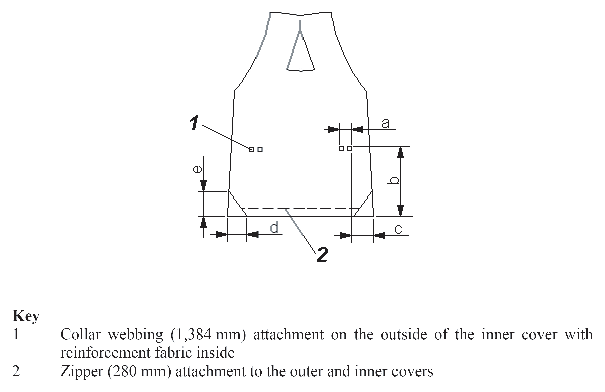

3.2.1.4 Attach one 89 mm black belt-loop webbing (component 3.5) to each

lobe of the "right" (exterior) side of the inside cover fabric. Join the shoulder

darts.

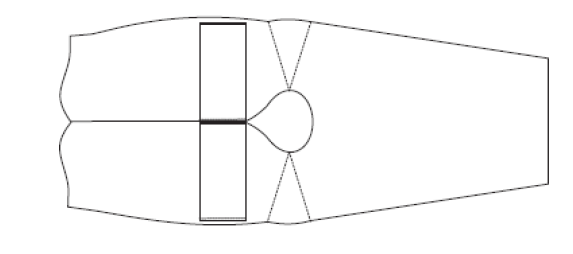

Figure A.4 – Completed inside cover

3.2.2 Assembling the collar cover

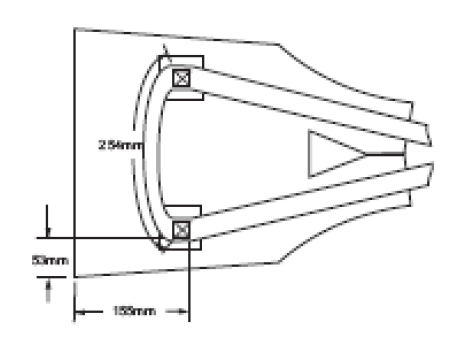

3.2.2.1 Attach the yellow collar attachment webbing (component 3.6) to the inside collar

cover (component 1.5), placing one reinforcement patch (component 1.6) under the fabric,

with a tack on each side, as in figure A.5. The webbing should be centred on the fabric,

creating a 254 mm loop measured from the edge of one tack to the edge of the other.

Figure A.5 – Collar attachment on collar cover

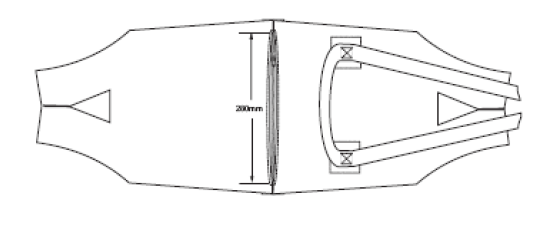

3.2.2.2 Sew the 280 mm zipper (component 6.5) to the inside and outer collar cover

fabric (component 1.5) as in figure A.6.

Figure A.6 – Joining the inside and outer collar cover

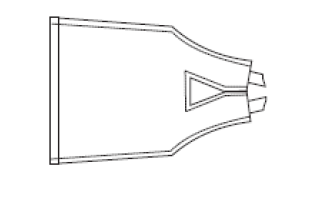

3.2.2.3 With the "right" (exterior) sides of the fabric together, join the sides of the

inside and outer collar cover fabric (component 1.5) at the sides and around the neck

opening. To allow access to the collar foam insert, do not join the fabric at the ends

of the zipper. Turn the collar cover right side out.

Figure A.7 – Completed collar cover

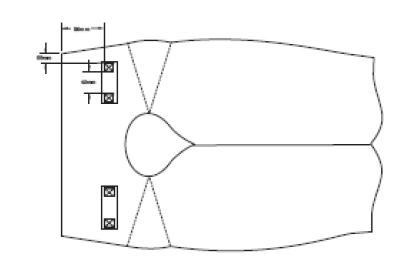

3.2.3 Assembling the outer cover

3.2.3.1 Attach one 76 mm black belt-loop webbing (component 3.4) to each shoulder on the

"right" (exterior) side of the front outer cover fabric (component 1.1) using double bar

tack stitches on each end, creating a 40 mm loop opening.

Figure A.8 – Attaching the shoulder loops

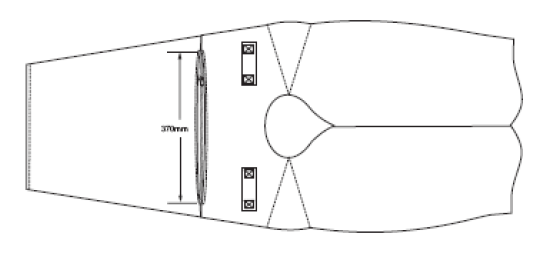

3.2.3.2 Sew the 370 mm zipper (component 6.6) to the back outer cover (component 1.2)

and front outer cover (component 1.1) as shown in figure A.9. Turn the bottom edge of

the back cover up 13 mm and topstitch.

Figure A.9 – Completed outer cover

3.2.4 Joining the collar to the front outer cover

Join the shoulder darts on the front outer cover (component 1.1). Lace the yellow collar

attachment webbing (component 3.6) through the black shoulder straps (component 3.4)

with the collar loop facing toward the cover fabric. Stitch the collar cover fabric tabs

to the neck seam.

