Section

9 Flat surfaces and flat tube plates

9.1 Stayed flat surfaces

9.1.1 Where

flat end plates are flanged for connection to the shell, the inside

radius of flanging is to be not less than 1,75 times the thickness

of the plate, with a minimum of 38 mm.

9.1.2 Where

combustion chamber or firebox plates are flanged for connection to

the wrapper plate, the inside radius of flanging is to be equal to

the thickness of the plate, with a minimum of 25 mm.

9.1.3 Where

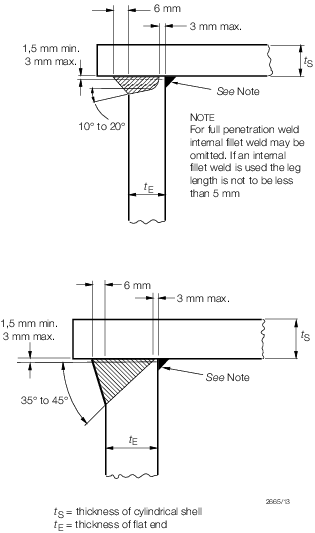

unflanged flat plates are connected to the shell by welding, typical

methods of attachment are shown in Figure 1.9.1 Typical attachment of unflanged flat end plates to shell . Similar forms of attachment may be used where unflanged

combustion chamber or firebox plates are connected to the wrapper

plate by welding.

Figure 1.9.1 Typical attachment of unflanged flat end plates to shell

9.1.4 Where

the flange curvature is a point of support, this is to be taken at

the commencement of curvature, or at a line distant 3,5 times the

thickness of the plate from the outside of the plate, whichever is

nearer to the flange.

9.1.5 Where

a flat plate is welded directly to a shell or wrapper plate, the point

of support is to be taken at the inside of the shell or wrapper plate.

9.1.6 The

thickness, t, of those portions of flat plates supported

by stays and around tube nests is to be determined by the following

formula:

where t, p, c and σ are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

d

|

= |

diameter

of the largest circle which can be drawn through at least three points

of support. At least one point of support must lie on one side of

any diameter of the circle. |

9.1.7 The

value of C in the formula in Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.6 is to be as follows:

-

Where plain bar

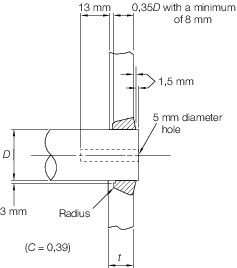

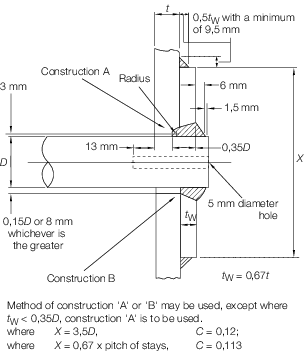

stays are strength welded into the plates as shown in Figure 1.9.2 Typical attachment of firebox, combustion chamber stays and bar stays

-

Where plain bar

stays pass through holes in the plates and are fitted on the outside

with washers as shown in Figure 1.9.3 Typical attachment of bar stays

|

C

|

= |

0,12

where the diameter of the washer is 3,5 times the diameter of the

stay |

|

C

|

= |

0,113

where the diameter of the washer is 0,67 times the pitch of the stays. |

-

Where the flat

plate is flanged for attachment to the shell, flue, furnace or wrapper

or, alternatively, is welded directly to shell, flue, furnace or wrapper, see

Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.4 and Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.5:

-

Where the support

is a gusset stay

-

Where the support

is a tube secured as shown in Figure 1.9.4 Detail of weld for tube

Figure 1.9.2 Typical attachment of firebox, combustion chamber stays and bar stays

Figure 1.9.3 Typical attachment of bar stays

9.1.9 In the

case of small boilers with a single tube nest of expanded tubes which

does not exceed an area of 0,65 m2, welded tubes need not

be fitted provided the tubes are beaded at the inlet end. In this

instance the support afforded by the expanded tubes is not to be taken

to extend beyond the line enclosing the outer surfaces of the tubes

except that, between the outside of the nest and the attachment of

the end plate to shell, there may be an unsupported width equal to

the flat plate margin, as given by the formula in Vol 2, Pt 8, Ch 1, 9.4 Flat plate margins 9.4.1. The required tube plate thickness

within such a tube nest is to be determined using the formula in Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.6, where:

|

d

|

= |

four

times the mean pitch, in mm, of the expanded tubes in the nest. |

9.1.10 The

thickness, t, of any tube plate in the tube area is to

be not less than that required for the surrounding plate determined

by Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.6 and in no case less

than:

-

12,5 mm where

the diameter of the tube hole does not exceed 50 mm, or

-

14 mm where the

diameter of the tube hole is greater than 50 mm.

