Section

2 Rudders

2.1 General

2.1.1 Requirements

are given in this Section for double and single plate rudders and

also for certain types of higher efficiency rudders.

2.1.2 The scantlings

of flanking rudders (rudders fitted forward of the propeller to improve

steering when navigating astern) are to be in accordance with the

requirements for rudders fitted abaft the propeller. However, the

scantlings are to be not less than required for an astern speed equal

to the normal service speed ahead. This type of rudder is to be provided

with stops at a maximum angle of helm of 45°.

2.1.3 The scantlings

of a bow rudder are to be in accordance with the requirements for

rudders out of the propeller slip stream applying the maximum speed,

ahead or astern, at which the rudder will be used or half the service

speed, whichever is the greater. Efficient arrangements are to be

provided for locking the rudder in the centreline position when not

in use, see

Pt 5, Ch 15, 1.6 Rudder, rudder stock, tiller and quadrant 1.6.4.

2.1.4 Rudder

systems of special design will be considered on the basis of these

Rules and full details on the loadings of these rudders are to be

given; model tests may be required to support the calculations.

2.1.5 Rudders

are to be efficiently supported in the ship’s structure by means

of suitable carriers in the steering gear flat, or in the solepiece

gudgeons. Where the weight of the rudder is supported by carrier bearings

the structure in way is to be adequately strengthened and the deck

plating increased in thickness.

2.1.6 Rudder

stocks are to be enclosed by watertight trunks or tubes which are

to be fitted with an efficient watertight gland or other approved

type of seal when the top of the trunks (steering gear flat) is less

than 300 mm above the deepest waterline in any trimmed condition.

2.1.7 Arrangements

to prevent the rudders from lifting are to be fitted. Their strength

and that of the supporting structure is to be such that damage to

the steering gear in case of touching bottom is prevented, see

Pt 5, Ch 15, 2.1 General 2.1.2.(b).

2.2 Rudder stock and bearings

2.2.1 The scantlings

of the rudder stock are to be not less than required by Table 12.2.1 Rudder stock diameter.

Table 12.2.1 Rudder stock diameter

| Item

|

Requirement

|

|

(1) Basic stock diameter, δS, at and below lowest

bearing for mild steel

|

mm mm

|

| (2) Stock diameter, δSO,

corrected for higher tensile steel

|

|

|

(3) Diameter in way of tiller, δSU

|

|

δsu |

= |

δSO in (1) with N = 0 |

For spade rudders:

δSU ≥ 0,7δS

|

| Symbols

|

|

For σo > 235 (24) = (235/σo)0,75

(24/σo)0,75

For σo ≤ 235 (24) = (235/σo) (24/σo)

|

PL |

= |

lateral force on rudder acting at centre of pressure blade |

| = |

117,5KRf(V +

5.6)2AR |

|

|

NOTE

Where the astern speed is expected to be more than 0,5 × the

speed ahead, δS will be specially considered.

σo is to be taken not greater than 70 per cent of

the ultimate tensile strength or

450 N/mm2 (45,9 kgf/mm2), whichever is

the lesser, so is not to be less than

200 N/mm2, see

Ch 5, 2.4 Mechanical tests 2.4.6 of the

Rules for the Manufacture, Testing and Certification of Materials, July 2022

.

|

Table 12.2.2 Rudder coefficient k

R

| Design

criteria

|

k

R

|

| Rudder in propeller slipstream

|

0,248

|

| Rudder out of propeller

slipstream

|

0,235

|

| Barge – non-self-propelled

|

0,226

|

| Symbols

|

|

|

Table 12.2.3 Position of centre of

pressure

| Design

criteria

|

Value of x

P to be used in Table 12.2.1 Rudder stock diameter

|

| Rectangular rudders

|

but not less than 0,12x

B

|

| Non-rectangular rudders

|

x

P as calculated from geometric form (see Note)

but not less than

|

| Symbols

|

|

x

B

|

= |

breadth of rudder, in metres |

|

x

L

|

= |

horizontal distance from leading edge of the rudder,

to the pintles, or axle, in metres |

|

x

P

|

= |

horizontal distance from the centreline of the rudder

pintles, or axle, to the centre of pressure, in metres |

|

x

S

|

= |

horizontal length of any rectangular strip of rudder

geometric form, in metres |

|

y

R

|

= |

depth of rudder on centreline of stock, in

metres |

|

|

NOTE

For rectangular strips the centre of pressure should be

assumed to be located 0,33x

S abaft leading edge of strip.

