Section

7 Towing and lifting arrangements

7.1 Application

7.1.1 Where it is intended to transport a dock gate by means of towing or where the dock

gate will be lifted into place, the strength of fittings and supporting hull

structures are to be assessed in accordance with the requirements of this

Chapter.

7.1.2 The arrangements, equipment and fittings of sufficient safe working load are to be

provided to enable the safe conduct of all towing and lifting operations.

7.1.3 Fittings means bollards and bitts, fairleads, stand rollers, chocks used

for the towing of the dock gate, and padeyes, lifting lugs, etc. used for the

lifting of the dock gate. Any weld or bolt or equivalent device connecting the

fitting to the supporting structure is part of the shipboard fitting. Other

components such as capstans, winches, etc. are not covered by this Chapter.

7.1.4 Supporting structures means that part of the dock gate on/in which the fitting is

placed and which is directly submitted to the forces exerted on the fitting. The

supporting structure of capstans, winches, etc. used for towing operations mentioned

above is also to comply with the requirements specified in this Chapter.

7.2 Towing

7.2.1 The strength of fittings used for normal towing operations at bow, sides

and stern and their supporting hull structures are to comply with the requirements

specified in this sub-Section.

7.2.2 Fittings for towing are to be located on stiffeners and/or girders which

are part of the deck construction so as to facilitate efficient distribution of the

towing load. Other arrangements are acceptable, provided that the strength is

confirmed adequate for the intended service.

7.2.3 The design load applied to fittings and supporting hull structure is not

to be less than 1,25 times the intended maximum towing load (e.g. static bollard

pull) as indicated on the towing arrangements plan.

7.2.4 When a safe towing load TOW greater than that determined according to

Pt 2, Ch 2, 7.2 Towing 7.2.16 is requested,

then the design load is to be increased in accordance with the appropriate

TOW/design load relationship given in this Section.

7.2.5 The side projected area is to be considered for selection of towing lines

and the loads applied to fittings and supporting hull structure.

7.2.6 The increase of the minimum breaking strength for synthetic ropes need

not to be considered for the loads applied to fittings and supporting hull

structure.

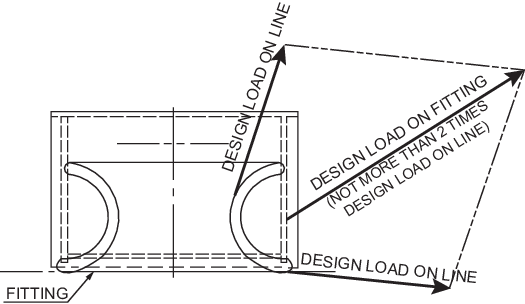

7.2.7 The design load is to be applied to fittings in all directions that could

occur by considering the arrangement shown on the towing and mooring arrangements

plan. Where the towing line takes a turn at a fitting, the total design load applied

to the fitting is equal to the resultant of the design loads acting on the line,

see

Figure 2.7.1 Design load applied to

fittings.

However, in no case does the design load applied to the fitting need to be greater

than twice the design load on the line.

Figure 2.7.1 Design load applied to

fittings

7.2.8 Fittings are to be selected from an acceptable National or International

standard and to be based on the intended maximum towing load (e.g. static bollard

pull) as indicated on the towing arrangements plan.

7.2.9 Towing bitts (double bollards) are to be chosen for the towing line

attached with an eye splice if the industry standard distinguishes between different

methods to attach the line, i.e. figure of eight or eye splice attachment.

7.2.10 When the fitting is not selected from an accepted industry standard, the

strength of the fitting based on net scantlings and its attachment to the dock gate

is to be adequate for the loads specified in Pt 2, Ch 2, 7.2 Towing 7.2.3 based on the

acceptance criteria given in Pt 2, Ch 2, 7.2 Towing 7.2.10 or Pt 2, Ch 2, 7.2 Towing 7.2.11 as appropriate.

Towing bitts (double bollards) are required to resist the loads caused by the towing

line attached with an eye splice. For strength assessment, beam theory or finite

element analysis using net scantlings is to be applied, as appropriate. Corrosion

additions and wear down allowance is to be added to the net scantlings as defined in

Pt 2, Ch 2, 7.2 Towing 7.2.13 and Pt 2, Ch 2, 7.2 Towing 7.2.15.

