Section

14 Construction

14.1 Access arrangements

14.1.1 In

watertube boilers, manholes are to be provided in all drums of sufficient

size to allow access for internal examination and cleaning, and for

fitting and expanding the tubes. In the case of headers for water

walls, superheaters or economisers, and of drums which are too small

to permit entry, sight holes or mudholes sufficiently large and numerous

for these purposes are to be provided.

14.1.2 Cylindrical

boilers are to be provided, where possible with means for ingress

to permit examination and cleaning of the inner surfaces of plates

and tubes exposed to flame. Where the boilers are too small to permit

this there are to be sight holes and mudholes sufficiently large and

numerous to allow the inside to be satisfactorily cleaned.

14.1.3 Where

the cross tubes of vertical boilers are large, there is to be a sight

hole in the shell opposite to one end of each tube sufficiently large

to allow the tube to be examined and cleaned. These sight holes are

to be in positions accessible for that purpose.

14.1.4 Manholes

in cylindrical shells should preferably have their shorter axes arranged

longitudinally.

14.1.5 Doors

for manholes, mudholes and sight holes are to be formed from steel

plate or other approved construction, and all jointing surfaces are

to be machined.

14.1.6 Doors

of the internal type are to be provided with spigots which have a

clearance of not more than 1,5 mm all round, i.e. the axes of the

opening are not to exceed those of the door by more than 3 mm. The

width of the manhole gasket seat is to be not less than 16 mm.

14.1.7 Doors

of the internal type for openings not larger than 230 mm x 180 mm

need be fitted with one stud only, which may be forged integral with

the door. Doors for openings larger than 230 mm x 180 mm are to be

fitted with two studs or bolts. The strength of the attachment to

the door is to be not less than the strength of the stud or bolt.

14.1.8 The

crossbars or dogs for doors are to be of steel.

14.1.9 For

smaller circular openings in headers and similar fittings, an approved

type of plug may be used.

14.1.10 Circular flat cover plates may be fitted to raised circular manhole frames

not exceeding 400 mm diameter, and for an approved design pressure not exceeding 1,8

MPa.

14.1.11 External

circular flat cover plates are to be in accordance with a recognised

National Standard.

14.2 Torispherical and semi-ellipsoidal ends

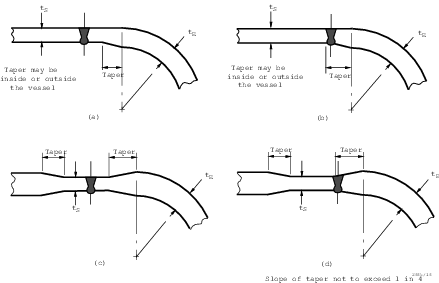

14.2.2 Where

the difference in thickness is the same throughout the circumference,

the thicker plate is to be reduced in thickness by machining to a

taper for a distance not less than four times the offset, so that

the two plates are of equal thickness at the position of the circumferential

weld. A parallel portion may be provided between the end of the taper

and weld edge preparation; alternatively, if so desired, the width

of the weld may be included as part of the smooth taper of the thicker

plate.

14.2.3 The

thickness of the plates at the position of the circumferential weld

is to be not less than that of an unpierced cylindrical shell of seamless

or welded construction, whichever is applicable, of the same diameter

and material, see

Vol 2, Pt 8, Ch 1, 4.1 Minimum thickness

Figure 1.14.1 Typical attachments of dished ends to cylindrical shells

14.3 Hemispherical ends

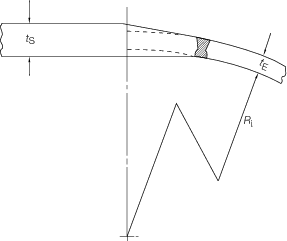

14.3.1 Where

hemispherical ends are butt welded to cylindrical shells, the thickness

of the shell is to be reduced by taper to that of the end, and the

centre of the hemisphere is to be so located that the entire tapered

portion of the shell and the butt weld are within the hemisphere, see

Figure 1.14.2 Attachment of hemispherical end to cylindrical shell.

Figure 1.14.2 Attachment of hemispherical end to cylindrical shell

14.3.2 If

the hemispherical end is provided with a parallel portion, the thickness

of this portion is to be not less than that of a seamless or welded

shell, whichever is applicable, of the same diameter and material.

14.4 Welded-on flanges, butt welded joints and fabricated branch pieces

14.4.1 Flanges

may be cut from plates or may be forged or cast. Hubbed flanges are

not to be machined from plate. Flanges are to be attached to branches

by welding. Alternative methods of flange attachment will be subject

to special consideration.

14.4.2 The

types of welded-on flanges are to be suitable for the pressure, temperature

and service for which the branches are intended.

14.4.3 Flange

attachments and pressure-temperature ratings in accordance with materials

and design of recognised standards will be accepted.

