Section

2 Rudders

2.1 General

2.1.2 For rudders

having an increased diameter of rudder stock, see

Figure 3.2.1 Rudder types, the increased diameter

is to be maintained to a point as far as practicable above the top

of the lowest bearing. This diameter may then be tapered to the diameter

required in way of the tiller. The length of the taper is to be at

least three times the reduction in diameter. Particular care is to

be taken to avoid the formation of a notch at the upper end of the

taper.

2.1.3 Sudden

changes of section or sharp corners in way of the rudder coupling,

jumping collars and shoulders for rudder carriers, are to be avoided.

2.2 Definition and symbols

2.2.1 Definitions

and symbols for use throughout this Section are indicated in the appropriate

tables.

2.3 Direct calculations

2.3.1 Where the

rudder is of a novel design, high aspect ratio or the speed of the

craft exceeds 45 knots the scantlings of the rudder and rudder stock

are to be determined by direct calculation methods incorporating model

test results and structural analysis, where considered necessary by

LR.

2.4 Equivalents

2.4.1 Alternative

methods of determining the loads will be specially considered, provided

that they are based on model tests, full scale measurements or generally

accepted theories. In such cases, full details of the methods used

are to be provided when plans are submitted for approval.

2.5 Rudder arrangements

2.5.1 Rudders

considered are the types shown in Figure 3.2.1 Rudder types, of double plate or single plate construction, constructed

from steel, stainless steel or aluminium alloy. Other rudder types

and materials will be subject to special consideration.

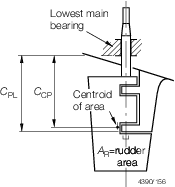

Figure 3.2.1 Rudder types

2.6 Rudder profile coefficient f

R

2.7 Rudder position coefficient f

p

2.8 Rudder speed coefficient f

v

2.9 Pintle arrangement coefficient N

2.9.1 The pintle

arrangement coefficient, N, for use in Table 3.2.6 Rudder stock diameter is to be as indicated in Table 3.2.4 Pintle arrangement coefficient

N

.

Table 3.2.5 Position of centre of

pressure

| Design criteria

|

Value of x

PF and x

PA to be used in Table 3.2.6 Rudder stock diameter

|

| Rectangular rudders;

|

|

|

|

| (a) Ahead condition

|

x

PF

|

=

|

(0,33ex

B-x

L), but not less than 0,12x

B

|

| (b) Astern condition

|

x

PA

|

=

|

(x

A- 0,25x

B), but not less than 0,12x

B

|

| Non-rectangular rudders;

|

|

| (a) Ahead condition

|

x

PF

|

=

|

as calculated from geometric form

(see Note) but not less than:

|

| (b) Astern condition

|

x

PA

|

=

|

as calculated from geometric form

(see Note) but not less than:

|

| Symbols

|

|

x

PF

|

= |

horizontal distance from the centreline of the rudder

pintles, or axle, to the centre of pressure in the ahead condition,

in metres |

|

|

x

PA

|

= |

horizontal distance from the centreline of the rudder

pintles, or axle, to the centre of pressure in the astern

condition, in metres |

|

|

x

B

|

= |

breadth of rudder, in metres |

|

|

y

R

|

= |

depth of rudder at centreline of stock, in metres |

|

|

|

|

x

L and x

A

|

= |

horizontal distances from leading and after edges,

respectively, of the rudder to the centreline of the rudder

pintles, or axle, in metres |

|

|

x

S

|

= |

horizontal length of any rectangular strip of rudder

geometric form, in metres |

|

|

e

|

= |

hull form factor at ahead condition |

|

| for

L < 65 m , e = 1,0

|

for

L ≥ 65 m, e= or or

|

e=

|

| whichever is the lesser, but not less than 1,0 and need not be taken

greater than 1,5

|

| L

R, B and C

b are as defined Pt 3, Ch 1, 6.2 Principal particulars is as defined in Table 3.2.6 Rudder stock diameter

|

| NOTE

|

| For

rectangular strips the centre of pressure is to be assumed to be located as

follows:

|

| (a)

0,33ex

S abaft leading edge of strip for ahead condition.

|

| (b)

0,25x

S from aft edge of strip for astern condition.