7.2.11 The net scantlings of the supporting structure for the fittings are to

be adequate for the loads specified in Pt 2, Ch 2, 7.2 Towing 7.2.3 based on the

acceptance criteria given in Pt 2, Ch 2, 7.2 Towing 7.2.11 or Pt 2, Ch 2, 7.2 Towing 7.2.12 as appropriate.

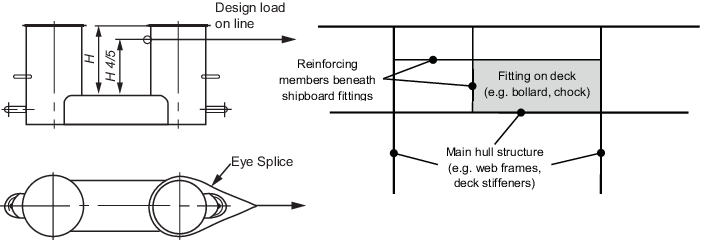

The reinforced members beneath fittings are to be effectively arranged for any

variation of direction (horizontally and vertically) of the towing forces acting

upon the fittings, see

Figure 2.7.2 Supporting hull

structure for a sample

arrangement. Proper alignment of the fitting and its supporting hull structure is to

be ensured. The acting point of the towing force on a fitting is to be taken at the

attachment point of a towing line or at a change in its direction. For bollards and

bitts, the attachment point of the towing line is to be taken not less than 4/5 of

the tube height above the base as indicated in Figure 2.7.2 Supporting hull

structure. Corrosion

additions and wear down allowance is to be added to the net scantlings as defined in

Pt 2, Ch 2, 7.2 Towing 7.2.13 and Pt 2, Ch 2, 7.2 Towing 7.2.15.

7.2.13 For strength calculations by means of finite element analysis, the

geometry is to be idealised as realistically as possible. The ratio of element

length to width is not to exceed 3. Girders are to be modelled using shell or plane

stress elements. Symmetric girder flanges are generally to be modelled by beam or

truss elements. At least three elements are to be used across the depth of the

girder. In way of small openings in girder webs the web thickness is to be reduced

to a mean thickness over the web height. Large openings are to be modelled.

Stiffeners are generally to be modelled by using shell, plane stress, or beam

elements. Stresses are to be read from the centre of the individual element. For

shell elements the stresses are to be evaluated at the mid-plane of the element. The

equivalent stress within the supporting structure of fittings is not to exceed the

specified minimum yield strength of the material.

Figure 2.7.2 Supporting hull

structure

7.2.14 An allowance for corrosion is to be added to the net thickness derived

as indicated below:

- For the supporting structure, a corrosion addition of 2 mm is to

be added to the net thickness derived.

- For pedestals and foundations on deck which are not part of a

fitting according to an accepted industry standard, 2,0 mm.

- For shipboard fittings not selected from an accepted industry

standard, 2,0 mm.

Table 2.7.1 Allowable stress within

the supporting structure of fittings

|

|

Normal stress, in

N/mm2

|

Shear stress, in

N/mm2

|

| Allowable stress

|

|

|

| where

σo = specified minimum yield strength of the

material in N/mm2

Note Normal stress

is defined as the sum of bending and axial stresses. No

stress concentration factors are accounted for and as such

may need to be considered separately.

|

7.2.15 In addition to the corrosion addition given in Pt 2, Ch 2, 7.2 Towing 7.2.13, the wear

allowance, tw, for fittings that are not selected from an

acceptable National or International Standard, is not to be less than 1,0 mm, added

to surfaces which are intended to regularly contact the line.

7.2.16 The safe towing load (TOW) is the load limit for towing purposes. TOW

used is not to exceed 80 per cent of the design load specified by Pt 2, Ch 2, 7.2 Towing 7.2.3.

7.2.17 TOW, in tonnes, of each fitting is to be marked (by weld bead or

equivalent) on the deck fittings used for towing.

7.2.18 The above requirements on TOW apply for the use with no more than one

towline. If not otherwise chosen, for towing bitts (double bollards) TOW is the load

limit for a towing line attached with an eye-splice.

