Section

2 Materials

2.1 Manufactured at approved works

2.1.1 The Rules for

Naval Ships state that ‘Materials are to be made at works which

have been approved by the Committee for the type of product being

supplied’. It is the building port Surveyor’s responsibility

to ensure that a Builder is aware of this requirement and verify that

it is complied with. Approved Works are detailed in the Lists of Approved

Manufacturers of Materials and Recognized Proving Establishments.

2.2 Verification of steel plate and sections

2.2.1 The need to

ensure that all structural material for classed ships is certified

by the Surveyors in accordance with LR’s requirements should

be impressed on Builders at the design stage, and it should be checked

that test certificates or shipping statements in accordance with LR’s

Rules are furnished by the steel manufacturers when the material is

delivered. It is appreciated that Surveyors in the building yards

cannot see and check every piece of material from its arrival at the

stockyard through to erection, but they must satisfy themselves by

random checks that the yard system is adequate in this respect. When

material is shot-blasted and primed on reception, the steelwork’s

identification marks should be clearly marked with the appropriate

colour code. This checking of material with the test certificates

should be done at the earliest possible stage in order to prevent

the use of material which has not been properly tested and verified

at the steelworks. These certificates also afford an early opportunity

to verify that material is being supplied to the approved scantlings.

2.3 Defects in steel products

2.3.1 Surface inspection

is the responsibility of the steelmaker and the Surveyor at the steelworks

does not normally undertake this work unless it is particularly specified.

Where defects are found after delivery to the Builder, any rectification

should be agreed and should generally be in accordance with the Rules

for Materials.

2.3.2 The limits

of depth and extent of rounded surface defects on plate, cast or forged

material in relation to the material plate thickness are shown in Table 3.2.1 .

Thickness

of

material (mm)

|

Maximum permissible

depth of defect (mm)

|

|

|

Area

affected

greater than 5%

|

Area

affected

less than 10%

|

| <8

|

0,2

|

0,4

|

| 8 to 25

|

0,3

|

0,5

|

| 25 to 40

|

0,4

|

0,6

|

| 40 plus

|

0,5

|

0,7

|

Note

1. Defects are to be measured after shot

blasting or plate cleaning.

Note

2. The depth of the deepest imperfection

is to be considered.

Note

3. Defects not exceeding the limits shown

need not be repaired.

Note

4. Fracture defects are always to be

repaired irrespective of their depth.

|

2.3.3 Defects are

to be made good by grinding only, subject to the plate thickness not

being reduced by more than seven per cent of the nominal thickness

or 3 mm, whichever is the lower, and the area involved not exceeding

two per cent of the surface area.

2.3.4 When the limits

in Table 3.2.1 are exceeded, plates

are to be made good by grinding followed by welding.

2.3.5 Where the depth

of the deepest imperfection exceeds 20 per cent of the nominal thickness,

or the defective area exceeds two per cent of the total surface area,

such areas are to be cropped and replaced, or the material rejected.

2.3.6 Complete removal

of the defects is to be verified by suitable non-destructive examination

techniques and after welding repair is to be proved free from further

defects.

2.3.7 Care is to

be taken in the repair of defects in higher tensile steel. Low hydrogen

electrodes with similar properties to the higher tensile steel are

to be used with preheating as necessary.

2.3.8 Plates in which

laminations are suspected or detected are to be ultrasonically tested

to determine the full extent of such laminations. Areas of lamination

are to be removed.

2.3.9 Defective plate,

with defects in excess of those stated, is to be cropped back and

replaced or material rejected.

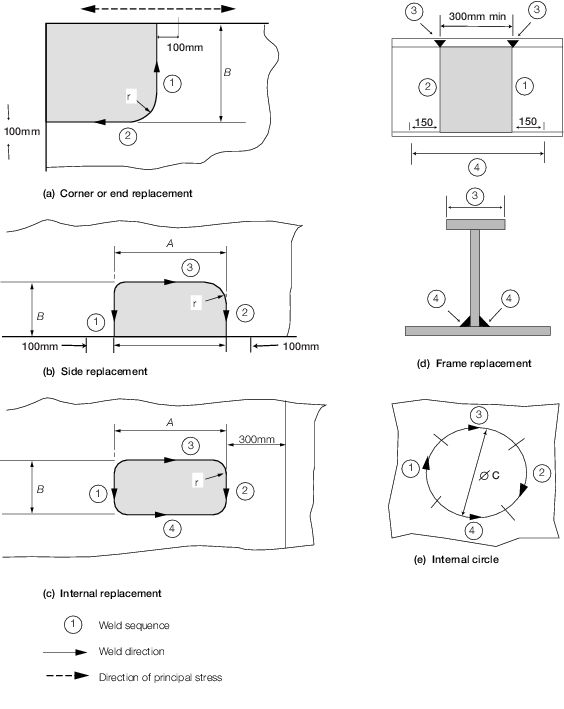

2.4 Part replacement of plates

2.4.1 When defects

exceed the limits shown below, the portion of the plate affected is

to be cropped and replaced. Plate inserts are to be arranged in accordance

with Table 3.2.1 Part replacement of plates and the alignment

of inserts is to be in accordance with Table 3.2.1 Part replacement of plates.