|

2.10 Centre of pressure

2.11 Rudder stock (tubular)

2.11.1 Tubular rudder stock scantlings are to be not

less than that necessary to provide the equivalent strength of a solid stock as required

by Table 3.2.6 Rudder stock diameter, and can be calculated from the following

formula:

where

|

d

E

|

= |

the diameter of the equivalent solid rudder stock, in mm |

|

d

1, d

2

|

= |

external and internal diameters, respectively of the tubular stock,

in mm |

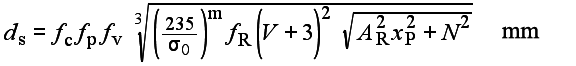

Table 3.2.6 Rudder stock diameter

| Requirement

|

|

1. Basic stock diameter, d

s, at and below lowest bearing:

|

|

|

2. Diameter in way of tiller, d

SU:

|

d

SU

|

= |

d

s calculated from (1) with N=0 |

|

|

3. Lateral force on rudder acting at centre of pressure of

blade, P

L:

|

|

|

| Symbols

|

|

f

c

|

= |

79 for craft of Rule length, L

R, 50 m and below varying up to 83,3 at a Rule length,

L

R, of 70 m. Intermediate values to be obtained by

interpolation |

| = |

83,3 for craft of Rule length, L

R, 70 m and above |

|

|

|

|

|

|

|

|

m

|

= |

0,75 for σ0 > 235 |

| = |

1,0 for σ0 ≤ 235 |

|

|

σ0

|

= |

minimum yield stress, in N/mm2, of material

used, and is not to be taken greater than 0,7 σT

|

|

|

σT

|

= |

ultimate tensile strength of the material used, in

N/mm2

|

|

|

V

|

= |

the maximum speed for the astern and ahead condition,

in knots. In no case to be less than 5 knots |

|

|

|

|

|

|

|

Note Where higher tensile steel is used for the rudder stock,

σ0 is not to be taken as greater than 450

N/mm2.

|

2.12 Single plate rudders

2.12.2 Rudder

arms are to be efficiently attached to the mainpiece.

Table 3.2.7 Single plate rudder

construction

| Item

|

Requirement

|

| Blade thickness

|

t

B = 0,0015Vy

W + 2,5 mm with a minimum of 10 mm

|

| Arms

|

Spacing ≤ 1000mm

|

|

Z

A = 0,0005V

2

x

a

2

y

W cm3

|

| Mainpiece

|

Diameter = d

s mm

|

| For spade rudders, the lower third may

taper down to 0,75d

s mm

|

| Symbols

|

|

t

B

|

= |

blade thickness, in mm |

|

y

W

|

= |

vertical spacing of rudder arms, in mm |

|

x

a

|

= |

horizontal distance from the aft edge of the rudder

to the centre of the rudder stock, in metres |

|

z

A

|

= |

section modulus of arm, in cm3

|

|

2.13 Double plate rudders

2.13.2 In way

of rudder couplings and heel pintles the plating thickness is to be

suitably increased.

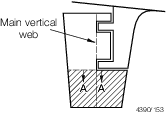

2.13.3 On semi-spade (Mariner) type rudders a notch effect in the corners in the

bottom pintle region is to be avoided (see AA, Figure 3.2.3 Semi-spade (mariner) type rudder). An insert plate, 1,6 times the Rule thickness

of the side plating, is to be fitted at this position, extending aft of the main

vertical web and having well rounded corners. The main vertical web is to be continuous

over the full depth of the rudder and have a thickness not less than three times the

thickness required by Table 3.2.8 Double plated rudder

construction, Item (4). Where an additional continuous main

vertical web is arranged to form an efficient box structure, the webs are to have a

thickness not less than required by Table 3.2.8 Double plated rudder

construction, Item (4).

2.13.4 Adequate

hand or access holes are to be arranged in the rudder plating in way

of pintles as required, and the rudder plating is to be reinforced

locally in way of these openings. Continuity of the modulus of the

rudder mainpiece is to be maintained in way of the openings.

Table 3.2.8 Double plated rudder

construction

| Item

|

Requirement

|

|

(1) Side plating

|

|

|

(2) Webs - vertical and horizontal

|

|

|

(3) Top and bottom plates and nose plates

|

As (1) above

|

|

(4) Mainpiece

|

|

| Stress due to bending ≤ 78,0

N/mm2

|

|

|

|

|

| Symbols

|

|

A

a

|

= |

panel aspect ratio, but is not to be taken as greater

than 2,0 |

|

F

a

|

= |

1,0 for mild steel, 0,95 for aluminium alloy and 0,9

for stainless steel. Other materials will be specially

considered. |

|

y

w

|

= |

vertical spacing, in mm, of the horizontal webs or

arms, but is not to exceed 900 mm |

|

t

N

|

= |

thickness, in mm, of top and bottom plates and nose

plate |

|

tS |

= |

thickness, in mm, of side plating |

|

tW |

= |

thickness, in mm, of webs |

|

Figure 3.2.3 Semi-spade (mariner) type rudder

2.13.5 Connection

of rudder side plating to vertical and horizontal webs, where internal

access for welding is not practicable, is to be by means of slot welds

onto flat bars on the webs. The slots are to have a minimum length

of 75 mm and in general, a minimum width of twice the side plating

thickness. The ends of the slots are to be rounded. The space between

the slots is not to exceed 150 mm and welding is to be based on a

weld factor of 0,44.

