4 Strength criteria

4.1 General

The following criteria are applicable to transverse bulkheads

with vertical corrugations (see figure

2a).

Requirements for local net plate thickness are given in 4.7

In addition, the criteria given in 4.2 and 4.5 are to be complied

with.

Where the corrugation angle 4 shown in figure 2a is less than 50°,

a horizontal row of staggered shedder plates is to be fitted at approximately

mid-depth of the corrugations (see figure 2a) to help preserve

dimensional stability of the bulkhead under flooding loads. The shedder

plates are to be welded to the corrugations by double continuous welding,

but they are not to be welded to the side shell.

The thicknesses

of the lower part of corrugations considered in the application of

4.2 and 4.3 are to be maintained for a distance from the inner bottom

(if no lower stool is fitted) or the top of the lower stool not less

than 0.15.ℓ.

The thicknesses of the middle part of

corrugations considered in the application of 4.2 and 4.4 are to be

maintained to a distance from the deck (if no upper stool is fitted)

or the bottom of the upper stool not greater than 0.3.ℓ.

4.2 Bending capacity and shear stress

The bending capacity is to comply with the following relationship:

where:

|

M

|

= |

bending

moment, in kN.m, as given in 3.1

|

|

Z

le

|

= |

section modulus of one half pitch corrugation, in cm3,

at the lower end of corrugations, to be calculated according to 4.3

|

|

Z

m

|

= |

section modulus of one half pitch corrugation, in cm3,

at the mid-span of corrugations, to be calculated according to 4.4

|

|

σ

a,le

|

= |

allowable stress, in FT/mm2, as given in 4.5, for

the lower end of corrugations

|

|

σ

a,m

|

= |

allowable stress, in N/ mm2 , as given in 4.5, for

the mid-span of corrugations.

|

In no case is Z

m to be taken greater

than the lesser of 1.15.Z

le, and 1.15.Z'le for calculation of the bending capacity, Z'le being

defined below.

In case effective shedder plates are fitted

which:

- are not knuckled;

- are welded to the corrugations and the top of the lower stool

by one side penetration weld or equivalent;

- are fitted with a minimum slope of 45° and their lower edge

is in line with the stool side plating;

or effective gusset plates are fitted which:

- are fitted in line with the stool side plating;

- have material properties at least equal to those provided for

the flanges,

the section modulus Z

le, in cm3,

is to be taken not larger than the value Z'le, in cm3,

given by:

where:

|

Z

g

|

= |

section modulus of one half pitch corrugation, in cm3,

according to 4.4, in way of the upper end of shedder or gusset plates,

as applicable

|

|

Q

|

= |

shear

force, in kN, as given in 3.2

|

|

h

g

|

= |

height, in m, of shedders or gusset plates, as applicable (see figures 3a, 3b, 4a and 4b)

|

|

s

1

|

= |

as given in 2.3.1 (a)

|

|

p

g

|

= |

resultant pressure, in kN/m2, as defined in 2.5, calculated in way of the

middle of the shedders or gusset plates, as applicable

|

|

δ

a

|

= |

allowable stress, in N/mm2, as given in 4.5.

|

Shear stresses τ are obtained by dividing the shear force Q by the shear area. The shear area is to be reduced in order

to account for possible non-perpendicularity between the corrugation

webs and flanges. In general, the reduced shear area may be obtained

by multiplying the web sectional area by (sin θ), θ

being the angle between the web and the flange.

When calculating

the section moduli and the shear area, the net plate thicknesses are

to be used.

The section moduli of corrugations are to

be calculated on the basis of the requirements standards given in

4.3 and 4.4.

