Section

4 Design of gearing

4.1 Symbols

4.1.1 For the

purposes of this Chapter the following symbols apply:

|

a

|

= |

centre

distance, in mm |

|

|

= |

Note: unless otherwise

specified, b is to be taken as the lesser value of b

1or b

2.

|

|

|

= |

In the case of double

helical gears b = 2b

B where b

B is the width of one helix.

|

|

d

|

= |

reference

diameter, in mm |

|

d

a

|

= |

tip diameter, in mm |

|

d

an

|

= |

virtual tip diameter, in mm |

|

d

b

|

= |

base diameter, in mm |

|

d

bn

|

= |

virtual base diameter, in mm |

|

d

en

|

= |

virtual diameter to the highest point of single tooth pair contact,

in mm |

|

d

f

|

= |

root diameter, in mm |

|

d

fn

|

= |

virtual root diameter, in mm |

|

d

n

|

= |

virtual reference diameter, in mm |

|

d

s

|

= |

shrink diameter, in mm |

|

d

w

|

= |

pitch circle diameter, in mm |

|

f

ma

|

= |

tooth flank misalignment due to manufacturing errors, in μm |

|

f

pb

|

= |

maximum base pitch deviation of wheel, in μm |

|

f

Sh

|

= |

tooth flank misalignment due to wheel and pinion deflections,

in μm |

|

f

Sho

|

= |

intermediary factor for the determination of f

Sh

|

|

g

α

|

= |

length of line of action for external gears, in mm: |

|

h

|

= |

total

depth of tooth, in mm |

|

h

ao

|

= |

basic rack addendum of tool, in mm |

|

h

F

|

= |

bending moment arm for root stress, in mm |

|

h

w

|

= |

sum of actual tooth addenda of pinion and wheel, in mm |

|

m

n

|

= |

normal module, in mm |

|

q

|

= |

machining

allowances, in mm |

|

q'

|

= |

intermediary

factor for the determination of C

γ

|

|

u

|

= |

|

|

v

|

= |

linear

speed at pitch circle, in m/s |

|

x

|

= |

addendum

modification coefficient |

|

y

α

|

= |

running in allowance, in μm |

|

y

β

|

= |

running in allowance, in μm |

|

z

n

|

= |

virtual number of teeth =

|

|

C

γ

|

= |

tooth mesh stiffness (mean total mesh stiffness per unit face

width), in N/mm μm |

|

F

t

|

= |

nominal tangential tooth load, in N |

|

F

β

|

= |

total tooth alignment deviation (maximum value specified), in μm |

|

F

βx

|

= |

actual longitudinal tooth flank deviation before running in,

in μm |

|

F

βy

|

= |

actual longitudinal tooth flank deviation after running in,

in μm |

|

Hv |

= |

Vickers hardness

number |

|

K

Fα

|

= |

transverse load distribution factor |

|

K

Fβ

|

= |

longitudinal load distribution factor |

|

K

Hα

|

= |

transverse load distribution factor |

|

K

Hβ

|

= |

longitudinal load distribution factor |

|

K

vα

|

= |

dynamic factor for spur gears |

|

K

vβ

|

= |

dynamic factor for helical gears |

|

K

γ

|

= |

load sharing factor |

|

P

|

= |

transmitted

power, in kW |

|

P

r

|

= |

radial pressure at shrinkage surface, in N/mm2

|

|

P

ro

|

= |

protuberance of tool, in mm |

|

R

a

|

= |

surface roughness − arithmetical mean deviation (C.L.A.)

