Section

8 Building tolerances and associated repairs

8.1 Tolerances - General

8.1.2 Tolerances

to be used for constructional misalignment for all materials are to

be discussed between Owners/Builders and the Surveyor and acceptable

Standards agreed subject to the requirements of this Chapter or National

Authority requirements where applicable. The permitted degree of inaccuracy/misalignment

will vary according to whether the defect is:

-

In primary structure.

-

In secondary structure.

-

Aesthetically pleasing.

8.2 Raw material surface tolerances

8.2.1 The surface

cleanliness of steel/aluminium alloy materials in preparation for

painting is to be in accordance with National or paint Manufacturer's

Standards.

8.2.2 Where approved

corrosion control coatings are to be used the quality of the surface

treatment is to be in accordance with the grade specified in the approval

documents.

8.3 Surface defects

8.3.1 The limits

of depth and extent of surface defects on plate, cast or forged materials

in relation to the material plate thickness are shown in Table 1.8.1 Limits of surface defects.

8.3.2 Defects

are to be made good by grinding only subject to the plate thickness

not being reduced by more than seven per cent of the nominal thickness

or 3 mm whichever is the lower, and the area involved not exceeding

two per cent of the surface area.

8.3.4 Where the

depth of the deepest imperfection exceeds 20 per cent of the nominal

thickness, or the defective area exceeds two per cent of the total

surface area, such areas are to be cropped and replaced. See

Pt 3, Ch 1, 8.5 Part replacement of plates.

8.3.5 Complete

removal of the defects is to be verified by suitable non-destructive

examination techniques and after welding the repair is to be proved

free from further defects. The complete removal of defects is to be

verified by nondestructive examination in accordance with the requirements

specified in Ch 13 Requirements for Welded Construction of the Rules

for Materials.

8.3.6 Care is

to be taken in the repair of defects in higher tensile steel, and

aluminium alloy materials. Low hydrogen electrodes with similar properties

to the higher tensile steel are to be used with preheating as necessary.

Aluminium alloys are to be heat treated after repair, see

Pt 7, Ch 2, 3 Procedures for welded construction.

Table 1.8.1 Limits of surface defects

| Normal

thickness of material (mm)

|

Maximum permissible depth of defect (mm)

|

| Area

affected - Unlimited

|

Area

affected ≤ 5% of Surface

|

| <

8

|

0,2

|

0,4

|

| 8 to

25

|

0,3

|

0,5

|

| 25 to

40

|

0,4

|

0,6

|

| ≥ 40

|

0,5

|

0,8

|

Note

1. Defects are to be measured after shot

blasting or plate cleaning.

Note

2. The depth of the deepest imperfection

is to be considered.

Note

3. Defects not exceeding the limits shown

need not be repaired.

Note

5. Defects exceeding the above limits are

to be repaired.

Note

6. Crack-like defects are always to be

repaired irrespective of their depth.

|

8.4 Plate laminations

8.4.1 Plates

in which laminations are suspected or detected are to be ultrasonically

tested to determine the full extent of such laminations.

8.4.2 Where laminations

are confined to the plate edge, are less than 300 mm long and whose

penetration is not more than half the plate thickness, then the defect

may be chipped or ground out and rebuilt with weld material.

8.4.3 Where laminations

are isolated, located near to the plate surface, and where the total

area of the defect does not exceed two per cent of the surface area

of the plate, the defect may be repaired as in Pt 3, Ch 1, 8.4 Plate laminations 8.4.2.

8.4.5 Complete

removal of the defect is to be verified by non-destructive examination,

and after welding, the repair is to be proved free from further defects.