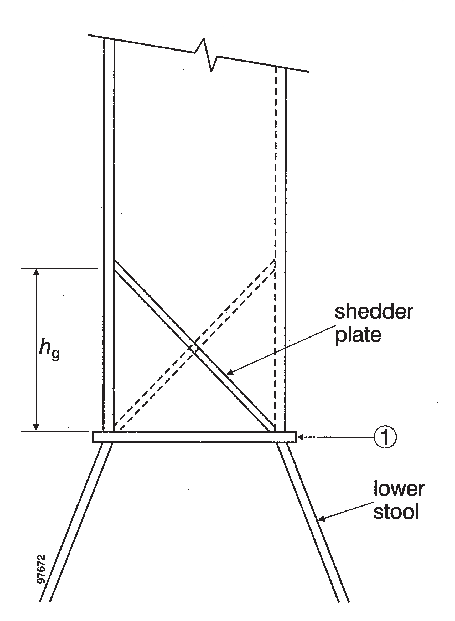

Figure 3a Symmetric shedder

plates

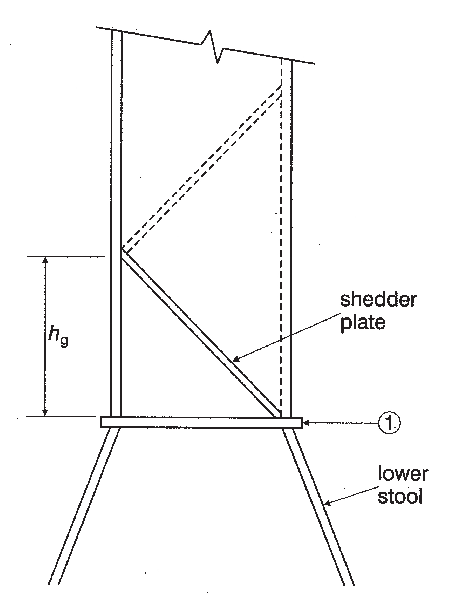

Figure 3b Asymmetric shedder

plates

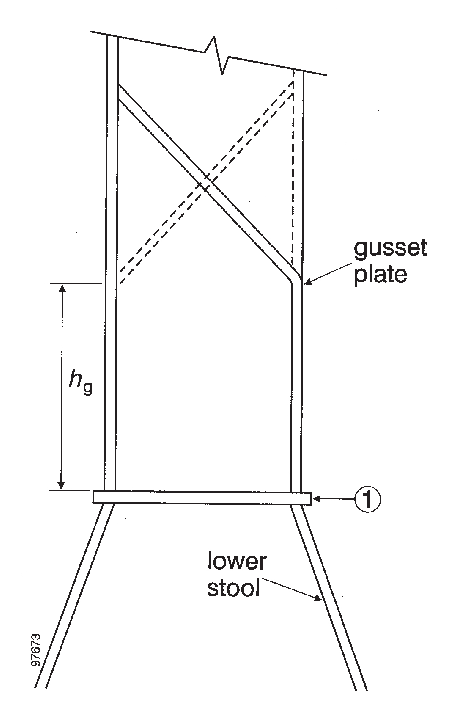

Figure 4a Symmetric

gusset/shedder plates

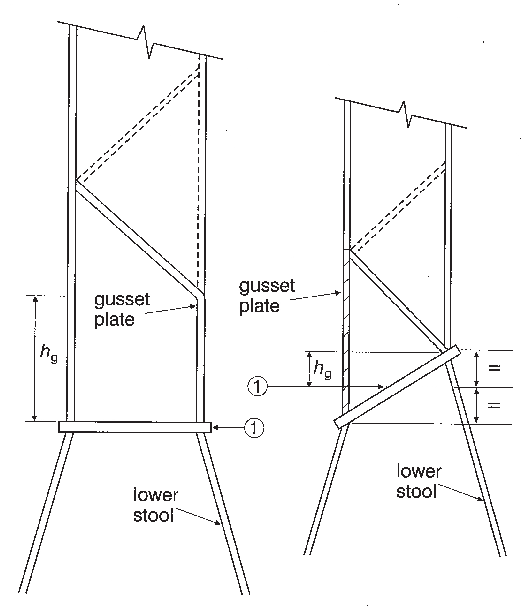

Figure 4b Asmmetric

gusset/shedder plates

Figure 5

4.3 Section modulus at the lower end of corrugations

The section modulus is to be calculated with the compression

flange having an effective flange width, b

cf,

not larger than as given in 4.6.1.

If the corrugation webs are not supported by local brackets

below the stool top (or below the inner bottom) in the lower part,

the section modulus of the corrugations is to be calculated considering

the corrugation webs 30%) effective.

