2 Lifejackets

2.1 Temperature cycling

test

A lifejacket should be subjected to the temperature cycling

as prescribed in 1.2.1 and

should then be externally examined. The lifejacket materials should

show no sign of damage such as shrinking, cracking, swelling, dissolution

or change of mechanical qualities.

2.2 Buoyancy test

The buoyancy of the lifejacket should be measured before

and after 24 h complete submersion to just below the surface in fresh

water. The difference between the initial buoyancy and the final buoyancy

should not exceed 5% of the initial buoyancy.

2.3 Fire test

A lifejacket should be subjected to the fire test prescribed

in 1.5. The lifejacket should

not sustain burning for more than 6 s or continue melting after being

removed from the flames.

2.4 Tests of components

other than buoyancy materials

All the materials, other than buoyancy materials, used in

the construction of the lifejacket, including the cover, tapes, seams

and closures should be tested to an international standard acceptable

to the Organizationfootnote to establish

that they are rot-proof, colour-fast and resistant to deterioration

from exposure to sunlight and that they are not unduly affected by

seawater, oil or fungal attack.

2.5 Strength tests

Body or lifting loop strength tests

2.5.1 The lifejacket should be immersed in water

for a period of 2 min. It should then be removed from the water and

closed in the same manner as when it is worn by a person. A force

of not less than 3,200 N (2,400 N in the case of a child or infant-size

lifejacket) should be applied for 30 min to the part of the lifejacket

that secures it to the body of the wearer (see figure 1) and separately to the

lifting loop of the lifejacket. The lifejacket should not be damaged

as a result of this test. The test should be repeated for each encircling

closure.

Shoulder lift test

2.5.2 The lifejacket should be immersed in water

for a period of 2 min. It should then be removed from the water and

closed on a form as shown in figure

2, in the same manner as when it is worn by a person. A force

of not less than 900 N (700 N in the case of a child- or infant-size

lifejacket) should be applied for 30 min across the form and the shoulder

section of the lifejacket (see figure

3). The lifejacket should not be damaged as a result of this

test. The lifejacket should remain secured on the form during this

test.

Figure 1 Body strength test arrangement for lifejackets

Figure 2 Test form for shoulder lift test for lifejackets

Figure 3 Shoulder life test arrangement for lifejackets

2.6 Tests for lifejacket

buoyancy material

The tests specified in 2.6.1 to 2.6.7 should be carried out on eight

specimens of each lifejacket-buoyancy material. A further four specimens of each

lifejacket-buoyancy material should be prepared for the test specified in 2.6.8. The

specimens should be at least 300 mm square and be of the same thickness as used in

the lifejacket. In the case of kapok, the entire lifejacket should be subjected to

the test. The dimensions should be recorded at the beginning and end of these tests.

Where multiple layers of materials are used to achieve the total thickness desired

for the lifejacket, the specimens should be of the thinnest material used.

Test for stability under temperature cycling

2.6.1 Six specimens should be subjected to temperature

cycling as prescribed in 1.2.1.

2.6.2 The dimensions of the specimens (except

kapok) should be recorded at the end of the last cycle. The specimens

should be carefully examined and should not show any sign of external

change of structure or of mechanical qualities.

2.6.3 Two of the specimens should be cut open

and should not show any sign of internal change of structure.

2.6.4 Four of the specimens should be used for

compression and water absorption tests, two of which should be so

tested after they have also been subjected to the diesel oil test

as prescribed in 1.4.

Tests for compression and water absorption

2.6.5 The tests should be carried out in fresh

water and the specimens should be immersed for a period of seven days

under a 1.25 m head of water.

2.6.6 The tests should be carried out:

-

.1 on two specimens as supplied;

-

.2 on two specimens which have been subjected

to the temperature cycling as prescribed in 2.6.1; and

-

.3 on two specimens which have been subjected

to the temperature cycling as prescribed in 2.6.1 followed by the

diesel oil test as prescribed in 1.4.

2.6.7 The results should state the buoyant force

in N which each specimen exerts when submerged in water after one

and seven days' immersion. The reduction of buoyancy should not exceed

10% for specimens which have been exposed to the diesel oil conditioning

and must not exceed 5% for all other specimens. The specimens should

show no sign of damage such as shrinking, cracking, swelling, dissolution

or change of mechanical qualities.

