Section

6 Forgings for turbines

6.1 Scope

6.1.1 Provision

is made in this Section for ferritic steel forgings for turbine rotors,

discs and spindles, turbine-driven generator rotors and compressor

rotors.

6.1.2 Plans for

rotor forgings are to state whether the rotor is intended for propulsion

or auxiliary machinery and the shaft power of auxiliary turbines.

In the case of a rotor which is to be tested for thermal stability,

the maximum operating temperature and the proposed test temperature

are also to be stated.

6.1.3 Specifications

of alloy steel forgings giving the proposed chemical composition,

heat treatment and mechanical properties are to be submitted for approval

with the plans of the components.

6.1.4 Where it

is proposed to use rotors of welded construction, the compositions

of the steels for the forgings are to be submitted for special consideration,

together with details of the proposed welding procedure. Welding procedure

tests may be required.

6.2 Manufacture

6.2.1 Forgings

are to be manufactured in accordance with the requirements of Ch 5, 1 General requirements, except that for rotors the forging

reduction is to be not less than 2,5 to 1. Where an upsetting operation

is included in the manufacturing procedure, the above requirement

applies to the cross-sectional area of the upset bloom and not to

that of the ingot.

6.3 Chemical composition

6.4 Heat treatment

6.4.1 Forgings

are to be supplied in the heat treated condition, and the thermal

treatment at all stages is to be such as to avoid the formation of

hair-line cracks. At a suitable stage of manufacture, the forgings

are to be reheated above the upper critical point to refine the grain,

cooled in an approved manner and then tempered to produce the desired

mechanical properties.

6.4.2 Where forgings

receive their main heat treatment before machining, they are to be

stress relieved after rough machining. Forgings which are heat treated

in the rough machined condition need not be stress relieved provided

that they have been slowly cooled from the tempering temperature.

6.4.3 The tempering

and stress relieving temperatures are to be not less than 550°C

for carbon and carbon-manganese steels, and not less than 600°C

for alloy steels. The holding times and subsequent cooling rates are

to be such that the forging in its final condition is free from harmful

residual stresses.

6.4.4 Details of

the proposed heat treatment for rotors of welded construction are

to be submitted for approval.

6.5 Mechanical tests

6.5.1 At least

one tensile test specimen, cut in a longitudinal direction, is to

be taken from each rotor forging. For forgings exceeding both 3 tonnes

in mass and 2000 mm in length, tests are to be taken from each end.

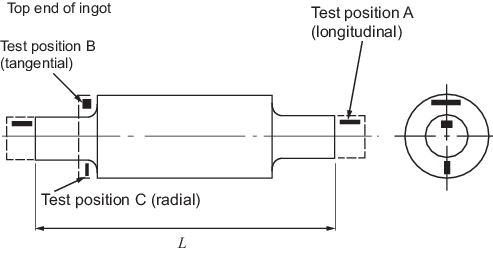

6.5.2 For rotor

forgings of all main propulsion machinery and of auxiliary turbines

exceeding 1100 kW, tangential and, where the dimensions permit, radial

tensile tests are to be taken from the end of the body corresponding

to the top end of the ingot, see

Figure 5.6.1 Test positions for turbine rotor

forgings.

Figure 5.6.1 Test positions for turbine rotor

forgings

6.5.4 For the tests required by Ch 5, 6.5 Mechanical tests 6.5.1 to Ch 5, 6.5 Mechanical tests 6.5.3, sufficient test material is to be left on each forging

and is not to be removed until all heat treatment, including stress relieving, has been

completed. In this connection, a thermal stability test does not form part of the heat

treatment of a turbine forging. Any excess test material is not to be completely severed

from a forging until all the mechanical tests have been completed with satisfactory

results.

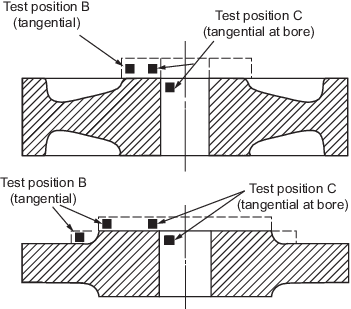

Figure 5.6.2 Test positions for turbine disc

forgings

6.6 Non-destructive examination

6.6.1 The end faces

of the body of rotor forgings and the end faces of the boss and the

bore surface of each turbine disc are to be machined to a fine smooth

finish for visual and magnetic particle examination.

6.6.2 The manufacturer

is to carry out an ultrasonic examination of each forging and is to

provide the Surveyor with a signed statement that such inspection

has not revealed any significant internal defects.

6.6.3 Rotor forgings

for propulsion machinery and for auxiliary turbines exceeding 1100

kW are to be hollow bored for internal examination. The surface of

the bore is to have a fine smooth finish and is to be examined by

means of an optical instrument of suitable magnification. Where the

bore size permits, magnetic particle examination is also to be carried

out. These examinations are to be confirmed by the Surveyor. Alternatively,

an approved method of ultrasonic examination may be accepted instead

of hollow boring. Details of the proposed method of ultrasonic examination

are to be submitted for special consideration.

Table 5.6.1 Mechanical properties for

acceptance purposes: carbon-manganese steel forgings for turbines - Normalised and

tempered

| Tensile strength

N/mm2

|

Yield stress

N/mm2 minimum

|

Elongation 5,65 % minimum % minimum

|

Reduction of area % minimum

|

| A

|

B

|

C

|

A

|

B

|

C

|

| 400 – 520

|

200

|

26

|

22

|

18

|

50

|

40

|

35

|

| 440 – 560

|

220

|

24

|

21

|

17

|

50

|

40

|

35

|

| 480 – 600

|

240

|

22

|

19

|

15

|

45

|

35

|

30

|

| 520 – 640

|

260

|

21

|

18

|

14

|

45

|

35

|

30

|

| 560 – 680

|

280

|

20

|

17

|

13

|

40

|

30

|

25

|

| 600 – 720

|

300

|

18

|

15

|

12

|

40

|

30

|

25

|

Columns A are applicable to longitudinal tests from rotor and spindle

forgings.

