Section

5 Local strength

5.1 General

5.2 Modulus of stiffeners, frames and longitudinals

5.2.1 For longitudinals, side frames and bulkhead stiffeners, the section modulus

required by the appropriate formula is generally applicable to that of the section in

association with 600 mm, or 40t, whichever is the greater, of attached plating.

Where the attached plating is of varying thickness, the mean thickness over the

appropriate span is to be used.

5.3 Tank plating

5.3.1 The thickness of boundary plating in ballast tanks, oil tanks, freshwater

tanks, and sewage tanks is to be not less than:

or 7,5 mm whichever is the greater

where

|

s

|

= |

stiffener

spacing, in mm |

|

f

|

= |

but need not to be taken greater than 1,0 but need not to be taken greater than 1,0 |

|

ρ |

= |

specific gravity of liquid carried in tank, but is not to be taken

less than 1,025 |

|

h

|

= |

maximum

head, in metres, obtained from the hydrostatic curves for that location

and related to a point one-third of the height of the plate. If the

plate is located in that part of the tank containing the air cushion,

then the head should be extended to the lower boundary of the air

cushion. For internal transverse or longitudinal watertight bulkheads, see

Pt 2, Ch 1, 1.6 Data required 1.6.1.(h)

|

|

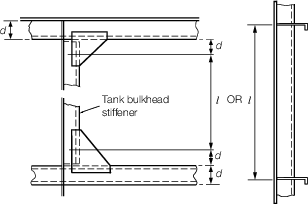

l |

= |

overall

length of the stiffener or length between span points, in metres, see

Figure 1.5.1 Span points.

|

Figure 1.5.1 Span points

5.4 Framing or tank stiffeners

5.4.1 The minimum

section modulus of stiffeners associated with plating in ballast tanks

is to be derived from the following:

5.4.2 The effective

section modulus of any transverse, web, stringer or girder is given

by:

where

|

a |

= |

the area of the face plate of the member, in cm2 |

|

dw |

= |

the depth, in mm, of the web between the inside of the face plate and the

attached plating. Where the member is at right angles to a line of corrugations,

the minimum depth is to be taken |

|

tw |

= |

the thickness of the web of the section, in mm |

|

A |

= |

the area, in cm2, of the attached plating, see

Pt 2, Ch 1, 5.4 Framing or tank stiffeners 5.4.4. |

If the calculated value of A is less than the face area a, then A

is to be taken as equal to a.

5.4.3 The effective area of attached load bearing plating, A, for transverses, webs,

stringers or girders, is to be determined as follows:

- For a member attached to plane plating:

|

A |

= |

10K

b

tp cm2, but is not to be taken less than

a. |

- For a member attached to corrugated plating and parallel to the

corrugations:

|

A |

= |

10b

tp cm2, but is not to be taken less than

a. |

- For a member attached to corrugated plating and at right angles to

the corrugations: A is to be taken as equivalent to the area of the face

plate of the member.

where

|

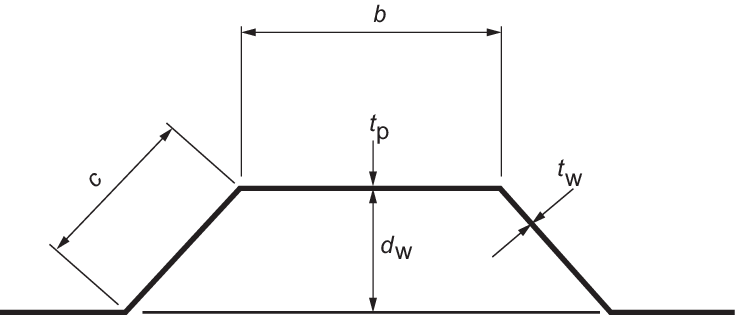

b |

= |

the actual width, in metres, of the load-bearing plating, i.e.