as determined by an instrument having a minimum wavelength cut-off

of 0,8 mm and for a sampling length of 2,5 mm, in μm |

|

S

pr

|

= |

residual undercut left by protuberance in mm |

|

S

F min

|

= |

minimum factor of safety for bending stress |

|

S

Fn

|

= |

tooth root chord in the critical section, in mm |

|

S

H min

|

= |

minimum factor of safety for Hertzian contact stress |

|

S

R

|

= |

rim thickness of gears, in mm |

|

Y

B

|

= |

rim thickness factor |

|

Y

R rel T

|

= |

relative surface finish factor |

|

Y

S

|

= |

stress correction factor |

|

Y

ST

|

= |

stress correction factor (relevant to the dimensions of the

standard reference test gears) |

|

Y

δ rel T

|

= |

relative notch sensitivity factor |

|

Z

E

|

= |

material elasticity factor |

|

Z

R

|

= |

surface finish factor |

|

= |

contact ratio factor |

|

αen

|

= |

pressure

angle at the highest point of single tooth contact, in degrees |

|

αn

|

= |

normal

pressure angle at reference diameter, in degrees |

|

αt

|

= |

transverse

pressure angle at reference diameter, in degrees |

|

αtw

|

= |

transverse

pressure angle at pitch circle diameter, in degrees |

|

αF en

|

= |

angle for application of load at the highest point of single

tooth contact, in degrees |

|

β |

= |

helix angle

at reference diameter, in degrees |

|

βb

|

= |

helix

angle at base diameter, in degrees |

|

γ |

= |

intermediary

factor for the determination of f

Sh

|

α

α

|

= |

transverse

contact ratio |

α

n

α

n

|

= |

virtual transverse contact ratio |

β

β

|

= |

overlap

ratio |

γ

γ

|

= |

total

contact ratio |

|

ρao

|

= |

tip

radius of tool, in mm |

|

ρc

|

= |

relative

radius of curvature at pitch point, in mm |

|

ρF

|

= |

tooth

root fillet radius at the contact of the 30o tangent, in

mm

|

|

σy

|

= |

yield

or 0,2 per cent proof stress, in N/mm2

|

|

σB

|

= |

ultimate

tensile strength, in N/mm2

|

|

σF

|

= |

bending

stress at tooth root, N/mm2

|

|

σF lim

|

= |

endurance limit for bending stress in N/mm2

|

|

σFP

|

= |

allowable

bending stress at the tooth root, in N/mm2

|

|

σH

|

= |

Hertzian

contact stress at the pitch circle, in N/mm2

|

|

σH lim

|

= |

endurance limit for Hertzian contact stress, in N/mm2

|

|

σHP

|

= |

allowable

Hertzian contact stress, in N/mm2

|

Subscript:

Note

a and z are considered positive

for both external and internal gearing for the purposes of these calculations.

4.2 Tooth form

4.2.1 The tooth

profile in the transverse section is to be of involute shape, and

the roots of the teeth are to be formed with smooth fillets of radii

not less than 0,25 m

n.

4.2.2 All sharp

edges left on the tips and ends of pinion and wheel teeth after hobbing

and finishing are to be removed.

4.3 Tooth loading factors

4.3.1 For values

of application factor, K

A, see

Table 1.4.1 Values of K

A

.

Table 1.4.1 Values of K

A

| Main

and auxiliary gears

|

K

A

|

| Main propulsion - electric motor or

gas turbine, reduction gears

|

1,15

|

| Main propulsion - diesel engine

reduction gears:

|

|

| Hydraulic coupling or equivalent on

input

|

1,10

|

| High elastic coupling on input

|

1,30

|

| Other coupling

|

1,50

|

| Auxiliary Gears:

|

|

| Electric, gas turbine and diesel

engine drives with hydraulic coupling or equivalent on input

|

1,00

|

| Diesel engine drives with high elastic

coupling on input

|

1,20

|

| Diesel engine drives with other

couplings

|

1,40

|

4.3.2 Load sharing

factor, K

γ. When a gear drives two or

more mating gears where the total transmitted load is not evenly distributed

between the individual meshes, a factor, K

γ,

is to be applied. K

γ is defined as the

ratio between the maximum load through an actual path and the evenly

shared load. This is to be determined by measurements. Where a value

cannot be determined in such a way, the values in Table 1.4.2 Values of K

y

may be considered:

Table 1.4.2 Values of K

y

|

|

K

y

|

| Spur Gear

|

1,0

|

| Epicyclic Gears

|

|

| Up to 3 planetary gears

|

1,0

|

| 4 planetary gears

|

1,2

|

| 5 planetary gears

|

1,3

|

| 6 planetary gears and over

|

1,4

|

4.3.3

Dynamic

factor, K

V, is to be calculated as

follows when all the following conditions are satisfied:

- spur gears (β = 0°) and helical gears with β ≤

30°

- pinion with relatively low number of teeth, z1 <

50

- solid disc wheels or heavy steel gear rim

Or this method may also be applied to all types of gears if:

And to helical gears where β > 30°

-

For spur gears and

for helical gears with ∊β ≥ 1:

Where K

A

F

t/b is less than 100 N/mm, the value 100 N/mm is to be used.

