Section

1 General

1.1 Application

1.1.1 The

requirements for longitudinal and transverse global strength are contained

within this Chapter.

1.1.2 This

Chapter contains Sections detailing the analysis requirements for

the following topics:

- Hull girder strength.

- Extreme strength assessment.

- Residual strength assessment

1.1.3

Section

2, Hull girder strength. This Section specifies the hull girder

strength requirements based on the conventional elastic design and

buckling analyses. All ships are to comply fully with the requirements

of this Section.

1.1.4

Section

3, Extreme strength assessment. This Section specifies the

requirements for the assessment of the extreme hull girder strength

to withstand wave loads that have a low probability of occurring during

the life of the ship. This is an optional assessment and ships which

comply with the extreme strength requirements can apply for the notation ESA1 or ESA2, see

Vol 1, Pt 1, Ch 2, 3.7 Hull strength notations 3.7.1

1.1.5

Section

4, Residual strength assessment. This Section specifies the

requirements for the assessment of the residual hull girder strength

after the ship has sustained structural damage. This is an optional

assessment and ships which comply with the residual strength requirements

can apply for the notation RSA1, RSA2 or RSA3, see

Vol 1, Pt 1, Ch 2, 3.7 Hull strength notations 3.7.1.

1.2 Hull girder strength notations

1.2.1 The

following notations are available for all ships with regard to global

hull girder strength aspects:

-

ESA1, ESA2 Extreme strength assessment.

-

RSA1, RSA2, RSA3 Residual strength assessment.

A distinction is made between levels of performance and levels

of assessment; the numeral in the notation reflects the level of assessment.

Levels of performance are denoted by the letters A, B, C for collision

or grounding damage and numerals I, II and III for damage from military

threats and are confidential to the Owner. See

Vol 1, Pt 6, Ch 4, 4.2 Extent of damage and analysis for non-military threats and Vol 1, Pt 4, Ch 2, 7 Residual strength for military threats.

1.2.2 The

performance of the ship with respect to extreme hull girder strength

aspects may be evaluated at two levels. ESA1, the lowest

level offers a basic assessment of the ship’s capability. ESA2, the higher level is a much more rigorous assessment of the

hull’s capability to withstand extreme sea states.

1.2.3 It is

recommended that ships of groups NS1 and NS2 should comply with ESA1. However, it is the responsibility of the Owner to specify

the level of extreme strength assessment required.

1.2.4 The

extreme strength assessment level adopted must reflect the performance

level required by other notations.

1.2.5 The

two levels of assessment available for the extreme strength assessment

notation are summarised as follows:

|

ESA1

|

= |

This uses elastic

theory, based on the section moduli and area, and determination of

the buckling strength to resist the global hull girder loads. The

assessment is to be made at a minimum of three locations. |

|

ESA2

|

= |

Uses a ‘2D’

ultimate strength beam representation and a failure level criterion

based on the section ultimate bending moments being satisfactory compared

to the design bending moments in both hogging and sagging. This will

require assessment using ultimate strength calculations at all critical

longitudinal locations. |

1.2.6 The

performance of the ship with respect to residual strength aspects

may be evaluated at several levels. The lowest level offers a basic

assessment of the ship’s capability to survive. Higher residual

strength levels are designed to show that the ship has an improved

performance with respect to hull’s capability to withstand increased

damage extents and scenarios.

1.2.7 Three

assessment and performance levels are available for the residual strength

assessment notation. RSA1, the assessment Level 1 residual

strength assessment, and performance level A are recommended as a

minimum for all ships of groups NS1 and NS2.

However, it is the responsibility of the Owner to specify the level

of residual strength assessment required.

1.2.8 The

residual strength assessment level adopted must reflect the performance

level required by other notations.