Figure A.10 – Joining the collar to the front outer cover

3.2.5 Assembling and attaching the hardware assemblies

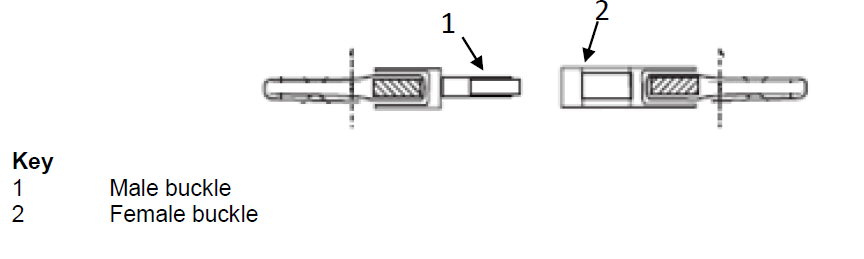

3.2.5.1 Construct the chest strap buckle assemblies by lacing the 127 mm black chest

strap webbing (component 3.1) through the male and female buckles (component 6.1) and

stitching, as shown in figure A.11.

Figure A.11 – Chest strap buckle assembly

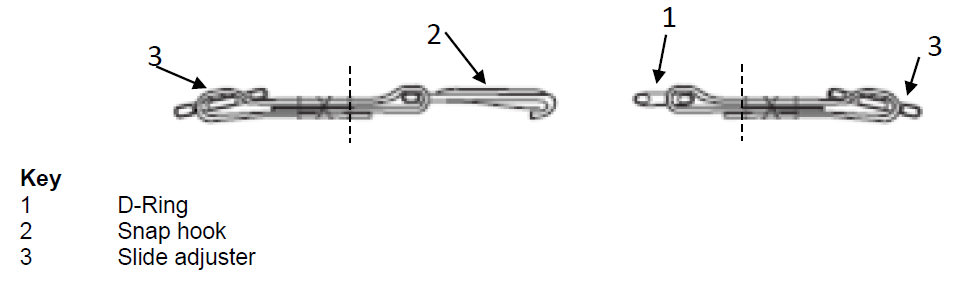

3.2.5.2 Construct the waist belt assemblies by lacing the 203 mm black waist belt

webbing (component 3.3) through the slide adjusters (component 6.2), snap hook

(component 6.3), and D-ring (component 6.4), and stitching as shown in figure A.12.

Figure A.12 – Waist belt assembly

3.2.5.3 Lace the left side yellow collar attachment webbing (component 3.6) through the

male chest strap buckle assembly. With one fabric reinforcement (component 1.6)

positioned on the "wrong" (interior) side of the front outer cover fabric (component

1.1), attach the chest strap buckle assembly to the yellow collar attachment webbing and

cover fabric with a box-X stitch. Repeat on the right side with the female chest strap

buckle assembly.

Figure A.13 – Attachment of chest strap buckle assembly

3.2.5.4 Lace the left side yellow collar attachment webbing (component 3.6) through the

snap hook waist belt assembly. Attach the waist belt assembly to the yellow collar

attachment webbing and the front outer cover fabric (component 1.1) with a box-X stitch.

Repeat on the right side with the D-ring waist belt assembly.

3.2.5.5 Stitch the yellow collar attachment webbing to cover front, between the two

buckle assemblies on each front forming a rectangle.

Figure A.14 – Chest and waist belt attachments

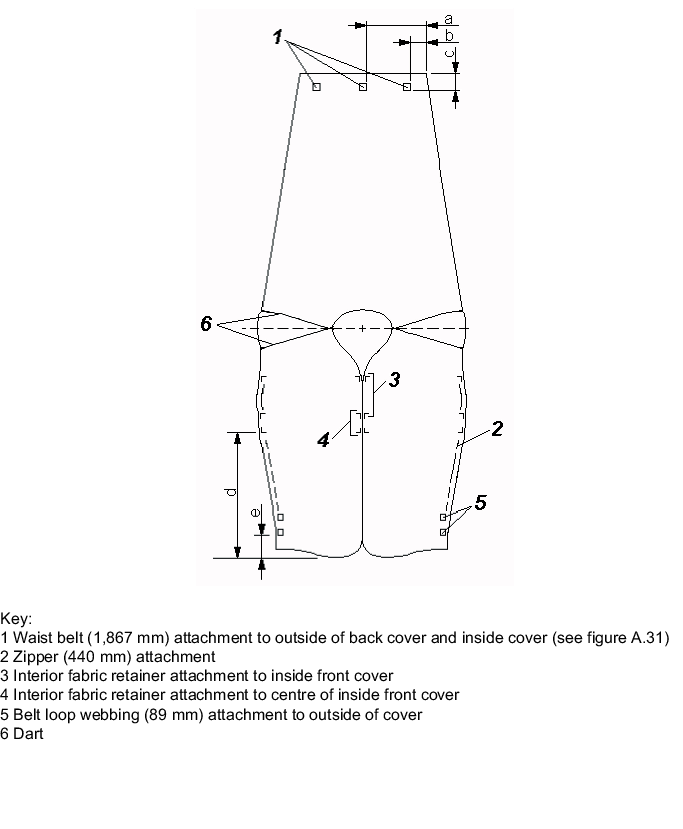

3.2.6 Joining the inside and outer covers

3.2.6.1 Join the inside cover fabric (component 1.3) to the front and back outer cover

fabric (components 1.1 and 1.2) at the sides by sewing a 440 mm zipper (component 6.7)

on the outside edge of each front.

Figure A.15 – Joining the inside and outer cover fabric

3.2.6.2 Join a centre gusset (component 1.4) to the left and right lobes of the outer

cover fabric, then join to the inside cover. The seam created by joining the outside

edges should be centred on the end of the gusset with the taper of the gusset forming a

point as it approaches the neck curve, as shown in figure A.16.