Tensile strength test

2.6.8 The tensile strength at break of the material

should be measured before and after the combined exposure described

in 2.6.6.3. When tested according to an international standard acceptable

to the Organizationfootnote, the materials

should have a minimum tensile strength of 140 kPa before exposure,

which should not be reduced by more than 25% following the combined

exposures. In the case of kapok, the protective cover should have

a minimum breaking strength of 13 kPa before exposure, which should

not be reduced by more than 25% following the combined exposures.

2.7 Donning test

2.7.1 To minimize the risk of incorrect donning

by uninitiated persons, often in adverse conditions, lifejackets should

be examined for the following features and tested as follows:

-

.1 fastenings necessary for proper performance

should be few and simple, and provide quick and positive closure that

does not require tying of knots;

-

.2 adult lifejackets should readily fit various

sizes of adults, both lightly and heavily clad; and

-

.3 all lifejackets should be capable of being

worn inside-out, or clearly in only one way.

Test subjects

2.7.2 These tests should be carried out with at

least 12 able-bodied persons who are completely unfamiliar with the

lifejacket and selected according to the heights and weights in table

2.1 and the following:

-

.1 small test subjects need not be adults;

-

.2 at least 1/3, but not more than 1/2 of test

subjects should be females, including at least 1 per height category

but excluding the tallest height;

-

.3 at least one male should be from the lowest

and highest weight group and one female should be from the lowest weight

group and one female should be more than 80 kg and 1.8 m;

-

.4 at least one subject should be selected from

each cell containing a "1"; and

-

.5 enough additional subjects should be selected

from cells containing a "X" to total the required number of test subjects,

with no more than one subject per cell. A uniform distribution across

weight ranges should be maintained.

Table 2.1 Test subject

selection for adult lifejackets

|

|

Weight range - kg

|

| Height range (m)

|

40 - 43

|

43 - 60

|

60 - 70

|

70 - 80

|

80 - 100

|

100 -

110

|

110 -

120

|

>120

|

| < 1.5

|

1

|

X

|

X

|

X

|

|

|

|

|

| 1.5 -

1.6

|

X

|

1

|

1

|

X

|

X

|

|

|

|

| 1.6 -

1.7

|

|

X

|

X

|

1

|

X

|

X

|

|

|

| 1.7 -

1.8

|

|

|

X

|

X

|

1

|

X

|

X

|

X

|

| 1.8 -

1.9

|

|

|

X

|

X

|

X

|

1

|

1

|

X

|

| > 1.9

|

|

|

|

|

X

|

X

|

X

|

1

|

Clothing

2.7.3 Each test subject should be tested wearing

the clothing specified for the test and appropriate to their size

as follows:

-

.1

Normal clothing means normal indoor

clothing, which would not normally interfere with the donning of a

lifejacket; and

-

.2

Heavy-weather clothing means the

attire appropriate for a hostile environment, including a hooded arctic

parka and warm cotton gloves.

2.7.4 Each test should be timed from when the

order is given until the test subject declares that donning is complete.

For assessment purposes donning is considered complete when the subject

has donned and securely adjusted all methods of securing the lifejacket

to the extent needed to meet the in-water performance requirements,

including inflation, if needed.

Test without instruction

2.7.4.1 The test subjects may be tested individually

or as a group. Wearing normal clothing, the first attempt should be

with no assistance, guidance or prior demonstration. The lifejacket,

with closures in the stored condition, should be placed on the floor,

face up, in front of the test subject. The instruction provided should

be identical for each subject and should be equivalent to the following:

"PLEASE DON THIS LIFEJACKET AS QUICKLY AS POSSIBLE AND ADJUST IT TO

A SNUG FIT SO YOU CAN ABANDON SHIP". The lifejacket should be capable

of being donned by at least 75 % of the subjects, and within 1 min.

If a subject dons the lifejacket substantially correctly but fails

to secure and/or adjust all closures, the jump test in 2.8.8 and in-water performance tests

in 2.8.5 and 2.8.6 should be performed with the

lifejacket as donned to establish whether the performance is acceptable

and the donning is successful.

Test after instruction

2.7.4.2 For each subject whose first attempt exceeds

1 min or is incomplete, after demonstration or instruction to familiarize

the subject with the donning procedure, the test subject should then

don the lifejacket without assistance while wearing normal clothing,

using the same instruction and timing method as in 2.7.4.1. Each subject

should correctly don the lifejacket within a period of 1 min.

