Section

2 Marking

2.1 General

2.1.1 Each lifting

appliance and each item of loose gear is to be clearly and permanently

marked with its safe working load, with an identification mark to

enable it to be readily related to its appropriate test certificate

and with the mark of the Surveyor or manufacturer who carried out

the proof test.

2.1.2 In view of

the importance of ensuring that each item of loose gear has the correct

safe working load for its particular position in the lifting appliance,

and to facilitate the ordering of replacements, it is recommended

that a Particulars Book or a fully detailed Rigging Plan and Block

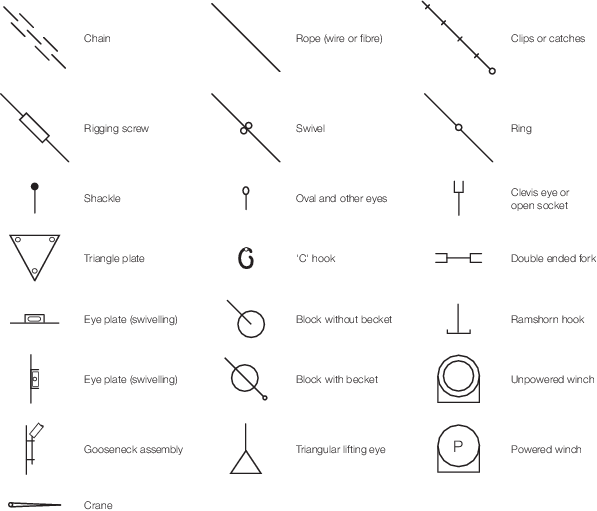

List be kept on board. Typical symbols used in rigging plans are given

in Figure 12.2.1 Symbols for fittings used in key

plans or rigging.

Figure 12.2.1 Symbols for fittings used in key

plans or rigging

2.2 Loose gear

2.2.1 Every item

of loose gear, including lifting beams and similar items, is to be

marked with:

-

The safe working load

of the item, in tonnes. For asymmetric lifting beams, the maximum

reaction at each lifting point is also to be marked.

-

An individual alphanumeric

identification mark to relate it to its test certificate.

-

A mark indicating the

grade of steel in accordance with Table 12.2.1 Material quality grade

marks.

-

The Surveyor’s

or manufacturer’s stamp.

-

For blocks, the maximum

rope diameter for which the block is designed.

-

For lifting beams and

similar items, the tare weight in tonnes.

-

Where appropriate,

an identification mark corresponding to the position of the item on

the ship’s Rigging Plan.

Table 12.2.1 Material quality grade

marks

| Quality grade

mark

|

Grade of steel

|

Ultimate tensile strength,

in N/mm2

|

| L

|

Mild

|

300

|

| M

|

Higher

tensile

|

400

|

| P

|

Alloy

|

500

|

| S

|

Alloy

|

630

|

| T

|

Alloy

|

800

|

2.2.2 Permanent

identification marks or symbols are to be made, with stamps having

rounded profiles (low stress stamps). The number of marks on an item

is to be kept to the minimum.

2.2.3 The use of

fractions and oblique strokes is to be avoided and a dot or hyphen

is preferable to a dividing line. Values of SWL are, generally, to

be marked to one place of decimals (except for 0,25 and 0,75) up to

100 t and in integers thereafter. The word ‘tonnes’ may

be abbreviated to ‘t’.

