Section

3 Design

3.1 Scope

3.1.1 The formulae

given in this Section are applicable to solid crankshafts, having

a main support bearing adjacent to each crankpin, and are intended

to be applied to a single crankthrow analysed by the static determinate

method.

3.1.2 Alternative

methods, including a fully documented stress analysis, will be specially

considered.

3.1.3 Calculations

are to be carried out for the maximum continuous power rating for

all intended operating conditions.

3.1.4 Designs

of crankshafts not included in this scope will be subject to special

consideration.

3.2 Information to be submitted

3.2.1 In addition

to detailed dimensioned plans, the following information is required

to be submitted:

- Engine type – 4SCSA/2SCSA/in line/vee.

- Output power at maximum continuous rating (MCR), in kW.

- Output speed at maximum continuous power, in rpm.

- Maximum cylinder pressure, in bar g.

- Mean indicated pressure, in bar g.

- Cylinder air inlet pressure, in bar g.

- Digitised gas pressure/crank angle cycle for MCR.

- Maximum pressure/speed relationship.

- Compression ratio.

- Vee angle and firing interval (if applicable), in degrees.

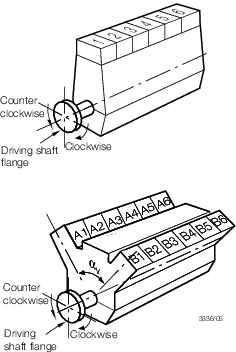

- Firing order numbered from driving end, see

Figure 2.3.1 Designation of cylinders.

- Cylinder diameter, in mm.

- Piston stroke, in mm.

- Mass of connecting rod (including bearings), in kg.

- Centre of gravity of connecting rod from large end centre, in

mm.

- Radius of gyration of connecting rod, in mm.

- Length of connecting rod between bearing centres, in mm.

- Mass of single crankweb (indicate if webs either side of pin are

of different mass values), in kg.

- Centre of gravity of crankweb mass from shaft axis, in mm.

- Mass of counterweights fitted (for complete crankshaft) indicate

positions fitted, in kg.

- Centre of gravity of counterweights (for complete crankshaft)

measured from shaft axis, in mm.

- Mass of piston (including piston rod and crosshead where applicable),

in kg.

- All individual reciprocating masses acting on one crank, in kg.

- Material specification(s).

- Specified minimum UTS, in N/mm2.

- Specified minimum yield strength, in N/mm2.

- Method of manufacture.

- Details of fatigue enhancement process (if applicable).

Figure 2.3.1 Designation of cylinders

3.3 Symbols

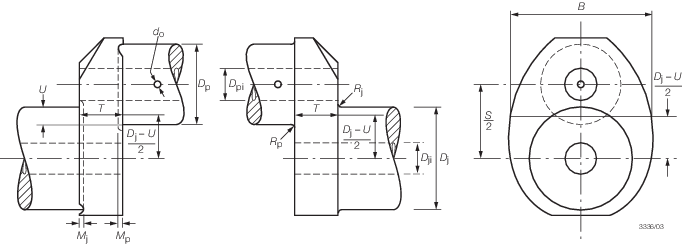

3.3.1 For the

purposes of this Chapter, the following symbols apply (see also

Figure 2.3.2 Crank dimensions necessary for the calculation of stress concentration factors):

|

h

|

= |

radial

thickness of web, in mm |

|

k

e

|

= |

bending stress factor |

|

B

|

= |

transverse

breadth of web, in mm |

|

D

p, D

j

|

= |

outside diameter of pin or main journal, in

mm |

|

D

pi, D

ji

|

= |

internal diameter of pin or main journal,

in mm |

|

d

o

|

= |

diameter of radial oil bore in crankpin, in mm |

|

F

|

= |

alternating

force at the web centre line, in N |

|

K

1

|

= |

fatigue enhancement factor due to manufacturing process |

|

K

2

|

= |

fatigue enhancement factor due to surface treatment |

|

M

b

|

= |

alternating bending moment at web centre line, in N-mm (NOTE:

alternating is taken to be  range value) range value)

|

|

M

BON

|

= |

alternating bending moment calculated at the outlet of crankpin

oilbore |

|

M

p, M

j

|

= |

undercut of fillet radius into web measured

from web face, in mm |

|

R

p, R

j

|

= |

fillet radius at junction of web and pin or

journal, in mm |

|

T

|

= |

axial

thickness of web, in mm |

|

T

a

|

= |

alternating torsional moment at crankpin or crank journal, in

N-mm (NOTE: alternating is taken to be  range value) range value)

