Section

6 Marine vibration excitation sources

6.1 Definition of excitation order

6.1.1 A term that is often used in relation to vibration excitations is ‘order’. First

order is invariably defined as propeller shaft frequency. For example, if operating

shaft Revolutions per minute (RPM) is 90, then first order is 90 cycles per minute

(CPM), or 1.5 cycles per second (Hz). Other orders may then be defined in relation

to this reference order. For the example of a four-bladed propeller, blade frequency

would then be 4 x 1.5 = 6 Hz, which could be termed propeller blade order, or more

specifically, fourth order.

6.2 Machinery

6.2.1 Slow Speed Diesel Main Engines

Slow speed Diesel engines are usually selected as the main engine in large cargo

ships for reasons of power and economy: however, they usually have significant

imbalances at several frequencies, and as they have to be bolted directly on to ship

structure due to their invariably large size and mass, vibration excitations can be

fully transmitted into the ship.

This type of engine is direct drive to the propeller shaft, that is, there is no

gearbox. Hence, engine crankshaft frequency and propeller shaft frequency are the

same. ‘Slow speed’ usually implies an operating RPM that is somewhere in the region

of 70 to 130 RPM.

Excitations typically include first order moments in the horizontal sense (engine

rotation about a vertical axis) and vertical sense (engine rotation about a

transverse axis), and also second order moment in the vertical sense. Sometimes, a

fourth order moment in the vertical sense may also be present.

At engine firing frequency (the order equals the number of engine cylinders for this

type of engine), invariably there is a transverse rocking moment (engine rotation

about a longitudinal axis) that is termed the ‘H-moment’. Sometimes, there can also

be a longitudinal force of significance that is generated in the crankshaft at

engine firing frequency and transmitted into the ship structure via the thrust

block.

Other slow speed Diesel engine excitations generally comprise engine twisting

moments, which are termed ‘X-moments’. These normally feature at several orders, but

because they are internal moments whereby they sum to zero in the external sense,

usually they only need to be considered if they are of large magnitude.

Because of the significant size, mass and vibration excitation characteristics of a

slow speed Diesel engine, it is recommended to include a coarse representation of

the engine in a ship finite element model; this also facilitates application of

engine excitation moments, and transverse top bracing, if fitted. Engine dimensions,

mass and vibration excitation details may be obtained from the engine builders or

the engine designers’ websites.

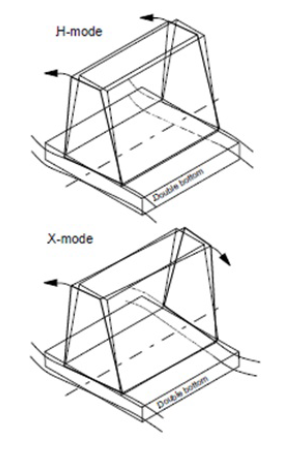

Figure 1.6.1 H-mode and X-mode vibration of slow speed diesel engines shows the typical vibration excitation

moments described above.

Figure 1.6.1 H-mode and X-mode vibration of slow speed diesel engines

6.2.2 Medium and High Speed Diesel Main Engines

Medium speed Diesel engines operate in the region of 500 RPM and high speed Diesel

engines in the region of 1000 RPM, through reduction gearboxes to the propeller

shaft.

They are significantly smaller and lighter than slow speed Diesel engines. Engine

manufacturers normally state for these types of engines that there is no significant

external imbalance that could affect global ship vibration, and they normally

specify resilient mounts together with suitable system connections. This should

always be arranged for passenger ships and ferries where low vibration is

required.

6.2.3 Diesel Electric and Auxiliary Machinery

Electric motors do not constitute a significant source of vibration within the

frequency range applicable to global ship vibration.

Power generation for supplying electric motors or auxiliary services is

usually provided by medium speed Diesel engines. Thereby, comments in Ch 1, 6.2 Machinery 6.2.2 apply.

6.2.4 Turbines

Steam turbines and gas turbines are in balance and do not emit vibration. If they do,

it is an indication of failure, such as a broken turbine blade.

6.2.5 Propeller Shafts

As mentioned in Ch 1, 1.1 General description of document the shafting system is subject to mandatory

classification rules, in relation to torsion, lateral and, in some cases also axial,

vibration.

Dynamic characteristics of shafting systems can affect vibration behaviour of ship

structure. Axial vibration of the shafting system can be transmitted into ship

structure via the thrust block. Torsion vibration of the shafting system would be

translated into axial vibration at the propeller, and could then also be transmitted

into the ship structure via the thrust block.

A non-uniform wake will cause fluctuating forces on a propeller which will be

transmitted to the shaft. Lateral modes of shafts may be excited by transverse and

vertical forces and moments which are developed in this way. Vibration may be

transmitted to the ship structure via the bearing housings. Avoidance of the

coincidence of a lateral mode of the shaft within 20 per cent of an excitation

source is typically required, though lateral modes may be sufficiently damped that

excessive vibration does not occur despite coincidence. The propeller blade passing

order is typically one of the more important sources of excitation for this

phenomenon.

Propulsion shafting system vibration analysis, including the engine crankshaft, is

often carried out by engine manufacturers and submitted via the Shipbuilder to

classification societies for approval. Alternatively, the calculations can be

carried out by consultants and submitted for approval, or performed by the

classification society.

