Section

3 Structural idealisation

3.1 General

3.1.1 For derivation

of scantlings of stiffeners, beams, girders, etc. the formulae in

the Rules are normally based on elastic or plastic theory using simple

beam models supported at one or more points and with varying degrees

of fixity at the ends, associated with an appropriate concentrated

or distributed load.

3.1.3 For flat

bar stiffeners, the ratio of depth to thickness should not exceed

16.

3.2 Geometric properties of section

3.2.1 The symbols

used in this sub-Section are defined as follows:

|

t

p

|

= |

the thickness, in mm, of the attached plating. Where this varies,

the mean thickness over the appropriate span is to be used |

|

f

|

= |

but is not to exceed 1,0. but is not to exceed 1,0. |

Values of this factor are given in Table 3.3.2 Values of f as a function

of l/b .

Table 3.3.2 Values of f as a function

of l/b

|

|

f

|

|

f

|

| 0,5

|

0,19

|

3,5

|

0,69

|

| 1,0

|

0,30

|

4,0

|

0,76

|

| 1,5

|

0,39

|

4,5

|

0,82

|

| 2,0

|

0,48

|

5,0

|

0,88

|

| 2,5

|

0,55

|

5,5

|

0,94

|

| 3,0

|

0,62

|

6 and above

|

1,00

|

Note Intermediate values to be obtained by linear

interpolation.

|

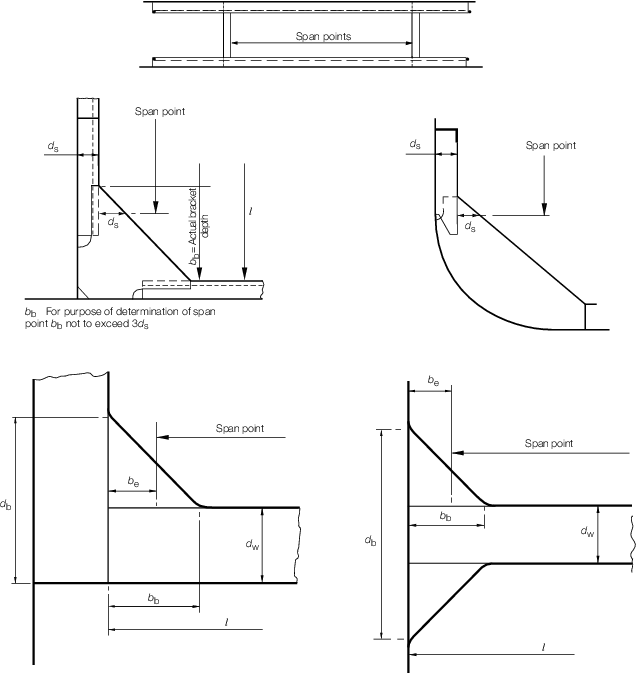

Figure 3.3.1 Determination of span points

Figure 3.3.2 Determination of load-bearing plating

3.2.2 The effective

geometric properties of rolled or built sections may be calculated

directly from the dimensions of the section and associated effective

area of attached plating. Alternatively, the geometric properties

may be taken from Pt 3, Ch 3, 5 Geometric properties of rolled sections. Where

the web of the section is not normal to the attached plating, the

angle is not normal to the attached plating, and exceeds 20, the properties

of the section are to be determined about an axis parallel to the

attached plating, alternatively, the required section modulus is to

be multiplied by a factor:

α is the angle between stiffener and plating.

3.2.3 The geometric

properties of rolled or built stiffener sections are to be calculated

in association with an effective area of attached load-bearing plating

of thickness t

p in mm and of width 500 mm;

for swedges, the width of plating is to be taken as the actual width

of flat plating between the swedges. The thickness, t

p,

is the actual thickness of the attached plating. Where this varies,

the mean thickness over the appropriate span is to be used.

