Section

2 General requirements

2.1 Pod arrangement

2.1.1 In general, for a ship to be assigned an unrestricted service notation, a

minimum of two podded propulsion units is to be provided where these form the sole means

of propulsion. For vessels where a single podded propulsion unit is the sole means of

propulsion, an evaluation of a detailed engineering justification will be conducted by

LR, see

Vol 2, Pt 4, Ch 4, 2.2 Documentation required for design review 2.2.2. This evaluation process will include the appraisal

of a Risk Assessment (RA) to verify that sufficient levels of redundancy and monitoring

are incorporated in the podded propulsion unitís support systems and operating

equipment.

2.2 Documentation required for design review

2.2.1 In addition

to the plans required by Vol 2, Pt 3, Ch 1 Gearing and Vol 2, Pt 3, Ch 2 Shafting Systems, Vol 2, Pt 4, Ch 1 Propellers, Vol 2, Pt 5 Shaft Vibration and Alignment, Vol 2, Pt 6, Ch 1 Steering Gear, Vol 2, Pt 7, Ch 3 Machinery Piping Systemsand Vol 2, Pt 9 Electrotechnical Systems and Vol 2, Pt 10 Human Factors, the following plans and information are

required to be submitted for appraisal. Where appropriate, the information

shall be contained in a System Design Description document, see

Vol 2, Pt 1, Ch 3, 3.5 System design description:

-

Description of

the shipís purpose/capabilities together with the podís

intended operational modes in support of these capabilities. The operational

modes are to include stopping the vessel and restrictions on steering

angles at different ship speeds. See also

Vol 2, Pt 4, Ch 4, 2.2 Documentation required for design review 2.2.1.(h).

- The declared steering angle limits are to be stated by the steering system

manufacturer for each podded propulsion unit;

-

Power transmitted

at MCR condition (shaft power and rpm) and other maximum torque conditions,

e.g. bollard pull.

-

Maximum transient

thrust, torque and other forces and moments experienced during all

envisaged operating modes as permitted by the steering and propulsor

drive control systems.

-

Details of the

electric propulsion motor short-circuit torque and motor air gap tolerance.

-

Sectional assembly

in the Z-X plane, see

Figure 4.2.1 Pod co-ordinate system.

-

Specifications

of materials and NDE procedures for components essential for propulsion

and steering operation, to include propulsion shaft and slewing ring

bearings, gearing and couplings, see

Vol 2, Pt 4, Ch 4, 3.1 General.

-

Details of the

intended manoeuvring capability of the ship in each operating condition.

-

Design loads for

both the pod structure and propeller together with podded propulsion

unit design operating modes,see

Vol 2, Pt 4, Ch 4, 2.4 Global loads 2.4.1, Vol 2, Pt 4, Ch 4, 5.3 Propulsion shafting 5.3.7, Vol 2, Pt 4, Ch 4, 5.6 Steering system 5.6.10 and Vol 2, Pt 4, Ch 4, 5.6 Steering system 5.6.11.

-

Supporting data

and direct calculation reports. This is to include, where applicable

an assessment of anticipated global accelerations acting on the ship's

machinery and equipment which may potentially affect the reliable

operation of the propulsion system for all foreseeable seagoing and

operating conditions. Typically, this may include response to slamming,

extreme ship motions and pod interaction. See also

Vol 2, Pt 4, Ch 4, 1.1 Application 1.1.5.

-

Structural component

details including: strut, pod body, bearing supports, bearing end

caps, shipís structure in way of podded propulsion unit integration

and a welding Table showing a key to weld symbols used on the plans

specifying weld size, type, preparation and heat treatment. The information

should include the following:

- Detailed drawings showing the structural arrangement, dimensions

and scantlings.

- Welding and structural details.

- Connections between structural components (bolting).

- Castings' chemical and mechanical properties.

- Forgings' chemical and mechanical properties.

- Material grades for plate and sections.

-

Nozzle structure,

its support arrangements, together with related calculations for all

foreseeable operating and seagoing conditions where the propeller

operates in a nozzle (duct), see

Vol 1, Pt 3, Ch 3, 5 Fixed and steering nozzles, bow and stern thrust units, ducted propellers.

-

Propeller shaft

bearing mounting and housing arrangement details, see also

Vol 2, Pt 4, Ch 4, 5.3 Propulsion shafting 5.3.6.

-

Details of propeller

shaft and steering bearings, where roller bearings are used supporting

calculations are to be submitted, see

Vol 2, Pt 4, Ch 4, 5.3 Propulsion shafting 5.3.7 and Vol 2, Pt 4, Ch 4, 5.6 Steering system 5.6.11.

-

Propeller shaft

seal details.

-

Details of propeller

shaft and pod steering securing/locking and means of aligning the

securing/locking arrangements.

-

Cooling systems

piping system schematic.

-

Details of any

lubricating oil conditioning systems (filtering/cooling/heating) and

control arrangements necessary to ensure the continuous availability

of the required lubricating oil quality to the propeller shaft bearings.

-

Details of installed

condition monitoring equipment.

-

Details of the

derivation of any duty factor used in the design of the steering gears.

-

Identification

of any potentially hazardous atmospheric conditions together with

details of how the hazard will be countered, this should include a

statement of the maximum anticipated air temperature within the pod

during full power steady state operation, see

Vol 2, Pt 4, Ch 4, 2.3 Pod internal atmospheric conditions.

-

Where provided,

access and closing arrangements for pod unit inspection and maintenance.