|

|

|

= |

|

|

αB

|

= |

bending

stress concentration factor for crankpin |

|

αT

|

= |

torsional

stress concentration factor for crankpin |

|

βB

|

= |

bending

stress concentration factor for main journal |

|

βQ

|

= |

direct

shear stress concentration factor for main journal |

|

βT

|

= |

torsional

stress concentration factor for main journal |

|

γB

|

= |

bending

stress concentration factor for radially drilled oil hole in the crankpin |

|

γT

|

= |

torsional

stress concentration factor for radially drilled oil hole in the crankpin |

|

σax

|

= |

alternating

axial stress, in N/mm2

|

|

σb

|

= |

alternating

bending stress, in N/mm2

|

|

σBON

|

= |

alternating

bending stress in the outlet of the oil bore, in N/mm2

|

|

σp, σj

|

= |

maximum bending stress in pin and main journal

taking into account stress raisers, in N/mm2

|

|

σBO

|

= |

maximum

bending stress in the outlet of the oil bore, in N/mm2

|

|

σQ

|

= |

alternating

direct stress, in N/mm2

|

|

σu

|

= |

specified

minimum UTS of material, in N/mm2

|

|

σy

|

= |

specified

minimum yield stress of material, in N/mm2

|

|

τa

|

= |

alternating

torsional stress, in N/mm2

|

|

τp, τj

|

= |

maximum torsional stress in pin and main journals taking into

account stress raisers, in N/mm2

|

|

τtob

|

= |

maximum

torsional stress in outlet of crankpin oil bore taking into account

stress raisers, in N/mm2.

|

Figure 2.3.2 Crank dimensions necessary for the calculation of stress concentration factors

3.4 Stress concentration factors

3.4.1

Geometric

factors. Crankshaft variables to be used in calculating the

geometric stress concentrations together with their limits of applicability

are shown in Table 2.3.1 Crankshaft variables.

Table 2.3.1 Crankshaft variables

| Variable

|

Range

|

| Lower

|

Upper

|

|

b = B/D

p

|

1,10

|

2,20

|

|

d

j = D

ji/D

p

|

0,00

|

0,80

|

|

d

p = D

pi/D

p

|

0,00

|

0,80

|

|

m

j = M

j/D

p

|

0,00

|

r

jB

|

|

m

p = M

p/D

p

|

0,00

|

r

p

|

|

r

jB = R

j/D

p

|

0,03

|

0,13

|

|

r

jT = R

j/D

j

|

0,03

|

0,13

|

|

r

p = R

p/D

p

|

0,03

|

0,13

|

|

t = T/D

p

|

0,20

|

0,80

|

|

d = d

o/D

p

|

0,00

|

0,20

|

u = U/D

p

See Note 2

|

|

0,50

|

Note

1. Where variables fall outside the

range, alternative methods are to be used and full details submitted

for consideration.

2. A lower limit of u can be

extended down to large negative values provided that:

- (i) If calculated f(rec) < 1 then the factor

f(rec) is not to be considered (f(rec) =

1)

- (ii) If u < –0,5 then f(ut) and f(ru)

are to be evaluated replacing actual value of u by –0,5.

|

3.4.2 Crankpin

stress concentration factors:

Bending

|

αB

|

= |

2,70

f(ut). f(t). f(b). f(r). f(dp). f(dj). f(rec) |

where

|

f(ut) |

= |

1,52 –

4,1t + 11,2t

2 – 13,6t

3 + 6,07t

4 – u (1,86

– 8,26t + 18,2t

2 –

18,5t

3 + 6,93t

4)

– u

2 (3,84 – 25,0t +

70,6t

2 – 87,0t

3 +

39,2t

4)

|

|

f(t) |

= |

2,18t

0,717

|

|

f(b) |

= |

0,684 –

0,0077b + 0,147b

2

|

|

f(r) |

= |

0,208r

p

(–0,523)

|

|

f(dp) |

= |

1 + 0,315(d

p) – 1,52(d

p)2 +

2,41(d

p)3

|

|

f(dj) |

= |

1 + 0,27d

j – 1,02(d

j)2 + 0,531(d

j)3

|

|

f(rec) |

= |

1 + (m

p + m

j) (1,8 + 3,2u)

valid only between u = –0,5 and 0,5

|

Torsion

|

αT

|

= |

0,8

f(ru). f(b). f(t) |

where

|

f(ru) |

= |

r

p

–(0,22 + 0,1u)

|

|

f(b) |

= |

7,9 –

10,65b + 5,35b

2 – 0,857b

3

|

|

f(t) |

= |

t

(–0,145)

|

3.4.3 Crank journal

stress concentration factors:

Bending

|

βB

|

= |

2,71fB(ut). fB(t). fB(b). fB(r).