3.2.4 The effective

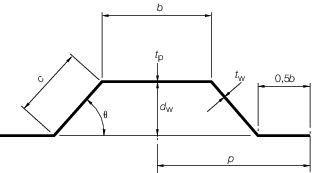

section modulus of a corrugation over a spacing, s, is

to be calculated from the dimensions, and for symmetrical corrugations,

may be taken as:

where d

w, b, t

p, c and t

w are

measured, in mm, and are as shown in Figure 3.3.3 Dimensions and symbols for corrugated bulkheads. The value of b is to be taken not greater

than 50t

p in this calculation, and θ

is to be not less than 40°. The moment of inertia is to be calculated

from:

3.2.5 For symmetrical

corrugations the following additional requirements are also to be

complied with:

-

the ratio b/t

p should not exceed

-

the ratio c/t

p should not exceed

k = see

Pt 3, Ch 2, 1.3 Steel 1.3.3

-

d

w is to be not less than 39le mm (for deep tank

bulkheads only),

-

the plating thickness at the middle of span le of

corrugated bulkheads is to extend not less than 0,2le above mid

span, (for definition of le, see

Pt 3, Ch 3, 3.3 Determination of span point).

3.2.6 The effective

section modulus of a built section may be taken as:

where

|

a

|

= |

the

area of the face plate of the member, in cm2

|

|

A

|

= |

the

area, in cm3, of the attached plating, see

Pt 3, Ch 3, 3.2 Geometric properties of section 3.2.7. If the calculated value of A is

less than the face area a, then A is to be taken as equal

to a

|

|

d

w

|

= |

the depth of the web between the inside of the face plate and

the attached plating. Where the member is at right angles to a line

of corrugations, the minimum depth is to be taken in, mm |

|

t

w

|

= |

the thickness of the web of the section, in mm. |

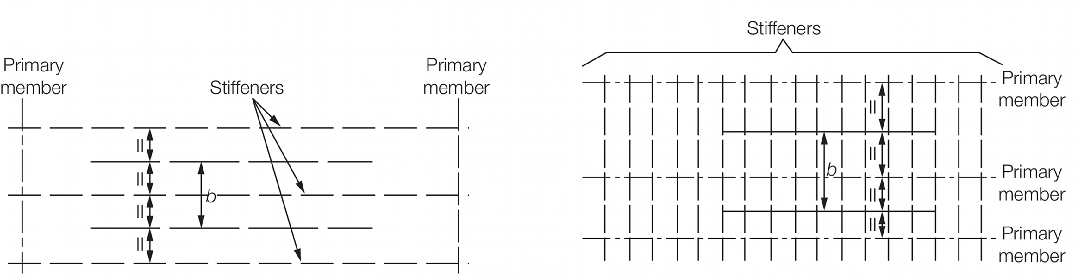

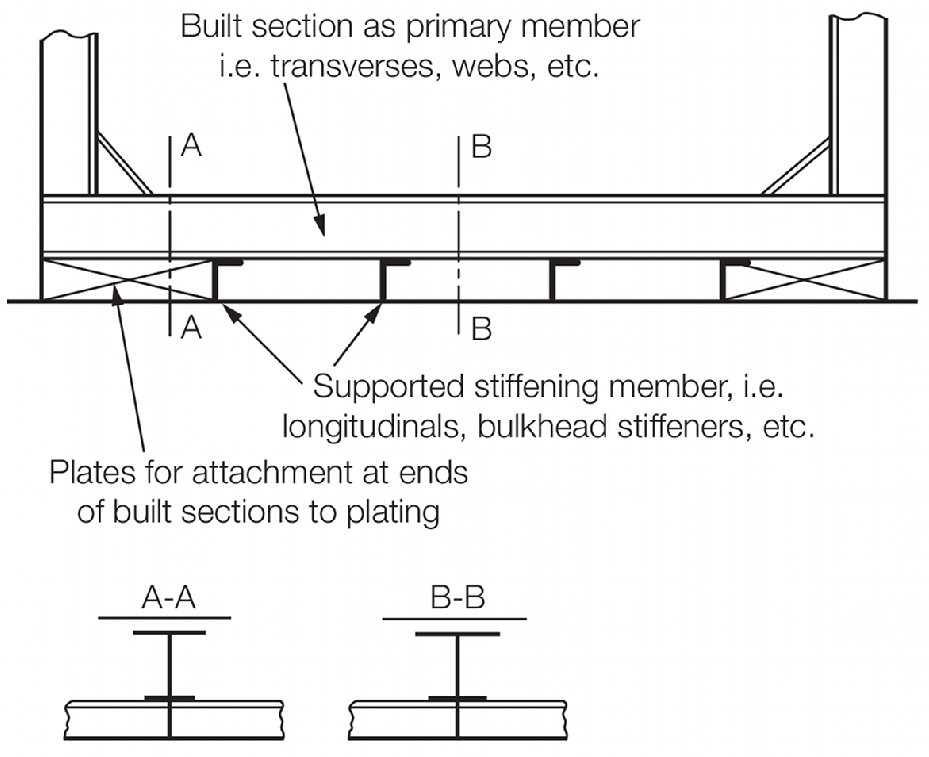

Rolled or built sections fitted on top of supported stiffening

members, see

Figure 3.3.4 Rolled or built sections fitted on top of supported stiffening members,