Figure A.16 – Joining the inside and outer over with the centre gusset

3.2.7 Finishing

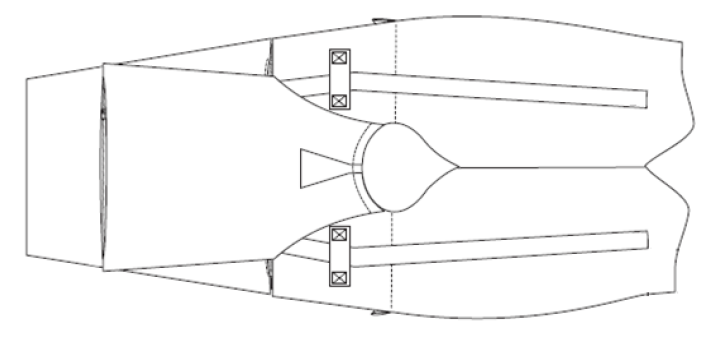

3.2.7.1 Turn the cover right-side out. Attach the 1867 mm black waist belt webbing

(component 3.3) to the back cover with three tacks, one centred on the fabric and one on

each corner of the fabric. Tack the free ends of the webbing with a box-X with ends

double folded. Top stitch through the inside and back outer covers, 80 mm from the foam

access zipper (component 6.6).

Figure A.17 – Attaching the waist belt

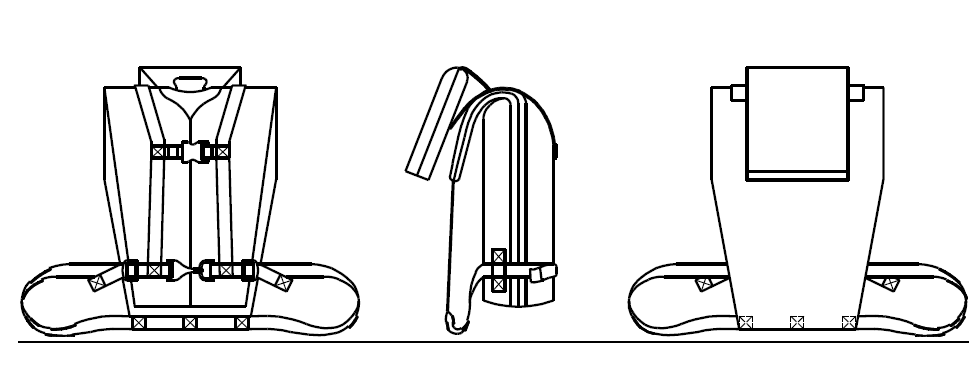

3.2.7.2 Lace the 1867 mm black waist belt webbing (component 3.3) through the slide

adjusters (component 6.2) on each waist belt assembly.

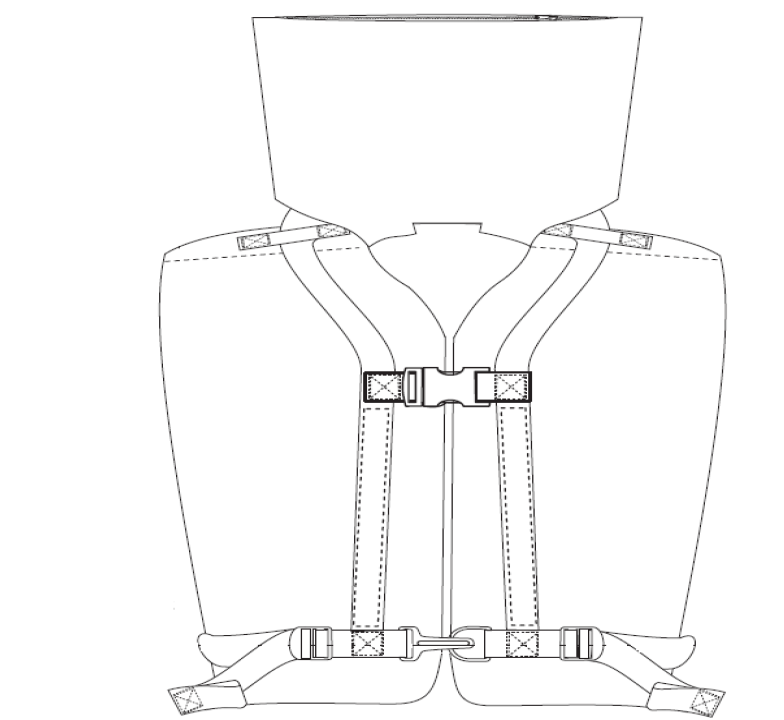

Figure A.18 – Completed RTD cover and hardware

3.3 Inserting the front foam

Slide the front foam inserts (components 2.2.1 and 2.2.2) under the interior fabric

retainers for foam inserts 1 (component 1.7). Slide the interior fabric retainers for

foam inserts 2 (component 1.8) through the slot in the front foam inserts (components

2.1.1 and 2.1.2). Wrap the interior fabric retainer for foam inserts around the foam

insert so that the retainer passes around the front of the RTD as shown in figure A.19.

Close the hook and loop fastener. Close the zipper (component 6.7).

Figure A.19 – Inserting the front foam

3.4 Validation

The proper assembly of the RTD should be verified according to the Guidelines developed

by the Organizationfootnote.