-

(a) Provided that effective shedder plates, as

defined in 4.2, are fitted (see figures

3a and 3b),

when calculating the section modulus of corrugations at the lower

end (cross-section (1) in figures

3a and 3b),

the area of flange plates, in cm2, may be increased by:

- where:

|

a

|

= |

width,

in m, of the corrugation flange (see figure 2a)

|

|

t

sh

|

= |

net shedder plate thickness, in mm |

|

t

f

|

= |

net flange thickness, in mm |

|

σ

Fsh

|

= |

minimum upper yield stress, in N/mm2, of the material

used for the shedder plates

|

|

σ

Ffl

|

= |

minimum upper yield stress, in N/mm2, of the material

used for the corrugation flanges.

|

-

(b) Provided that effective gusset plates, as

defined in 4.2, are fitted (see figures 4a and 4b), when calculating

the section modulus of corrugations at the lower end (cross-section

(1) in figures 4a and 4b), the area of flange plates,

in cm2, may be increased by (7.h

g.t

gu)

- where:

|

h

g

|

= |

height of gusset plate, in m (see figures 4a and 4b), not to be taken greater

than ( .s

gu) .s

gu)

|

|

s

gu

|

= |

width of the gusset plates, in m |

|

t

gu

|

= |

net gusset plate thickness, in mm, not to be taken greater than t

f

|

|

t

f

|

= |

net flange thickness, in mm, based on the as-built condition. |

-

(c) If the corrugation webs are welded to a sloping

stool top plate which is at an angle not less than 45° with the

horizontal plane, the section modulus of the corrugations may be calculated

considering the corrugation webs fully effective. In case effective

gusset plates are fitted, when calculating the section modulus of

corrugations the area of flange plates may be increased as specified

in (b) above. No credit can be given to shedder plates only.

For angles less than 45°, the effectiveness of the web may

be obtained by linear interpolation between 30% for 0° and 100%

for 45°.

4.4 Section modulus of corrugations at cross-sections

other than the lower end

The section modulus is to be calculated with 'the corrugation

webs considered effective and the compression flange having an effective

flange width, b

cf, not larger than as given

in 4.6.1.

4.5 Allowable stress check

The normal and shear stresses σ and τ are not to exceed the allowable values σ

a and τ

a, in N/mm2, given

by:

where:

|

σ

F

|

= |

the minimum upper yield stress, in N/mm2, of the

material.

|

4.6 Effective compression flange width and shear

buckling check

4.6.1 Effective width of the compression flange

of corrugations

4.6.2 Shear

The buckling check is to be performed for the web plates

at the corrugation ends.

The shear stress τ is not to exceed the critical

value τ

c, in N/mm2, as obtained

from the following:

where:

|

τ

F

|

= |

|

|

σ

F

|

= |

minimum upper yield stress, in N/mm2, of the material

as given in 4.6.1

|

|

τ

E

|

= |

|

|

|

= |

k

t, E, t and c are given by:

|

|

k

t

|

= |

6.34 |

|

E

|

= |

modulus

of elasticity of material as given in 4.6.1 |

|

t

|

= |

net

thickness, in mm, of corrugation web |

|

c

|

= |

width,

in m, of corrugation web (see figure

2a).

|

4.7 Local net plate thickness

The bulkhead local net plate thickness t, in

mm, is given by:

where:

|

s

w

|

= |

plate width, in m, to be taken equal to the width of the corrugation

flange or web, whichever is the greater (see figure 2a)

|

|

p

|

= |

resultant

pressure, in kN/m2, as defined in 2.5, at the bottom of each strake

of plating; in all cases, the net thickness of the lowest strake is

to be determined using the resultant pressure at the top of the lower

stool, or at the inner bottom, if no lower stool is fitted or at the

top of shedders, if shedder or gusset/shedder plates are fitted.

|

|

σ

F

|

= |

minimum upper yield stress, in N/mm2, of the material.

|

For built-up corrugated bulkheads, when the thicknesses of the

flange and web are different, the net thickness of the narrower plating

is to be not less than t

n, in mm, given by:

where:

|

s

n

|

= |

the width, in m, of the narrower plating. |

The net thickness of the wider plating, in mm, is not to be

taken less than the maximum of the following values:

and

where:

|

t

np

|

= |

actual net thickness of the narrower plating and not to be greater

than

|

|