fB(dj). fB(dp). f(rec)

|

where

|

fB(ut)

|

= |

1,2

– 0,5t + 0,32t

2 – u (0,80 – 1,15t + 0,55t

2)

– u

2 (2,16 – 2,33t +

1,26t

2)

|

|

fB(t)

|

= |

2,24t

0,755

|

|

fB(b)

|

= |

0,562

+ 0,12b + 0,118b

2

|

|

fB(r)

|

= |

0,191r

jB

(–0,557)

|

|

fB(dj)

|

= |

1

– 0,644d

j + 1,23(d

j)2

|

|

fB(dp)

|

= |

1–

0,19d

p + 0,0073(d

p)2

|

|

f(rec) |

= |

1 + (m

p + m

j) (1,8 + 3,2u)

valid only between u = –0,5 and 0,5

|

Direct shear

|

β

Q

|

= |

3,01fQ(u). fQ(t). fQ(b). fQ(r).

fQ(dp). f(rec)

|

where

|

f

Q

(u)

|

= |

1,08 + 0,88u – 1,52(u)2

|

|

fQ(t)

|

= |

|

|

fQ(b)

|

= |

b – 0,5

|

|

fQ(r)

|

= |

0,533r

JB

(–0,204)

|

|

fQ(dp)

|

= |

1

– 1,19d

p + 1,74(d

p)2

|

|

f(rec) |

= |

1 + (m

p + m

j) (1,8 + 3,2u)

valid only between u = –0,5 and 0,5

|

Torsion

|

βT

|

= |

0,8f(ru).

f(b). f(t) |

where

|

f(ru) |

= |

r

jT

– (0,22 + 0,1

u

)

|

|

f(b) |

= |

7,9 –

10,65b + 5,35b

2 – 0,857b

3

|

|

f(t) |

= |

t

(–0,145)

|

3.4.4 Crankpin

oil bore stress concentration factors for radially drilled oil holes:

3.4.5 Where experimental

measurements of the stress concentrations are available, these may

be used. The full documented analysis of the experimental measurements

are to be submitted for consideration.

3.5 Nominal stresses

3.5.1 The nominal alternating bending stress, σb, is to be calculated

from the maximum and minimum bending moment at the web centreline taking into account

all forces being applied to the crank throw in one working cycle with the crankthrow

simply supported at the mid length of the main journals.

3.5.2 Nominal

bending stresses are referred to the web bending modulus.

3.5.3 Nominal

alternating bending stress:

|

σb

|

= |

|

where

|

Zweb

|

= |

|

|

k

e

|

= |

0,8 for crosshead engines |

| = |

1,0 for trunk piston engines. |

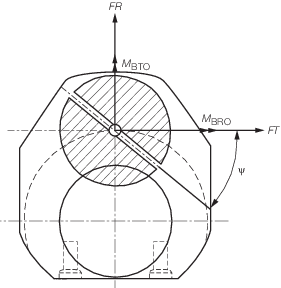

3.5.4 Nominal

alternating bending stress in the outlet of the crankpin oil bore:

where

M

BON is taken as the  range value range value

|

M

BON

|

= |

(M

BOmax – M

BOmin) (M

BOmax – M

BOmin) |

The two relevant bending moments are taken in the crankpin cross-section through the oil

bore.

|

M

BRO

|

= |

bending moment of the radial component of the connecting-rod

force |

|

M

BTO

|

= |

bending moment of the tangential component of the connecting-rod

force |

|

Z

crankpin

|

= |

|

|

Z

crankpin

|

= |

related

to the cross-section of axially bored crankpin. |

Figure 2.3.3 Crankpin section through the oil bore

3.5.5 The nominal

direct shear stress in the web for the purpose of assessing the main

journal is to be added algebraically to the bending stress, using

the alternating forces which have been used in deriving M

b in Pt 5, Ch 2, 3.5 Nominal stresses 3.5.3.

3.5.6 Nominal

stress is referred to the web cross-section area or the pin cross-section

area as applicable.

3.5.7 Nominal

alternating direct shear stress:

|

σQ

|

= |

|

3.5.8 The nominal

alternating torsional stress, τa, is to be taken into

consideration. The value is to be derived from forced-damped vibration

calculations of the complete dynamic system. Alternative methods will

be given consideration. The engine designer is to advise the maximum

level of alternating vibratory stress that is permitted.