-

Heat balance calculations

for the pod unit taking into account electrical thermal rises when

the pod is operating at maximum continuous operating conditions, heat

transfer and maximum sea-water/air temperatures, see

Vol 2, Pt 4, Ch 4, 5.7 Ventilation and Cooling Systems 5.7.4.

-

Details of proposed testing and trials required by Vol 2, Pt 1, Ch 3, 15.2 Testing and trials.

-

Details of emergency

steering and pod securing arrangements, see

Vol 2, Pt 4, Ch 4, 5.3 Propulsion shafting 5.3.11.

-

Quality plan for

electronic control systems and electrical actuating systems.

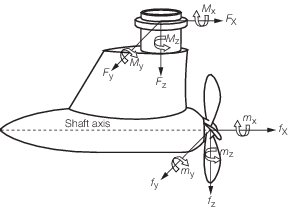

Figure 4.2.1 Pod co-ordinate system

2.2.2 Where

an engineering justification report is required, the following supporting

information is to be submitted:

- A Risk Assessment (RA) in accordance with Vol 2, Pt 1, Ch 3, 18 Risk Assessment (RA) is to be carried out, see

Vol 2, Pt 4, Ch 4, 2.1 Pod arrangement 2.1.1. The RA is to identify components where failure

could cause loss of all propulsion, steering capability or other Mobility systems or

Ship Type systems, and the proposed arrangements for preventing and mitigating the

effects of such a failure.

- Design standards and assumptions.

- Limiting operating parameters.

- A statement and evidence in respect of the anticipated reliability

of any components.

2.2.3 Recommended

installation, inspection, maintenance and component replacement procedures, see also

Vol 2, Pt 4, Ch 4, 4.1 Pod structure 4.1.2. This

is to include any in-water/underwater engineering procedures where

recommended by the pod manufacturer. See also

Vol 2, Pt 4, Ch 4, 5.5 Bearing lubrication system 5.5.7 and Vol 2, Pt 4, Ch 4, 8 Installation, maintenance and replacement procedures.

2.3 Pod internal atmospheric conditions

2.3.1 Machinery

and electrical equipment installed within the pod unit are to be suitable

for operation, without degraded performance, at the maximum anticipated

air temperature and humidity conditions within the pod unit with the

pod operating at its maximum continuous rating in sea water of not

less than 32įC after steady state operating conditions have been

achieved.

2.3.2 Precautions

are to be taken to prevent as far as reasonably practicable the possibility

of danger to personnel and damage to equipment arising from the development

of hazardous atmospheric conditions within the pod unit. Circumstances

that may give rise to these conditions are to be identified and the

counter measures taken are to be defined.

2.4 Global loads

2.4.1 The

overall strength of the podded propulsion unit structure is to be

based upon the maximum anticipated inservice loads, including, the

effects of ship manoeuvring and of ship motion, see

Table 3.2.1 Ship motions in Vol 1, Pt 5, Ch 3.

This is to include the effects of any pod to pod and/or pod to ship

hydrodynamic interference effects. The designer is to supply the following

maximum load and moment values to which the unit may be subjected

with a description of the operating condition at which they occur.

-

F

x, Force in the longitudinal direction;

-

F

y, Force in the transverse direction;

-

F

z, Force in the vertical direction including

self weight, in water, augmented by the shipís pitch and heave

motion and flodded volume where applicable, see

Vol 2, Pt 4, Ch 4, 4.3 Direct calculations 4.3.3 and Vol 1, Pt 5, Ch 3 Local Design Loads;

-

M

x, moment at the slewing ring about the

pod unitís global longitudinal axis;

-

M

y, moment at the slewing ring about the

pod unitís global transverse axis;

-

M

z, moment at the slewing ring about the

pod unitís vertical axis (maximum dynamic duty steering torque

on steerable pods).

The directions of the X, Y and Z axes, with the origin at the

centre of the slewing ring, are shown in Figure 4.2.1 Pod co-ordinate system.

2.4.2 Where

the maximum forces and moments defined in Vol 2, Pt 4, Ch 4, 2.4 Global loads 2.4.1 cannot be accurately calculated,

then an estimate of these loadings is to be stated together with an

assessment of the associated error tolerances for the sequences of

permitted design manoeuvres, see

Vol 2, Pt 4, Ch 4, 1.1 Application 1.1.7. Typically this will include

emergency astern manoeuvres, zig zag manoeuvres and pod interaction.

Such estimates are to be defined on a load versus pod angle basis.

In the case of pod to pod and/or pod to ship hydrodynamic interaction

effects, these must be defined for the most severely affected propulsor

including cases where pod units are capable of being independently

steered.

2.4.3 Where

control systems are installed to limit the operation of the podded

drive to defined angles at defined ship speeds, this information may

be taken into consideration when determining the pod unit loading.

2.4.4 Where

pod units are fixed about their Z axis, then maximum global loads,

to be used as the basis of the structural appraisal, are to be determined

for inflows in 5 degree increments between the extremes of anticipated

inflow angle during manoeuvring with ship at full speed and maximum

propeller thrust.

2.4.5 The

podded propulsor is to be capable of withstanding a blade root failure

due to fatigue occurring at the maximum rated output of the podded

propulsor without initiating a failure in other parts of the propulsor

system. After a blade failure, the podded propulsor is to be capable

of reduced power operation in accordance with the manufacturer's instructions.

2.5 Ice Class Requirements

|