2.13.7 Where

the fabricated mainpiece of a spade rudder is connected to the horizontal

coupling flange by welding, a full penetration weld is required.

2.14 Composite rudders

2.14.1 The requirements in this section are based on spade rudder constructions of composite

material with an aspect ratio not less than 3,0. Requirements for rudders with a

lesser aspect ratio will be specially considered. Requirements for rudders made from

a metal stock and composite blade will be specially considered. Requirements for

rudder arrangements with pintles will be specially considered.

2.14.2 The requirements in this section are based on construction using carbon/epoxy

composite but can be used for alternative constructions using other reinforcement

and matrix materials with due consideration for the properties of these

materials.

2.14.3 The requirements in this section are based on a structural arrangement with a single

stock of generally rectangular or trapezoid shape, extending from the upper bearing

through the lower bearing, down to not less than 0,75 times the height of the rudder

blade from the upper edge of the rudder blade. In this arrangement, the blade is

moulded around a core made of structural foam bonded to the fore and aft side of the

stock. The foam transfers the shear load to the stock. The bending in the horizontal

plane is taken by the skin of the blade.

2.14.4 The requirements are based on the stock being built from interleaved layers of

unidirectional fibres providing bending strength and biaxial fibres to provide

torsion and shear strength, wrapped around a foam core.

2.14.5 The limiting stress fraction, fσ, to be used in the

design is 0,25.

2.14.6 At and below the lower bearing, at any section along the length of the stock the

amount of biaxial material is to be sufficient to withstand the combined action of

shear load and torsion without exceeding the limiting stress fraction. The shear

load can be taken as:

|

Qbs |

= |

(fp/0.248)^3 *

(V+3)^2*Art*fR/10 kN |

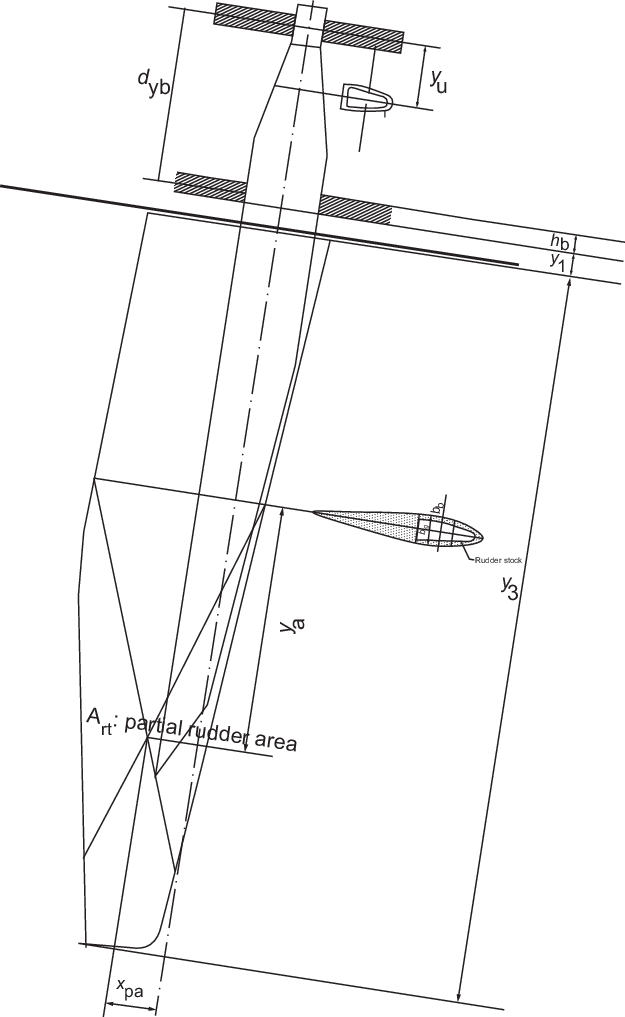

Where

|

Art |

= |

area of rudder blade between the position of the section and the lower

end of the rudder, in m2 |

The torsion can be taken as:

V, fp, fR

see

Table 3.2.5 Position of centre of

pressure

2.14.7 At and below the lower bearing, at any section along the length of the stock the

amount of unidirectional material is to be sufficient to withstand the combined

action of bending moment, shear load and torsion without exceeding the limiting

stress fraction. The bending moment can be taken as:

where

|

ya |

= |

distance between the position of the section and the centroid of the

rudder area below the section, in metres. |

2.14.8 At and above the lower bearing, at any section along the length of the stock the

amount of biaxial material is to be sufficient to withstand the combined action of

shear load and torsion without exceeding the limiting stress fraction. The position

of the tiller is to be considered.