for (a) one-half of the sum of spacings between parallel adjacent members or

equivalent supports, or for (b) the breath of flat panel of corrugated

bulkhead, see

Figure 1.5.2 Corrugation dimensions

|

|

K |

= |

load bearing factor to be taken as  , but is not to exceed 1,0 , but is not to exceed 1,0 |

|

l |

= |

the overall length, in metres, see

Figure 1.5.1 Span points

|

|

tp |

= |

the thickness, in mm, of the attached plating. Where this

varies, the mean thickness over the appropriate span is to be used, see

Figure 1.5.2 Corrugation dimensions. |

Figure 1.5.2 Corrugation dimensions

5.4.4 For girders, etc. which are symmetrical on each side of the bulkhead, the

attached plating is to be ignored and the effective section modulus is given by:

5.5 Top deck plating

5.5.1 The thickness of plating for the middle 0,4L

D is to be as required for longitudinal strength. For 0,1L

D, at each end of the dock, the thickness is not to be less than 6,5 mm,

(with an increase of 3 per cent for every 25 mm that the spacing of longitudinals

exceeds 610 mm), unless local conditions or transverse strength considerations require a

greater thickness. For the intermediate lengths the thickness of the deck is to be

given proportionate values.

5.6 Top deck longitudinals

5.6.1 The top

deck should, in principle, be stiffened longitudinally for the middle

0,4L

D. The scantlings will generally be those

required to obtain the area necessary for the section modulus derived

from longitudinal strength considerations but are to be not less than

specified in Pt 2, Ch 1, 5.6 Top deck longitudinals 5.6.2 for longitudinals

at the ends.

5.6.2 For 0,1L

D, at each end of the dock, the scantlings of the longitudinals are to be

such that the stress under a loading of 14,37 kN/m2 does not exceed 131

N/mm2. The loading may be required to be increased to suit the special

requirements of a particular dock. The scantlings of the longitudinals in the

intermediate lengths are to be interpolated between those required for the middle and

end portions.

5.7 Safety deck plating

5.7.1 The thickness of plating of the safety deck, is to be not less than:

|

t |

= |

|

or 7,5 mm whichever is the greater

where

|

s

|

= |

stiffener

spacing, in mm |

|

f |

= |

but need not to be taken greater than 1,0 but need not to be taken greater than 1,0 |

|

C

|

= |

stowage

rate, in m3/tonne, but is to be taken as not less than

1,39 m3/tonne

|

|

h

|

= |

height

from top of safety deck beam to top of upper deck beam at side |

|

l |

= |

overall

length of beam or longitudinal between support points, in metres. See

Figure 1.5.1 Span points.

|

5.7.2 Where

air pipes project into the wing ballast tanks (see

Pt 2, Ch 1, 6.1 Air pipes under safety deck 6.1.1), it may be that the pressure

in the air cushion exceeds the loading obtained from the above stowage

rate and head, in which case the scantlings are to be calculated on

the basis of this higher loading.

5.7.3 The section

modulus of the beams or longitudinals under the safety deck, including

associated plating, is to be in accordance with the following:

where l, h, s and C are as defined in Pt 2, Ch 1, 5.7 Safety deck plating 5.7.1.

5.8 Framing

5.9 Transverse and web frames

5.9.2 The loading on deep side frames and bottom transverses is to be obtained

from an analysis of the hydrostatic curves. The permissible stress in transverses and

deep frames is to be 131 N/mm2.

5.10 Cross ties

5.10.1 The

sectional area of cross ties, where fitted between the inner and outer

wing walls, is to be not less than:

where

|

h

|

= |

the

maximum head, in metres, at the cross tie under consideration, and

is assumed to occur when the ballast water is level with that tie

and the dock is lifting to its maximum capacity. The required value

is to be obtained from an analysis of the hydrostatic curves |

|

s

|

= |

spacing

of transverses, in metres |

|

le

|

= |

0,7

of total span of cross tie, in metres |

|

v

|

= |

one-half

the distance between the centre of the adjacent cross ties and the

centre of the bottom or deck transverse, in metres |

|

r

|

= |

minimum

radius of gyration of pillar cross-section, in mm. |

As a first approximation, A may be taken as:

and the radius of gyration estimated for a suitable

section having this area. If the area calculated using this radius

of gyration differs by more than 10 per cent from the first approximation,

a further calculation using the radius of gyration corresponding to

the mean area of the first and second approximation is to be made.