1.2.9 The three levels of assessment available for the residual strength

assessment notation are summarised as follows:

|

RSA1

|

= |

This uses elastic

theory, based on the remaining section moduli and area after damage,

and determination of the buckling strength to resist the global hull

girder loads. The assessment is to be made at a minimum of three critical

sections. |

|

RSA2

|

= |

Uses a ‘2D’

ultimate strength beam representation and a failure level criterion

based on the section ultimate bending moments being satisfactorily

compared to the design bending moments in both hogging and sagging.

The assessment is to be made at a minimum of three critical sections. |

|

RSA3

|

= |

Uses a ‘3D’

definition of a section of the hull girder and relies on geometric

and material failure criteria implicit in the chosen finite element

code. It could also include coupled Euler-Lagrange formulations to

specifically account for internal and external blast effects, UNDEX

shock and whipping. |

1.3 Symbols and definitions

1.3.1 The

symbols and definitions applicable to this Chapter are defined below

or in the appropriate sub-Section.

|

L

R

|

= |

Rule length of the ship, in metres |

|

σ

ο

|

= |

specified minimum yield strength of the material, in N/mm2

|

|

τ

ο

|

= |

|

1.3.2 The

strength deck is to be taken as follows:

-

Where there is

a complete upper deck, the strength deck is the upper deck.

-

Where the upper deck is stepped, as in the case of ships with a

raised quarterdeck, the strength deck is also stepped, see

Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus. Adequate provision should be made for the transfer of load between

the stepped decks.

1.4 Calculation of hull section modulus

1.4.1 In general, the effective sectional area of continuous longitudinal

strength members, after deduction of openings, is to be used for the calculation of

midship section modulus.

1.4.2 Structural members which contribute to the overall hull girder strength are

to be carefully aligned so as to avoid discontinuities resulting in abrupt variations of

stresses and are to be kept clear of any form of openings which may affect their

structural performances.

1.4.3 In general, short superstructures or deckhouses will not be accepted as

contributing to the global longitudinal or transverse strength of the ship. However,

where it is proposed to include substantial, continuous stiffening members, special

consideration will be given to their inclusion on submission of the designer’s/builder’s

calculations, see also

Vol 1, Pt 6, Ch 4, 2.5 Superstructures global strength

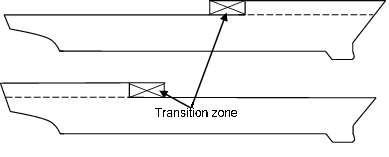

1.4.4 A transition zone, see

Figure 4.1.1 Strength deck stepping, is

to be assumed at the ends of stepped decks where the longitudinal structural material

cannot be included in the calculation of the section modulus of hull sections. The

length of the zone is to be taken as four times the deck height. Local insert plates are

to be fitted in the side shell as appropriate with a thickness at least 25 per cent

greater than the adjacent plating. They are to extend a minimum of one primary frame

spacing forward and aft, but are to be not less than 1500 mm each way from the end of

the transition zone. For vessels with complex arrangements or geometries, shadow area

plans are to be submitted.

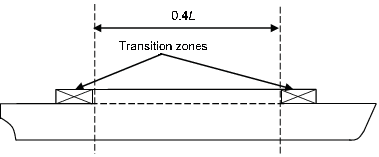

1.4.5 A superstructure deck can only be considered as a strength deck and

included in the calculation of the section modulus of hull sections if it extends over

the full 0,4LR midship region and out to the side shell with the

transition zones being located outside the 0,4LR midship region,

see

Figure 4.1.2 Strength deck stepping, superstructure deck.

Figure 4.1.1 Strength deck stepping

Figure 4.1.2 Strength deck stepping, superstructure deck

1.4.6 Where continuous deck longitudinals or deck girders are arranged above the

strength deck, special consideration may be given to the inclusion of their sectional

area in the calculation of the hull section modulus, Z. The lever is to be taken

to a position corresponding to the height of the longitudinal member above the moulded

deck line at side amidships. Each such case will be individually considered.

1.4.7 Adequate transition arrangements are to be fitted at the ends of effective

continuous longitudinal strength members in the deck and bottom structures.