The shear load to be considered can be taken as the reaction force in the upper bearing.

|

Fub |

= |

Qbl *

(y1+(y3+hb)/2)/dyb

kN |

where

-

y3 is defined as in Figure 3.2.1 Rudder types

-

Fbl is Qbs taken at the lower bearing

position.

-

dyb is the vertical distance centre to centre between the

upper and lower bearing.

-

hb is height of lower bearing.

The torsion load can be taken as the torsion load in way of the lower bearing.

2.14.9 At and above the lower bearing, at any section along the length of the stock the

amount of unidirectional material is to be sufficient to withstand the combined

action of bending moment, shear load and torsion without exceeding the limiting

stress fraction. The bending moment can be taken as:

where

|

yu |

= |

distance between the position of the section and the centroid of the

upper bearing, in metres. |

2.14.10 The laminate in way of the mounting position of the tiller is to be suitably

protected and reinforced where necessary to take the loads from the tiller.

2.14.11 The shear strength of the foam and the bonding to the stock are to be not less than:

|

qbs |

= |

(fp/0.248)^3 *

(V+3)^2*fR/10 *

bb/bs N/mm2

|

Figure 3.2.4 Composite rudder

dimensions

2.14.12 The laminate of the skin of the blade is determined by the envelope of the following

criteria:

- tensile stress due to load carried to stock

- compressive stress due to load carried from blade to stock

- wrinkling under this compressive stress

- minimal weight of reinforcement criterion as for shell laminate.

- below the lower end of the stock, strength required to support the part of the

blade below.

2.14.13 The lower end of the blade, extending below the stock, can be executed as a

sacrificial piece to save the stock in case of grounding.

2.15 Cast metal rudders

2.15.1 Where

rudders are cast, the mechanical and chemical properties of the metal

are to be submitted for approval. If the rudder stock is cast integral

with the rudder blade, abrupt changes of section and sharp corners

are to be avoided.

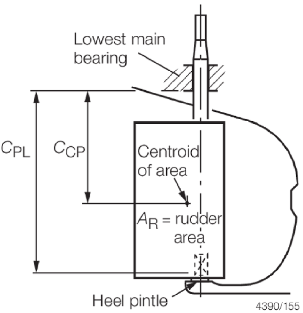

2.16 Lowest main bearing requirement

2.16.1 The design

of the lowest bearing is to comply with the requirements of Table 3.2.9 Lowest main bearing

requirements.

Table 3.2.9 Lowest main bearing

requirements

| Item

|

Requirement

|

| Lowest main

bearing

|

Depth Z

B, in mm

|

Minimum bearing

housing wall thickness, in mm

|

| 1,5d

s ≥ Z

B ≥ 1,0d

s

|

lesser of 0,2d

s or 100

|

| Bearing pressure (on the

projected area of the lowest main bearing), where the projected area is to

be taken as the length x diameter

|

Bearing

material

|

Maximum pressure, in

N/mm2

see Note 4

|

| Metal

|

7,0

|

| Synthetic

|

5.5

|

| Clearance in lowest main

bearing on the diameter (note should be taken of the manufacturer’s

recommended clearances, particularly where bush material requires

pre-soaking)

|

Bearing

material

|

Minimum

clearance, in mm

see Note 3

|

| Metal,

see Note 2

|

0,001d

s + 1,0

|

| Synthetic

|

0,002d

s + 1,0

but not less than 1,5

|

| Symbols

|

|

|

Note

1. Where web stiffening is fitted on the

bearing, a reduction in wall thickness will be considered.

Note

2. For bearings which are pressure

lubricated the clearance must be restricted to enable the pressure to

be maintained.

Note

3. Value of proposed minimum clearance is

to be indicated on plans submitted for approval.

Note

4. Proposals for higher pressures or

other materials will be specially considered on the basis of

satisfactory test results.

|

2.17 Bearings

2.17.1 Bearings are to be of approved materials and effectively secured to prevent

rotational and axial movement.

2.17.2 Where it is proposed to use stainless steel for liners or bearings for

rudder stocks and/or pintles, the chemical composition is to be submitted for approval.

Where the two surfaces are stainless steel materials, they should have suitable

resistance to galling. When stainless steel material is used, arrangements to ensure an

adequate supply of seawater to the bearing are to be provided to protect against

stagnant sea-water initiated corrosion.