Heavy-weather clothing test

2.7.4.3 Each subject should then don the lifejacket

without assistance while wearing heavy-weather clothing, using the

same instruction and timing method as in 2.7.4.1. Each subject should

don the lifejacket correctly within a period of 1 min.

2.8 Water performance

tests

2.8.1 This portion of the test is intended to determine

the ability of the lifejacket to assist a helpless person or one in an exhausted or

unconscious state and to show that the lifejacket does not unduly restrict movement.

The in-water performance of a lifejacket is evaluated by comparison to the

performance of a suitable size standard reference lifejacket, i.e. Reference Test

Device (RTD) as specified in appendices 1 to 3. All tests should be carried out in

fresh water under still conditions. Each test for a candidate lifejacket and the

relevant RTD should be conducted on the same day.

Test subjects

2.8.2 These tests should be carried out with at

least 12 persons as described in 2.7.2.

Only good swimmers should be used, since the ability to relax in the

water is rarely otherwise obtained.

Clothing

2.8.3 Subjects should wear only swimming costumes.

Preparation for water performance tests

2.8.4 The test subjects should be made familiar with

each of the tests set out below, particularly the requirement regarding relaxing

and exhaling in the face-down position. The test subject should don the

lifejacket, unassisted, using only the instructions provided by the manufacturer.

Prior to taking the measurements in 2.8 and 2.9, the proper fit, donning, and

fastening of the RTD on the subject should be checked and corrected as necessary.

After entering the water, care should be taken to ensure that there is no

significant amount of air unintentionally trapped in the lifejacket or swimming

costume.

Righting tests

2.8.5 Each test subject should assume a prone,

face down position in the water, but with the head lifted up so the

mouth is out of the water. The subject's feet should be supported,

shoulder width apart, with the heels just below the surface of the

water. After assuming a starting position with the legs straight and

arms along the sides, the subject should then be instructed in the

following sequence to allow the body to gradually and completely relax

into a natural floating posture: allow the arms and shoulders to relax;

allow the legs to relax; and then the spine and neck, letting the

head fall into the water while breathing out normally. During the

relaxation phase, the subject should be maintained in a stable face

down position. Immediately after the subject has relaxed with the

face in the water, simulating a state of utter exhaustion, the subject's

feet should be released. The period of time until the mouth of the

test subject comes clear of the water should be recorded to the nearest

1/10 of a second, starting from when the subject's feet are released.

The above test should be conducted for a total of six times, and the

highest and lowest times discarded. The test should then be conducted

for a total of six times in the RTD and the highest and lowest times

discarded.

Static balance measurements

2.8.6 At the conclusion of the righting tests

without making any adjustments in body or lifejacket position, measurements

should be made with the subject floating in the relaxed face-up position

of static balance resulting from the preceding tests. The following

measurements should be made (see figure

4):

-

.1 freeboard − the distance measured perpendicularly

from the surface of the water to the lowest point of the subjects

mouth where respiration may be impeded, if the mouth were not held

shut. The lowest side of the mouth should be measured if the left

and right sides are not level;

-

.2 faceplane angle − the angle, relative

to the surface of the water, of the plane formed between the most

forward part of the forehead and the chin;

-

.3 torso angle − the angle, relative to

vertical, of the line formed by the forward points of the shoulder

and hipbone (ilium portion of the pelvis); and

-

.4 list angle − the angle relative to the

surface of the water and a line between the left and right shoulder

or a line through the ears if only the head is tilted.

Figure 4 Static balance measurements

Assessment

2.8.7 After the water tests described in 2.8.5

and .6 above:

-

.1

Turning time: The average turn time for all subjects in the candidate

lifejacket should not exceed the average time in the RTD plus 1 s, and the

number of "no-turns", if any, should not exceed the number in the RTD;

-

.2

Freeboard: The average freeboard of all the subjects' should not be

less than the average for the RTD; minus 10 mm

-

.3

Torso angles: The average of all subjects' torso angles should be not

less than the average for the RTD minus 10°;

-

.4

Faceplane angles: The average of all subjects' faceplane angles

should be not less than the average for the RTD minus 10°;

-

.5

Lifejacket light location: The

position of the lifejacket light should permit it to be visible over

as great a segment of the upper hemisphere as is practicable.