Numerical values for the factor K

1 are to

be as specified in the Table 1.4.3 Values of K

1

Table 1.4.3 Values of K

1

|

|

K

1

ISO accuracy Grade

|

|

|

3

|

4

|

5

|

6

|

7

|

8

|

| Spur Gears

|

2,1

|

3,9

|

7,5

|

14,9

|

26,8

|

39,1

|

| Helical Gears

|

1,9

|

3,5

|

6,7

|

13,3

|

23,9

|

34,8

|

-

For all accuracy grades the factor K

2 is

to be in accordance with the following:

- for spur gears K

2 = 0,0193

- for helical gears K

2 = 0,0087

Factor K

3 is to be in accordance with

the following:

-

For helical gears

with overlap ratio ∊β < 1, the value K

v is to be determined by linear interpolation between values

determined for spur gears (K

vα) and helical

gears (K

vβ) in accordance with:

K

vα is the K

v value

for spur gears, in accordance with Pt 11, Ch 1, 4.3 Tooth loading factors 4.3.3

K

vβ is the K

v value

for helical gears, in accordance with Pt 11, Ch 1, 4.3 Tooth loading factors 4.3.4.(b)

4.3.5

Longitudinal

load distribution factors, K

Hβ and K

Fβ:

Calculated values of K

Hβ >

2 are to be reduced by improved accuracy and helix correction as necessary:

where

|

F

β

y

|

= |

F

β

x − y

β and

|

|

F

β

x

|

= |

1,33 f

Sh + f

ma

|

|

f

ma

|

= |

F

β at the design stage, or

F

β at the design stage, or

|

|

f

ma

|

= |

F

β where helix correction

has been applied

F

β where helix correction

has been applied

|

|

f

Sh

|

= |

|

where

|

F

Sho

|

= |

23γ10−3 μm mm/N for gears without

helix correction or crowning and without end relief, or

|

|

|

= |

12γ10−3 μm mm/N for gears without helix correction but with crowning, See Note 1

|

|

|

= |

16γ10−3 μm mm/N for gears without helix correction but with end

relief, where

|

|

γ |

= |

for single helical and spur gears for single helical and spur gears

|

|

|

= |

for double helical gears for double helical gears

|

The following minimum values are applicable, these also being

the values where helix correction has been applied:

|

f

Sho

|

= |

10 x 10−3 μm mm/N for helical gears, or

|

|

|

= |

5 x 10−3 μm

mm/N for spur gears

|

For through-hardened steels and surface hardened

steels running on through-hardened steels:

|

yβ

|

= |

up to an upper limit value of up to an upper limit value of

|

|

yβ

|

= |

m, and m, and

|

For surface hardened steels, when

|

y

β

|

= |

0,15F

β

x up to an upper

limit value of

|

where

|

|

= |

|

Note

1.

is to be taken as the smaller of is to be taken as the smaller of

Note

2. For double helical gears  is to be substituted for b in the equation

for n. is to be substituted for b in the equation

for n.

4.3.6

Transverse

load distribution factors, K

H

α and K

F

α

-

Values K

Hα and K

Fα for gears with total

contact ratio ∊γ ≤ 2

-

Values K

Hα and K

Fα for gears with total

contact ratio ∊γ > 2

Limiting conditions for KHα:

If  when calculated in accordance with (a) or (b), then when calculated in accordance with (a) or (b), then

If K

Hα< 1 when calculated in

accordance with (a) or (b), then K

Hα =1

Limiting conditions for K

Fα:

If  when calculated in accordance with (a) or (b), then when calculated in accordance with (a) or (b), then

If K

Fα< 1 when calculated in

accordance with (a) or (b), then K

Fα=1

When tip relief is applied f

pb is to

be half of the maximum specified value:

|

= |

for through-hardened steels, when |

|

= |

and |

|

y

α

|

= |

0,075 f

pb for surface hardened steels,

when

|

y

α ≤ 3 μm

When pinion and wheel are manufactured from different

materials:

Note Tip relief is to take the form of either tip and root

relief on the pinion, or tip relief on pinion and wheel.

4.3.7

Tooth

mesh stiffness, C

γ:

where

|

|

= |

|

For internal gears Z

n2 = ∞

Other calculation methods for C

γ will

be specially considered.