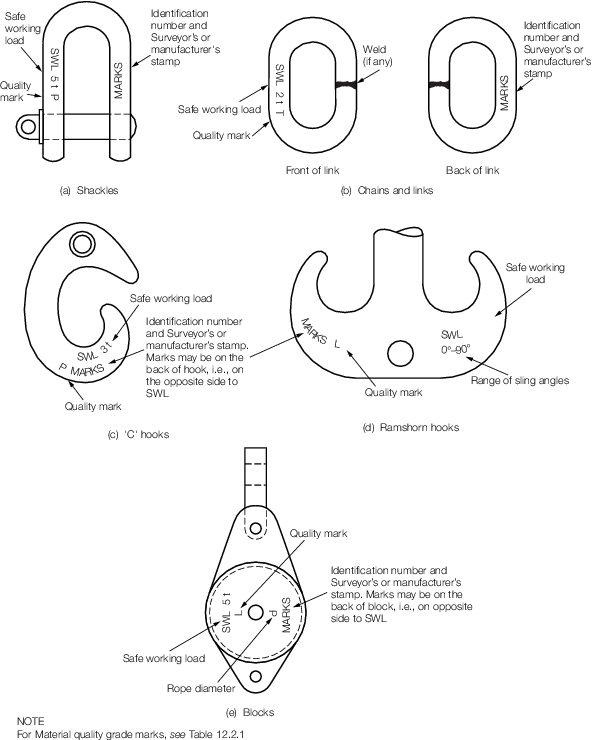

2.2.4 Recommended

sizes of marks are given in Table 12.2.2 Size of marks based

on the diameter of the part to be marked or on the SWL of the item

as appropriate. Typical arrangements of marks are shown in Figure 12.2.2 Typical marks for loose

gear.

Table 12.2.2 Size of marks

| Item

|

Diameter of part to be marked,

in mm

|

SWL of item, in tonnes

|

Recommended size of mark,

in

mm

|

| Chains, links, rings,

shackles, eyes (without collar), swivels

|

Less

than 12,5

|

|

3,0

|

| 12,5

to 26

|

|

4,5

|

| Over

26

|

|

6,0

|

| Eyes (with collar),

triangle plates, rope sockets, hooks, blocks

|

|

Up to

2

|

3,0

|

| 2 to 8

|

4,5

|

| Over 8

|

6,0

|

| Lifting

beams, spreaders, frames

|

|

All

|

Minimum 75

|

Figure 12.2.2 Typical marks for loose

gear

2.3 Steel wire and fibre ropes, including slings

2.3.1 The following

information is to be marked on a disc or tally attached to the rope

or sling, or an approved electronic capture system:

-

An individual identification

mark to relate the rope to its test certificate.

-

The Surveyor’s

or manufacturer’s stamp.

2.3.3 Markings

on slings are also to include the number of legs and the safe working

load in straight lift and when the angle between the legs and the

vertical is 45°.

2.3.4 The identification

mark on synthetic or fibre slings is also to show its:

- SWL in straight lift;

- SWL when the angle between the legs and the vertical is 45°;

- Material;

- Nominal length;

- Manufacturer’s or supplier’s name.

2.4 Derricks, cranes and launch and recovery systems for diving operations

2.4.1 Every lifting

appliance is to be conspicuously and permanently marked near the heel

of the boom, jib or equivalent component with its safe working load

and the minimum operating angle or limiting radius as indicated in Table 12.2.3 Typical marks on lifting

appliances.

Table 12.2.3 Typical marks on lifting

appliances

| Description

|

Mark

|

| Swinging

derrick with boom as normally rigged

|

SWL 10 t

(30°)

|

| Swinging

derrick with alternative rig

|

SWL 3/10

t (30°)

|

| Derricks

used in union purchase to be marked on inboard side of boom

|

SWL (U)

3 t

|

| Crane of

constant capacity over full range of radii

|

SWL 10 t

(4 m/20 m radius)

|

| Crane of

variable load/radius characteristics

|

A plate

indicating the characteristics is to be permanently attached to the

crane

|

2.4.2 Where more

than one method of rig is possible, or, for derricks, where union

purchase operation is proposed, the safe working load for each method

of rig is to be marked.

2.4.3 The letters

and numbers are to be not less than 75 mm high and painted in yellow

or white on a dark background or black on a light background.

2.4.4 The heel

fitting of the appliance is to be marked with the number of the relevant

test certificate and with the Surveyor’s stamp. The stamps are

to have rounded profiles (low stress stamps).

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|