Section

16 Longitudinal strength calculations

16.1 Longitudinal extent of strength assessment

16.1.1 The stiffness, yield strength, buckling strength and hull girder strength

assessment are to be carried out with due consideration given to locations where

there are significant changes in the hull cross-section.

16.2 Symbols

16.2.1 The symbols used in this Section are defined as follows:

|

Cw |

= |

Waterplane coefficient at scantling draught T, to be taken as:

|

|

Aw |

= |

Waterplane area at scantling draught T, in m2 |

|

E |

= |

Modulus of elasticity, in N/mm2 |

|

Ms |

= |

Design still water bending moment, sagging (negative) and hogging

(positive), in kNm |

|

= |

Maximum permissible still water bending moment, sagging (negative) and

hogging (positive), in kNm, to be taken negative or positive according

to the convention given in Pt 3, Ch 4, 5.3 Design still water bending moments 5.3.2 |

|

Mw |

= |

Design hull vertical wave bending moment, sagging (negative) and hogging

(positive), in kNm, to be taken negative or positive according to the

convention given Pt 3, Ch 4, 5.3 Design still water bending moments 5.3.2 |

|

MU |

= |

Hull girder ultimate bending moment capacity, in kNm |

|

Qs |

= |

Design hull still water shear force, in kN, to be taken as

negative or positive according to the convention given in Pt 3, Ch 4, 6.4 Design still water shear force 6.4.2

|

|

= |

Permissible hull still water shear force, in kN. |

|

Qw |

= |

Design hull wave shear force, in kN, to be taken as

negative or positive according to the convention given in Pt 3, Ch 4, 6.4 Design still water shear force 6.4.2 |

|

qv |

= |

Shear flow along the cross-section under consideration |

|

Inet |

= |

Net vertical hull girder moment of inertia at the

cross-section under consideration, in m4, to be determined

using net scantlings as defined in Table 8.16.3 Combination of still water and wave bending moments and shear forces |

|

σHG |

= |

Hull girder bending stress, in N/mm2 |

|

τHG |

= |

Hull girder shear stress, in N/mm2 |

|

z |

= |

Vertical co-ordinate of location under consideration, in m |

|

zn |

= |

Distance from baseline to the horizontal neutral axis, in m |

16.3 Corrosion margin and net thickness

16.3.1 The strength is to be assessed using the net thickness approach for all

scantlings.

16.3.2 The net thickness of the plates, webs and flanges is obtained as follows:

|

tnet |

= |

tas_built-tvol_add-αtc |

Table 8.16.1 Values of corrosion addition factor

| Structural requirement

|

Property/analysis type

|

Corrosion

addition factor, α

|

| Strength

assessment

|

Section

properties

|

0,5

|

| Buckling strength

|

Section

properties (stress determination)

|

0,5

|

| Buckling

capacity

|

1,0

|

| Hull girder ultimate strength

|

Section

properties

|

0,5

|

| Buckling/collapse capacity

|

0,5

|

16.3.3 Where voluntary additions are to be applied, they are to be clearly indicated on the

plans.

16.3.4 The total corrosion addition for both sides of a structural member is obtained as follows:

Where:

16.3.5 For an internal member within a given compartment, the total corrosion addition is

obtained as follows:

16.3.6 The corrosion addition of a stiffener is to be determined based on the compartment in

which it is located, see

Pt 4, Ch 8, 16.3 Corrosion margin and net thickness 16.3.6

Table 8.16.2 Corrosion addition for one side of a structural member

| Compartment type

|

One side

corrosion addition tc or tc2

in mm

|

| Exposed to

sea water

|

1,0

|

| Exposed to

atmosphere

|

1,0

|

| Ballast

water tank

|

1,0

|

| Void and dry

spaces

|

0,5

|

| Fresh water,

fuel oil and lube oil tank

|

0,5

|

| Accommodation spaces

|

0,0

|

| Container

holds

|

1,0

|

| Compartment

types not mentioned above

|

0,5

|

16.3.8 The net cross-sectional area, the moment of inertia about the axis parallel to the

attached plate and the associated neutral axis are to be determined through applying

a corrosion magnitude of deducted from the surface of the profile cross-section.