2.17.3 Synthetic rudder bearing materials are to be of a type approved by LR.

2.17.4 When roller bearings are used on the rudder stock, the bearing must be of a size,

material and type suitable to sustain the loads from the rudder. Arrangement must be

made in the design to make them watertight.

2.18 Liners

2.18.1 Where

liners are fitted to rudder stocks or pintles, they are to be shrunk

on or otherwise efficiently secured.

2.18.3 When

stainless steel liners are used, arrangements to ensure an adequate

supply of sea-water to the liner are to be provided.

2.19 Pintles

2.19.2 Where

the lower pintle is housed above the rudder gudgeon see

Figure 3.2.5 Lower pintle housed above rudder gudgeon, and not below as shown

in Figure 3.2.6 Lower pintle housed below rudder gudgeon, C

PL is to be measured to the top of the gudgeon.

Figure 3.2.5 Lower pintle housed above rudder gudgeon

Table 3.2.10 Pintle requirements

| Item

|

Requirement

|

|

(1) Pintle diameter, see Note 2

|

|

| For

single pintle rudders and lower pintle of semi-spade rudders:

|

|

| but for

semi spade rudders need not be taken greater than A

R

|

| Upper

pintle on semi-spade rudders:

|

|

or 0,35A

R m2, whichever is the greater

|

| For

rudders with two or more pintles (except semi-spade rudders):

|

|

|

(2) Maximum pintle taper

|

Method of assembly

|

Taper (on diameter)

|

| Manual assembly, key fitted

|

1 in 6

|

| (pintle ≤ 200mm diameter)

|

| Manual assembly, key fitted

|

1 in 9

|

| (pintle ≤ 400mm diameter)

|

| For

keyed and other manually assembled pintles with diameters between 200mm and

400mm, the taper is to be obtained by interpolation.

|

| Hydraulic assembly, dry fit

|

1 in 12

|

| Hydraulic assembly, oil

injection

|

1 in 15

|

|

(3) Bearing length

|

Z

PB ≥ 1,2δPL mm

|

| May be

less for very large pintles if bearing pressure is not greater than that

given in (4), but Z

PB must not be less than 1,0δPL mm

|

|

(4) Bearing pressure (on projected area)

|

Bearing material

|

Pressure

|

| Metal

|

7,0

N/mm2

|

| Synthetic

|

5,5

N/mm2

|

| Using

force acting on bearing:

|

|

|

A

PL as for item (1)

|

|

(5) Gudgeon thickness in way of pintle (measured outside bush

if fitted)

|

but need not normally exceed 125mm

|

|

(6) Pintle clearance (note should be taken of the

manufacturer's recommended clearances particulary where bush material

requires pre-soaking). Value of proposed minimum clearance is to be

indicated on plans submitted for approval.

|

Bearing material

|

Minimum clearance, mm

|

| Metal

|

0,001δPL + 1,0

|

| Synthetic

|

0,002δPL + 1,0 but not

less than 1,5

|

| Symbols

|

|

δPL

|

= |

pintle diameter, in mm |

|

A

PL

|

= |

rudder area supported by the pintle, in m2

|

|

N

PL

|

= |

number of pintles on the rudder |

|

Z

PB

|

= |

pintle bearing length, in mm |

|

P

PL

|

= |

force acting on bearing, in kN |

|

b

G

|

= |

thickness of gudgeon material in way of pintle, in

mm |

|

Note

1. Proposals for higher pressures or

other materials will be specially considered on the basis of

satisfactory test results.

Note

2. The length of the pintle housing in

the gudgeon is not to be less than the maximum pintle diameter.

|

Figure 3.2.6 Lower pintle housed below rudder gudgeon

2.19.3 Special

attention is to be paid to the fit of the pintle taper into its socket.

To facilitate removal of the pintles, it is recommended that the taper

is to be not less than half the maximum value given in Table 3.2.10 Pintle requirements.

2.19.4 The distance

between the lowest rudder stock bearing and the upper pintle is to

be as short as possible.

2.19.5 Where

liners are fitted to pintles, they are to be shrunk on or otherwise

efficiently secured. If liners are to be shrunk on, the shrinkage

allowance is to be indicated on the plans. Where liners are formed

by stainless steel weld deposit, the pintles are to be of weldable

quality steel and details of the procedure are to be submitted.

2.19.6 The bottom

pintle on semi-spade (Mariner) type rudders are:

-

If inserted into

their sockets from below, to be keyed to the rudder or sternframe

as appropriate or to be hydraulically assembled, with the nut adequately

locked, or

-

If inserted into

their sockets from above, to be provided with an appropriate locking

device, the nut being adequately secured.

2.20 Bolted couplings

2.20.1 Rudder

coupling design is to be in accordance with Table 3.2.11 Rudder couplings to stock.