|

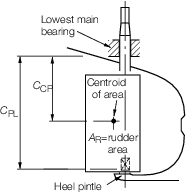

Table 12.2.4 Pintle arrangement coefficient,

N

see Fig. 12.2.1

Table 12.2.5 Rudder coefficient f

| Rudder angle

|

2 × 35°

|

2 × 45°

|

2 × 55°

|

Rudder

profile

Type 1

|

1,0

|

1,23

|

1,43

|

Rudder profile

Type 2

|

1,60

|

1,97

|

-

|

Rudder profile

Type 3

|

1,15

|

1,42

|

1,64

|

| Symbols

|

| Rudder

profile Types 1, 2, and 3, see

Figure 12.2.3 Rudder profile types

|

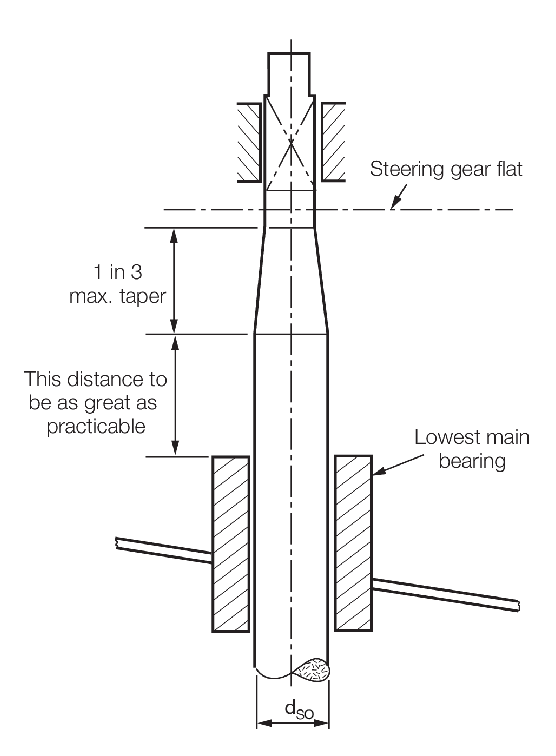

Figure 12.2.1 Pintle arrangements

2.2.2 For rudders

having an increased diameter of the rudder stock in way of the rudder, see

Figure 12.2.2 Taper of rudder stock, the

increased diameter is to be maintained to a point as far as practicable

above the top of the lowest bearing. This diameter may then be tapered

to the diameter required in way of the upper bearing and further to

the diameter at tiller. The length of the taper is to be at least

three times the reduction in diameter. Particular care is to be taken

to avoid the formation of a notch at the upper end of the taper. The

design of the upper part of the rudder stock and of the upper rudder

stock bearing is to take account of any forces which may be imposed

by the steering engine, especially in the case where two or more rudders

are activated by one steering engine.

Figure 12.2.2 Taper of rudder stock

Figure 12.2.3 Rudder profile types

2.2.3 Sudden

changes of section or sharp corners in way of the rudder coupling,

and shoulders for rudder carriers are to be avoided. Jumping collars

are not to be welded to the rudder stock. Keyways in the rudder stock

are to have rounded ends and the corners at the base of the keyway

are to be radiused.

2.2.4 The design

of the lowest bearing is to comply with the requirements of Table 12.2.6 Lowest main bearing

requirements.