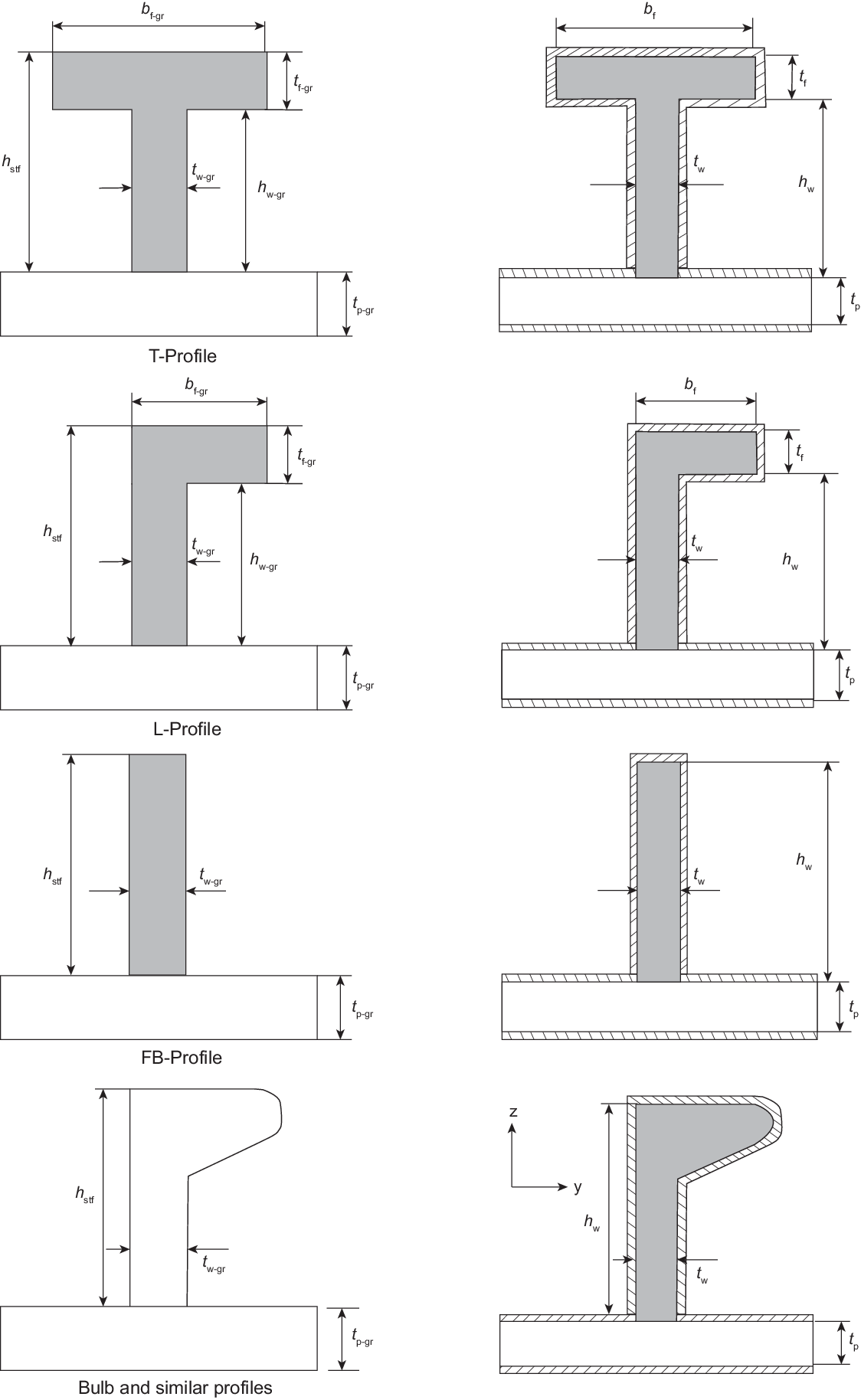

Figure 8.16.1 Net sectional properties of

supporting members

16.4 Permissible still water bending moments and shear forces

16.4.1 The permissible still water bending moments,

Ms in kNm, and still water shear

forces, Qs in kNm, are to be

calculated at each section along the ship’s length

for design loading conditions as specified in Pt 3, Ch 4, 5.3 Design still water bending moments.