Columns B are applicable to tangential tests from

rotor forgings.

Columns C are applicable to radial tests from

rotor forgings.

Intermediate values may be obtained by

interpolation.

|

6.7 Thermal stability tests

6.7.1 Thermal stability

tests after heat treatment and rough machining of the turbine rotors,

referred to in the relevant Rules dealing with design and construction,

are to be undertaken in properly constructed furnaces, using accurate

and reliable measuring equipment. Each test is to be carried out in

accordance with the following recommended procedure:

-

Five bands are to be

machined concentric with the axis of rotation. Two of these are to

be reference bands and are to be positioned at or near the locations

of the bearings. The remaining three bands are to be test bands located

one as near as possible to the mid-length, and the other two near

each end of the body. Where the length of a rotor is such that five

bands cannot be provided, alternative proposals are to be submitted

to the Surveyor for his approval.

-

Four positions, 90°

apart, are to be stamped A, B, C and D on the coupling end of the

rotor.

-

The whole of the body,

and as much of the shaft at either end as will include the positions

of the glands, is to be enclosed in the furnace. In the case of a

rotor having an overhung astern wheel, the astern wheel is also to

be enclosed in the furnace during the first test.

-

The rotor is to be

rotated at a uniform and very low speed.

-

The deflections at

all bands are to be recorded at the A, B, C and D positions. Initial

cold readings are to be taken prior to heating.

-

The rotor is to be

heated uniformly and slowly. Temperatures are to be recorded continuously

at the surface of the rotor and, if practicable, in the bore at the

mid-length of the body. In no circumstances is the surface temperature

to exceed the temperature at which the rotor was tempered. During

heating, the rate of rise of temperature is to be such as to avoid

excessive temperature gradients in the rotor.

-

The maximum or holding

temperature is to be not less than 28°C above the maximum operating

temperature of the rotor. For the purposes of the test, the holding

period is to start when the rotor has attained a uniform and specified

temperature. The rotor is to be held under the specified temperature

conditions until not less than three consecutive hourly readings of

deflections show the radial eccentricity to be constant within 0,006

mm on all test bands.

-

The turbine rotor is

to be rotated during cooling until the temperature is not more than

100°C. The rate of cooling is to be such as to avoid excessive

temperature gradients in the rotor.

-

Final cold readings

are to be taken.

Table 5.6.2 Mechanical properties for

acceptance purposes: alloy steel forgings for turbines - Quenched and tempered or

normalised and tempered

| Tensile strength

N/mm2 (see Note)

|

Yield stress

N/mm2 minimum Normalised and tempered

|

Yield stress

N/mm2 minimum Quenched and tempered

|

Elongation on 5,65 % minimum % minimum

|

Reduction of area % minimum

|

| A

|

B

|

C

|

A

|

B

|

C

|

| 500 –

650

|

275

|

–

|

22

|

20

|

18

|

50

|

40

|

35

|

| 550 –

700

|

300

|

–

|

20

|

18

|

16

|

50

|

40

|

35

|

| 600 –

750

|

330

|

410

|

18

|

16

|

14

|

50

|

40

|

35

|

| 650 –

800

|

355

|

450

|

17

|

15

|

13

|

50

|

40

|

35

|

|

|

|

|

|

|

|

|

|

|

| 700 –

850

|

385

|

490

|

16

|

14

|

12

|

45

|

35

|

30

|

| 750 –

900

|

–

|

530

|

15

|

13

|

11

|

45

|

35

|

30

|

| 800 –

950

|

–

|

590

|

14

|

12

|

10

|

45

|

35

|

30

|

| 850 –

1000

|

–

|

640

|

13

|

11

|

9

|

40

|

30

|

25

|

|

|

|

|

|

|

|

|

|

|

| 900 –

1050

|

–

|

690

|

13

|

11

|

9

|

40

|

30

|

25

|

| 950 –

1100

|

–

|

750

|

12

|

10

|

8

|

40

|

30

|

25

|

| 1000 –

1150

|

–

|

810

|

12

|

10

|

8

|

40

|

30

|

25

|

Columns A are applicable to longitudinal tests from rotor and spindle

forgings.

Columns B are applicable to tangential tests from

rotor and spindle forgings, and to tangential tests from discs – test

position B in Figure 5.6.2 Test positions for turbine disc

forgings.

Columns C are

applicable to radial test from rotor forgings and to tangential tests from

discs – test position C in Figure 5.6.2 Test positions for turbine disc

forgings.

Intermediate values

may be obtained by interpolation.

|

6.7.2 The movements

of the axis of the rotor in relation to the reference bands are to

be determined from polar plots of the deflection readings. The radial

movement of the shaft axis, as determined by the difference between

the final hot and the final cold movements, is not to exceed 0,025

mm on any one band. As verification that test equipment and conditions

are satisfactory, it is required that similar determinations of differences

between initial cold and final cold movements do not exceed 0,025

mm on any one band.

6.7.3 If the results

of the test on a rotor fail to meet either or both of the requirements

in Ch 5, 6.7 Thermal stability tests 6.7.2, the test may be repeated

if requested by the maker and agreed by the Surveyor. In the case

of a rotor failing to meet the requirements of a thermal stability

test, the rotor is deemed unacceptable. Proposals for the rectification

of thermal instability of a rough machined rotor are to be submitted

for special consideration.

|