Jump and drop tests

2.8.8 Without readjusting the lifejacket, the

test subject should jump vertically into the water, feet first, from

a height of at least 1 m while holding the arms over the head. Upon

entering the water, the test subject should relax to simulate a state

of utter exhaustion. The freeboard to the mouth should be recorded

after the test subject comes to rest. The test should be repeated

from a height of at least 4.5 m but, when jumping into the water,

the test subject should hold on to the lifejacket during water entry

to avoid possible injury. Upon entering the water, the test subject

should relax to simulate a state of utter exhaustion. The freeboard

to the mouth should be recorded after the test subject comes to rest.

The lifejacket and its attachments should be examined for any damage.

If injury is believed likely from any jump or drop test the lifejacket

should be rejected or the test delayed until tests from a lower height

or with additional precautions demonstrate that the risk from the

required test is acceptable.

Assessment

2.8.9 Following the drop test, the lifejacket

should:

-

.1 surface the test subject in a face up

position with an average freeboard for all the subjects of not less than the

average determined for the RTD after the turning test in accordance with

2.8.6 minus 15 mm;

-

.2 not be dislodged or cause harm to the test

subject;

-

.3 have no damage that would affect its in-water

performance or buoyancy; and

-

.4 have no damage to its attachments.

Stability test

2.8.10 The test subject should attain a relaxed

face-up position of static balance in the water. The subject should

be instructed to assume a foetal position as follows: "place your

elbows against your sides, your hands on your stomach, under the lifejacket

if possible, and bring your knees up as close to your chest as possible."

The subject should be rotated clockwise around the longitudinal axis

of the torso by grasping the subject's shoulders or upper areas of

the lifejacket so that the subject attains a 55 ± 5 degree

list. The subject should then be released. The subject should return

to a stable face-up position. The test should then be conducted with

the subject rotated counter-clockwise. The entire test should then

be repeated with the test subject wearing the RTD. The candidate lifejacket

should not roll any subject face down in the water. The number of

subjects who are returned to the stable face-up foetal position in

the candidate lifejacket should be at least equal to the number who

are returned to the stable face-up foetal position in the RTD.

Swimming and water emergence test

2.8.11 All test subjects, without wearing the

lifejacket, should attempt to swim 25 m and board a liferaft or a

rigid platform with its surface 300 mm above the water surface. All

test subjects who successfully complete this task should perform it

again wearing the lifejacket. At least two thirds of the test subjects

who can accomplish the task without the lifejacket should also be

able to perform it with the lifejacket.

2.9 Infant and children's

lifejacket tests

As far as possible, similar tests should be applied for approval of

lifejackets suitable for infants and children. The tests may be modified for child

test subjects under 12 years of age who are not comfortable in water, so as to ensure

their safety and cooperation.

Infant and child test subjects

2.9.1 For child-size lifejackets, tests should

be carried out with at least 9 able-bodied persons, and for infant-size

lifejackets, tests should be carried out with at least 5 able-bodied

persons. All test subjects should be selected according to table 2.2 or table 2.3 as follows:

-

.1 One subject should be selected per each cell

containing a "1".

-

.2 Remaining subjects should be selected from

cells containing an "X", without repeating a cell.

-

.3 At least 40% of the subjects should be male

and at least 40% female.

-

.4 Devices for infants should be tested on infants

as small as 6 kg mass.

-

.5 A manikin or manikins may be substituted for

test subjects if the manikin or manikins have been demonstrated to provide

representative results compared to human subjects.

Table 2.2 Selection of child

test subjects

| Height range

(cm)

|

Weight range (kg)

|

| 14-17

|

17-20

|

20-22

|

22-25

|

25-28

|

28-30

|

30-33

|

33-36

|

36-38

|

38-41

|

41-43

|

| 79-105

|

1

|

X

|

|

|

|

|

|

|

|

|

|

| 90-118

|

|

X

|

1

|

|

|

|

|

|

|

|

|

| 102-130

|

|

|

|

1

|

X

|

|

|

|

|

|

|

| 112-135

|

|

|

|

|

X

|

1

|

|

|

|

|

|

| 122-150

|

|

|

|

|

|

|

1

|

1

|

X

|

|

|

| 145-165

|

|

|

|

|

|

|

|

|

X

|

1

|

1

|

Table 2.3 Selection of

infant test subjects

Height

range

(cm)

|

Weight range (kg)

|

| Less than 11

|

11-14

|

14-17

|

| Less than

83

|

1

|

X

|

|

| 79-105

|

X

|

1

|

1

|

| 90-118

|

|

|

X

|

2.9.2 When conducting water performance tests

under 2.8, infant and child-size

lifejackets should meet the following requirements for their critical

flotation stability characteristics:

-

.1

Turning time: The average turn time for all subjects in the candidate

lifejacket should not exceed the average time in the appropriate size RTD

plus 1 s;

-

.2

Freeboard: The average results for clearance of the mouth above the

water for all subjects should not be less than the average for the

appropriate size RTD minus 10 mm;

-

.3

Torso angle: The average of all

subjects' results should be not less than the average for the appropriate

size RTD minus 10°;

-

.4

Faceplane angle: The average of all subjects results should be not

less than the average for the appropriate size RTD minus 10°; and

-

.5

Mobility: Mobility of the subject

both in and out of the water should be given consideration in determining

the acceptability of a device for approval and should be compared

to mobility when wearing the appropriate size RTD when climbing out

of the water, going up and down stairs, picking up an article from

the floor, and then drinking from a cup.

2.9.3 Infant lifejackets should meet the requirements

of 2.9.2.1 and 2.9.2.2, however, the requirements for torso angle, faceplane and

mobility may be relaxed if necessary in order to:

-

.1 contribute to the rescue of the infant by a

caretaker;

-

.2 allow the infant to be fastened to a caretaker

and contribute to keeping the infant close to the caretaker;

-

.3 keep the infant dry, with free respiratory

passages;

-

.4 protect the infant against bumps and jolts

during the evacuation; and

-

.5 allow a caretaker to monitor and control heat

loss by the infant.

2.10 Tests for inflatable

lifejackets

2.10.1

Inflation tests

-

2.10.1.1 Two inflatable lifejackets should be

subjected to the temperature cycling test prescribed in 1.2.1 in the uninflated condition

and should then be externally examined. The inflatable lifejacket

materials should show no sign of damage such as shrinking, cracking,

swelling, dissolution or change of mechanical qualities. The automatic

and manual inflation systems should each be tested immediately after

each temperature cycling test as follows:

-

.1 After a high temperature cycle, the two inflatable

lifejackets should be taken from the stowage temperature of +65°C.

One should be activated using the automatic inflation system by placing

it in seawater at a temperature of +30°C and the other should

be activated using the manual inflation system. Each should fully

inflate. Each lifejacket should then be subjected to the tests in

paragraphs 2.2, 2.3 and 2.5. A lifejacket that has been inflated automatically

with one compartment uninflated should be subjected to the test in

paragraph 2.2 and the test repeated until each compartment has been

tested in the uninflated condition. For the fire test in paragraph

2.3, one lifejacket should be inflated and one uninflated.

-

.2 After a low temperature cycle, the two inflatable

lifejackets should be taken from the stowage temperature of -30°C.

One should be activated using the automatic inflation system by placing

it in seawater at a temperature of -1°C and the other should be

activated using the manual inflation system. Each should fully inflate.

Each lifejacket should then be subjected to the tests in

paragraphs 2.2, 2.3 and 2.5. A lifejacket that has been inflated automatically

with one compartment uninflated should be subjected to the test in

paragraph 2.2 and the test repeated until each compartment has been

tested in the uninflated condition. For the fire test in paragraph

2.3, one lifejacket should be inflated and one uninflated.

-

2.10.1.2 After exposure to a temperature of -15°C

for a period of at least 8 h, two lifejackets should be activated

using the manual inflation system and should fully inflate.

-

2.10.1.3 After exposure to a temperature of +40°C

for a period of at least 8 h, two lifejackets should be activated

using the manual inflation system and should fully inflate.

2.10.2 The test in 2.7 should be conducted using lifejackets both in the inflated

and uninflated conditions.

2.10.3 The tests in 2.8 should be conducted using lifejackets that have been inflated

both automatically and manually, and also with one of the compartments

uninflated. The tests with one of the compartments uninflated should

be repeated as many times as necessary to perform the test once with

each compartment in the uninflated condition.

2.10.4

Tests of materials for inflatable

bladders, inflation systems and components

The material used for the inflatable bladder, inflation system

and components should be tested to establish that they are rot-proof,

colour fast and resistant to deterioration from exposure to sunlight

and that they are not duly affected by seawater, oil or fungal attack.

-

2.10.4.1

Coated fabrics

Coated fabrics used in the construction of inflatable buoyancy

chambers should comply with the following requirements:

-

.1 Coating adhesion should be tested in accordance

with ISO 2411:2000 using the method described in paragraph 5.1 at 100 mm/min and

should be not less than 50 N per 50 mm width.

