Section

4 Global strength assessment

4.1 General

4.1.1 The verification of the stress level, buckling capability and deflection of the dock

gate’s primary members is to be assessed by direct calculation.

4.1.2 In general, the direct calculation is to be based on a three-dimensional (3-D) FEA

carried out in accordance with the procedures contained in this Section. Where

alternative procedures are proposed, these are to be agreed with LR before

commencement.

4.1.4 A detailed report of the calculations is to be submitted and is to

include the following information. The report must show compliance with the

specified structural design criteria given in Pt 2, Ch 2, 4.8 Structural design criteria.

- list of plans used, including dates and versions;

- detailed description of structural model, including all

modelling assumptions;

- plots to demonstrate correct structural modelling and

assigned properties;

- details of material properties used for all components;

- details of boundary conditions including seal stiffness

properties;

- details of applied loading and confirmation that individual

and total applied loads are correct;

- details of boundary support forces and moments;

- plots and results that demonstrate the correct behaviour of

the structural model to the applied loads;

- summaries and plots of global and local deflections;

- summaries and sufficient plots of von Mises, directional and

shear stresses to demonstrate that the design criteria are not exceeded in any

manner;

- plate buckling analysis and results;

- tabulated results showing compliance, or otherwise, with the

design criteria; and

- proposed amendments to structure, where necessary, including

revised assessment of stresses and buckling properties.

4.2 Type of analysis

4.2.1 Linear elastic methods capable of accounting for the following are to be used:

- global shear lag effects;

- asymmetry between the supports and the dock gate

centreline;

- global deformation of the dock gate; and

- rotation/deformation at the boundaries.

4.2.2 Non-linear methods need not normally be employed; however, if they are

used then the following aspects are to be considered:

- Loss of stiffness/strength in the event of severe buckling;

and

- Loss of contact at the boundaries.

Non-linear methods are to be agreed with LR prior to the commencement of any

investigations.

4.3 Net scantling approach

4.3.1 The global FEM strength assessment is to be carried out based on net

scantlings, i.e. an appropriate corrosion addition, tc, see

Pt 2, Ch 2, 4.4 Corrosion additions, is to be

deducted from the gross offered thickness.

4.3.2 The gross offered thickness, t, is the gross thickness provided at the

newbuilding stage, which is obtained by deducting any thickness for voluntary

addition from the as-built thickness, i.e. any additional thickness specified by the

Owner or builder is not to be included when considering compliance with the

Rules.

4.3.3 The strength assessment methods prescribed are to be assessed by

applying the corrosion reduction given in Table 2.4.1 Assessment for

corrosion to the

offered gross scantlings where half of the applied corrosion addition is to be

deducted from both sides of the structural members being considered.

Table 2.4.1 Assessment for

corrosion

| Structural

requirement

|

Property/analysis

type

|

Applied corrosion

addition

|

| Strength

assessment by FEM

|

Tanks

|

0,5

tc

|

| Buckling capacity

|

tc

|

| Fine mesh

|

0,5

tc

|

4.3.4 The net sectional properties of stiffeners are obtained by deducting half the applied

corrosion addition from each surface of the profile cross-section.

4.4 Corrosion additions

4.4.2 A reserve thickness, tres, of 0,5 mm is also to be included.

4.4.3 The total corrosion addition, in mm, for both sides of the structural member is

obtained by the following formula:

4.4.4 For an internal member within a given compartment, the total corrosion addition, in

mm, is obtained from the following formula:

Table 2.4.2 Corrosion addition for one side of a structural member

| Compartment type

|

Structural member

|

tc1 or tc2

|

| Ballast water and flood water

|

All members

|

1,0

|

| Exposed vehicle deck

|

Deck plating

|

3,5

|

| Exposed to atmosphere

|

All members

|

1,0

|

| Exposed to sea water

|

All members

|

1,0

|

| Void spaces

|

Spaces not normally accessed, e.g.

access only via bolted manhole openings, pipe tunnels, inner

surface of stool space

|

0,5

|

| Dry spaces

|

Internals of machinery spaces, pump

room, etc.

|

0,5

|

| Other tanks and spaces

|

All members

|

0,5

|

4.5 Modelling

4.5.1 A 3-D FE model of the complete dock gate is to be used to assess the primary

structure.

4.5.2 The proposed scantlings, excluding any Owner’s extras, are to be used throughout the

model. The selected size and type of elements are to provide a satisfactory

representation of the deflection and stress distributions within the model.

4.5.3 In general, the plate element mesh is to follow the primary stiffening arrangement.

The minimum mesh size requirements are:

- transversely, one element between every longitudinal

stiffener;

- longitudinally, three or more elements between web

frames;

- vertically, one element between every stiffener; and

- three or more elements over the depth of floors, side

transverses, vertical webs and horizontal stringers of bulkheads.

The mesh density of the side shell plating in way of the side frames is to be similar

to those adjacent to the side shell plating.