9.1.11 Alternative

methods of support will be specially considered.

9.1.12 The

spacing of tube holes is to be such that the minimum width, b,

in mm of any ligament between tube holes is not less than:

for expanded tubes:

for welded tubes:

where

|

d

|

= |

diameter

of the hole drilled in the plate, in mm. |

9.1.13 Where

a flat plate has a manhole or sight hole and the opening is strengthened

by flanging, the total depth, H, of the flange, measured

from the outer surface of the plate, is to be not less than:

where

|

t

|

= |

thickness

of plate, in mm |

|

H

|

= |

depth

of flange, in mm |

|

W

|

= |

minor

axis of manhole or sight hole, in mm. |

9.1.14 Where

the flat top plates of combustion chambers are supported by welded-on

girders, the equation in Vol 2, Pt 8, Ch 1, 9.1 Stayed flat surfaces 9.1.6 is

to apply as follows:

-

In the case of

welded-on girders provided with waterways

|

d

|

= |

|

where

|

X

|

= |

width

of waterway in the girder plus the thickness of the girder, in mm |

|

Y

|

= |

pitch

of girders, in mm. |

-

In the case of

continuously welded-on girders

where

|

D

|

= |

distance

between inside faces of girders, in mm. |

9.2 Combustion chamber tube plates under compression

9.2.1 The

thickness of combustion chamber tube plates under compression due

to the pressure on the top plate, based on a compressive stress not

exceeding 96 N/mm2 is to be determined by the following

formula:

where t and p are as defined

in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

d

|

= |

internal

diameter of the plain tubes, in mm |

|

s

|

= |

pitch

of tubes, in mm, measured horizontally where tubes are chain pitched,

or diagonally where the tubes are staggered pitched and the diagonal

pitch is less than the horizontal pitch |

|

W

|

= |

internal

width of the combustion chamber, in mm, measured from tube plate to

back chamber plate. |

9.3 Girders for combustion chamber top plates

9.3.1 The

formula in 9.3.2 is applicable to plate girders welded to the top

combustion chamber plate by means of a full penetration weld.

9.3.2 The

thickness of steel plate girders supporting the tops of combustion

chambers is to be determined by the following formula:

where t and p are as defined

in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

d

|

= |

effective

depth of girder, in mm |

|

l

|

= |

length

of girder measured internally from tube plate to back chamber plate,

in mm |

|

s

|

= |

pitch

of the girders, in mm |

|

R

20

|

= |

specified minimum tensile strength of the girder plate, in N/mm2.

|

9.4 Flat plate margins

9.4.1 The

width of margin, b, of a flat plate which may be regarded

as being supported by the shell, furnaces or flues to which the flat

plate is attached is not to exceed that determined by the following

formula:

where p, c and σ are as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

t

|

= |

thickness

of the flat plate, in mm |

|

b

|

= |

width

of margin, in mm |

9.4.2 Where

an unflanged flat plate is welded directly to the shell, furnaces

or flues and it is not practicable to effect the full penetration

weld from both sides of the flat plate, the constant C used

in the formula in Vol 2, Pt 8, Ch 1, 9.4 Flat plate margins 9.4.1 is

to be:

9.4.3 In the

case of plates which are flanged, the margin is to be measured from

the commencement of curvature of flanging, or from a line 3,5 times

the thickness of the plate measured from the outside of the plate,

whichever is nearer to the flange.

9.4.4 Where

the flat plate is not flanged for attachment to the shell, furnaces

or flues, the margin is to be measured from inside of the shell or

the outside of the furnaces or flues, whichever is applicable.

9.4.5 In no

case is the diameter D, in mm, of the circle forming

the boundary of the margin supported by the uptake of a vertical boiler

to be greater than determined by the following formula:

where p is as defined in Vol 2, Pt 8, Ch 1, 1.2 Definition of symbols

|

d

|

= |

external

diameter of uptake, in mm |

|

d

i

|

= |

internal diameter of uptake, in mm |

|

A

|

= |

cross-sectional

area of the uptake tube material, |

|