-

.2 Coating adhesion should be tested when wet

following ageing according to ISO 188:2007 with an exposure of 336

± 0.5 h in fresh water at (70 ± 1)°C, following

which the method at ISO 2411:2000, paragraph

5.1 should be applied at 100 mm/min and should not be less

than 40 N per 50 mm width.

-

.3 Tear strength should be tested in accordance

with ISO 4674-1:2003 and ISO 4674-2:1998 using method A1 and should

not be less than 35 N.

-

.4 Resistance to flex cracking should be tested

in accordance with ISO 7854:1995 method A using 9000 flex cycles,

there should be no visible cracking or deterioration.

-

.5 Breaking strength should be tested in accordance

with ISO 1421:1998 using the constant-rate-of-extension (CRE) or constant-rate-of-traverse

(CRT) method, following conditioning for 24 ± 0.5 h at room

temperature and should not be less than 200 N per 50 mm width.

-

.6 Breaking strength should be tested in accordance

with ISO 1421:1998 using the CRE or CRT method, following conditioning

immersed in fresh water for 24 ± 0.5 h at room temperature

and should not be less than 200 N per 50 mm width.

-

.7 Elongation to break should be tested in accordance

with ISO 1421:1998 using the CRE or CRT method following conditioning

at room temperature for 24 ± 0.5 h and should not be more than

60%.

-

.8 Elongation to break should be tested in accordance

with ISO 1421:1998 using the CRE or CRT method following conditioning

immersed in fresh water at room temperature for 24 ± 0.5 h

and should not be more than 60%.

-

.9 The resistance to exposure to light when tested

in accordance with ISO 105-BO2:1994 and the contrast between the unexposed

and exposed samples should not be less than class 5.

-

.10 The resistance to wet and dry rubbing when

tested in accordance with ISO 105-X12:2001 and should not be less

than class 3.

-

.11 The resistance to seawater should not be less

than class 4 in accordance with ISO 105 EO2:1994 and the change in

colour of the specimen should not be less than class 4.

-

2.10.4.2

Operating head load test

The operating head load test should be carried out using two

lifejackets one lifejacket to be conditioned at -30°C for 8 h

and the other at +65°C for 8 h. After mounting on the manikin

or the test form the lifejackets should be inflated, and a steady

force of 220 ± 10 N applied to the operating head as near as

possible to the point where it enters the buoyancy chamber. This load

should be maintained for 5 min during which the direction and angle

in which it is applied should be continuously varied. On completion

of the test the lifejacket should remain intact and should hold its

pressure for 30 min.

-

2.10.4.3

Pressure test

-

2.10.4.3.1

Overpressure test: The

inflatable buoyancy chambers should be capable of withstanding an

internal over pressure at ambient temperature. A lifejacket should

be inflated using the manual method of inflation, after inflation

the relief valves should be disabled and a fully charged gas cylinder

according to the manufacturers recommendation should be fitted to

the same inflation device and fired. The lifejacket should remain

intact and should hold its pressure for 30 min. The lifejackets should

show no signs of damage such as cracking, swelling or changes of mechanical

qualities and that there has been no significant damage to the lifejacket

inflation component. All fully charged gas cylinders used in this

test should be sized according to the markings on lifejacket.

-

2.10.4.3.2

Relief valve test: With

one buoyancy chamber inflated, the operating head on the opposite

buoyancy chamber should be fired manually, using a fully charged gas

cylinder according to the manufacturers recommendations. The operation

of the relief valves should be noted to ensure that the excess pressure

is relieved. The lifejacket should remain intact and should hold its

pressure for 30 min. The lifejackets should show no signs of damage

such as cracking, swelling or changes of mechanical qualities and

that there has been no significant damage to the lifejacket inflation

component.

-

2.10.4.3.3

Air retention test: One

inflation chamber of a lifejacket is filled with air until air escapes

from the over-pressure valve or, if the lifejacket does not have an

over-pressure valve, until its design pressure, as stated in the plans

and specifications, is reached. After 12 h the drop in pressure should

not be greater than 10%. This test is then repeated as many times

as necessary to test a different chamber until each chamber has been

tested in this manner.