Table 3.2.11 Rudder couplings to stock

| Arrangement

|

Parameter

|

Requirement

|

| Horizontal

coupling

|

Vertical coupling

|

|

(1) Bolted couplings (see Notes)

|

n

|

≥

6

|

|

≥ 8

|

| δb

|

|

|

|

|

m

|

0,00071nd

Sδb

2

|

|

0,00043d

s

3

|

|

t

f

|

δb

see Note 1

|

|

δb

|

αmax

see Note 2

|

|

-

|

αas built

see Note 2

|

≤ αmax

|

-

|

|

w

f

|

0,67δb

|

|

0,67δb

|

|

(2) Conical couplings

|

θt

|

|

|

l

t

|

≥1,5d

s

|

|

|

|

|

w

|

|

|

P

u

|

Approximately equal to

|

|

P

o

|

Approximately equal to

|

|

σ

o

|

|

| Symbols

|

|

n

|

= |

number of bolts in coupling |

|

|

δb

|

= |

diameter of coupling bolts, in mm |

|

|

|

|

m

|

= |

first moment of area of bolts about centre of

coupling, in cm3

|

|

|

k

1

|

= |

the greater of k

s and k

f

|

|

|

|

|

|

|

|

|

R

|

= |

palm radius between rudder stock and connected flange,

not smaller than  , in mm , in mm |

|

|

t

f

|

= |

minimum thickness of coupling flange, in mm |

|

|

t

fa

|

= |

as built flange thickness, in mm |

|

|

αmax

|

= |

maximum allowable stress concentration factor |

|

|

αas built

|

= |

stress concentration factor for as built

scantlings |

| = |

|

|

|

w

f

|

= |

width of flange material outside the bolt holes, in

mm |

|

|

θ

t

|

= |

taper of conical coupling, on the diameter,

e.g.: |

| = |

|

|

t

t

|

= |

length of taper, in mm |

|

|

= |

required mean grip stress, in N/mm2

|

|

|

w

|

= |

corresponding push-up of rudder stock, in mm |

|

|

P

u, P

o

|

= |

corresponding push-up, pull-off loads respectively,

in N |

|

|

σo

|

= |

minimum yield stress of stock and gudgeon material,

in N/mm2. σo is not to be taken greater than

70 per cent of the ultimate tensile strength |

|

R

R

|

= |

effective weight of rudder, in N |

|

|

= |

mean diameter of coupling taper, in mm |

|

|

= |

diameter of coupling taper at any position, in

mm |

|

|

= |

mean external diameter of gudgeon housing, in mm |

|

|

= |

external diameter of gudgeon housing at any position,

in mm |

|

|

= |

|

|

|

f

|

= |

|

|

|

M

T

|

= |

maximum torque applied to stock, and is to be taken

as the greater of M

F, M

A or M

W. |

|

|

M

F

|

= |

P

L

X

PF x 106 Nmm in the ahead condition |

|

|

M

A

|

= |

P

L

X

PA x 106 Nmm in the astern condition |

|

|

M

W

|

= |

the torque generated by the steering gear at the

maximum working pressure supplied by the manufacturer, in Nmm.

M

W is not to exceed the greater of 3,0M

F or 3,0M

A

|

|

|

|

|

|

|

K

1, K

2, K

3

|

= |

constants depending on the type of assembly adopted as

follows: |

|

|

|

K

1

|

K

2

|

K

3

|

|

|

Oil injection

method

|

with

key

|

15

|

0,0064

|

0,025

|

|

|

Oil injection

method

|

without

key

|

15

|

0,0036

|

0,025

|

|

|

Dry fit method

|

with

key

|

12

|

0,0128

|

0,170

|

|

|

Dry fit method

|

without

key

|

12

|

0,0072

|

0,170

|

Note

1. For spade rudders with horizontal

coupling, t

f is not to be less than 0,25d

s.

Note

3. Where materials vary for individual

components, scantling calculations for such components are to be based

on d

s for the relevant material.

|

2.20.2 Where

coupling bolts are required they are to be fitted bolts. Suitable

arrangements are to be made to lock the nuts.

2.20.3 For rudders

with horizontal coupling arrangements, where the upper flange is welded

to the rudder stock, a full penetration weld is required and its integrity

is to be confirmed by non-destructive examination. Such rudder stocks

are to be subjected to a furnace post-weld heat treatment (PWHT) after

completion of all welding operations. For carbon or carbon manganese

steels, the PWHT temperature is not to be less than 600oC.

