Section

5 Gravity base design

5.1 General

5.1.1 ISO 19901-4 Petroleum and natural gas industries – Specific

requirements for offshore structures – Part 4: Geotechnical and foundation

design considerations presents an acceptable basis of design for gravity

base foundations with ISO 19903 Petroleum and natural gas industries – Fixed

concrete offshore structures containing further guidance for large concrete

gravity base foundations. Gravity base design should consider

horizontal-moment-vertical and torsion (HMVT) loading. In addition, the following

provides further guidance on gravity base design.

5.1.2 Gravity base design requires consideration of cyclic loading effects and

the possibility of pore pressure build-up. Where a gravity base is equipped with

drainage measures, it should be ensured they will function properly throughout a

structure's life. For example, a gravel layer may be vulnerable to ingress or

migration of the underlying seabed upwards, thus reducing permeability; or drainage

channels may become blocked with fine material.

5.1.3 Gravity base design should give careful consideration to soil layering and in

particular to the presence of layers that may cause preferential sliding, or for

example other unusual soils such as peat that may affect the performance of the

foundation.

5.1.4 It is generally expected where soil conditions are complex, simplified

methodology for uniform soil conditions such as that presented in ISO 19901-4

Petroleum and natural gas industries – Specific requirements for offshore

structures – Part 4: Geotechnical and foundation design considerations can

be used to design, or size, the gravity base foundation. The preliminary analyses

should then be followed up by finite element analyses to validate the design and

take account of other factors such as more complex layering or soil stiffness

response.

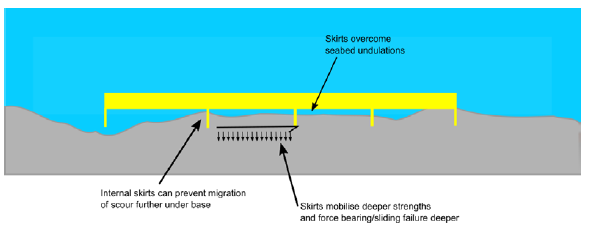

5.1.5 As shown in Figure 3.5.1 Purpose and uses of skirts (exaggerated features for clarity) a gravity base may be equipped with skirts, with

possible reasons including:

- mobilising strength of deeper layers below seabed for bearing capacity;

- to improve sliding capacity by mobilising soil strength below the seabed;

- to overcome small seabed irregularities; and

- to provide some degree of scour protection; especially where skirts are

compartmentalised to prevent ingress of scour further below the

foundation.

5.1.6 Where skirts are used, it should be ensured they can penetrate the seabed and achieve

their intended purpose. Penetration may be inhibited by hazards such as boulders or

gravel layers. If full penetration is not achieved, then remedial measures, such as

under-base grouting, may be required to ensure the gravity base performance remains

satisfactory.

Figure 3.5.1 Purpose and uses of skirts (exaggerated features for clarity)

5.2 Sliding capacity of un-skirted gravity base on clay

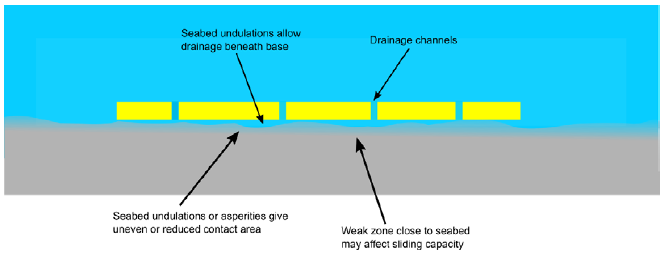

5.2.1 Where a gravity base on clay seabed is not equipped with skirts the sliding capacity

needs careful consideration. Figure 3.5.2 Some issues with un-skirted foundation on clay (exaggerated features for

clarity) shows a gravity base placed onto

a clay seabed and some of the aspects that influence capacity are discussed further.

It is important that the soil characteristics immediately at the seabed (i.e. within

the top few centimetres) are characterised in terms of their capacity for sliding

resistance. Murff (2012), for example, suggests there is almost always a thin

veneer of very weak soil right at seabed. A CPT pushed from seabed is unlikely to

accurately measure the resistance in the top few centimetres of soil. It may be

possible to extract information about the top few centimetres of soil from sample

data or to use specialist equipment such as box core or t-bar if the aspect is

critical to design.