4.5.4 Secondary stiffening members are to be modelled using line elements positioned in the

plane of the plating having axial and bending properties (bars). The bar elements

are to have:

- a cross-sectional area representing the stiffener area,

excluding the area of attached plating; and

- bending properties representing the combined plating and

stiffener inertia.

4.5.6 In general, the use of triangular plate elements is to be kept to a minimum. Where

possible, they are to be avoided in areas where there are likely to be high stresses

or a high stress gradient. These include areas:

- in way of lightening/access holes; and

- adjacent to brackets, knuckles or structural

discontinuities.

4.5.7 Access openings, lightening holes, etc. in primary structures are to be

represented in areas of interest, e.g. where they are of sufficient size to

influence member stiffness. Additional mesh refinement could be necessary to model

these openings, but it could be sufficient to represent the effects of the opening

by deleting the appropriate elements.

4.5.8 The lightweight of the dock gate is to be represented in the model.

4.5.9 Solid ballast shall be included in the model in its correct position and

can be modelled as lumped masses attached to appropriate model nodes provided that

the load is appropriately distributed to local nodes. Ballast which is moveable such

as pig iron is to be assumed to be located in its most unfavourable position.

4.5.10 The effects of added mass (i.e. entrained water located outside the dock gate, but

which is considered to move with the dock gate) are to be considered using a method

which is to be agreed with LR.

4.5.11 A grillage model can be used subject to agreement with LR.

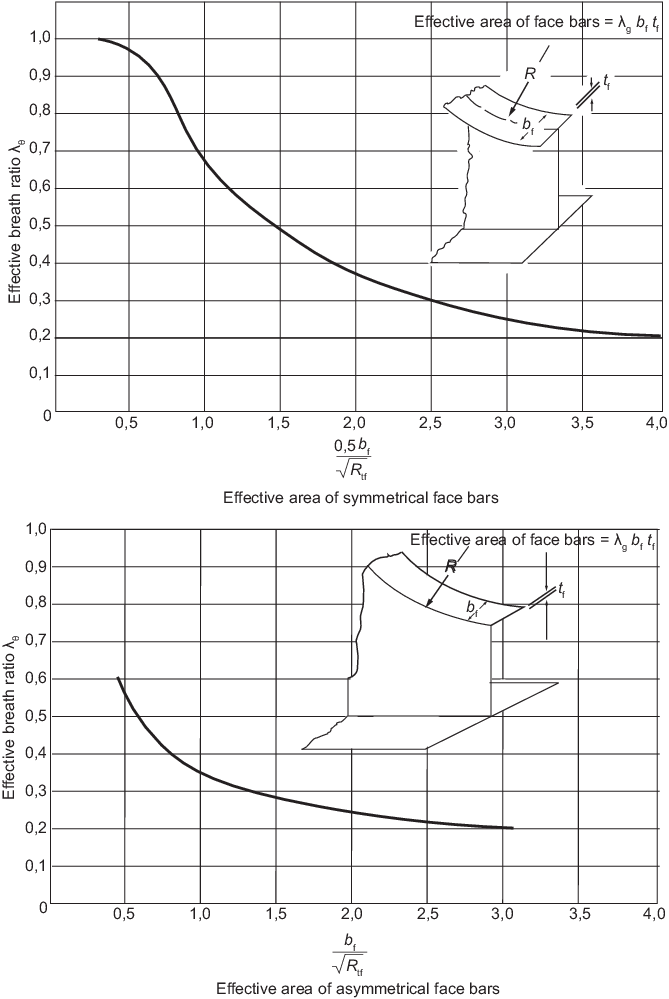

Table 2.4.3 Line element effective

cross-section area

| Structure represented by

element

|

Effective area, Ae

|

| Primary

member face bars

|

Symmetrical

|

Ae = 100%

An

|

| Asymmetrical

|

Ae = 100%

An

|

| Curved

bracket face bars (continuous)

|

Symmetrical

|

See

Figure 2.4.1 Effective area of face

bars

|

| Asymmetrical

|

| Straight

bracket face bars (discontinuous)

|

Symmetrical

|

Symmetrical

|

Ae = 100%

An

|

| Asymmetrical

|

Asymmetrical

|

Ae = 60%

An

|

| Straight

bracket face bars (continuous around toe curvature)

|

Straight portion

|

Symmetrical

|

Ae = 100%

An

|

| Asymmetrical

|

Ae = 60%

An

|

| Curved portion

|

Symmetrical

|

See

Figure 2.4.1 Effective area of face

bars

|

| Asymmetrical

|

| Web

stiffeners – sniped both ends

|

Flat bars

|

Ae = 20% of stiffener

area

|

| Other sections

|

|

| Web

stiffeners – sniped one end, connected other end

|

Flat bars

|

Ae = 75% of stiffener

area

|

| Other sections

|

|

| Note Consistent

units to be used throughout

|

| Symbols

|

| A

|

= cross-section area of

stiffener and associated plating

|

| An

|

= average face bar area

over length of line element

|

| Ap

|

= cross-section area of

associated plating

|

| I

|

= cross-section area of

associated plating

|

| Y0

|

= moment of inertia of

stiffener and associated plating

|

| r

|

= radius of gyration

|

Figure 2.4.1 Effective area of face

bars

4.6 Boundary conditions

4.6.1 In general, the dock gate will be supported vertically at the sill base and laterally

on two sides. The support will be provided via a soft seal and the stiffness of the

seals is to be included in the analysis.