3.5.10 Nominal

alternating torsional stress:

|

τa

|

= |

|

where

|

ZT

|

= |

torsional

modulus of crankpin and main journal |

| = |

|

|

D

|

= |

outside

diameter of crankpin or main journal, in mm |

|

d

|

= |

inside

diameter of crankpin or main journal, in mm. |

τa is to be ascertained from assessment of the torsional vibration

calculations where the maximum and minimum torques are determined for every mass point

of the complete dynamic system and for the entire speed range by means of a harmonic

synthesis of the forced vibrations from the 0,5th order up to and including the 12th

order for 4-stroke cycle engines. Whilst doing so, allowance must be made for the

damping that exists in the system and for unfavourable conditions (misfiring in one of

the cylinders when no combustion occurs but only compression cycle). The speed step

calculation shall be selected in such a way that any resonance found in the operational

speed range of the engine shall be detected.

3.5.11 For the

purpose of the crankshaft assessment, the nominal alternating torsional

stress considered in calculations is to be the highest calculated

value, according to the method described in Pt 5, Ch 2, 3.5 Nominal stresses 3.5.9, occurring at the most torsionally loaded mass point

of the crankshaft system.

3.5.12 The approval

of the crankshaft will be based on the installation having the largest

nominal alternating torsional stress (but not exceeding the maximum

figure specified by the engine manufacturer). For each installation

it is to be ensured by calculation that the maximum approved nominal

alternating torsional stress is not exceeded.

3.5.13 In addition

to the bending stress, σb, the axial vibratory stress,

σax, is to be taken into consideration, for crosshead

type engines. For trunk type engines, σax = 0. The

value is to be derived from forced-damped vibration calculations of

the complete dynamic system. Alternative methods will be given consideration.

The engine designer is to advise the maximum level of alternating

vibratory stress that is permitted. The corresponding crankshaft free-end

deflection is also to be stated.

3.6 Maximum stress levels

3.6.2 Outlet

of crankpin oil bore:

3.6.3 Crank journal

fillet.

3.7 Equivalent alternating stress

3.7.1 Equivalent

alternating stress of the crankpin, σep, or crank journal,

σej, is defined as:

|

σep, σej

|

= |

|

where

|

σ |

= |

σp or

σj N/mm2

|

|

τ |

= |

τp or

τj N/mm2.

|

3.7.2 Equivalent

alternating stress for the outlet of the crankpin oil bore σeob,

is defined as:

3.8 Fatigue strength

3.8.1 The fatigue

strength of a crankshaft is based upon the crankpin and crank journal

as follows:

|

σfp

|

= |

|

To calculate the fatigue strength in the oil bore

area, replace R

p with  do and σfp with σfob. do and σfp with σfob.

|

σfj

|

= |

|

where

|

σu

|

= |

UTS

of crankpin or crank journal as appropriate |

|

K

1

|

= |

fatigue endurance factor appropriate to the manufacturing process |

|

|

= |

1,05 for continuous

grain-flow (CGF) or die-forged |

|

|

= |

1,0 for freeform

forged (without CGF) |

|

|

= |

0,93 for cast steel

manufactured using a LR approved cold rolling process |

|

K

2

|

= |

fatigue enhancement factor for surface treatment. |

|

|

= |

These treatments

are to be applied to the fillet radii. |

A value for K

2 will be assigned upon

application by the engine designers. Full details of the process,

together with the results of full scale fatigue tests will be required

to be submitted for consideration. Alternatively, the following values

may be taken (surface hardened zone to include fillet radii):

|

K

2

|

= |

1,15 for induction hardened |

Where a value of K

1 or K

2 greater than unity is to be applied, then details of the manufacturing

process are to be submitted.

3.9 Acceptability criteria

3.9.1 The acceptability

factor, Q, is to be greater than 1,15:

|

Q |

= |

for crankpin, journal and the outlet of crankpin oil bore for crankpin, journal and the outlet of crankpin oil bore

|

where

|

σf

|

= |

σfp or σfj or σfob

|

|

σe

|

= |

σep or σej or σeob.

|

3.10 Oil hole

3.10.1 The junction

of the oil hole with the crankpin or main journal surface is to be

formed with an adequate radius and smooth surface finish down to a

minimum depth equal to 1,5 times the oil bore diameter.

3.10.2 Fatigue

strength calculations or alternatively fatigue test results may be

required to demonstrate acceptability.

3.10.3 When

journal diameter is equal to or larger than the crankpin diameter,

the outlets of main journal oil bores are to be formed in a similar

way to the crankpin oil bores, otherwise separate fatigue strength

calculations or, alternatively, fatigue test results may be required.

3.11 Shrink fit of semi-built crankshafts

3.12 Alternative method for calculation of stress concentration factors

3.12.1 LR will give consideration to crankshaft design using an alternative method

given in the LR Guidance Notes for the Calculation of Stress Concentration Factors,

Fatigue Enhancement Methods and Evaluation of Fatigue Tests for Crankshafts.

|