Section

5 Hull envelope plating

5.1 General

5.1.1 This Section covers the requirements for the shell envelope plating,

viz., keel, bottom, bilge and side shell plating. For deck plating, see

Pt 4, Ch 1, 4 Deck plating and continuous longitudinal hatch side coamings . The thickness of shell envelope plating amidships is to be

not less than required in Table 1.5.1 Shell envelope plating, but for ships over 65 m in length, the

thickness of the bottom plating may require to be increased to obtain the midship

section modulus required in Pt 3, Ch 4 Longitudinal Strength.

5.2 Keel

5.2.1 The thickness

and breadth of the keel plate is to comply with the requirements of Table 1.5.1 Shell envelope platingand is to be maintained

over the full length of the ship

5.3 Shell plating

5.3.1 The thickness

of bottom shell and side shell plating is to be maintained over 0,5L amidships. Thicknesses are to comply with Table 1.5.1 Shell envelope plating and may be tapered to the

end thickness in the fore end and aft end of the ship, see

Pt 3, Ch 5 Fore End and Aft End Structure, according to the requirements

for taper given inPt 3, Ch 3, 2.5 Principles for taper.

Where the bottom is transversely framed, the bottom is, in general,

to be reinforced with additional longitudinal stiffeners.

Table 1.5.1 Shell envelope plating

| Item and parameter

|

Requirement

|

| (1)

|

Plate keel breadth

|

0,1B but not less than 0,75 m

|

|

|

Thickness

|

As bottom plating t

b When there is a rise of floor, the thickness is to be increased

by 1 mm

|

| (2)

|

Bar keel thickness

|

t = 0,37L + 10 mm

|

| Height

|

d

k = 0,7L + 75 mm

|

| (3)

|

Bottom plating thickness

|

The greater of:

|

|

|

|

t

b = (5,6 + 0,054L)

|

| (4)

|

Bilge plating thickness

|

t = t

b + 2 mm

|

| (5)

|

Bilge chine bars

|

|

| (a) Round bars diameter

|

3t

b mm, but not less than 30 mm

|

| (b) Square bars side

|

3t

b mm, but not less than 30 mm

|

| (c) Angle bars flange

thickness

|

t = 2t

b mm

|

| (6)

|

Side shell plating

|

The greater of:

|

| Thickness

|

t = (5,6 + 0,054L)

|

|

|

t = 10s

|

| (7)

|

Minimum width

sheerstrake

|

W

sh = 0,08D m

|

|

|

but not less than 0,20

m

|

| (8)

|

Sheerstrake

thickness

|

t = side shell thickness + 5 mm

|

| (9)

|

Doublers clear of

sheerstrake (when fitted)

|

|

| Width

|

W

d = between 0,10 and 0,45 m

|

| Thickness

|

The greater of

|

|

|

t = 30W

d

|

|

|

t = required thickness for the side shell plating

|

| Symbols

|

|

L, B, D, s, k and t are as defined

in Pt 4, Ch 1, 1.5 Symbols and definitions 1.5.1

|

|

|

d

k = height of bar keel

|

|

|

t

b = thickness of bottom plating, in mm

|

|

|

5.4 Bilge plating

5.4.1 The thickness

of the bilge plating is to be maintained from amidships to well beyond

the forward and aft shoulder of the bilge, but at least over the midship

region. For definition of shoulders, see

Pt 3, Ch 5, 2.4 Shell plating 2.4.2.

5.4.2 The bilge

radius is to be at least 10 times the thickness of the bilge plating

and the bilge strake is to extend at least 100 mm on either side of

the radius of the bilge plate.

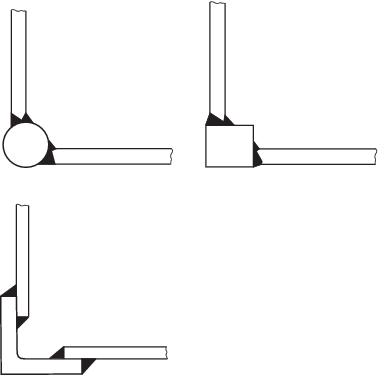

5.4.3 Square

bilges, constructed by solid round, square or externally fitted angle

bars, see

Figure 1.5.1 Square bilge arrangements,

are to comply with Table 1.5.1 Shell envelope plating.

The bottom plating and the side shell plating, adjacent to the round,

square or angle bars need not be increased in thickness above that

of the bottom plating or side shell plating in way.

Figure 1.5.1 Square bilge arrangements

5.5 Sheerstake

5.5.1 The width

and thickness of the sheerstrake is to comply with Table 1.5.1 Shell envelope plating, and is to be maintained

over the length of the hatch opening, including one frame space forward

and aft of the hatch opening, but at least over 0,5L amidships.

5.6 Shell openings

5.6.1 Openings

in the shell plating are to have well-rounded corners; compensation

is generally only required for openings having a width greater than

250 mm. Openings in way of or near to the bilge radius fitted in the

midship region are to be circular or elliptical.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|