Table 12.2.6 Lowest main bearing

requirements

| Item

|

Requirements

|

| Lowest

main bearing

|

Depth zB, in mm

|

| 1,5δSO ≥ z

B ≥ 1,0δSO

|

| For

spade rudders:

|

| 1,5δSO ≥ z

B ≥ 1,3δSO

|

| Bearing pressure (on the

projected area of the lowest main bearing), where the area is to be taken as

the projected length × diameter

|

Bearing

material

|

Maximum pressure, in N/mm2

(kgf/cm2)

|

| Metal

|

6,87 (70,0)

|

| Synthetic

|

4,41 (45,0)

|

| Lignum Vitae

|

2,45 (25,0)

|

| Clearance in lowest main

bearing on the diameter (note should be taken of the manufacturer's

recommended clearances, particularly where bush material requires

pre-soaking)

|

Bearing

material

|

Clearance, in mm

|

| Metal (see note)

|

0,001δSO + 1,0

|

| Synthetic

|

0,002δSO + 1,0

but not less than 1,5

|

| Symbols

|

|

z

B

|

= |

depth of lowest bearing, in mm |

|

|

NOTE

For bearings which are pressure lubricated the clearance

must be restricted to enable the pressure to be maintained.

|

2.2.5 Where

liners are fitted to rudder stocks or pintles, they are to be shrunk

on or otherwise efficiently secured. If liners are to be shrunk on,

the shrinkage allowance is to be indicated on the plans. Where liners

are formed by stainless steel weld deposit, the stocks and pintles

are to be of weldable quality steel, and details of the procedure

are to be submitted, see also

Pt 3, Ch 12, 2.2 Rudder stock and bearings 2.2.6.

2.2.6 Where

it is proposed to use stainless steel liners and bushes for rudder

stock and/or pintle bearings, the chemical composition and mechanical

properties are to be submitted for approval. Materials for bushes

and liners are to have a suitable difference in hardness. Synthetic

rudder bearing materials are to be of a type approved by Lloyd’s

Register (hereinafter referred to as LR).

2.3 Rudder construction – Doubled plated

2.3.1 The scantlings

of a double plated rudder are to comply with Table 12.2.7 Double plated rudder

construction, but the thickness of

the rudder plating may require to be increased in way of the rudder

coupling and the heel pintle.

Table 12.2.7 Double plated rudder

construction

| Item

|

Requirements

|

|

(1) Side plating

|

|

t

|

= |

3yW (1,45 + 0,1  ) + 2 mm ) + 2 mm |

|

|

(2) Webs - vertical and horizontal

|

As (1) above

|

|

(3) Top and bottom plates

|

As (1) above using y

W = maximum rudder width, in metres, at top or bottom, but not

less than 0,9 m

|

|

(4) Nose plates

|

tN ≥ 1,25t from (1)

|

|

(5) Mainpiece - fabricated

|

Breadth and width ≥ δSO

|

tM

|

= |

5 + 0,56 mm mm |

|

|

rectangular, see Note

|

Minimum fore and aft extent of side

plating = 0,2x

B

|

| Stress due to bending ≤ 5,0

kgf/mm2

|

|

(6) Mainpiece - tubular, see Note

|

Inside diameter ≥ δSO

tM as for (5)

Side plating as for (1)

Bending stress as for (5)

|

| Symbols

|

|

tM

|

= |

thickness of side plating and vertical webs forming

mainpiece or of tube, in mm |

|

tN

|

= |

thickness of nose plate, in mm |

|

yW

|

= |

vertical spacing, in metres, of the horizontal webs,

but is not to exceed 0,9 m |

|

xB

|

= |

breadth of rudder on centreline of stock, in

metres |

|

|

|

2.3.2 Adequate

hand or access holes are to be arranged in the rudder plating in way

of the pintles as required and the rudder plating is to be reinforced

locally in way of these openings. Continuity of the modulus of the

rudder mainpiece is to be maintained in way of the openings.