5.2.2 It is likely that there are small undulations of the seabed leading to an uneven and

reduced contact area, as shown in Figure 3.5.2 Some issues with un-skirted foundation on clay (exaggerated features for

clarity). Depending on the level of

applied load, this uneven contact area may allow drained conditions to develop. The

contact area may also depend on the applied vertical load relative to the vertical

bearing capacity and the degree of horizontal or moment loading that is applied.

High applied stress on a limited contact area of the asperities may have the effect

of increasing contact area by local failure of the soil. Uneven seabed may also have

the effect of providing drainage channels meaning that the sliding capacity on clay

may be drained or partially drained, rather than undrained.

5.2.3 In addition, the foundation itself may have holes or drainage channels. In view of

the above, consideration of an undrained case with full contact area may not be

applicable and drained loading may tend to dominate the design for sliding

resistance on clay.

5.2.4 Eurocode 7: Geotechnical design worked examples specifies a limit

of H/V < 0,4 and similarly ISO 19905-1 Petroleum and natural gas

industries -- Site-specific assessment of mobile offshore units - Part 1:

Jack-ups suggests that sliding capacity on clay should take into account an

alpha value as determined by the pile capacity method for shaft friction in clays in

the Annex A of ISO 19901-4 Petroleum and natural gas industries – Specific

requirements for offshore structures – Part 4: Geotechnical and foundation

design considerations. Neither of these criteria is particularly applicable

to the problem of sliding resistance and more detailed discussion of sliding

resistance of foundations on clay is given by Steenfelt (2017) taking into

account the drained properties of the soil with appropriate material or resistance

factors, rather than an arbitrary limit as suggested above.

5.2.5 Where sliding resistance on clay is a critical aspect then laboratory testing, field

testing and further analyses may be appropriate to enable an optimised design.

Figure 3.5.2 Some issues with un-skirted foundation on clay (exaggerated features for

clarity)

5.3 Design of gravel beds and rock berms

5.3.1 Gravel or rockfill beds are sometimes used to improve the engineering characteristics

of the seabed, often in the following ways:

- improvement of bearing capacity by spreading bearing pressure to reduce

loads on weaker layers;

- remediation of seabed features including seabed roughness or seabed slope;

- prevention of scour;

- provide drainage and prevent build-up of excess pore pressure beneath the

foundation; and

- a combination of the above factors.

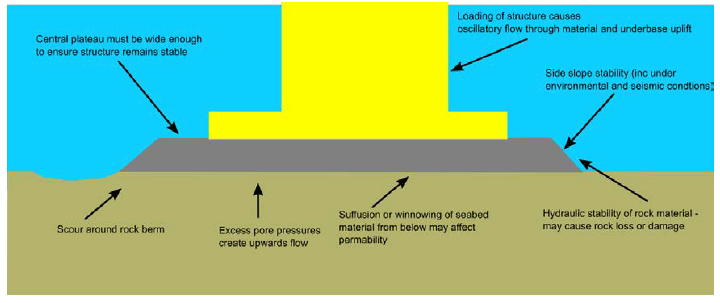

5.3.2 Figure 3.5.3 Gravel bed or rock berm design issues shows some of the key engineering issues that should be considered

when designing a gravel bed. It should be noted that sliding capacity may be

affected by the pore pressure regime within the gravel bed and potential for uplift

due to hydrodynamic pressures.

5.3.3 A rock berm should be considered as an additional soil layer and should be considered

in all relevant analyses including that for capacity and stiffness.

5.3.4 A general approach for rock berm design is presented in CIRIA (2012) and

Kellezi and Stadsgaard (2012).

5.3.5 In addition to the usual requirements of a design basis, the design of the rock berm

should take account of various considerations to ensure that the central load

bearing section remains suitable for its purpose throughout the design life. These

include:

- lateral dimensions to take into account edge effects such as side slope

stability or internal stability. For gravel pads the side slope stability

may become a critical aspect. In general, the role of the side slope is to

ensure that the central crest (or plateau) of the gravel pad remains intact.