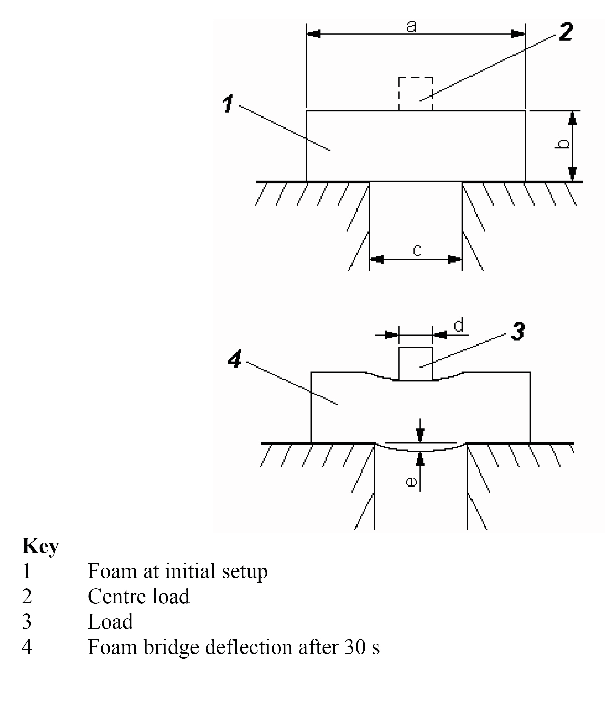

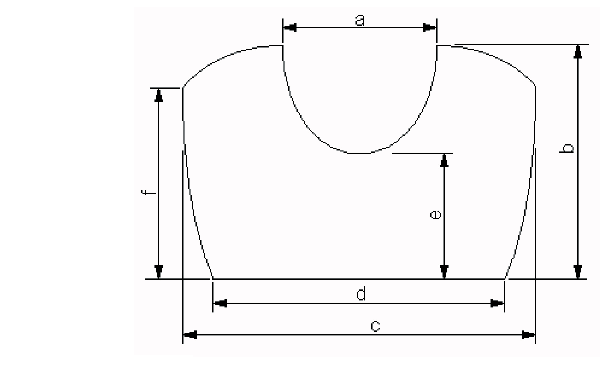

Figure A.20 – Foam bridge deflection test

Table A.1 - Specifications for the

foam bridge deflection test

|

|

Dimension shown in figure A.20

|

Load mass

|

| Foam type

|

a

(Length)

mm

|

(Not

shown)

(Width)

mm

|

b

(Thickness)

mm

|

c

(Span)

mm

|

d

(Load

width)

mm

|

e

(Deflection)

mm

|

kg

|

| Stiff

|

394

|

110

|

83

|

300

|

120

|

< 20

|

8.6

|

| Soft

|

394

|

110

|

45

|

150

|

30

|

≥ 25

|

0.75

|

Table A.2 - Parts, quantity and

assembly

| Component

|

Description

|

Quantity

|

See

figure

|

Construction

notes

|

| 1 Cover fabric

|

420 denier nylon, with ravel resistant

coating, orange

|

|

|

|

| 1.1 Front outer cover

|

|

1

|

A.21

|

|

| 1.2 Back outer cover

|

|

1

|

A.21

|

|

| 1.3 Inside cover

|

|

1

|

A.22

|

|

| 1.4 Centre

gusset

|

|

2

|

A.23

|

|

| 1.5 Collar,

outer and inside cover

|

|

2

|

A.24

|

|

| 1.6 Fabric

reinforcement

|

|

4

|

A.25

A.33

|

Attach to

inside of collar cover, as attachment 1, for reinforcement at webbing

attachment (see figure A.33).

|

| 1.7 Interior

fabric retainers for foam inserts 1

|

|

2

|

A.26

A.1

|

Attach to

inside of front cover, as attachment 3, stitch to cover at each side to form

a foam retainer for inside front foam insert components 2.2.1 and 2.2.2 (see

figure A.1).

|

| 1.8

Interior fabric retainers for foam inserts 2

|

|

|

A.26

A.3

|

Attach hoop

and loop fasteners to the ends and stitch at centre to the inside of front

cover, as attachment 4, to form a foam retainer for front foam insert

components 2.1.1 and 2.1.2 (see figure A.3).

|

| 2

Foam

|

|

|

|

|

| 2.1

Stiff

|

See tables

A.1 and A.3

|

|

|

|

| 2.1.1

Front foam insert, right side

|

81 mm

thick

|

1

|

A.27

|

|

| 2.1.2

Front foam insert, left side

|

81 mm

thick

|

1

|

A.27

|

|

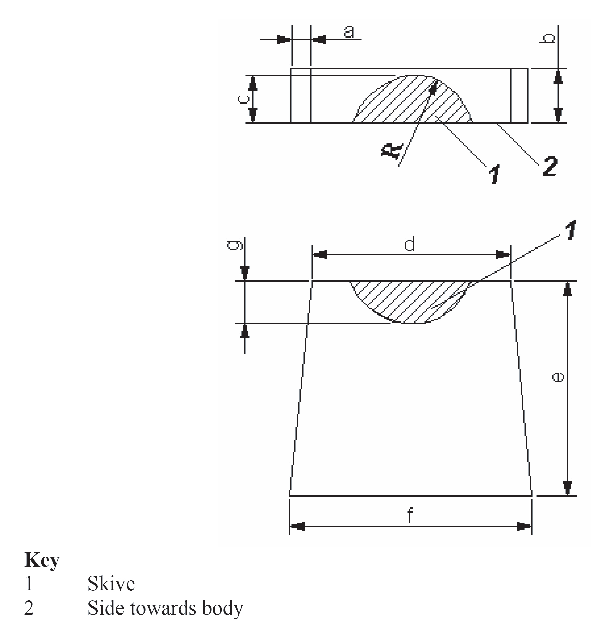

| 2.1.3

Collar foam insert

|

56 mm

thick

|

1

|

A.29

|

|

| 2.2

Soft

|

See tables

A.1 and A.3

|

|

|

|

| 2.2.1

Inside front foam insert, right side

|

46 mm

thick

|

1

|

A.28

|

|

| 2.2.2

Inside front foam insert, left side

|

46 mm

thick

|

1

|

A.28

|

|

| 2.2.3

Back foam insert

|

25 mm

thick

|

1

|

A.30

|

|

| 3

Webbing

|

25 mm,

polypropylene, with easy adjustment and no significant slippage when used

with the specified hardware.

|

|

|

|

| 3.1 Chest

strap

|

127 mm,

black

|

2

|

A.11

A.31

|

On left

side of front cover, attach webbing with male buckle. On right side of front

cover attach webbing with female buckle. The free ends of the chest strap

are folded under the yellow webbing (collar attachment webbing), with

reinforcing fabric (see figure A.25) on inside of cover fabric. A box-x

stitch is used to attached the chest strap to the front cover.