2.3.4 Connection

of rudder side plating to vertical and horizontal webs, where internal

access for welding is not practicable, is to be by means of slot welds

on to flat bars on the webs. The slots are to have a minimum length

of 75 mm and in general, a minimum width of twice the side plating

thickness or 20 mm whichever is the greater. The ends of the slots

are to be rounded. The space between the slots is not to exceed 150

mm. Alternatively the side plating may be fitted in panels, fillet

welded all round either directly on to webs of increased thickness

or on to flat bars on the webs.

2.3.5 Double

plate rudders are to be efficiently coated internally and means for

draining the rudder are to be provided in way of the lowest part of

the rudder when the rudder is mounted in its normal position.

2.3.7 Where

the fabricated mainpiece of a spade rudder is connected to the horizontal

coupling flange by welding, a full penetration weld is required.

2.4 Rudder construction – Single plated

2.4.1 The scantlings

of a single plated rudder are to be not less than required by Table 12.2.8 Single plate rudder

construction.

Table 12.2.8 Single plate rudder

construction

| Item and

parameter

|

Requirements

|

| Blade thickness

|

The greater of:

|

t

|

= |

5 + 0,02δSO + 10yW mm |

|

|

|

| Section modulus of arms

|

|

Z

|

= |

0,25 × y

W

2 × x

W(V + 5,6)2 cm3

|

|

| Diameter of mainpiece

|

Diameter = δSO mm,

see Note to Table 12.2.7 Double plated rudder

construction

|

| Symbols

|

|

xW

|

= |

breadth of rudder blade aft of stock, in metres |

|

yW

|

= |

vertical spacing, in metres, of the arms, but is not

to exceed 0,9 m |

|

V

|

= |

ship’s speed, in km/h |

|

Z

|

= |

section modulus, in cm3

|

|

2.4.3 Rudder

arms are to be efficiently attached to the mainpiece.

2.5 Rudder couplings

2.5.1 Rudder

coupling design is to be in accordance with Table 12.2.9 Rudder couplings to stock. Conical couplings will

be specially considered.

Table 12.2.9 Rudder couplings to stock

| Arrangement

|

Parameter

|

Requirements

|

| Horizontal

coupling

|

Vertical

coupling

|

| Bolted couplings

|

n

|

≥ 6

|

≥ 8

|

| δb

|

|

|

|

m

|

0,00071nδS δb

2 δb

2

|

0,00043  δS

3 δS

3

|

|

t

f

|

≥ δb

(see Note 1)

|

δb

|

αmax

(see Note 2)

|

|

-

|

αas built

(see Note 2)

|

≤ αmax

|

-

|

|

w

f

|

0,67δb

|

0,67δb

|

| Symbols

|

|

k1

|

= |

the greater of k

s and k

f

|

|

kf

|

= |

upper coupling flange material factor |

|

ks

|

= |

rudder stock material factor |

|

m

|

= |

first moment of area of bolts about centre of

coupling, in cm3

|

|

n

|

= |

number of bolts in coupling |

|

tf

|

= |

minimum thickness of coupling flange, in mm |

|

tfa

|

= |

as built flange thickness, in mm |

|

w

f

|

= |

width of flange material outside the bolt holes, in

mm |

|

R

|

= |

palm radius between rudder stock and connected

flange, not smaller than  , in mm , in mm |

|

|

αas built

|

= |

stress concentration factor for as built

scantlings |

| = |

|

|

αmax

|

= |

maximum allowable stress concentration factor |

|

δb

|

= |

diameter of coupling bolts, in mm |

|

PL

|

= |

lateral force acting on the rudder, in N, is to be

calculated for both ahead and astern conditions. The greater of the

two values is to be used |

|

MT |

= |

maximum turning moment applied to stock, and is take to be as the

greates of:

- The torque generated by the steering gear att he maximum

working pressure (see

Pt 5, Ch 15, 1.2 Definitions 1.2.8 )

|

|

V

|

= |

maximum service speed with the ship in the loaded

condition, in km/h |

|

|

Note

1. For spade rudders with horizontal

coupling, t

f is not to be less than 0,25δSO.