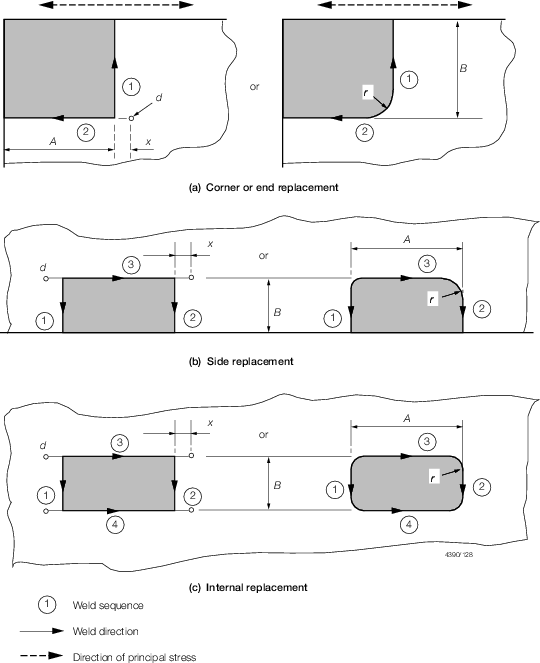

8.5 Part replacement of plates

8.6 Structural misalignment and fit (steel and aluminium)

8.6.3 Welding

defects are generally to be dealt with in accordance with Ch 13 Requirements for Welded Construction of the Rules for Materials. Limits

for weld undercut and remedial action to be taken depend on plate

thickness and are to be discussed and agreed by the Builder and the

Surveyor prior to commencement of repairs.

8.7 Post welding plate deformation

8.7.3 Local heating

of steel is not to exceed 900oC (red heat) when flame straightening

is employed.

8.7.4 Local heating

of aluminium alloys is not to be carried out. All repairs are to be

by renewal of plating.

Table 1.8.2 Part replacement of plates

| A x B

|

Parts

to be replaced

|

Shell,

strength deck, tank top, top and bottom strakes of longitudinal

bulkheads

|

Elsewhere

|

| End and

corner of plate

|

1000 x

1000

|

1000 x

300

|

| Side of

plate

|

1000 x

300

|

1000 x

300

|

| Insert

|

1000 x

300

|

1000 x

300

|

| Line of plate replacement to be not less than 100

from extreme edge of defect.

|

| All dimensions are in mm.

|

|

Note

1. All dimensions are minimum.

Note

2. Rolling direction of replaced plate to

be the same as that of the parent plate.

Note

3. Minimum distance from outermost defect

to line of weld – 100 mm.

|

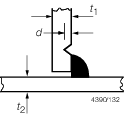

Note

4. Dimensions in millimetres:

|

d

|

= |

1,5 x plate thickness with minimum 6 and maximum

20 |

|

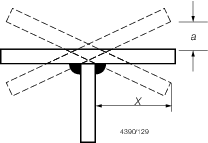

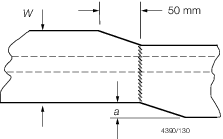

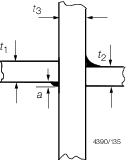

Table 1.8.3 Structural misalignment and fit

(steel and aluminium)

| Joint

|

Location

|

Acceptable dimensions (mm)

|

Remedial action

|

|

Fabricated frames

|

a ≤ ± 0,03 x

|

a > ± 0,03 x

|

Reject

|

| Beams,

girders and longitudinals

|

|

|

|

|

Butt

welded face flats primary structure

|

a ≤ 0,03W(max 6 mm)

|

a > 0,03W

|

Reject

|

| Secondary structure

|

a ≤ 0,04W (max 8 mm)

|

a > 0,04W

|

Reject

|

|

Obtuse

angle fillet weld

|

a ≤ t

1/2

|

a > t

1/2

|

Reject

|

|

All

areas

|

d ≤ 0,1t

1 (max 0,8 mm)

|

d > 0,1t

1

|

Repair

by welding or grinding depends on thickness ‘t

1’ in accordance with 8.3

|

|

All

areas

|

d ≤ 0,1t

(max 0,8 mm)

|

d > 0,1t

|

As

above

|

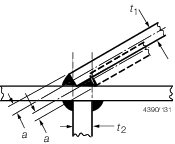

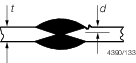

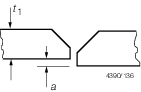

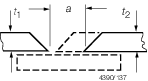

Table 1.8.4 Structural misalignment and fit

(steel and aluminium)

| Joint

|

Location

|

Permitted

misalignment

|

Remedial action

|

|

All

areas (Continuous fillet weld)

|

a (mm)

|

a (mm)

|

Increase weld leg length by ‘a’

|

|

|

0,25t

1 to 0,5t

1 (t

1 max = 5 mm)

|

| <

0,25t

1 (a max = 1 mm)

|

0,5t

1 to t

1 (t

1 max = 15 mm)

|

Vee material to +/–45o.