16.5 Hull moment of inertia

16.6 Design vertical wave bending moments

16.6.1 The appropriate hogging or sagging design hull vertical wave bending

moment, at any position along the ship, may be taken as follows:

|

Mw |

= |

|

Where:

f1 is the ship service factor, to be taken as 0,85

CW and C3 are given in Pt 4, Ch 8, 16.2 Symbols 16.2.1 and Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.2 respectively

f2 is the hogging,ffH , or the sagging,

ffS correction factor

ffH is the hogging (positive) moment correction factor and is to be

taken as:

|

ffH |

= |

not to be taken greater than 1,1 not to be taken greater than 1,1 |

ffS is the sagging (negative) moment correction factor and is to be

taken as:

|

ffS |

= |

, not to be taken less than 1,0 , not to be taken less than 1,0 |

fbow and Kf are given in Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.3 and Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.4 respectively

Kf is given in Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.4

B and L are given in Pt 4, Ch 8, 1.5 Symbols and definitions

16.6.2 The wave parameter, C3, is to be taken as:

|

C3 |

= |

|

|

C3 |

= |

|

Where:

|

L4 |

= |

|

16.6.3 The bow flare shape, fbow coefficient is to be taken as:

|

fbow |

= |

|

Where:

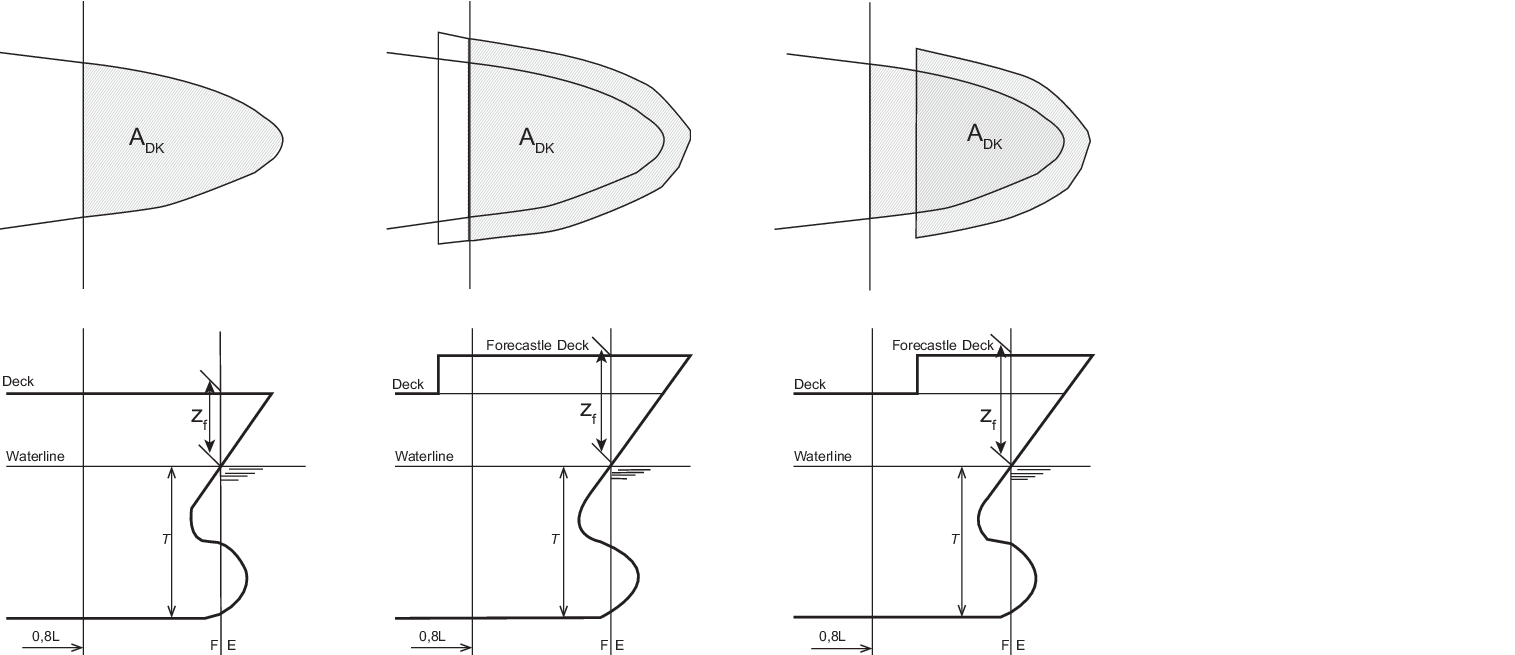