As such the slope angle should be selected such that it remains stable under

the possible load conditions including that imparted from the foundation

itself, environmental loading or other sources of loading or degradation

such as seismic;

- scour impacting stability of the gravel or rock bed;

- rock grading to ensure stability under environmental loading (i.e. wave and

current). This may also consider whether no rock loss is acceptable or some

rock loss is acceptable;

- rock grading such that it acts as a filter layer to prevent upwards

migration of the underlying soils or gradual sinking of the rock into the

seabed (Nielson et al., 2014) and to ensure sufficient permeability

of the rock to allow sufficient drainage. These two requirements sometimes

conflict each other and CIRIA (2012) contains further guidance. It

may also be necessary to use different rock grading in the rock berm to

achieve the requirements. In general, it is difficult to ensure the as

installed gravel material will satisfy a closed-filter criterion due to loss

of fines during placement. Therefore, a common approach is to use an open

filter criterion and ensure that the rock bed is thick enough to provide

sufficient drainage where required, or to demonstrate that the critical

gradient of the underlying soils will not be exceeded;

- seismic conditions and stability of the rock under seismic loading. Seismic

loading may cause degradation of underlying soil and this should be taken

into account;

- penetration of rock dump into the underlying seabed affecting the required

rock volumes;

- the rock should be competent material with good engineering properties and

this should be established during the design process and validated during

the production and installation of the rock; and

- the requirement for installation survey of rock dump and, perhaps, a

pre-installation survey where the foundation is to be installed a

significant time later. The survey should take into account the tolerances

to be achieved including overall sizing, level and surface roughness or

allowable undulations.

Figure 3.5.3 Gravel bed or rock berm design issues

5.4 Sliding capacity of gravity base on gravel beds and rock berms

5.4.1 A key issue when using a gravel bed is to determine the sliding friction that may be

effective between the foundation and gravel or rock. Hutchinson et al. (2010)

outline some of the key developments in international practice for the design of

breakwaters against sliding, along with some field scale testing on the impact of

base roughening on interface friction between rock and a pre-cast concrete base.

5.4.2 The interface friction between concrete and rock or gravel will depend on many

factors. This includes the relative roughness of the concrete compared to the

particle size distribution of the gravel or rock which will determine how readily

the gravel particles engage at the interface.

5.4.3 CIRIA (2012) presents a methodology based upon the residual angle of the rock

material, surface roughness, contact stress and normalised strength of the rock.

This method could be used as an initial design assumption. However, where sliding is

a critical aspect of design, and in absence of relevant testing or data already

available, it is recommended that testing is performed to justify the design

parameters used to provide an optimised design.

5.4.4 Deliberate roughening of the underside of a gravity base may be used to increase

interface friction. Deliberate roughening measures may include serrations such as

those presented by Hutchinson et al. (2010), or the use of other measures

such as studs reported by McNulty et al. (2002). In addition, or as an

alternative, ballast may be used to increase the vertical contact stress of the

foundation. McNulty et al. (2002) also discuss the placement of gravel in

mounds, rather than a continuous blanket, to ensure more even contact stress across

the whole gravity base footprint.

5.5 Sliding capacity of steel on rock

5.5.1 Where steel mudmats are required to generate sliding capacity on rock the sliding

capacity can be determined using an alpha based approach dependent on unconfined

compression strength as outlined in Ziogos et al. (2015). As described in the

paper, the roughness of the steel and basic angle of friction of the rock play an

important role in mobilisation of interface friction.

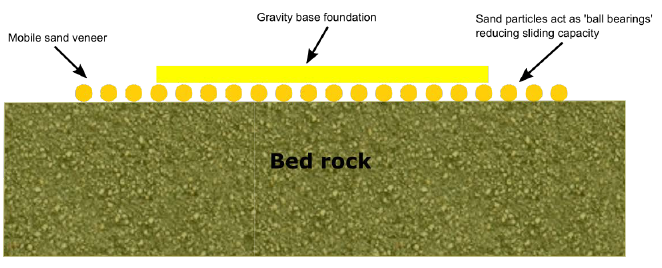

5.5.2 It should be noted that sliding capacity on rock could be adversely influenced by the

presence of a sand veneer, or mobile sand, therefore this possibility should be

considered during foundation assessment, as shown in Figure 3.5.4 Effect of mobile sand veneer on mobilisation of interface friction for

rock. It is important that the

assessment of friction takes into account the seabed conditions which are not

necessarily the same as the measured properties of the rock and steel

interfaces.

Figure 3.5.4 Effect of mobile sand veneer on mobilisation of interface friction for

rock

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|