|

| 3.2 Waist

belt

|

203 mm,

black

|

2

|

A.12

A.31

|

On left side

attach waist belt with slide and buckle clip waist belt. On right side

attach bottom belt with D-ring and slide.

|

| 3.3 Waist

belt

|

1,867 mm,

black

|

1

|

A.31

A.32

A.17

|

Form 40 mm

tab on each end. Attach to back cover using three box-x stitches (after

front and back covers are assembled).

|

| 3.4 Belt

loop on front cover

|

76 mm,

black

|

2

|

A.31

A.8

|

Attach

webbing to front outer cover and form a belt loop (one on each side) by two

sets of double bar tack stitches

|

| 3.5 Belt

loop on inside cover

|

89 mm,

black

|

2

|

A.32

A.4

|

Attach

webbing to inside cover and form a belt loop (one on each side) by two box-x

stitches

|

| 3.6

Collar attachment

|

1,384 mm,

yellow

|

1

|

A.14

A.6

A.31

A.33

|

Attach

webbing to collar and reinforcing fabric, in two places using box-x

stitch

|

| 4 Hook

and loop fastener

|

50 mm × 70

mm, black generic

|

2

|

A.2

A.26

|

Hook and

loop fasteners are attached to the ends of interior fabric retainer for foam

insert

|

| 5

Thread

|

Generic

synthetic

|

AR

|

|

|

| 6

Hardware

|

|

|

|

|

| 6.1

Buckle

|

Male and

female 25 mm, plastic

|

1

|

|

Chest

strap

|

| 6.2

Slide

|

Adjuster 25

mm, plastic, 1,600 N single-end strength

|

2

|

|

Waist

belt

|

| 6.3 Snap

Hook

|

25 mm, SS,

1,600 N single-end strength

|

1

|

|

Waist

belt

|

| 6.4

D-ring

|

25 mm, SS,

1,600 N single-end strength

|

2

|

|

Waist

belt

|

| 6.5

Zipper

|

280 mm,

open-ended plastic (zipper chain and pulls)

|

1

|

A.6

A.33

|

Foam access

for collar cover

|

| 6.6

Zipper

|

370 mm,

plastic (zipper chain and pulls)

|

1

|

A.9

A.31

|

Foam access

for back cover

|

| 6.7

Zipper

|

440 mm,

plastic (zipper chain and pulls)

|

2

|

A.15

A.31

A.32

|

Foam access

for front cover

|

Table A.3 - Foam insert

specifications

| Values in Newtons (N)

|

|

|

Front right

|

Front left

|

Inside front

right

|

Inside front

left

|

Back

|

Collar

|

| Foam typea

|

Stiff

|

Stiff

|

Soft

|

Soft

|

Soft

|

Stiff

|

| Buoyancyb

|

34 ± 1,1

|

34 ± 1,1

|

17,75 ± 0,65

|

17,75 ± 0,65

|

18,5 ± 0,7

|

28 ± 0,8

|

| a The buoyancy of most foams will change over time with the

greatest change occurring in the first several months after manufacture. The

exact kind of foam selected with need to be evaluated to determine the

amount of additional buoyancy needed at the time of manufacture to maintain

the values specified.