- ADK is the projected area in the horizontal

plane of the uppermost deck, in m2, including the forecastle

deck, if any, forward of 0,8L from the AP, see also

Figure 8.16.2 Projected area ADK and vertical distance zf. Any other structures, e.g. plated bulwark,

are to be excluded.

- AWLis the waterplane area, in m2, at draught

T, forward of 0,8L from the AP

- zf is the vertical distance, in m, from the

waterline at draught T, to the uppermost deck at side (or forecastle deck),

measured at the FP, see also

Figure 8.16.2 Projected area ADK and vertical distance zf. Any other structures, e.g. plated bulwark,

are to be excluded.

Figure 8.16.2 Projected area ADK and vertical distance zf

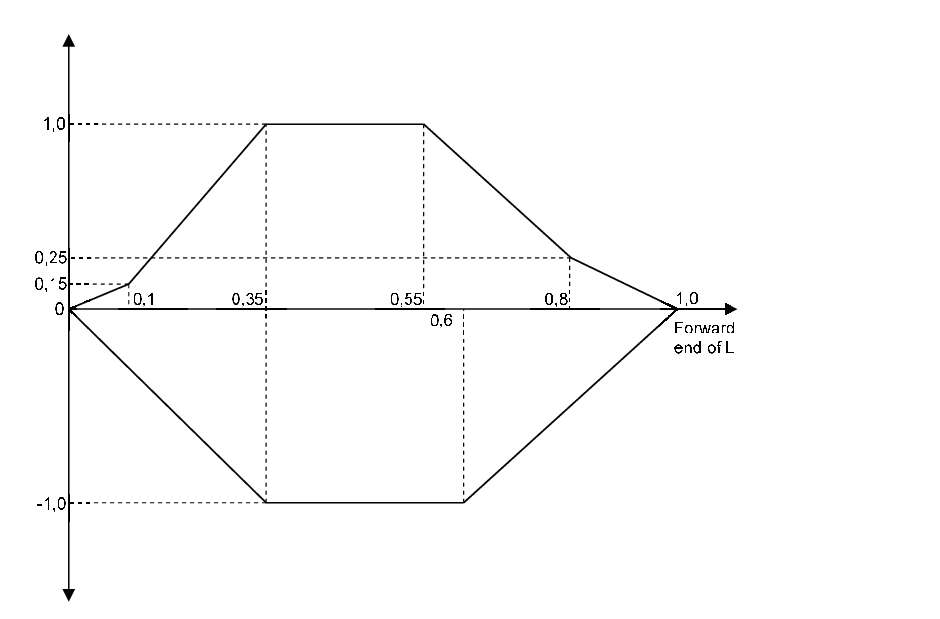

16.6.4 The distribution of the vertical wave bending moment, Kf , is to be

taken as:

- Hogging (positive) moments, see also Figure 8.16.3 Distribution of vertical wave bending moment Mw along the ship

length

|

Kf |

= |

0 at aft end of L |

| = |

0,15 at 0,1 L

|

| = |

1,0 between 0,35 L and 0,55 L

|

| = |

0,25 at 0,8 L

|

| = |

0 at forward end of L

|

- Sagging (negative) moments, see also Fig 8.16.3

|

Kf |

= |

0 at aft end of L |

| = |

-1,0 between 0,35 L and 0,6 L |

| = |

0 at forward end of L |

Intermediate values are to be obtained by linear interpolation.