4.4 Tooth loading for surface stress

4.4.1 The Hertzian contact stress, σH, at

the pitch circle is not to exceed the allowable Hertzian contact stress, σHP.

and

for the pinion/wheel combination for the pinion/wheel combination

where

Z

∊, contact ratio factor is to be calculated as follows:

for helical

gears:

for spur gears

where:

The peak to valley roughness determined for the pinion

R

Z1 and for the wheel R

Z2 are mean values for the peak to valley roughness R

z measured on several tooth flanks.

relative radius of curvature:

where:

For internal gears, d

b has a negative sign.

If R

a, the surface roughness of the tooth flanks is given then the following

approximation may be applied:

C

ZR is to be taken from Table 1.4.4 Values of C

ZR

.

For values of Z

x, see

Table 1.4.5 Values of Zx

σH lim,

see

Table 1.4.6 Values of endurance limit for

Hertzian contact stress, σ H lim

S

H min,

see

Table 1.4.7 Factors of safety

Table 1.4.4 Values of C

ZR

|

σH lim

|

CZR

|

|

σH lim

< 850 N/mm2

|

0,150

|

| 850 N/mm2 ≤ σH

lim

≤ 1200 N/mm2

|

=0,32-0,0002∙σH lim

|

|

σH lim

>1200 N/mm2

|

0,080

|

Table 1.4.5 Values of Zx

| Pinion heat treatment

|

Z

x

|

| Carburised and

induction-hardened

|

m

n ≤ 10

|

1,00

|

| 10 < m

n < 30

|

1,05 - 0,005m

n

|

| 30 ≤ m

n

|

0,9

|

|

|

|

|

| Nitrided

|

m

n < 7,5

|

1,00

|

| 7,5 < m

n<30

|

1,08 - 0,005mn

|

| 30 ≤ m

n

|

0,75

|

|

|

|

|

| Through-hardened

|

All modules

|

1,00

|

Table 1.4.6 Values of endurance limit for

Hertzian contact stress, σ H lim

| Heat treatment

|

|

| Pinion

|

Wheel

|

|

| Through-hardened

|

Through-hardened

|

0,46σB2 + 255

|

| Surface-hardened

|

Through-hardened

|

0,42σB2 + 415

|

| Carburised, nitrided or

induction-hardened

|

Soft bath nitrided

(tufftrided)

|

1000

|

| Carburised, nitrided or

induction-hardened

|

Induction-hardened

|

0,88HV

2 + 675

|

| Carburised or nitrided

|

Nitrided

|

1300

|

| Carburised

|

Carburised

|

1500

|

Table 1.4.7 Factors of safety

|

|

S

H min

|

S

F min

|

| Main propulsion gears

|

1,40

|

1,80

|

| Auxiliary gears

|

1,15

|

1,40

|

4.5 Tooth loading for bending stress

4.5.1 The bending

stress at the tooth root, σF is not to exceed the

allowable tooth root bending stress σFP:

Note If b

1 and b

2 are

not equal to the load bearing width of the wider face taken is not

to exceed that of the smaller plus 2m

n.

For values of S

F min, see

Table 1.4.7 Factors of safety

Stress correction factor Y

ST =

2.

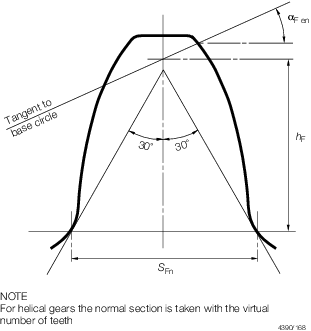

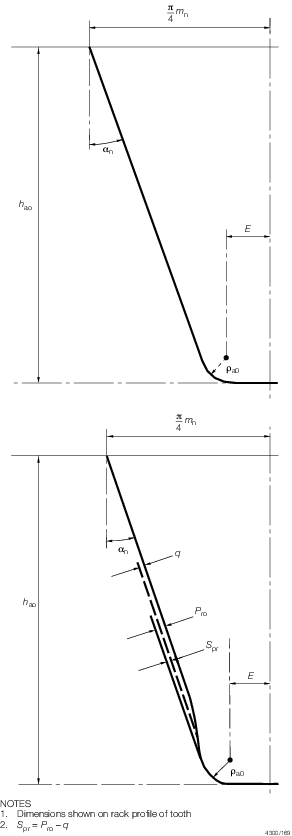

4.5.2

Tooth

form factor, Y

F:

where h

F, αFen and S

Fn are shown in Figure 1.4.1 Normal tooth section.