-

2.10.4.4

Compression test

The inflatable lifejacket, packed in the normal manner should

be laid on a table. A bag containing 75 kg of sand and having a base

of 320 mm diameter should be lowered onto the lifejacket from a height

of 150 mm in a time of 1 second. This should be repeated ten times,

after which the bag should remain on the jacket for not less than

3 h. The lifejacket should be inflated by immersion into water and

should inflate fully, the jacket to be inspected to ensure that no

swelling or change of mechanical properties has occurred, the jacket

should be checked for leaks.

-

2.10.4.5

Test of metallic components

-

2.10.4.5.1 Metal parts and components of a lifejacket

should be corrosion-resistant to seawater and should be tested in

accordance with ISO 9227:2006 for a period of 96 h. The metal components

should be inspected and should not be significantly affected by corrosion,

or affect any other part of the lifejacket and should not impair the

performance of the lifejacket.

-

2.10.4.5.2 Metal components should not affect

a magnetic compass of a type used in small boats by more than 5°,

when placed at a distance of 500 mm from it.

-

2.10.4.6

Inadvertent inflation test

-

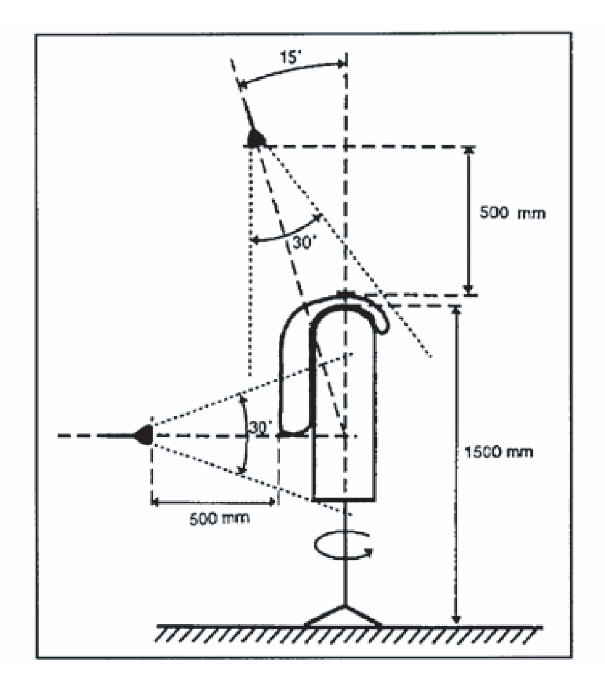

2.10.4.6.1 The resistance of an automatic inflation

device to inadvertent operation should be assessed by exposing the

entire lifejacket to sprays of water for fixed period. The lifejacket

should be fitted correctly to a free-standing manikin of adult size,

with a minimum shoulder height of 1,500 mm (see figure 5), or alternatively to

an appropriately sized form as shown in figure 2. The lifejacket should

be deployed in the mode in which it is worn ready for use but not

deployed as used in the water (i.e. if it is equipped with a cover

which is normally worn closed, then the cover should be closed for

the test). Two sprays should be installed so as to spray fresh water

onto the lifejacket, as shown in the diagram. One should be positioned

500 mm above the highest point of the lifejacket, and at an angle

of 15° from the vertical centre line of the manikin and the bottom

line of the lifejacket. The other nozzle should be installed horizontally

at a distance of 500 mm from the bottom line of the lifejacket, and

be pointed directly at the lifejacket. These nozzles should have a

spray cone of 30°, each orifice being 1.5 ± 0.1 mm in diameter,

and the total area of the orifice should be 50 ± 5 mm2,

the orifice being evenly spread over the spray nozzle area.

-

2.10.4.6.2 The air temperature should be 20°C,

and water should be supplied to the spray nozzles at a flow of 600 l/h, and a temperature of 18°C to 20°C.

-

2.10.4.6.3 The sprays should be turned on, and

the lifejacket should be exposed to the following series of tests

to assess the ability of the jacket to resist inadvertent inflation:

-

.1 5 min with the high spray on the front of the

lifejacket;

-

.2 5 min with the high spray on the left side

of the lifejacket;

-

.3 5 min with the high spray on the back of the

lifejacket; and

-

.4 5 min with the high spray on the right side

of the lifejacket.

During exposures .1, .2 and .4, the horizontal spray should

be applied for 10 periods of 3 s each to the front, left or right

sides (but not back) as with the high spray.

-

2.10.4.6.4 After completing the above test, the

lifejacket should be removed from the manikin and immersed in water

to verify that the auto-inflation system functions.

Figure 5 Test set-up for test of automatic inflation system

|