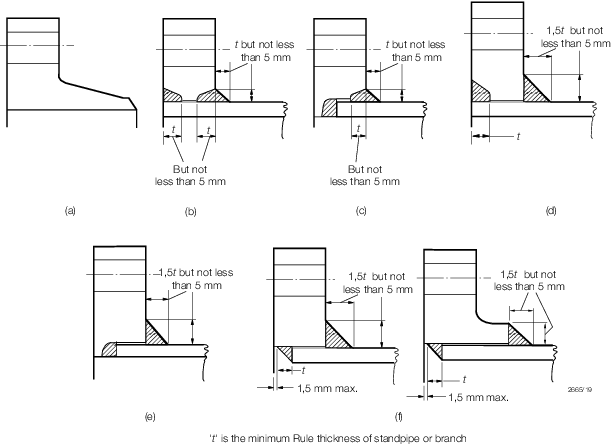

14.4.4 Typical

examples of welded-on flange connections are shown in Figure 1.14.3 Typical examples of welded flange connections(a) to (f), and limiting

design conditions for the flange types are shown in Table 1.14.1 Limited design conditions for

flanges. In Figure 1.14.3 Typical examples of welded flange connections, t is

the minimum Rule thickness of the standpipe or branch.

Figure 1.14.3 Typical examples of welded flange connections

Table 1.14.1 Limited design conditions for

flanges

Flange

type

|

Maximum

pressure

|

Maximum

temperature

|

Maximum

pipe o.d.

|

Minimum

pipe bore

|

|

|

|

°C

|

mm

|

mm

|

| (a)

|

Pressure-temperature ratings

to be in accordance with a recognised standard

|

No restriction

|

No restriction

|

No restriction

|

| (b)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

No

restriction

|

168,3 for alloy

steels*

|

No

restriction

|

| (c)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

No

restriction

|

168,3 for alloy

steels*

|

75

|

| (d)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

425

|

No

restriction

|

No

restriction

|

| (e)

|

Pressure-temperature ratings to be in accordance with a recognised

standard

|

425

|

No

restriction

|

75

|

| (f)

|

Pressure-temperature ratings

to be in accordance with a recognised standard

|

425

|

No restriction

|

No restriction

|

| *No restriction for carbon steels

|

14.4.5 Welded-on

flanges are not to be a tight fit on the branch. The maximum clearance

between the bore of the flange and the outside diameter of the branch

is to be 3 mm at any point, and the sum of the clearances diametrically

opposite is not to exceed 5 mm.

14.4.6 Where

butt welds are employed in the attachment of flange type (a), or in

the construction of standpipes or branch pieces, the adjacent pieces

are to be matched at the bores. This may be effected by drifting,

roller expanding or machining, provided the pipe wall is not reduced

below the designed thickness. If the parts to be joined differ in

wall thickness, the thicker wall is to be gradually tapered to that

of the thinner at the butt joint.

14.4.7 Welding

may be carried out by means of the shielded metal arc, inert gas metal

arc, oxy-acetylene or other approved process, but in general, oxy-acetylene

welding is suitable only for flange type (a) and is not to be applied

to branches exceeding 100 mm diameter or 9,5 mm thick. The welding

is to be carried out in accordance with the appropriate paragraphs

of Vol 2, Pt 1, Ch 4 Requirements for Fusion Welding of Pressure Vessels and Piping.

14.4.8 Threaded

sleeve joints complying with Vol 2, Pt 7, Ch 1, 5.6 Socket weld joints 5.6.1 may be used on the steam and water piping of small

oil fired package boilers of the once through coil type, used for

auxiliary or domestic purposes, where the feed pump capacity limits

the output.

14.5 Welded attachments to pressure vessels

14.5.1 Unless

the actual thickness of the shell or end is at least twice that required

by calculation for a seamless shell or end, whichever is applicable,

doubling plates with well rounded corners are to be fitted in way

of attachments such as lifting lugs, supporting brackets and feet,

to minimise load concentrations on pressure shells and ends. Compensating

plates, pads, brackets and supporting feet are to be bedded closely

to the surface before being welded, and are to be provided with a

‘tell-tale’ hole not greater than 9,5 mm in diameter,

open to the atmosphere to provide for the release of entrapped air

during heat treatment of the vessel, or as means of indicating any

leakage during hydraulic testing and in service. See

Vol 2, Pt 1, Ch 4 Requirements for Fusion Welding of Pressure Vessels and Piping

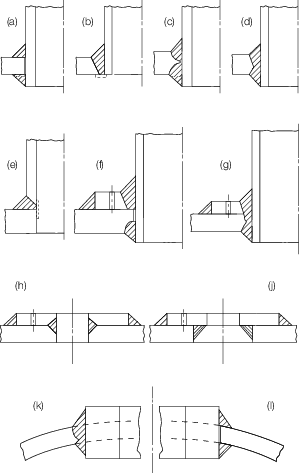

14.5.3 Where

fillet welds are used to attach standpipes or set-in pads, there are

to be equal sized welds both inside and outside the vessel, see

Figure 1.14.4 Typical acceptable methods of attaching branches and pads(a) and (l). The leg

length of each of the fillet welds is to be not less than 1,4 times

the actual thickness of the thinner of the parts being joined.

14.6 Fitting of tubes in water tube boilers

14.6.1 The

tube holes in drums or headers are to be formed in such a way that

the tubes can be effectively tightened in them. Where the tube ends

are not normal to the tube plates, there is to be a neck or belt of

parallel seating of at least 13 mm in depth, measured in a plane through

the axis of the tube at the holes. Where the tubes are practically

normal to their plates, this parallel seating is to be not less than

9,5 mm in depth.

14.6.2 Tubes

are to be carefully fitted in the tube holes and secured by means

of welding, expanding and belling or by other approved methods. Tubes

are to project through the neck or belt of parallel seating by at

least 6 mm and where they are secured from drawing out by means of

bellmouthing only, the included angle of belling is to be not less

than 30°.

Figure 1.14.4 Typical acceptable methods of attaching branches and pads

|