2.20.4 The connecting

bolts for coupling the rudder to the rudder stock are to be positioned

with sufficient clearance to allow the fitting and removal of the

bolts and nuts without contacting the palm radius, R, see

Figure 3.2.7 Rudder stock connection. The

surface forming the palm radius is to be free of hard and sharp corners

and is to be machined smooth to the Surveyor's satisfaction. The surface

in way of bolts and nuts is to be machined smooth to the Surveyor's

satisfaction.

2.20.5 For spade

rudders fitted with a fabricated rectangular mainpiece, the mainpiece

is to be designed with its forward and aft transverse sections at

equal distances forward and aft of the rudder stock transverse axis, see

Figure 3.2.7 Rudder stock connection.

2.21 Conical couplings

2.21.1 Where

a rudder stock is connected to a rudder by a keyless fitting, the

rudder is to be a good fit on the rudder stock cone. During the fit-up,

and before the push-up load is applied, an area of contact of at least

80 per cent of the theoretical area of contact is to be achieved,

and this is to be evenly distributed. The relationship of the rudder

to stock at which this occurs is to be marked, and the push-up then

measured from that point. The upper edge of the upper mainpiece bore

is to have a slight radius. After final fitting of the stock to the

rudder, positive means are to be used for locking the securing nut

to the stock.

2.21.2 Where

a keyed tapered fitting of a rudder stock to a rudder is proposed,

a securing nut of adequate proportions is to be provided. After the

final fitting of the stock to the rudder, positive means are to be

used for locking this nut.

2.22 Rudder carrier arrangements

2.22.1 The weight

of the rudder is to be supported at the heel pintle or by a carrier

attached to the rudder head. The hull structure supporting the carrier

bearing is to be adequately strengthened. The plating under all rudder-head

bearings or rudder carriers is to be increased in thickness.

2.23 Anti-jump collars

2.23.1 Suitable

arrangements are to be provided to prevent the rudder from lifting.

2.23.2 Jumping

collars are not to be welded to the rudder stock.

2.24 Drain plugs

2.24.1 Where

rudders are of plated construction, drain plugs are to be provided

to ensure that all compartments can be adequately drained. These plugs

are to be locked and details of their scantlings, arrangements and

position clearly indicated on the rudder plan.

2.25 Corrosion protection

2.25.1 All metalwork

is to be suitably protected against corrosion. This may be by coating

or, where applicable, by a system of cathodic protection, see

Ch 15 Corrosion Prevention of the Rules for Materials.

2.25.2 Metalwork

is to be suitably cleaned before the application of any coating. Where

appropriate, blast cleaning or other equally effective means are to

be employed for this purpose.

2.26 Dissimilar materials

2.26.1 Where

materials vary for individual components, they are to be compatible

to avoid galvanic corrosion. Scantling calculations for the components

are to be based on d

s for the relevant material, see

Table 3.2.6 Rudder stock diameter.

2.27 Internal coatings

2.27.1 Internal

surfaces of the rudder are to be efficiently coated or the rudder

is to be filled with foam plastics. Where it is intended to fill the

rudder with plastic foam, details of the foam are to be submitted.

2.28 Pressure testing

2.29 Tiller arms, quadrants

2.29.2 The steering

gear is to be mounted on a seat and adequately secured.

2.30 Connecting bars

2.31 Keys and keyways

2.31.1 Where

the tiller or quadrant is bolted, a key having an effective cross-sectional

area in shear of not less than 0,25d

SU

2 mm2 is to be fitted. The thickness of the key is to be not less

than d

SU/6 mm. Alternatively, the rudder stock

may be machined to a square section in lieu of fitting a key. d

SU is as defined in Table 3.2.6 Rudder stock diameter.

2.31.2 Keyways

are to extend over the full depth of the tiller boss.

2.31.3 Keyways

in the rudder stock are to have rounded ends and the corners at the

base of the keyway are to be radiused.

2.32 Stopping arrangements

2.32.1 Suitable

rudder stops are to be provided to limit the rudder angle to the desired

level port and starboard. These stops are to be of substantial construction

and efficiently connected to the supporting structure.

2.33 Novel designs

2.33.1 Where

rudders are of a novel design they may be specially considered on

the basis of the Rules. Alternatively the Builder's/designer's calculations

are to be submitted for consideration.

2.34 FRP double plated rudders

2.34.1 FRP double plated rudders are to have an internal structure of suitable strength and

material. Details of the rudder are to be submitted to LR for approval.

2.34.2 Where rudder blades are moulded in halves they are to be effectively joined together by

means of external overbonding of the joint or suitable mechanical fastening or

equivalent.

2.34.3 The internal structure of FRP double plated rudders may be a metallic framework. It is

to be made up of a mainpiece fitted with arms, within the blade, or an equivalent

arrangement. Both halves of the rudder blade moulding are to be effectively connected to

the metallic framework and mainpiece by either mechanical means or suitable bonded

connection.