E, h

ao, αn, S

pr and ρao are shown

in Figure 1.4.2 External tooth forms.

where

|

d

an

|

= |

d

n + d

a - d

|

|

|

= |

|

where

|

αen

|

= |

|

|

|

= |

|

Table 1.4.8 Values of endurance limit for

bending stress, σ F lim

| Heat treatment

|

σF lim N/mm2

|

| Through-hardened carbon steel

|

0,09σB + 150

|

| Through-hardened alloy steel

|

0,1σB + 185

|

| Soft bath nitrided

(Tufftrided)

|

330

|

| Induction hardened

|

0,35 HV + 125

|

| Gas nitrided

|

390

|

| Carburised A

|

450

|

| Carburised B

|

410

|

Note

1. A is applicable for Cr Ni Mo

carburising steels.

Note

2. B is applicable for other carburising

steels.

|

Figure 1.4.1 Normal tooth section

4.5.3 For internal

tooth forms the form factor is calculated, as an approximation, for

a substitute gear rack with the form of the basic rack in the normal

section, but having the same tooth depth as the internal gear:

where αF en is taken as being equal

to αn

d

en2 is calculated as d

en for external gears, and

4.5.4

Stress

concentration factor, Y

s

where

|

L

|

= |

|

|

q

s

|

= |

|

when q

s < 1 the value of Y

s is to be specially considered.

The formula for Y

s is applicable to external gears with αn =

20o but may be used as an approximation for other pressure

angles and internal gears.

Figure 1.4.2 External tooth forms

4.5.5

Helix

angle factor Y

β

but

Y

b ≥ 1

− 0,25 β ≥ 0,75

β ≥ 0,75

4.5.6

Rim

thickness factor, Y

B

Factor Y

B is to be determined as follows:

-

For external gears

If S

R/h ≥ 1,2 then Y

B = 1

If 0,5 < S

R/h <1,2 then

where

|

S

R

|

= |

rim thickness of external gears, mm |

The case S

R/h ≤ 0,5 is

to be avoided.

-

For internal gears

If S

R/mn ≥ 3,5 then Y

B = 1

If 1,75 < S

R/mn < 3,5

then

Where

S

R = rim thickness

of internal gears, mm

The case S

R/mn ≤ 1,75

is to be avoided.

4.5.7

Deep

tooth factor Y

DT

The deep tooth factor, Y

DT, adjusts

the root stress to take into account high precision gears and contact

ratios within the range of virtual contact ratio 2,05 ≤ ∊αn ≤ 2,5 where:

Factor Y

DT is to be determined

from Table 1.4.9 Values of deep tooth factor,

Y

DT

:

Table 1.4.9 Values of deep tooth factor,

Y

DT

|

|

Y

DT

|

| ISO Accuracy Grade ≤ 4 and

∊αn > 2,5

|

0,7

|

| ISO Accuracy Grade ≤ 4 and 2,05 <

∊αn ≤ 2,5

|

2,366 – 0,666⋅ ∊αn

|

| In all other cases

|

1,0

|

4.5.8

Relative

notch sensitivity factor, Yδ rel T

ρ’ = slip-layer thickness is to be taken

from Table 1.4.10 Slip-layer thickness, ρ’

Table 1.4.10 Slip-layer thickness, ρ’

| Material

|

ρ’, (mm)

|

| Case

hardened steels, flame or induction hardened steels

|

0,0030

|

| Through-hardened steels, yield point

R

e =

|

500 N/mm2

|

0,0281

|

|

|

600 N/mm2

|

0,0194

|

|

|

800 N/mm2

|

0,0064

|

|

|

1000 N/mm2

|

0,0014

|

| Nitrided

steels

|

0,1005

|

Note The given values of ρ’ can be interpolated for values of

R

e not stated above

|

4.5.9

Relative

surface finish factor, Y

R rel T

|

Y

R rel T

|

= |

1,674 − 0,529 (6R

a + 1)0,1 for

through-hardened, carburised and induction hardened steels, and

|

| = |

4,299 − 3,259 (6R

a +

1)0,005 for nitrided steels.

|

4.5.10

Size

factor, Y

x

|

Y

x

|

= |

1,00, when m

n ≤ 5

|

| = |

1,03 − 0,006m

n for

through-hardened steels

|

| = |

0,85, when m

n ≥

30

|

| = |

1,05 − 0,01 m

n for

surface-hardened steels

|

| = |

0,80, when m

n ≥

25.

