Section

2 Structural design

2.1 General

2.1.2 For

derivation of scantlings of stiffeners, beams, girders, etc. the formulae

in the Rules are normally based on elastic or plastic theory using

simple beam models supported at one or more points and with varying

degrees of fixity at the ends, associated with an appropriate concentrated

distributed load.

2.1.3 The

stiffener, beam or girder strength is defined by a section modulus

and moments of inertia requirements. In addition there are local requirements

for web thickness and flange thickness.

2.2 Effective width of attached plating

2.2.1 For

stiffening members, the geometric properties of rolled or built sections

are to be calculated in association with an effective area of attached

load bearing plating of thickness, t

p, in

mm and an effective breadth, t

p in mm.

2.2.2 The

effective breadth of attached plating to secondary stiffener members b

e, in mm, is to be taken as the lesser of:

-

The actual spacing

of the stiffeners, b, and

-

The greater of

40t

p and 600 mm

-

The effective

breadth of attached plating to primary support members (girders, transverses,

webs, etc.) is to be taken as follows:

but is not to exceed S

S and l are defined in Vol 1, Pt 6, Ch 1, 1.3 Symbols and definitions.

2.3 Section properties

2.3.1 The

effective geometric properties of rolled or built sections are to

be calculated directly from the dimensions of the section and associated

effective area of attached plating. Where the web of the section is

not normal to the actual plating, and the angle exceeds 20°, the

properties of the section are to be determined about an axis parallel

to the attached plating.

2.3.2 If applicable,

idealised section properties may be calculated as described in the

Complementary Rules.

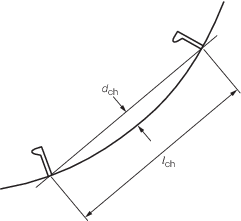

2.4 Convex curvature correction

2.4.1 The

thickness of plating as determined by the Rules may be reduced where

significant curvature exists between the supporting members. In such

cases a plate curvature correction factor may be applied:

see

Figure 2.2.1 Convex curvature

Figure 2.2.1 Convex curvature

2.4.2 The

required section modulus of transverse main and ‘tween deck

frames, which have reasonably constant convex curvature over their

entire length, may be corrected for curvature as follows:

2.5 Aspect ratio correction

2.5.1 The

thickness of plating as determined by the Rules may be reduced when

the panel aspect ratio is taken into consideration. In such cases

a panel aspect ratio correction factor may be applied:

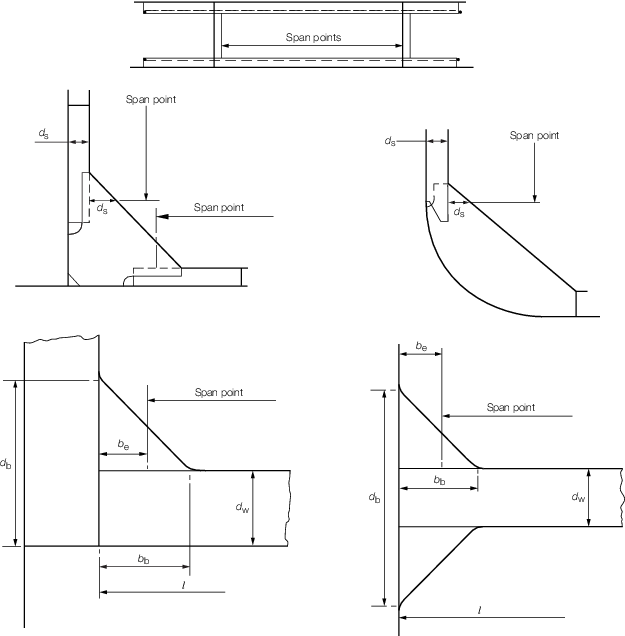

2.6 Determination of span length

2.6.1 The

effective length, l

e, of a stiffening member

is generally less than the overall length, l, by an amount

which depends on the design of the end connections. The span points,

between which the value of l

e is measured

are to be determined as follows:

-

For rolled

or built secondary stiffening members: The span point is to

be taken at the point where the depth of the end bracket, measured

from the face of the member, is equal to the depth of the member.

Where there is no end bracket, the span point is to be measured between

primary member webs. For double bottom construction the span may be

reduced by the depth of primary member web stiffener, see

Figure 2.2.2 Definition of span points.

-

For primary

support members: The span point is to be taken at a point distant

from the end of the member,

Figure 2.2.2 Definition of span points

2.7 Proportions of stiffener sections

2.8 Grillage structures

2.8.1 For

complex girder systems, a complete structural analysis using numerical

methods may have to be performed to demonstrate that the stress levels

are acceptable when subjected to the most severe and realistic combination

of loading conditions intended.

2.8.2 General

or special purpose computer programs or other analytical techniques

may be used provided that the effects of bending, shear, axial load

and torsion are properly accounted for and the theory and idealisation

used can be justified.

2.8.3 In general,

grillages consisting of slender girders may be idealised as frames

based on beam theory provided proper account of the variations of

geometric properties is taken. For cases where such an assumption

in not applicable, finite element analysis or equivalent methods may

have to be used.

2.9 Detail design

2.9.1 Items

such as details of end connections and scantlings of end brackets

are to be in compliance with the Complementary Rules.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|