|

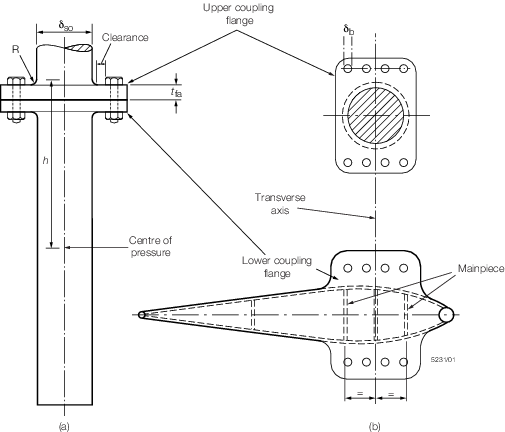

Figure 12.2.4 Rudder stock connection

2.5.2 For rudders

with horizontal coupling arrangements, where the upper flange is welded

to the rudder stock, a full penetration weld is required and its integrity

is to be confirmed by non-destructive examination. Such rudder stocks

are to be subjected to a furnace post-weld heat treatment (PWHT) after

completion of all welding operations. For carbon or carbon manganese

steels, the PWHT temperature is to be not less than 600°C.

2.5.3 The connecting bolts for coupling the rudder to the rudder stock are to be

positioned with sufficient clearance to allow the fitting and removal of the bolts and

nuts without contacting the palm radius, R, see

Pt 3, Ch 12, 2.5 Rudder couplings 2.5.1. The surface forming the palm radius is to

be free of hard and sharp corners and is to be machined smooth to the Surveyor’s

satisfaction. The surface in way of bolts and nuts is to be machined smooth and to the

Surveyor’s satisfaction.

2.5.4 For spade rudders fitted with a fabricated rectangular mainpiece, the

mainpiece is to be designed with its forward and aft transverse sections at equal

distances forward and aft of the rudder stock transverse axis, see

Pt 3, Ch 12, 2.5 Rudder couplings 2.5.1.

2.6 Pintles

2.6.2 When coned

pintles are fitted special attention is to be paid to the fit of the

pintle taper into its housing. The pintle taper is not to exceed one

in six on the diameter, but to facilitate removal of the pintles it

is recommended that the taper be not less than 1 in 12 on the diameter.

Table 12.2.10 Pintle requirements

| Item

|

Requirements

|

|

(1) Pintle diameter (measured outside liner if fitted)

|

|

δPL

|

= |

|

where for single pintle rudders:

|

A

PL

|

= |

|

and for rudders with two or more pintles:

|

A

PL

|

= |

|

|

|

(2) Bearing length

|

z

PB ≥ 1,2δPL

|

|

(3) Gudgeon thickness in way of pintle (measured outside bush

if fitted)

|

b

G ≥ 0,5δPL

|

|

(4) Recommended pintle clearance (note should be taken of the

manufacturer's recommended clearances, particularly where bush material

requires pre-soaking)

|

Bearing

material

|

Clearance, in

mm

(on diameter)

|

| Metal

|

0,001δPL + 1,0

|

| Synthetic

|

0,002δPL + 1,0

but not less than 1,5

|

| Symbols

|

|

b

G

|

= |

thickness of gudgeon material in way of pintle, in

mm |

|

z

PB

|

= |

pintle bearing length, in mm |

|

A

PL

|

= |

rudder area supported by the pintle, in m2

|

|

N

PL

|

= |

number of pintles on the rudder |

|

V

|

= |

ship speed, in km/h, but not less than 12 km/h |

|

δPL

|

= |

pintle diameter, in mm |

|

Note Proposals for higher pressures or other materials will be

specially considered on the basis of satisfactory test results.

|

Figure 12.2.5 Dimensions for pintle requirements

|