1.4.8 Scantlings of all continuous longitudinal members of the hull girder based

on the minimum section stiffness requirements determined from 2.2 are to be maintained

within 0,4L

R amidships. However, in special cases, based on consideration of type of

ship, hull form and loading conditions, the scantlings may be gradually reduced towards

the ends of the 0,4L

R part, bearing in mind the desire not to inhibit the ship’s loading and

operational flexibility.

1.4.9 Structural material which is longitudinally continuous but which is not

considered to be fully effective for longitudinal strength purposes will need to be

specially considered. The global longitudinal strength assessment must take into account

the presence of such material when it can be considered effective. The consequences of

failure of such structural material and subsequent redistribution of stresses into or

additional loads imposed on the remaining structure must be considered.

1.4.10 In particular, all longitudinally continuous material will be fully

effective in tension whereas this may be not be so in compression due to a low buckling

capability. In this case, it may be necessary to derive and apply different hull girder

section moduli to the hogging and sagging bending moment cases.

1.4.11 Openings in decks, longitudinal bulkheads and other longitudinal effective

material having a length in the fore and aft directions exceeding 0,1B m or 2,5 m

or a breadth exceeding 1,2 m or 0,04B m, whichever is the lesser, are in all

cases to be deducted from the sectional areas used in the section modulus calculation.

1.4.12 Openings smaller than stated in Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus 1.4.11, including manholes, need not be deducted provided

they are isolated and the sum of their breadths or shadow area breadths, see

Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus 1.4.15, in one transverse section does reduce the section

modulus at deck or bottom by more than 3 per cent.

1.4.13 The expression 0,06 (B

1 – Σb

1 ), where B

1 equals the breadth of the ship at the section considered and Σb

1 equals the sum of breadths of deductible openings, may be used for deck

openings in lieu of the 3 per cent limitation of reduction of section modulus in Vol 1, Pt 6, Ch 4, 1.4 Calculation of hull section modulus 1.4.12.

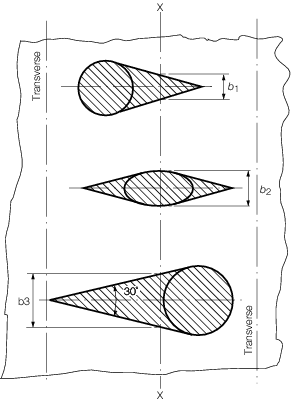

Figure 4.1.3 Isolated openings

1.4.14 Where a large number of openings are proposed in any transverse space,

special consideration will be required.

1.4.15 Where calculating deduction-free openings, the openings are assumed to have

longitudinal extensions as shown by the shaded areas in Figure 4.1.3 Isolated openings The shadow area is obtained by drawing two

tangent lines to an opening angle of 30°. The section to be considered is to be

perpendicular to the centreline of the ship and is to result in the maximum deduction in

each transverse space.

1.4.16 Isolated openings in longitudinals or longitudinal girders need not be

deducted if their depth does not exceed 25 per cent of the web depth or 75 mm, whichever

is the lesser.

1.4.17 Openings are considered isolated if they are spaced more than 1 m

apart.

1.4.18 A reduction for drainage holes and scallops in beams and girders, etc. is

not necessary so long as the global section modulus at deck or keel is reduced by no

more than 0,5 per cent.

1.5 General

1.5.1 The

Level 1 assessment procedures specified in Clasifications Register’s

(hereinafter referred to as 'LR') Structural Detail Design Guide for

fatigue design assessment, FDA, are to be generally applied

to the construction details of all ships.

1.6 Direct calculations

1.6.1 Direct

calculations using finite element analysis may be necessary for ships

with complicated longitudinal structural arrangements such as ships:

- of novel design;

- with significant discontinuous longitudinal material;

- with large deck openings, or where warping stresses in excess

of 14,7 N/mm2 are likely to occur;

- with large openings in the side shell, especially in way of the

sheerstrake.

|