Section 1 Calculation procedure

1.1 The stress

in individual plies of a laminate is calculated in accordance with

Pt 8, Ch 3, Pt 8, Ch 3, 1 General of the Rules

and Regulations for the Classification of Special Service Craft (hereinafter

referred to as the Rules for Special Service Craft), based on bending

moment (see

Ch 3, 1 Calculation procedure 1.9) and

the laminate stiffness of a 1 cm wide elemental strip of material.

1.3 In this example

the maximum bending moment is determined from Pt 8, Ch 3, Pt 8, Ch 3, 1 General of the Rules for Special Service Craft

and occurs under the web at the base of the stiffener. It should be

noted that no reduction in the bending moment, M

b,

due to aspect ratio effect is given since the panel aspect ratio,

i.e. panel length/panel breadth is greater than 2. See Pt

8, Ch 3, Pt 8, Ch 3, 1 General of the Rules for

Special Service Craft.

1.4 The laminate

section modulus calculation is shown in Table 3.1.1 Tabulation of single skin

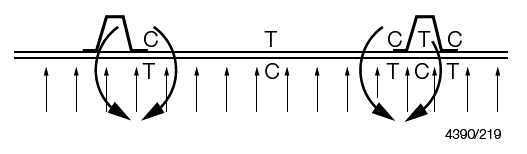

laminiate calculations at the end of this Section. From Figure 3.1.3 Regions of tension (T) and compression (C) in example model it will be noted that there

will be positions where tension and compression considerations will

apply. Such calculations are ideally suited to computer based investigation.

Table 3.1.1 Tabulation of single skin

laminiate calculations

|

|

Ply No.

|

Discription

|

Gc

|

Weight

|

t

|

lever @

|

E

|

E.t

|

E.t.x

|

I @

|

EI @

|

| (g/m2)

|

(mm)

|

base, x (mm)

|

(N/mm2)

|

|

|

base

|

base

|

Dry

see note

|

1

|

CSM

|

0,33

|

600

|

1,250

|

10,149

|

7200

|

9000

|

91341

|

1289,2

|

9281917

|

|

|

2

|

CSM

|

0,33

|

600

|

1,250

|

8,899

|

7200

|

9000

|

80091

|

991,5

|

7139017

|

|

|

3

|

CSM

|

0,33

|

600

|

1,250

|

7,649

|

7200

|

9000

|

68841

|

733,0

|

5277367

|

|

|

4

|

CSM

|

0,33

|

600

|

1,250

|

6,399

|

7200

|

9000

|

57591

|

513,5

|

3696967

|

|

|

5

|

WR

|

0,5

|

600

|

0,734

|

5,407

|

14000

|

10276

|

55562

|

214,9

|

3008869

|

|

|

6

|

CSM

|

0,33

|

600

|

1,250

|

4,415

|

6950

|

8688

|

38355

|

245,3

|

1704699

|

|

|

7

|

CSM

|

0,33

|

600

|

1,250

|

3,165

|

6950

|

8688

|

27496

|

126,8

|

881558

|

|

|

8

|

WR

|

0,5

|

600

|

0,734

|

2,173

|

14500

|

10643

|

23127

|

35,0

|

507333

|

|

|

9

|

CSM

|

0,33

|

600

|

1,250

|

1,181

|

6950

|

8688

|

10260

|

19,1

|

132482

|

|

|

10

|

CSM

|

0,268

|

225

|

0,556

|

0,278

|

6290

|

3497

|

972

|

0,6

|

3604

|

| Totals

|

|

|

|

|

10,774

|

|

|

86479

|

453637

|

|

31633812

|

Note 'Dry' indicates the inner surface or the hull and 'wet'

the outside of the shell laminate

|

1.5 In order to

apply a more detailed investigation it is necessary to establish the

position of the neutral axis. However, in relatively balanced laminates

this may be assumed to be at mid-depth. The procedure is simply to

carry out the calculations assuming compressive properties on one

face and tensile properties on the other face. Subsequently, the properties

should be reversed and the layer stress calculations repeated. The

calculated values should then be compared with the appropriate ultimate

properties, i.e. dependent upon whether tension or compression considerations

apply.

1.6 In the example

the moments were evaluated about the base, which was taken to be the

outer (wet) surface. The stiffness, EI, per 1 cm width,

about the neutral axis, is determined using the parallel axis theorem:

In general:

|

EI

sect

|

= |

ΣEI

base – (ΣEt)

x 10 x y

2

|

where

|

y

|

= |

distance

of neutral axis above the base (mm) |

1.7 A factor of

10 (width in mm) is introduced to correct the value of area used in

the parallel axis theorem, since a 1 cm wide strip of material is

considered in the calculations.

From the tabulation:

|

EI

sect

|

= |

31633812 – (86479 x 10 x 5,2462)

|

1.8 From Pt 8,

Ch 3, Pt 8, Ch 3, 1 General of the Rules for Special

Service Craft the individual layer stresses (tensile consideration)

are determined from:

1.9 More generally,

the calculation of the stresses in individual layers becomes:

where

|

E

i

|

= |

E

ti or E

ci for

the ply relative to its position above or below the neutral axis

|

|

y

i

|

= |

distance from the neutral axis to the outer extremity of an

individual ply, i, in mm.

|

1.10 Consider

the following typical arrangement and the associated stresses for

a single shell panel outside of the slamming zone:

Consider the outer (wet) surface:

Consider the 225g/m2 chopped strand mat reinforcement in tension:

|

σti

|

= |

693

x 10-6 x E

i

y

i

|

|

|

= |

693 x 10-6 x

6290 x 5,246

|

1.11 From Pt 8, Ch 3, Pt 8, Ch 3, 3.1 General 3.1.1 of the SSC Rules.

σult tension= 82,2 N/mm2 for CSM at G

c =0,286

Hence, stress fraction = 22,9/82,2

= 0,278.

Figure 3.1.3 Regions of tension (T) and compression (C) in example model

1.12 From Table 7.3.1 Limiting stress criteria for local

loading in Pt 8, Ch 7 of the Rules

for Special Service Craft, the limiting tensile stress fraction is

0,33 for the side shell outside of the slamming zone. Hence, the calculated

stress fraction is lower than the limiting stress factor and is therefore

acceptable.

1.13 Similarly,

consider the 600g/m2 woven roving reinforcement in tension:

|

σti

|

= |

693

x 10-6 x E

i

y

i

|

|

|

= |

693 x 10-6 x

14500 x (5,246 – 0,556 – 1,25)

|

|

σult tention

|

= |

190 N/mm2 for woven roving at G

c =

0,5

|

Stress fraction = 34,6/190 = 0,182

Hence

acceptable.

1.14 Consider

the inner (dry) surface:

The 600 g/m2 chopped strand mat reinforcements at

the inner surface in compression:

|

σci

|

= |

693

x 10-6 x E

i

y

i

|

|

|

= |

693 x 10-6 x

7200 x (10,744 – 5,246)

|

|

σult comp

|

= |

122 N/mm2 for CSM at G

c =

0,33

|

Stress fraction = 27,6/122 = 0,226

Hence

acceptable.

|