7.3 Lifting

7.3.1 The strength of fittings used to lift a dock gate in and out of water and

their supporting hull structures are to comply with the requirements of this

sub-Section.

7.3.2 Padeyes and lifting lugs are to be located on stiffeners and/or girders which are

part of the deck construction so as to facilitate efficient distribution of the

lifting load. Other arrangements are acceptable, provided that the strength is

confirmed adequate for the intended service.

7.3.3 The provision of padeyes is to be such that a uniform lift is achieved with no

off-centre loading of the lifting appliance occurring.

7.3.4 The design of padeyes is to be in accordance with a recognised national or

international standard.

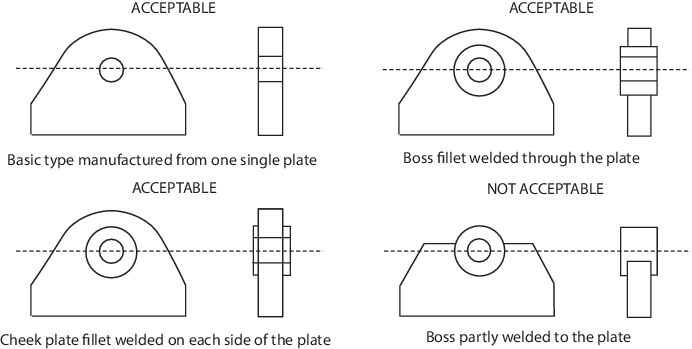

7.3.5 The padeye can be manufactured from one single plate, have a cheek plate

fillet welded on each side of the plate or have a boss which is fillet welded

through the plate, see

Figure 2.7.3 Acceptable padeye

design. Padeyes

where the boss is only partly welded to the plate are not permitted.

Figure 2.7.3 Acceptable padeye

design

7.3.6 All padeyes and lifting lugs are to be marked with their specific SWL. The locations

and SWL of the padeyes and lifting lugs is to be recorded on the towing and lifting

arrangement plan.

7.3.7 All padeyes and lifting lugs are to be tested to 1,5 times the SWL, as a vertical

load only.

7.3.8 The net scantlings of supporting structures are to be assessed in

accordance with Pt 2, Ch 2, 7.2 Towing 7.2.9 to Pt 2, Ch 2, 7.2 Towing 7.2.12 where the design

load is to be taken as the SWL of the padeye and the acceptance criteria are given

in Table 2.7.2 Allowable stress within

the supporting structure of padeyes. The reinforced members beneath the

padeye are to be effectively arranged for any variation of direction (horizontally

and vertically) of the lifting forces acting upon the padeye. Corrosion additions

and wear down allowance is to be added to the net scantlings as defined in Pt 2, Ch 2, 7.2 Towing 7.2.13.

Table 2.7.2 Allowable stress within

the supporting structure of padeyes

|

|

Normal stress, in

N/mm2

|

Shear stress, in

N/mm2

|

| Allowable stress

|

|

|

| where

σo = specified minimum yield strength of the

material in N/mm2

Note Normal stress

is defined as the sum of bending and axial stresses. No

stress concentration factors are accounted for and as such

may need to be considered separately.

|

7.3.9 The global strength of the dock gate (longitudinal and transverse)

during lifting operations is to be assessed taking into account the hoisting speed

of the lifting appliance, the stiffness of the wires, the residual weights, liquids,

etc, on the pontoon and the distribution of the padeyes.

7.4 Towing and lifting arrangements plan

7.4.1 The SWL and TOW for the intended use for each shipboard fitting is to be noted in the

towing and lifting arrangements plan which is to be made available for towing and

lifting operations. It is to be noted that TOW is the load limit for towing purposes

and SWL that for lifting purposes.

7.4.2 Information provided on the plan is to include in respect for each shipboard fitting:

- location on the pontoon;

- fitting type;

- SWL/TOW;

- manner of applying towing line load, including limiting

fleet angles; and

- manner of applying lifting load, including limiting

angles.

Note that item (c) is subject to approval. Fleet angle is defined as the maximum

angle the line deviates from a direction perpendicular to the drum axis of a towing

winch. The limiting angles for the purposes of lifting are defined as the maximum

angles assumed in the derivation of the SWL for each padeye.

|