In some cases therefore, it may be relevant to consider longitudinal dynamic forces

emanating from the propulsion shafting system in relation to ship vibration

analysis, which would be primarily with respect to engine firing frequency of slow

speed Diesel engines.

For certain passenger ships which have relatively stringent vibration criteria, in a

few cases, excitation from the propulsion system at first order (propeller shaft

frequency) has been noticed in measurements. In theory, this should not exist unless

there is an imbalance in the system due to a fault. Where no fault is evident, the

behaviour essentially remains unexplained. Another feature that has sometimes been

noticed during measurements for multiple screw passenger ships is gradual alteration

in phase between the propulsion systems, causing variation in measurements over

time. This ‘propeller beating’ effect can be subjectively annoying. It can often be

controlled by phase-locking the propeller shafts, preferably at the most favourable

phase relationship for minimising vibration response.

6.3 Propulsors

6.3.1 Open Propellers

Propellers gain in terms of propulsive efficiency by being located behind the ship,

in water that is moving at a velocity relative to the ship, which is lower than the

ship speed: the so-called ‘wake’. However, there is a penalty in terms of vibration,

because the water flow speed varies around the propeller disk. Hence, when the

propeller rotates, dynamic forces are generated at the propeller shaft bearings, and

through the water on to the hull surface above the propeller. Where propeller

cavitation exists, the latter effect dominates propeller excited vibration.

The degree of non-uniformity of the wake, that is, irregularity of flow into the

propeller disc, depends upon the position of the propeller and the after-body form

of the ship. For a full form ship with a single propeller, such as a typical tanker,

the wake may be quite irregular, with low velocity flow at the top of the propeller

disk, and high at the bottom: in such conditions, significant cavitation may be

generated around the top blade position. For a ship of finer form with a single

propeller, the wake would tend to be more uniform, leading to lower dynamic forces.

For twin screw ships and pod arrangements, propellers would usually be positioned in

relatively uniform flow, which is favourable from the vibration point of view.

Propeller excitation of the hull can be thought of as consisting of a non-cavitating

part, resulting from blade loading and thickness, and a cavitating part. For ships

fitted with fixed pitch propellers, the non-cavitating part will dominate at low

ship speeds where cavitation is not very pronounced. The non-cavitating pressure

excitation resembles a sine wave with the blade passing frequency. At the ship’s

normal continuous rating, hull pressure is, typically, dominated by pressure

radiated by cavitation dynamics. Cavitation is relatively repeatable per blade

passage; however, temporal variations in the inflow can produce differences in

practice.

Open propellers normally have four, five or six blades. During the design phase,

propeller dynamic forces for input to a ship vibration analysis can be obtained from

specialist calculations or model measurements. Reliable predictions from

calculations are essentially limited to blade frequency and, somewhat less

accurately, at twice the blade frequency; however, these are usually adequate to

cover the frequency range that is relevant for global ship vibration. Calculations

to predict excitation levels at higher orders are generally not reliable: these

orders can be relevant in relation to noise and vibration of local panels close to

the propeller. Model measurements can provide propeller excitation forces at blade

and at twice the blade frequencies: also at higher orders, however, these have not

always proven to be reliable.

Propeller dynamic forces at shaft bearings input to a ship vibration analysis would

typically include longitudinal force (thrust variation) at the thrust block

position, and transverse and vertical forces at the stern tube bearing position

(shaft bracket locations for a twin screw arrangement).

Hull surface forces are applied to the hull above the propeller. LR uses total

integrated hull surface force and applies it to a single substantial structural

point above the propeller. In the past, forces distributed over an area of points

above the propeller, together with phase differences between the points, were

investigated, but the increased complication was generally not justified by the

improved correlation with full-scale measurements for global ship vibration

responses.

Recommended minimum propeller clearances are stated in LR Rules and

Regulations for the Classification of Ships, Part 3, Chapter 3, 3.15.

6.3.2 Ducted Propellers

Ducted propellers can include:

- propellers in conventional positions with nozzles fitted (a common

arrangement for tugs that require high thrust at low speed);

- water jets for high speed small craft;

- azimuthing thrusters with propellers that incorporate nozzles; and

- tunnel thrusters for manoeuvring purposes (usually only in port or

restricted waters).

Generally, it is not possible to obtain reliable predictions of dynamic forces from

ducted propellers by calculation or model tests. Hence, predictive analysis is

usually confined to resonance avoidance for large deck panels local to these

devices. Thrusters can be of the ‘fixed RPM, variable pitch’ or ‘variable RPM, fixed

pitch’ types. The former type is easier to deal with from the resonance avoidance

point of view.

6.4 Sea Waves

6.4.1 Springing

Sea waves can induce ship vibration of a continuous nature, mostly at the lowest

vertical natural frequency of the hull (2-node vertical) in way of the resonance

with wave encounter frequency, which is termed ‘springing’. Generally, this is not

significant with regard to acceptable levels of ship vibration from the habitability

point of view, but may be of relevance in relation to structural fatigue for certain

types of vessel.

6.4.2 Slamming and Whipping

Slamming impacts at the ends of a ship, that depend upon hull form, draught, sea

conditions, ship speed and heading, can cause transient global vibration in the form

of whipping, as well as local response. In most cases, structural strength issues

are more relevant to consider than aspects of vibration, since comfort issues can

usually be addressed by a change of ship speed and/or heading.

|