Figure 8.16.3 Distribution of vertical wave bending moment Mw along the ship

length

16.7 Design vertical wave shear force

16.7.1 The design hull wave shear force, Qw , at any position

along the ship is to be taken as:

|

Qw |

= |

|

Where:

|

f1 |

= |

ship service factor, to be taken as 0,85 |

Cw, C3 and Kf are

defined in Pt 4, Ch 8, 16.2 Symbols, Pt 4, Ch 8, 16.7 Design vertical wave shear force 16.7.2

and Pt 4, Ch 8, 16.7 Design vertical wave shear force 16.7.3

respectively B and L are given in Pt 4, Ch 8, 1.5 Symbols and definitions 1.5.1

16.7.2 The wave parameter, C3, is to be taken as:

|

C3 |

= |

|

|

C3 |

= |

|

Where:

|

L4 |

= |

|

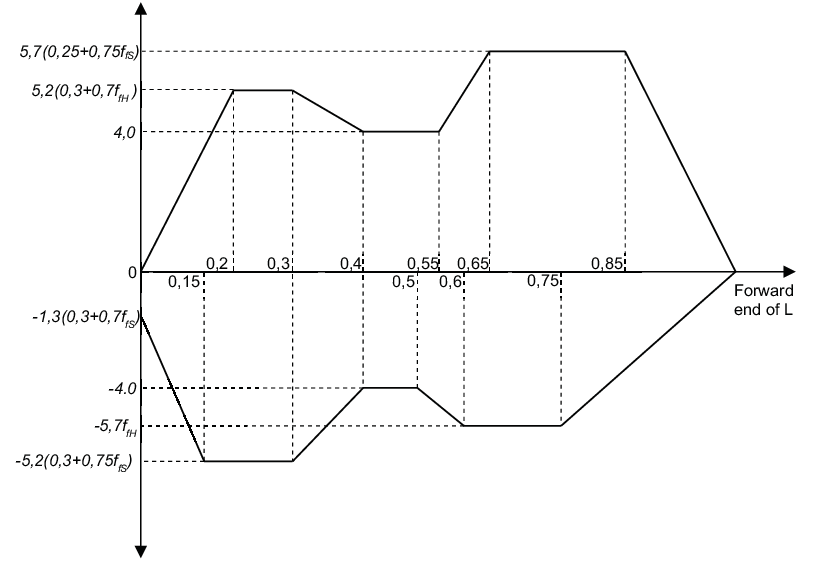

16.7.3 The distribution of the wave shear force, Kf , is to

be taken as follows, see also Figure 8.16.4 Distribution of vertical shear force Qw along the ship

length.

- Positive shear force

|

Kf |

= |

0 at aft end of L |

|

Kf |

= |

5,2(0,3 + 0,7 ffH) between 0,2

L and 0,3 L |

|

Kf |

= |

4,0 between 0,4 L and 0,55 L |

|

Kf |

= |

5,7 (0,25 + 0,75 ffS) between

0,65 L and 0,85 L |

|

Kf |

= |

0 at forward end of L |

- Negative shear force

|

Kf |

= |

–1,3(0,3 + 0,7 ffS) at aft end of

L |

|

Kf |

= |

–5,2(0,3 + 0,7 ffS) between 0,15

L and 0,3 L |

|

Kf |

= |

-4,0 between 0,4 L and 0,5 L |

|

Kf |

= |

-5,7 ffH between 0,6 L and

0,75 L |

|

Kf |

= |

0 at forward end of L |

Intermediate values of Kf to be obtained by linear

interpolation.

ffH and ffS are as defined in Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.1.

Figure 8.16.4 Distribution of vertical shear force Qw along the ship

length

16.8 Permissible hull girder stresses

16.8.1 The permissible combined (still water plus wave) stress for hull vertical

bending, σ , is given by:

|

σ |

= |

|

16.8.2 The permissible shear stress, τ , is given by:

|

τ |

= |

|

16.9 Hull girder stresses

Where:

Qw and Qs are defined in Table 8.16.3 Combination of still water and wave bending moments and shear forces.