Table 3.2.1 Part replacement of plates

| A x B

|

Parts to be replaced

|

Strength members

|

Elsewhere

|

| End and corner of plate

|

300 x 1000

|

300 x 300

|

| Side of plate

|

300 x 300

|

300 x 300

|

| Insert

|

300 x 300

|

300 x 300

|

| C

|

Circular insert

|

dia. 300

|

dia. 150

|

Line of plate replacement to be not less than 100 from extreme

edge of defect.

All dimensions are in mm.

Weld

sequence given by figure (1)

|

|

Note

1. All dimensions are minimum.

Note

2. Rolling direction of replaced plate to

be the same as that of the parent plate.

Note

3. Minimum distance from outermost defect

to line of weld – 100 mm.

|

Note

4. Dimensions in millimetres:

r = 12%B, 5t or 75 mm whichever is the greater.

Note

5. Stiffener web butt weld scallop to be

filled on final pass (4).

Note

6. Insert welds are not to be within 75

mm of butts, seams, internal structure or other inserts.

|

2.5 Structural forgings, castings and prefabrications

2.5.1 All large or

important forgings, castings and prefabrications, such as sternframes,

rudders, rudderstocks, rudder axles, quadrants or tillers, require

to be examined and tested in accordance with the Rules for Materials

by the Surveyor attending the manufacturer’s works. Procedures

for the identification and certification of all such items (excluding

prefabrications) are detailed in the Rules for Materials and the Surveyors

at the building yard should ensure that they receive appropriate certificates

for the items intended for the vessel building under their survey.

The markings on the items should be checked against the certificates.

2.5.2 When, at the

manufacturer’s request, limitations have been agreed upon the

extent of Non-Destructive Examination (NDE) carried out on an item

in a semi-finished, rough machined, or part machined condition, the

Surveyor at the manufacturers will have made a statement to this effect

on the certificate for the item. When work is subsequently carried

out upon such an item at the shipyard, the Surveyor at the building

port should consider further NDE. Where further NDE is carried out

on the item, this should be indicated on its final certificate.

2.6 Raw material surface tolerances

2.6.1 The surface

cleanliness of the materials in preparation for painting is to be

in accordance with national or paint manufacturer’s standards.

2.6.2 Where approved

corrosion control coatings are to be used, the quality of surface

treatment is to be in accordance with the grade specified in the approval

documents.

2.7 Welding consumables

2.7.1 All welding

consumables are to be approved in accordance with the requirements

of the Rules for Materials, and selected from the List of Approved

Welding Consumables for use in Ship Construction.

2.7.2 Surveyors should

satisfy themselves that all storage spaces provided by the Builder

will maintain welding consumables in good condition. They should also

ensure satisfactory arrangements for their maintenance after issue

to the work force, and for compliance with manufacturer’s instructions

regarding use of their product. Systematic checks should be made on

the consumables being used, having regard to the grades of steel and

welding positions involved.

2.8 Non-destructive examination

2.8.2 Acceptance

criteria are given in Table 3.2.2 Weld defect acceptance levels for

fabrication.

Table 3.2.2 Weld defect acceptance levels for

fabrication

| Defect type

|

Permitted

maximum

|

| Undercut

|

Slight intermittent undercut is

permitted, provided the depth does not exceed 0,5 mm

|

| Shrinkage grooves/root

concavities

|

Slight intermittent shrinkage grooves,

and root concavities permitted to a maximum depth of 1,2 mm

|

| Excess penetration

|

3 mm max

|

| Misalignment

|

t/5 but 3 mm max

|

| Crack (including lamellar

tears)

|

Not permitted

|

|

Lack of root fusion

Lack of side-wall fusion

Lack of inter-run fusion

Lack of root penetration

|

Not permitted

Not permitted

Not permitted

Slight lack of penetration permitted (L = t but

25 mm max)

Aggregate length not to exceed t in a length of

12t

|

| POROSITY

|

|

| Individual pore

|

3mm for t up to 50 mm

4,5 for t over 50 mm and up to 75mm

6,0 mm for t over 75 mm

|

| Uniformly distributed

porosity

|

2% by area of the weld

|

| SLAG

|

|

| Individual and parallel to weld

axis

|

L = t but 25 mm max

W = 1,5 mm max

|

| Linear group

|

Aggregate length not to exceed

t in a length of 12t

|

| Symbols

|

|

t

|

= |

plate thickness of thinnest plate in welded

connection |

|

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|