|

| b Buoyancy distribution: 69 % front ± 1.5 percentage

points

|

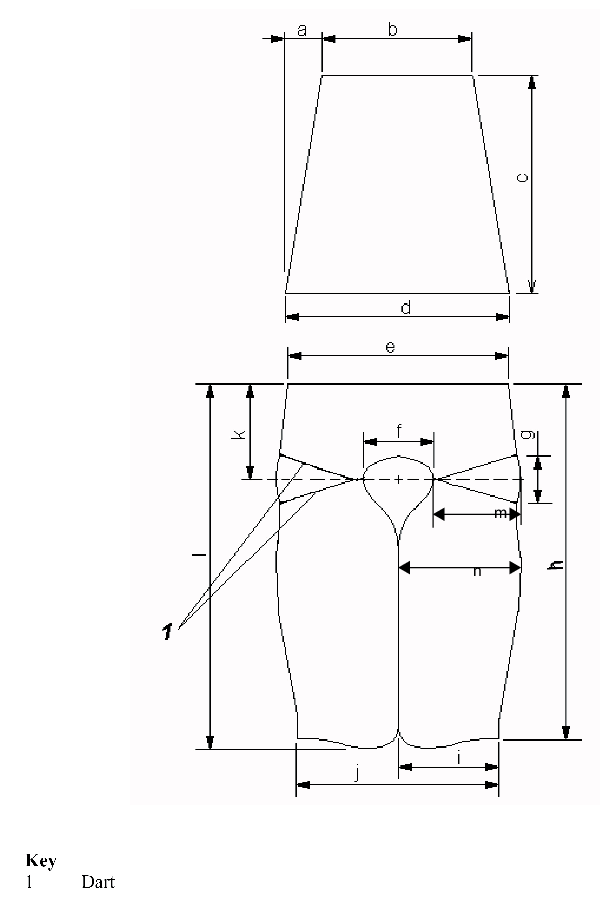

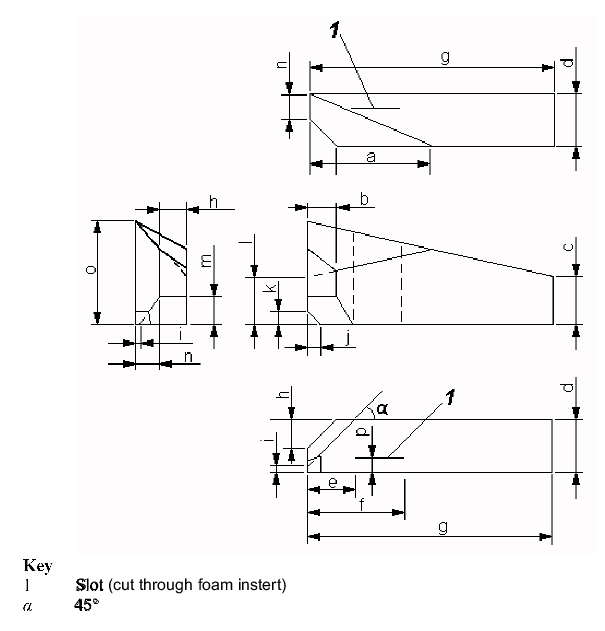

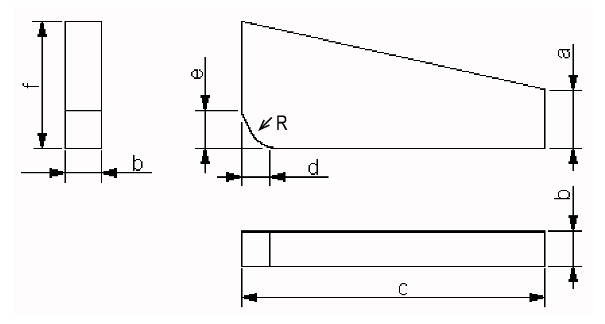

Table A.4 - List of dimensions

shown in figures A.21 to A.33

| Dimensions in

millimetres

|

| Letter

|

Figure

|

| A.21

|

A.22

|

A.23

|

A.24

|

A.25,

A.26

|

A.27

|

A.28

|

A.29

|

A.30

|

A.31

|

A.32

|

A.33

|

|

a

|

66

|

298

|

23

|

308

|

73

|

198

|

76

|

20

|

188

|

120

|

138

|

19

|

|

b

|

298

|

100

|

497

|

75

|

73

|

46

|

46

|

56

|

274

|

18

|

18

|

155

|

|

c

|

427

|

1106

|

586

|

10

|

130

|

76

|

394

|

51

|

414

|

35

|

35

|

53

|

|

d

|

430

|

199

|

102

|

288

|

205

|

84

|

38

|

216

|

343

|

55

|

295

|

25

|

|

e

|

423

|

398

|

|

342

|

72

|

76

|

51

|

229

|

147

|

95

|

55

|

45

|

|

f

|

141

|

597

|

|

396

|

470

|

157

|

165

|

259

|

223

|

320

|

|

|

|

g

|

100

|

1124

|

|

65

|

|

394

|

|

45

|

|

90

|

|

|

|

R

|

|

|

|

|

|

|

51

|

70

|

|

|

|

|

|

h

|

705

|

141

|

|

|

|

46

|

|

|

|

40

|

|

|

|

i

|

199

|

|

|

|

|

8

|

|

|

|

55

|

|

|

|

j

|

398

|

|

|

|

|

20

|

|

|

|

225

|

|

|

|

k

|

197

|

|

|

|

|

20

|

|

|

|

80

|

|

|

|

l

|

723

|

|

|

|

|

76

|

|

|

|

|

|

|

|

m

|

176

|

|

|

|

|

46

|

|

|

|

|

|

|

|

n

|

245

|

|

|

|

|

38

|

|

|

|

|

|

|

|