γ s, γ w are partial safety factors to be taken as:

-

qv is calculated in accordance with the ShipRight

Procedure Additional calculation procedures for longitundinal

strength

Table 8.16.3 Combination of still water and wave bending moments and shear forces

| Load

case

|

Bending moment

|

Shear force

|

| Still water,

Ms

|

Wave,

Mw

|

Location,

x

|

Still water,

Qs

|

Wave,

Qw

|

| Hogging

|

M

smax

|

M

wmax

|

|

Qsmax

|

Qwmax

|

|

Qsmin

|

Qwmin

|

| Sagging

|

M

smin

|

M

wmin

|

|

Qsmin

|

Qwmin

|

|

Qsmax

|

Qwmax

|

| Symbols

|

| Msmax = positive still water bending moment

at the cross-section under consideration

|

| Msmin = negative still water bending moment

at the cross-section under consideration

|

| Mwmax = wave bending moment at the

cross-section under consideration, to be taken as the positive value

of Mw as defined in Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.1

|

| Mwmin = wave bending moment at the

cross-section under consideration, to be taken as the negative value

of Mw as defined in Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.1

|

| Qsmax = positive still water shear force at

the cross-section under consideration

|

| Qsmin = negative still water shear force at

the cross-section under consideration taken as

|

| Qwmax = maximum value of the wave shear force

at the cross-section under consideration, to be taken as the

positive value of Qw as defined in Pt 4, Ch 8, 16.7 Design vertical wave shear force 16.7.1

|

| Qwmin = minimum value of the wave shear force

at the cross-section under consideration, to be taken as the

negative value of Qw as defined in Pt 4, Ch 8, 16.7 Design vertical wave shear force 16.7.1

|

| x =

longitudinal coordinate or a location under consideration

|

16.10 Buckling strength assessment

16.10.1 The following requirements apply to plate panels and longitudinal

stiffeners subject to hull girder bending and shear stresses.

16.10.2 The acceptance criteria for the buckling assessment are defined as follows:

Where:

- ηact is the maximum utilisation factor

16.10.3 The utilisation factor, η act, is given by:

|

ηact |

= |

|

16.10.4 Failure state limits are defined in ShipRight Procedure Additional

calculation procedures for longitudinal strength for the following items:

- Elementary plate panels

- Overall stiffened panels

- Longitudinal stiffeners

Each failure limit state is defined by an equation and, γc, is to be

determined such that it satisfies the equation.

16.10.6 The following two stress combinations are to be considered for each of

the load cases defined in Pt 4, Ch 8, 16.9 Hull girder stresses 16.9.1. The stresses are

to be derived at the load calculation points defined in Pt 4, Ch 8, 16.10 Buckling strength assessment 16.10.7 and Pt 4, Ch 8, 16.10 Buckling strength assessment 16.10.8

- Longitudinal framing

Stress combination 1

with:

|

σx |

= |

σHG |

|

σy |

= |

0 |

|

τ |

= |

0,7 τHG |

Stress combination 2 with:

|

σx |

= |

0,7 σHG |

|

σy |

= |

0 |

|

τ |

= |

τHG |

- Transverse framing

Stress combination 1 with:

|

σx |

= |

0 |

|

σy |

= |

σHG |

|

τ |

= |

0,7 τHG |

Stress combination 2 with:

|

σx |

= |

0 |

|

σy |

= |

0,7 σHG |

|

τ |

= |

τHG |

16.10.8 The hull girder stresses for longitudinal stiffeners are to be calculated at the

following load calculation points:

- At the mid length of the stiffener under consideration

- At the intersection point between the stiffener and its attached

plate

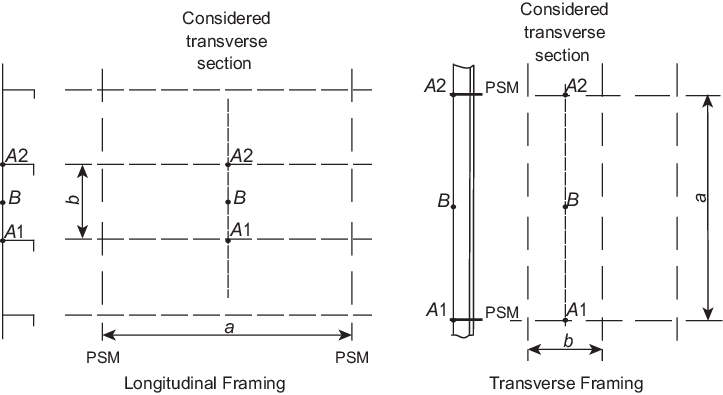

Table 8.16.4 Load calculation points

(LCP) for plate buckling assessment

| LCP coordinates

|

Hull girder bending stress

|

Hull girder shear stress

|

| x coordinate

|

Mid length of the elementary

plate panel (EPP)

|

| y coordinate

|

Both upper and lower ends of the EPP, points A1 and

A2 in Figure 8.16.

|

Mid-point of EPP, point B in Figure 8.16.

|

| z coordinate

|

Distance from baseline to

load calculation point

|

Figure 8.16.6 Load calculation points

for plate buckling

16.11 Hull girder ultimate strength

16.11.1 The hull girder ultimate strength assessment is to be carried out for

ships with a length L greater than or equal to 150 m.

16.11.3 The hull girder ultimate bending capacity,MU , is

defined as the maximum bending moment capacity of the hull girder beyond which the

hull structure collapses.

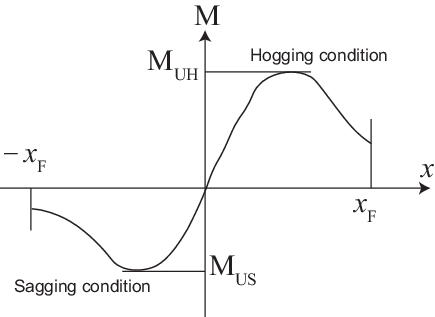

16.11.5 The ultimate bending moment capacities of a hull girder transverse

section, in hogging and sagging conditions, are defined as the maximum values of the

curve of bending moment M versus the curvature Χ of the transverse

section considered

16.11.6 The hull girder ultimate bending capacity, MU, is to

be calculated using the incremental-iterative method as given in Chapter 4 of

ShipRight Procedure Additional calculation procedures for longitudinal

strength.

16.11.7 The vertical hull girder bending moment, M in hogging and sagging conditions,

to be considered in the ultimate strength check is to be taken as:

Where:

|

Ms |

= |

permissible still water bending moment, in kNm, as defined

in Pt 4, Ch 8, 16.4 Permissible still water bending moments and shear forces 16.4.1 |

|

Mw |

= |

vertical wave bending moment, in kNm, as defined in Pt 4, Ch 8, 16.6 Design vertical wave bending moments 16.6.1

|

|

γs

|

= |

partial safety factor for the still water bending moment, to be taken as

1,0 |

|

γw |

= |

partial safety factor for the vertical wave bending moment, to be taken

as 1,2 |

16.11.8 The hull girder ultimate bending capacity at any hull transverse section is to

satisfy the following criteria:

Where:

|

M |

= |

vertical bending moment, in kNm, as defined in Pt 4, Ch 8, 16.11 Hull girder ultimate strength 16.11.7 |

|

MU |

= |

hull girder ultimate bending moment capacity, in kNm, as

defined in Pt 4, Ch 8, 16.11 Hull girder ultimate strength 16.11.6

|

|

γM |

= |

partial safety factor covering material, geometric and strength

prediction uncertainties, to be taken as 1,05 |

|

γDB |

= |

partial safety factor covering the effect of double bottom bending, to

be taken as:

|

γDB |

= |

1,15 for hogging condition |

|

γDB |

= |

1,0 for sagging condition |

|

- For cross-sections where the double bottom breadth of the inner bottom is

less than that at amidships or where the double bottom structure differs

from that at amidships (e.g. engine room sections), the factor,

γDB, for the hogging condition may be specially

considered.

Figure 8.16.7 Bending moment M versus curvature Χ

|