are to have a modulus not less than two thirds of the modulus required

for the primary member in the same position. This section should be

attached at both ends of the plating for at least one stiffener spacing

and should also be properly attached to the supported stiffeners.

3.2.7 The geometric

properties of primary support members, i.e. girders, transverses,

webs, stringers, etc. are to be calculated in association with an

effective area of attached load-bearing plating, A, determined

as follows:

-

For a member attached

to plane plating:

-

For a member attached

to corrugated plating and parallel to the corrugations:

See

Figure 3.3.3 Dimensions and symbols for corrugated bulkheads

-

For a member attached

to corrugated plating and at right angles to the corrugations:

A is to be taken as equivalent to the area of the face plate

of the member.

Figure 3.3.3 Dimensions and symbols for corrugated bulkheads

Figure 3.3.4 Rolled or built sections fitted on top of supported stiffening members

3.3 Determination of span point

3.3.1 The effective span, l

e, of a stiffening member is generally less than the overall length,

l, by an amount which depends on the design of the end connections. The span

points, between which the value of l

e is measured, are to be determined as follows:

-

For rolled or built

stiffener sections, swedges and corrugations:

|

|

The span point is to be taken

at the point where the depth of the end bracket, measured from the

face of the stiffener is equal to the depth of the stiffener. Where

there is no Rule end bracket, the span point is to be taken at the end

of the stiffener.

|

-

For primary support

members, i.e. girders, transverses, webs, stringers, etc.:

|

|

The span point is

to be taken at a point distant b

e from the end of the member,

|

where:

See also

Pt 3, Ch 3, 3.2 Geometric properties of section 3.2.1.

3.3.2 It is assumed

that the ends of stiffening members are substantially fixed against

rotation and displacement. If the arrangement of supporting structure

is such that this condition is not achieved, consideration will be

given to the effective span to be used for the stiffener.

3.4 Calculation of hull section modulus

3.4.1 All continuous

longitudinal structural material is to be included in the calculation

of the inertia of the hull midship section, and the lever z is,

except where otherwise specified for particular ship types, to be

measured vertically from the neutral axis to the top of keel and to

the moulded strength deck line at the side. The strength deck is to

be taken as follows:

-

Where there is a

complete upper deck and no effective superstructure, the strength

deck is the upper deck.

-

Where there is an

effective superstructure or a stepped deck the position of the strength

deck will be specially considered.

3.4.2 An effective

superstructure is a superstructure extending over the full breadth

of the ship and which exceeds 0,20L in length or 10 m

whichever is the greater and is situated within the 0,5L region.

3.4.3 Lightening

holes in girders need not be deducted, provided that their depth does

not exceed 20 per cent of the web depth.

3.4.4 Isolated

weld scallops, drain and air holes in longitudinals need not be deducted,

provided that their depth does not exceed 65 mm. In no case is the

opening to be greater than 25 per cent of the web depth. Such openings

are considered isolated if they are spaced not less than 1 m apart.

3.4.5 In general,

isolated deck openings need not be deducted, but compensation may

be required. See individual ship type Chapters.

3.4.6 Where trunk decks or continuous hatch coamings are effectively supported by

longitudinal bulkheads or deep girders, they are to be included in the longitudinal

sectional area when calculating the hull section modulus. The lever zt

is to be taken as:

m but not less than z

where

|

y

|

= |

horizontal distance from top of continuous strength member to the

centreline of the ship, in metres |

|

z

|

= |

vertical distance from the newtral axis to the moulded deck line

at side, in metres |

|

zc

|

= |

vertical distance from the neutral axis to the top of the

continuous strength member, in metres |

zc and y are to be measured to the point giving the largest

value of zt

|