4.6.2 The stiffness and damping characteristics of the seals are to be provided

by the gate designer or seal manufacturer together with how these properties can

vary around the dock gate perimeter when different seal stiffnesses are specified by

the designer. The stiffnesses of seals employed in the structural models are to be

consistent with the direction of displacement of the seals, i.e. for translations

perpendicular to the compression axis of the seal, shear stiffness of the seal is to

be modelled.

4.6.3 The lateral sway of the dock walls should not impose in-plane forces on the dock gate

other than those transferred via seal shear stiffness and friction. If there is

insufficient edge clearance between the dock walls and the dock gate to ensure that

this condition is met, then the interaction between the walls and the dock gate is

to be addressed.

4.7 Application of loads

4.7.1 The load scenarios given in Pt 2, Ch 2, 4.7 Application of loads 4.7.2 to Pt 2, Ch 2, 4.7 Application of loads 4.7.5 are to be

considered where the applied loads are to be taken as the loads given in Pt 2, Ch 2, 2.1 General (as appropriate) are to be

multiplied by the load factors given in Pt 2, Ch 2, 4.7 Application of loads 4.7.6 and Pt 2, Ch 2, 4.7 Application of loads 4.7.7.

4.7.2 The following load scenarios are to be considered:

- normal operating; and

- extreme.

4.7.3 The normal operating scenarios comprise the following:

- lightweight only;

- lightweight + hydrostatic (operating);

- lightweight + hydrostatic (operating) + wind;

- lightweight + deck loads + hydrostatic (operating);

- lightweight + deck loads + hydrostatic (operating) +

wind;

- lightweight + internal loads;

- lightweight + hydrostatic (operating) + internal loads +

deck loads + wind; and

- lightweight + air pressure test load.

4.7.4 The extreme scenarios comprise the following:

- lightweight + deck loads + hydrostatic (maximum credible).

4.7.5 Other load scenarios can be considered at the request of the Owner.

4.7.7 Consideration can be given to reducing the partial load factors for secondary loads

in accordance with BS 6349 Maritime Works. Note that hydrostatic loading is

considered to be a primary load.

Table 2.4.4 Partial load factors

| Load

|

Load scenario, see

Pt 2, Ch 2, 4.7 Application of loads 4.7.2

|

| Normal

|

Extreme

|

| Lightweight

|

1,35

|

1,0

|

| Hydrostatic - maximum credible

level

|

N/A

|

1,35

|

| Hydrostatic - otherwise

|

1,5

|

N/A

|

| Deck loading

|

1,5

|

1,0

|

| Wind loading

|

1,35

|

N/A

|

| Internal loads

|

1,0

|

N/A

|

| Test loads

|

1,0

|

N/A

|

4.8 Structural design criteria

4.8.1 The stresses resulting from the application of all load scenarios are not to exceed

the following:

- combined stress – 1,0 σo;

- direct stress – 0,9 σo;

- shear stress – 0,5 σo.

σo is defined in Pt 2, Ch 2, 1.4 Materials.

4.8.2 Stress criteria are based on the coarse mesh described in Pt 2, Ch 2, 4.5 Modelling 4.5.4. If a finer mesh is used,

then stress can be averaged over an area equal to the size of the coarse mesh

element in way of the structure being considered. The averaging is to be based only

on elements with their boundary located within the desired area. Stress averaging is

not to be carried out across structural discontinuity or abutting structure.

4.8.3 For all load scenarios, except for the extreme load scenarios, plate buckling is to

be investigated for all areas of primary structure. The factor against buckling is

to be taken as 1,1.

4.8.4 Panel buckling calculations are to be based on the net thickness of the plating.

4.8.5 In general, the applied stresses for buckling assessment are to be increased by a

factor equal to the original thickness divided by the thickness after corrosion.

4.8.6 When the calculated elastic critical buckling stress, σ c,

exceeds 50 per cent of the specified minimum yield stress, then the buckling stress

is to be adjusted for the effects of plasticity using the Johnson-Ostenfeld

correction formula, given below:

- when σc≤0,5σo

σcr = σo

- when σc>0,5σo

where

|

σcr |

= |

the critical buckling stress corrected for plasticity

effects, in N/mm2 |

|

σc |

= |

the elastic critical buckling stress, in

N/mm2 |

σo is defined in Pt 2, Ch 2, 1.4 Materials

4.8.7 Deflections of individual panels under lateral hydrostatic loading shall not exceed

1/200 of the principal panel dimension.

4.8.8 Deflections of any stiffener supporting plate subjected to hydrostatic loading shall

not exceed 1/200 of the stiffener span.

4.9 Additional requirements for floating dock gates

|