2.34.4 When the internal structure of the FRP double plated rudder is metallic or of a

material that may detach from the blades at the point where the structure extends

outside the rudder blade, a suitable seal is to be provided to avoid ingress of

water.

2.34.5 Rudders

are to be filled with a suitable material upon completion of the join

up, details of the filler material are to be submitted.

2.34.6 The diameter

of the top of the rudder mainpiece must not be less than that of the

rudder stock. For spade rudders this diameter may be gradually reduced

for the lower third to not less than 75 per cent of the rudder stock

diameter.

2.34.7 The rudder

arms are to be efficiently attached to the mainpiece.

2.34.8 The laminate

weight of moulded fibre reinforced plastics double plate rudders is

to be determined by direct calculation, subject to a minimum laminate

thickness of 5 mm.

2.35 Rudder tube arrangements

2.35.1 The rudder

tube construction may be of aluminium alloy, steel, bronze or fibre

reinforced plastic.

2.35.2 The scantlings

of rudder tubes will be individually considered.

2.35.3 For steel

and aluminium hulls, the bottom shell in way of the rudder tubes is

to be additionally reinforced by means of an insert plate to increase

the bottom shell thickness by 50 per cent.

2.35.4 For F.R.P

hulls, the bottom shell laminate in way of the rudder tubes is to

be locally increased by 50 per cent. The increased thickness in way

of the rudder tube need not exceed the rule keel thickness requirement.

2.35.5 For F.R.P

sandwich hulls the shell in way of the rudder tube connection is to

be either:

-

Reduced from the

sandwich hull construction to single skin laminate for a distance

of a least three times the rudder tube diameter about the rudder stock

axis. The single skin region is to be additionally reinforced by a

minimum of 50 per cent of the sum of the inner and outer sandwich

laminate subject to this being at least equivalent to a 50 per cent

increase in thickness of the Rule minimum bottom shell laminate for

a single skin F.R.P. craft of the equivalent Rule length L

R. The reinforced laminate need not be greater than the Rule

keel laminate thickness.

-

Reduced from the

sandwich hull construction to a single skin laminate for a distance

of three times the rudder tube diameter about the rudder stock axis.

After bonding in the rudder tube to the single skin laminate the foam

core and inner skin are then reinstated.

-

Proposals to replace

the sandwich core with a core having higher core shear strength and

compressive strength than that of the adjacent structure prior to

bonding the tube to the inner and outer skins will be the subject

of special consideration.

2.35.6 The rudder

tube may be connected to the shell by bonding, bolting or welding

as applicable depending upon the construction material of the shell.

2.35.7 When

bonding in rudder tubes the bonding angle is to be not less than the

Rule minimum bottom shell weight. F.R.P. tubes are to be thoroughly

abraded and degreased prior to installation and laminating. Bonded

in metallic tubes are to be knurled in way of the bonding material

and thoroughly degreased prior to installation.

2.35.8 Where

rudder tubes are to be retained by bolting they are to be provided

with a substantial flange securely attached to the hull structure.

Where bolts are used, the nuts are to be suitably locked.

2.35.9 Where

rudder tubes are to be welded to hull insert plates full penetration

welding is required.

2.35.10 Rudder

tubes are to be supported by suitable brackets and deep floors to

avoid hard spots on the shell and to ensure continuity of the main

hull structure.

2.35.11 Rudder

bearings are to be secured against rotation within the rudder tubes

by suitable pinch bolting or keys. Details are to be submitted for

approval.

2.36 Watertight arrangement

2.36.1 In rudder trunks which are open to the sea, a seal is to be fitted above the

deepest load waterline, to prevent water from entering the steering gear compartment and

the lubricant from being washed away from the rudder carrier. If the top of the rudder

trunk is below the deepest waterline two separate seals are to be provided. Rudder trunk

boundaries, where exposed to the sea, are to have a corrosion protection coating applied

in accordance with the manufacturer's instructions.

2.36.2 Lip seals or 'O' rings may be used either in isolation or in combination

with one or other of the seal arrangements.

2.36.3 A watertight gland body may be used. It is then to be formed by the top of

the fabricated or cast rudder tube, the gland packing being retained against the top

bearing or a check in the wall of the rudder tube and is compressed by a gland packet

which may be of the flange type, screwed cap or other suitable arrangement.

2.37 In-water Survey requirements

2.37.1 Where

an *IWS (In-water Survey) notation is to be assigned, see

Pt 1, Ch 2, 3.8 Other hull notations, means

are to be provided for ascertaining the rudder pintle and bush clearances

and for verifying the security of the pintles in their sockets with

the craft afloat.

|