1 Data

1.1 General information

| Shipbuilder

|

JAPAN Shipbuilding

Company

|

| Hull no.

|

12345

|

| IMO no.

|

94111XX

|

| Ship type

|

Bulk carrier

|

1.2 Principal particulars

| Length overall

|

250.0 m

|

| Length between

perpendiculars

|

240.0 m

|

| Breadth, moulded

|

40.0 m

|

| Depth, moulded

|

20.0 m

|

| Summer load line draught,

moulded

|

14.0 m

|

| Deadweight at summer load line

draught

|

150,000 tons

|

1.3 Main engine

| Manufacturer

|

JAPAN Heavy Industries

Ltd.

|

| Type

|

6J70A

|

| Maximum continuous rating

(MCR)

|

15,000 kW x 80 rpm

|

| SFC at 75% MCR

|

165.0 g/kWh

|

| Number of sets

|

1

|

| Fuel type

|

Diesel Oil

|

1.4 Auxiliary engine

| Manufacturer

|

JAPAN Diesel Ltd.

|

| Type

|

5J-200

|

| Maximum continuous rating

(MCR)

|

600 kW x 900 rpm

|

| SFC at 50% MCR

|

220.0 g/kWh

|

| Number of sets

|

3

|

| Fuel type

|

Diesel Oil

|

1.5 Ship speed

| Ship speed in deep water at summer load line draught

at 75% of MCR

|

14.25 knots

|

2 Power curves

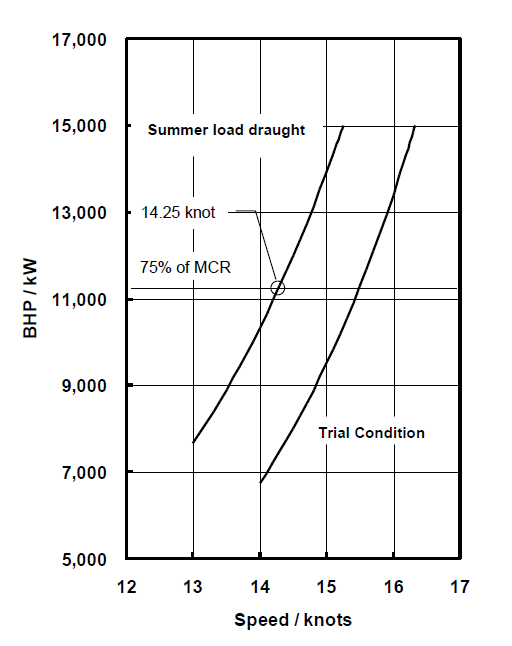

The power curves estimated at the design stage and modified after the

speed trials are shown in figure 2.1.

Figure 2.1: Power curves

3 Overview of propulsion system and electric power supply system

3.1 Propulsion system

3.1.2 Propeller

| Type

|

Fixed pitch propeller

|

| Diameter

|

7.0 m

|

| Number of blades

|

4

|

| Number of sets

|

1

|

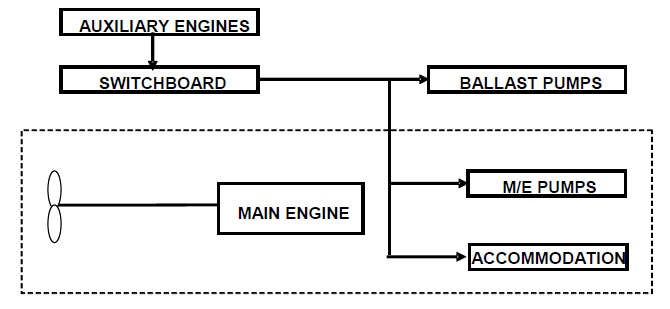

3.2 Electric power supply system

3.2.1 Auxiliary engines

- Refer to paragraph 1.4 of this appendix.

3.2.2 Main generators

| Manufacturer

|

JAPAN Electric

|

| Rated output

|

560 kW (700 kVA) x 900

rpm

|

| Voltage

|

AC 450 V

|

| Number of sets

|

3

|

Figure 3.1: Schematic figure of propulsion and electric power

supply system

4 Estimation process of power curves at design stage

Power curves are estimated based on model test results. The flow of the estimation

process is shown below.

Figure 4.1: Flow-chart of process for estimating power curves

5 Description of energy saving equipment

5.1 Energy saving equipment the effects of which are expressed as

PAEeff(i) and/or Peff(i) in the EEDI

calculation formula

N/A

5.2 Other energy saving equipment

(Example)

5.2.1 Rudder fins

5.2.2 Propeller boss cap fins

(Specifications, schematic figures and/or photos, etc. for each piece of

equipment or device should be indicated. Alternatively, attachment of a commercial

catalogue may be acceptable.)

6 Calculated value of attained EEDI

6.1 Basic data

|

Type of ship

|

Capacity DWT

|

Speed

Vref

(knots)

|

| Bulk Carrier

|

150,000

|

14.25

|

6.2 Main engine

MCRME

(kW)

|

Shaft gen.

|

PME

(kW)

|

Type of fuel

|

CFME

|

SFCME

(g/kWh)

|

| 15,000

|

N/A

|

11,250

|

Diesel Oil

|

3.206

|

165.0

|

6.3 Auxiliary engines

| PAE

(kW)

|

Type of fuel

|

CFAE

|

SFCAE(g/kWh)

|

| 625

|

Diesel Oil

|

3.206

|

220.0

|

6.4 Ice class

N/A

6.5 Innovative electrical energy efficient technology

N/A

6.6 Innovative mechanical energy efficient technology

N/A

6.7 Cubic capacity correction factor

N/A

6.8 Calculated value of attained EEDI

attained EEDI: 2.99 g-CO2/ton mile

7 Calculated value of attained EEDIweather

7.1 Representative sea conditions

|

|

Mean

wind

speed

|

Mean

wind

direction

|

Significant

wave height

|

Mean

wave

period

|

Mean

wave

direction

|

| BF6

|

12.6 (m/s)

|

0 (deg.)*

|

3.0 (m)

|

6.7(s)

|

0 (deg.)*

|

* Heading direction of wind/wave in relation to the ship's

heading, i.e. 0 (deg.) means the ship is heading directly into the wind.

7.2 Calculated weather factor, fw

7.3 Calculated value of attained EEDIweather

attained EEDIweather: 3.32 g-CO2/ton

mile