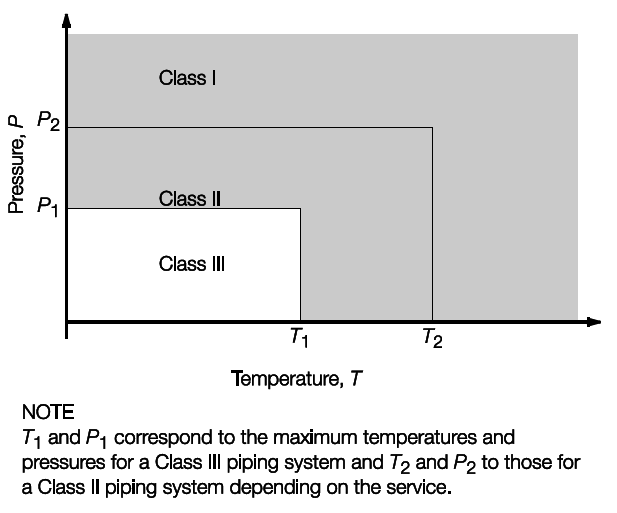

3.1.1 Pressure piping systems are divided into three classes for the purpose of

assigning appropriate testing requirements, types of joints to be adopted, heat

treatment and weld procedure.

3.1.2 Dependent on the service for which they are intended, Class II and III pipes are not to

be used for design pressure or temperature conditions in excess of those shown in Table 1.3.1 Maximum pressure and temperature

conditions for Class II and III piping systems.

Where either the maximum design pressure or temperature exceeds that applicable to Class

II pipes, Class I pipes are to be used. To illustrate this, see

Figure 1.3.1 Classes of piping system.

Figure 1.3.1 Classes of piping system

Table 1.3.1 Maximum pressure and temperature

conditions for Class II and III piping systems

| Piping system

|

Class II

|

Class III

|

| P2

|

T

2

|

P1

|

T

1

|

|

|

bar

|

oC

|

bar

|

oC

|

| Steam

|

16,0

|

300

|

7,0

|

170

|

| Thermal

oil

|

16,0

|

300

|

7,0

|

150

|

Flammable

liquids,

see Note 1

|

16,0

|

150

|

7,0

|

60

|

| Other media,

see Note 2

|

40,0

|

300

|

16,0

|

200

|

|

Note 1. Flammable liquids

include: fuel oil, lubricating oil and flammable hydraulic oil.

Note 2. Including water, air, gases, non-flammable hydraulic oil.

|

3.1.4 Class II and III pipes are not to be used for toxic media.

3.1.5 Class I pipes are generally required for corrosive media. Class II pipes may be used for

corrosive media where special safeguards for reducing the potential for leakage and

limiting its consequences are provided, e.g. the use of pipe ducts, shielding,

screening, etc. in such a way that a leakage will not cause a potential hazard or damage

to surrounding areas. Class III pipes are not to be used for corrosive media. Materials

used for piping for corrosive media are to be specially considered.