o

|

|

|

|

|

|

165

|

|

|

|

|

|

|

|

p

|

|

|

|

|

|

25

|

|

|

|

|

|

|

Table A.5 – List of dimensions shown in figures A.35 and A.36

|

|

Dimensions in

millimetres

|

|

|

Dimension

|

| a

|

b

|

c

|

d

|

e

|

f

|

g

|

h

|

i

|

j

|

k

|

l

|

| A.35

|

450

|

530

|

980a

|

90

|

60

|

340

|

20

|

310

|

70

|

50

|

60

|

260

|

| A.36

|

260

|

340

|

230

|

120

|

215

|

210

|

60

|

290

|

|

|

|

|

|

|

|

|

m

|

n

|

o

|

p

|

q

|

r

|

|

|

|

|

|

|

| A.35

|

240

|

270

|

130

|

80

|

70

|

30

|

|

|

|

|

|

|

| A.36

|

|

|

|

|

|

|

|

|

|

|

|

|

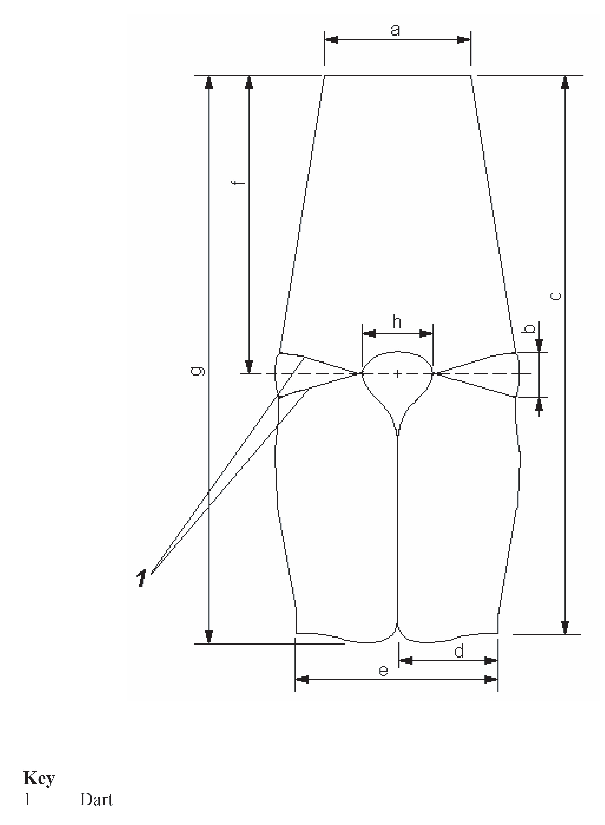

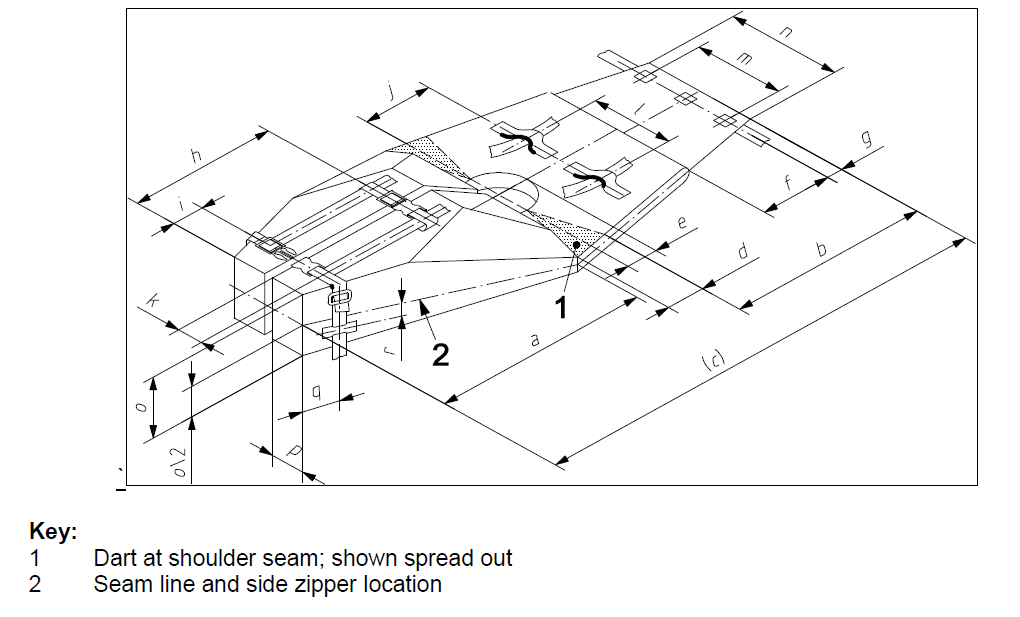

Figure A.21 – Outer cover, front and back sections

Figure A.22 – Inside cover

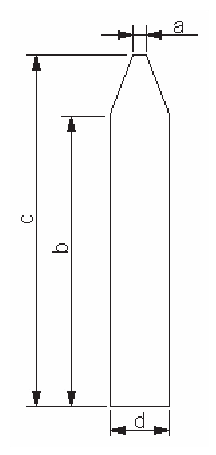

Figure A.23 – Centre gusset

Figure A.24 – Outer and inside cover, collar

Figure A.25 – Fabric reinforcement

Figure A.26 – Interior foam

retainer

Figure A.27 – Front foam insert

Figure A.28 – Inside front foam insert

Figure A.29 – Collar foam insert

Figure A.30 – Back foam

insert

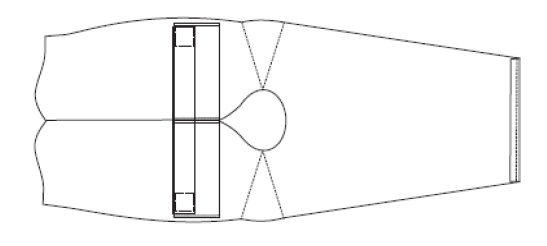

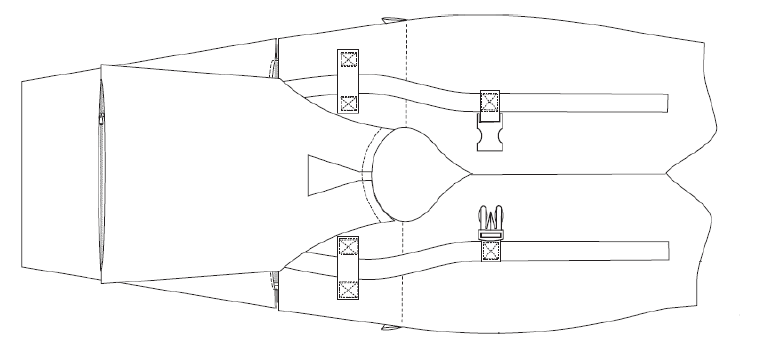

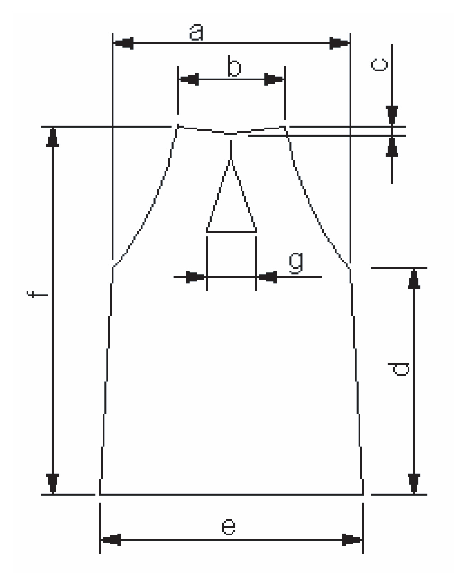

Figure A.31 – Attachments to front and back cover (dimensions on pattern,

before sewing)

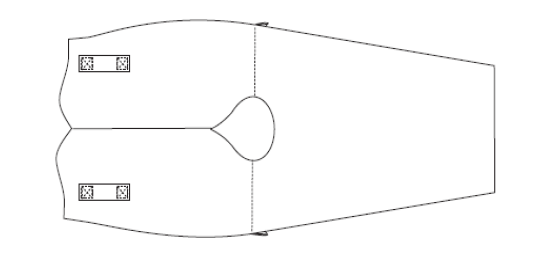

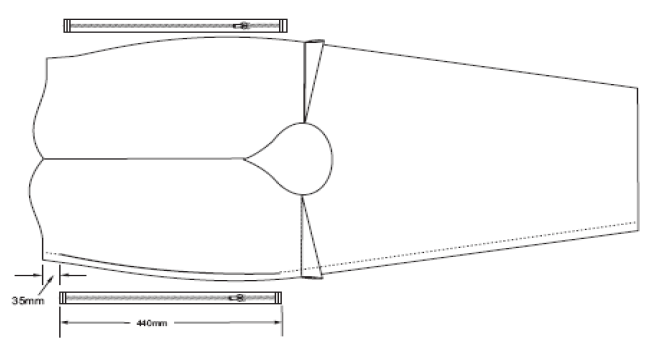

Figure A.32 – Attachments to inside cover (dimensions on pattern, before

sewing)