Fit backing strip and weld. Remove backing strip and complete weld.

|

|

a > t

1

|

Realign and

replace

|

| All

areas (intermittent weld)

|

< 0,25t

1

|

0,25 to

0,5t

1 (t

1 max = 3 mm)

|

Increase

weld lengths by 50%

|

| 0,25t

1 to 0,5t

1 (t

1 max = 5 mm)

|

Continuous

weld

|

|

a > t

1

|

As for

continuous weld above

|

|

Strength

members

|

a ≤ t

2/3

|

t

2/3 ≤ a ≤ t

1/2

|

Increase

weld leg length of welds by 10%

|

| Others

|

a ≤ t

2/2

|

a > t

2/2

|

Realign

|

| Higher

tensile steel joint in designated critical areas

|

a ≤ t

3/3

|

a > t

3/3

|

Realign

|

|

Strength

members

|

a ≤ 0,15t

1(max 3,0 mm)

|

a > 0,15t

1

|

Realign

|

| Others

|

a ≤ 0,2t

1 (max 3,0 mm)

|

a > 0,2t

1

|

Realign

|

|

All

areas

|

a in accordance with weld procedure

|

a ≤ t

1

|

Build one

side of butt until a in accordance with weld procedure.

|

|

a >t

1 (max 10 mm)

|

Cut back 150 mm and fit insert

plate

|

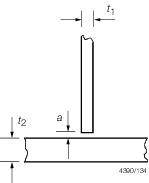

Table 1.8.5 Structural misalignment and fit

(steel and aluminium)

| Joint

|

Location

|

Acceptable dimensions (mm)

|

Remedial action

|

|

All

|

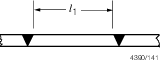

1 ≥ 40 mm

1 ≥ 40 mm

|

–

|

Adjust to

suit

|

|

All

|

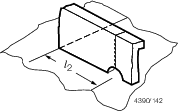

2 ≥ 20 mm

2 ≥ 20 mm

|

–

|

Adjust to

suit

|

|

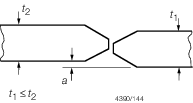

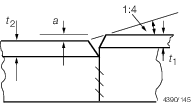

All

|

1 > 50 mm

1 > 50 mm

|

1 < 30 mm

1 < 30 mm

|

Treat as

an insert

|

|

All

|

2 ≥ 20 mm

2 ≥ 20 mm

|

2 < 15 mm

2 < 15 mm

|

Adjust to

suit

|

|

All

|

a ≤ 1,0

|

a < 5

|

Increase weld leg length by actual ‘a’

|

| All

|

a ≤ 1,0

|

a ≤ 5

|

Adjust to suit

|

|

Strength members

|

a ≤ 0,15t

1 (max 3,0 mm)

|

a > 0,15t

1

|

Reject

|

| Other

|

a ≤ 0,2t

1 (max 3,0 mm)

|

a > 0,2t

1

|

Reject

|

|

All

|

For

angle or tee longitudinal a ≤ 0,2t

1

|

a > 0,2t

1

|

Reject

|

| For offset bulb

longitudinal a ≤ 0,2t

2

|

a > 0,2t

2

|

Reject

|

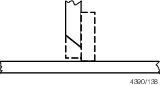

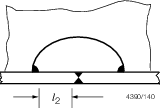

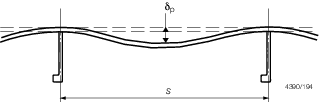

Table 1.8.6 Plate deformation limits

| Position

|

s/t

|

δp/s

|

| in

0,6L amidship

|

≤ 80

|

1/100

|

|

|

> 80

|

1/75

|

| Remainder

|

all

|

1/50

|

where

|

s

|

= |

stiffener spacing, in mm |

|

t

|

= |

plating thickness, in mm |

|

δp

|

= |

panel deflection, in mm |

|

Figure 1.8.1 Measurement of plate deformation

|