5.10.2 For

the sides of hollow square cross ties or web plates of Channel or I

sections, the ratio of the breadth to the thickness is not to exceed:

whichever is the greater. The thickness of hollow

square cross ties is to be not less than 7,5 mm.

5.10.3 For

ordinary angle or channel sections, the ratio of the breadth to the

thickness of the flanges is not to exceed:

whichever is the greater.

5.10.4 For

fabricated sections or the flanges of I section pillars, the

ratio of the breadth to the thickness of face plates is not to exceed:

whichever is the greater.

5.10.5 Diagonal

cross ties will be specially considered.

5.11 Watertight bulkhead plating and stiffeners

5.12 Non-watertight floors and side girders

5.12.1 The

spacing of open floors under pontoon/caisson deck should in principle

be not greater than 6,0 m. Where larger spacings are proposed, direct

calculations will be necessary to demonstrate their suitability.

5.12.2 Side girders below pontoon deck should be designed to withstand localised

loads in way of side blocks where appropriate.

5.13 Local strength of the structure in way of keel blocks and supporting

structure

5.13.1 The

loading to be taken (over the whole length of the dock) by the keel

blocks and supporting structure is to be:

where the spacing between keel blocks is significant the loading may be required to be

increased.

5.14 Platforms extending from ends of dock

5.14.1 The loading on these structures is generally to be assumed as 5750

N/m2. If a heavier loading is anticipated or required, the plans are to be

marked accordingly.

Table 1.5.1 Non-watertight pillar

bulkheads

| Parameter

|

Requirement

|

|

(1) Minimum thickness of plating

|

7,5 mm in pontoons

|

|

(2) Maximum stiffener spacing

|

1500 mm

|

|

(3) Minimum depth of stiffeners or corrugations

|

100

mm

|

150

mm

|

|

(4) Cross-sectional area (including plating) for rolled,

built or swedged stiffeners supporting beams, longitudinals, girders or

transverses

|

(a)

where  ≤ 80, ≤ 80,

|

A = A

1

|

|

|

(b)

where  ≥ 120, ≥ 120,

|

A = A

2

|

|

|

(c)

where 80 <  < 120, < 120,

|

A is obtained by interpolation between A

1 and A

2

|

| (5) Cross-sectional area (including

plating) for symmetrical corrugation

|

(a) where  ≤ ≤

|

A = A

1

|

|

|

(b) where  ≥ ≥

|

A = A

2

|

| Symbols

|

|

A

|

= |

cross-sectional area of stiffener and attached

plating, in cm2

|

|

A

1

|

= |

|

As a first approximation A

1 may be taken as

|

A

2

|

= |

|

As first approximation A

2 may be taken as

|

P

|

= |

load, in kN, supported by the pillar. The greater of

either the load due to the head of water acting on the pontoon deck

and bottom plating (obtainable by analysis of hydrostatic curves),

or the load due to the weight of the ship on the keel blocks as

detailed in Pt 2, Ch 1, 5.13 Local strength of the structure in way of keel blocks and supporting structure 5.13.1

|

|

le

|

= |

effective length of pillar, in metres, and is taken

as 0,8 of the total depth of the non-watertight girder or

bulkhead |

|

s

|

= |

spacing of stiffeners, in mm |

|

r

|

= |

radius of gyration of stiffener and attached plating,

in mm |

| = |

mm for rolled, built or swedged stiffeners mm for rolled, built or swedged stiffeners |

| = |

mm for symmetrical corrugation mm for symmetrical corrugation |

|

I |

= |

moment of inertia of stiffener and attached plating,

in cm4 |

|

λ |

= |

|

d

w, t

p, b, c are as defined in Figure 1.5.2 Corrugation dimensions

|

5.15 Swing bridges at end of dock

5.15.1 The loading on this connecting bridge is generally to be assumed as 3590

N/m2. If a heavier loading is anticipated or required, the plan is to be

marked accordingly.

|