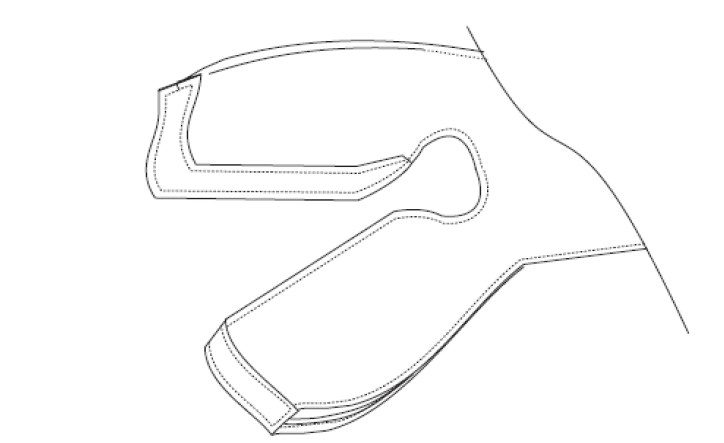

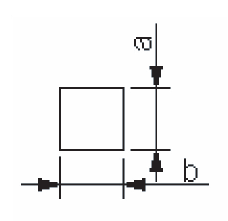

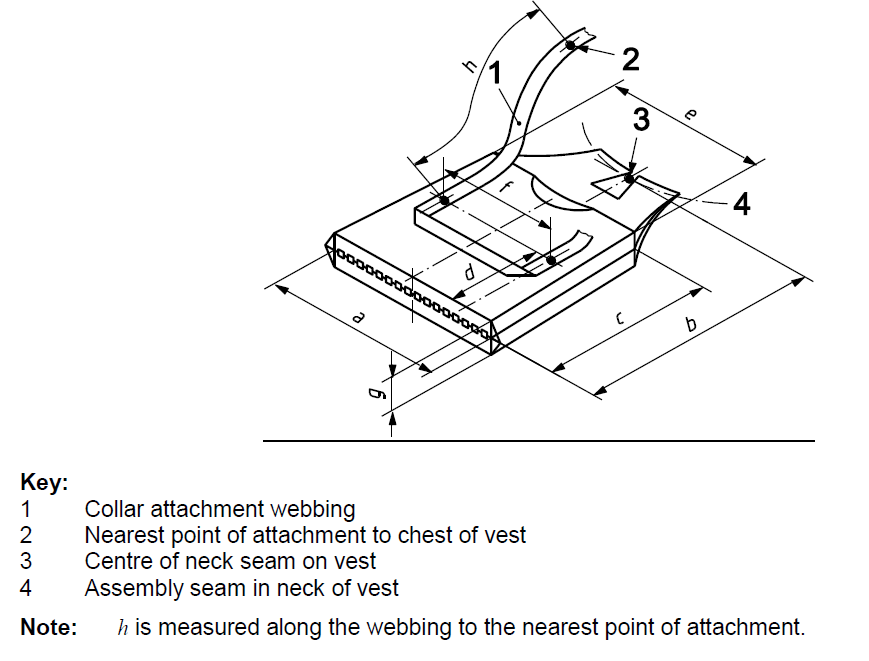

Figure A.33 – Attachments to outer and inside collar cover (dimensions on

pattern, before sewing)

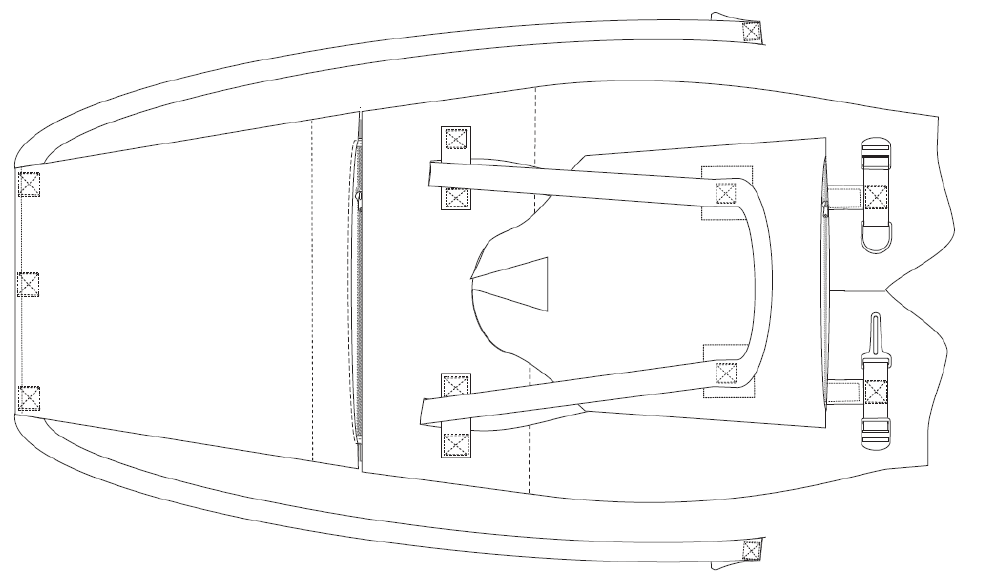

Figure A.34 – Assembly views of

finished RTD

Figure A.35 – Assembly

dimensions of finished RTD body with collar removed

Figure A.36 – Assembly

dimensions of finished RTD collar