|

4.5.11

Design

factor, Y

D

|

Y

D

|

= |

0,83 for gears treated with a controlled shot peening process |

| = |

1,5 for idler gears |

| = |

1,25 for shrunk on gears, or |

| = |

|

| = |

1,00 or any combination of the

above — e.g. Y

D= (0,83 × 1,5)

for an idler gear treated with a controlled shot peening process.

|

4.6 Factors of safety

4.7 Design of enclosed gear shafting

4.7.1 The following

symbols apply:

P in kW and R in rpm, see

Pt 11, Ch 1, 1.2 Power ratings 1.2.1.

|

L

|

= |

span

between shaft bearing centres, in mm |

|

σn

|

= |

normal

pressure angle at the gear reference diameter, in degrees |

|

β |

= |

helix angle

at the gear reference diameter, in degrees |

|

d

w

|

= |

pitch circle diameter of the gear teeth, in mm |

|

σu

|

= |

specified

minimum tensile strength of the shaft material, in N/mm2

|

Note Numerical value used for σu is not to

exceed 800 N/mm2 for gear and thrust shafts and 1100 N/mm2for quill shafts.

4.7.2 This sub-Section

is applicable to the main and ancillary transmission shafting, enclosed

within the gearcase.

4.7.3 The diameter

of the enclosed gear shafting adjacent to the pinion or wheel is to

be not less than the greater of d

b or d

t, where:

where

|

S

b

|

= |

45 + 0,24 (σu — 400) and

|

|

S

s

|

= |

42 + 0,09 (σu — 400).

|

4.7.4 For the

purposes of the above it is assumed that the pinion or wheel is mounted

symmetrically spaced between bearings.

4.7.5 Outside

a length equal to the required diameter at the pinion or wheel, the

diameter may be reduced, if applicable, to that required for d

t.

4.7.6 For bevel

gear shafts, where a bearing is located adjacent to the gear section,

the diameter of the shaft is to be not less than d

t.

Where a bearing is not located adjacent to the gear the diameter of

the shaft will be specially considered.

4.7.7 The diameter

of quill shaft (not axially constrained and subject only to external

torsional loading) is to be not less than given by the following formula:

Diameter of quill shaft =

4.7.8 Where

a shaft, located within the gearcase, is subject to the main propulsion

thrust, the diameter at the collars of the shaft transmitting torque,

or in way of the axial bearing where a roller bearing is used as a

thrust bearing, is to be not less than 1,1 d

t.

For thrust bearings located outside the gearcase see

Pt 11, Ch 2, 2 Particulars to be submitted.

4.8 Gear wheels

4.8.1 In general,

arrangements are to be made so that the interior structure of the

wheel may be examined. Alternative proposals will be specially considered.

4.9 External shafting and components

4.10 Clutch actuation

4.10.1 Where

a clutch is fitted in the transmission, normal engagement shall not

cause excessive stresses in the transmission or the driven machinery.

Inadvertent operation of any clutch is not to produce dangerously

high stresses in the transmission or driven machinery.

4.11 Gearcases

4.11.1 Gearcases

and their supports are to be designed sufficiently stiff such that

misalignment at the mesh due to movements of the external foundations

and the thermal effects under all conditions of service do not disturb

the overall tooth contact.

4.11.2 Inspection

openings are to be provided at the peripheries of gearcases to enable

the teeth of pinions and wheels to be readily examined. Where the

construction of gearcases is such that sections of the structure cannot

be readily be moved for inspection purposes, access openings of adequate

size are also to be provided at the ends of the gearcases to permit

examination of the structure of the wheels. Their attachment to the

shafts is to be capable of being examined by removal of bearing caps

or by equivalent means.

4.11.3 For

gearcases fabricated by fusion welding the carbon content of the steels

should generally not exceed 0,23 per cent. Steels with higher carbon

content may be approved subject to satisfactory results from weld

procedure tests.

4.11.4 Gearcases

are to be stress relieved upon completion of all welding.

4.11.5 Gearcases

manufactured from material other than steel will be considered upon

full details being submitted.

4.12 Backlash

4.12.1 The

normal backlash between any pair of gears should not be less than:

4.13 Alignment

4.13.1 Reduction

gears with sleeve bearings, for main and auxiliary purposes are to

be provided with means for checking the internal alignment of the

various elements in the gearcases.

4.13.2 In the

case of separately mounted reduction gearing for main propulsion,

means are to be provided by the gear manufacturer to enable the Surveyors

to verify that no distortion of the gearcase has taken place, when

chocked and secured to its seating on board the craft.

|