Section

3 Secondary member end connections

3.1 General

3.1.1 Secondary

members, that is longitudinals, beams, frames and bulkhead stiffeners

forming part of the hull structure, are generally to be connected

at their ends in accordance with the requirements of this Section.

3.1.2 Where

end connections are fitted in accordance with these requirements,

they may be taken into account in determining the effective span of

the member. For determination of span point,see

Pt 3, Ch 3, 3.3 Determination of span point.

3.2 Symbols

3.2.1 The symbols

used in this Section are defined as follows:

|

Z

|

= |

the

section modulus of the stiffening member, in cm3

|

3.3 Basis for calculation of bracket connections

3.3.1 Scantlings

of bracket connections are based on the following criteria:

-

Where a bracket

is connecting a stiffener to a primary member, the bracket is to be

based on the modulus of the stiffener;

-

Where a main transverse

frame terminates, the bracket at the head of the frame is to be based

on the modulus of the frame;

-

Where, in the midship

region, a longitudinal strength member is cut at a transverse supporting

member and the continuity of strength is provided by brackets, the

bracket is to be based on the cross-sectional area and the modulus

of the longitudinal member. Care is to be taken to ensure correct

alignment of the brackets on each side of the primary member;

-

Elsewhere, the lesser

modulus of the members being connected by the bracket.

3.4 Scantlings of end brackets

3.4.3 Where

the bracket is lapped on to the stiffening member, the length and

width of overlap is to be adequate to provide for the required area

of welding, but the length of overlap should be not less than the

depth of the stiffener.

3.4.4 For the

purpose of these Rules, bracket connections not complying with these

minimum requirements are considered as bracketless connections.

3.5 Arrangement and details

3.5.1 The modulus

of the bracket through the throat is to be not less than that of the

smaller stiffening member to be connected.

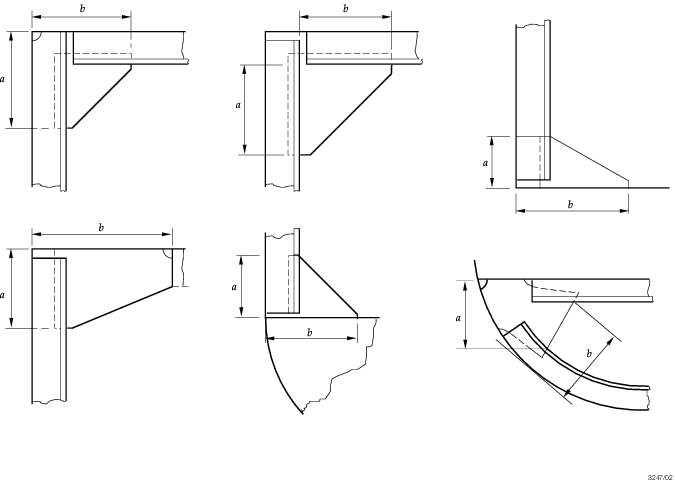

Figure 10.3.1 Diagrammatic arrangements of stiffener end brackets

Table 10.3.1 Bracket scantlings

| Parameter

|

Requirement

|

| Length of a bracket

|

The greater of the following:

|

l |

= |

+ 80 + d

s mm, or + 80 + d

s mm, or |

|

| Thickness

of a bracket

|

|

|

(a) unflanged

|

|

t

|

= |

5 +  mm mm |

see Note

|

|

(b) flanged

|

The greater of the following:

|

t

|

= |

4 +  mm, or mm, or |

|

| Flange width

|

|

t

|

= |

mm mm |

|

| Symbols

|

|

b

f

|

= |

breadth of the flange, in mm |

|

d

s

|

= |

depth of the stiffening member, in mm |

|

l |

= |

arm length of bracket, in mm |

|

Note Where the length of the free edge of a bracket exceeds

50t mm, edge stiffening is to be fitted or the thickness is

to be suitably increased.

|

3.5.2 The design

of end connections and their supporting structure is to be such as

to provide adequate resistance to rotation and displacement of the

joint.

3.5.3 The toes

of brackets should not land on unstiffened panels of plating. Special

care should be taken to avoid notch effects at the toes of brackets.

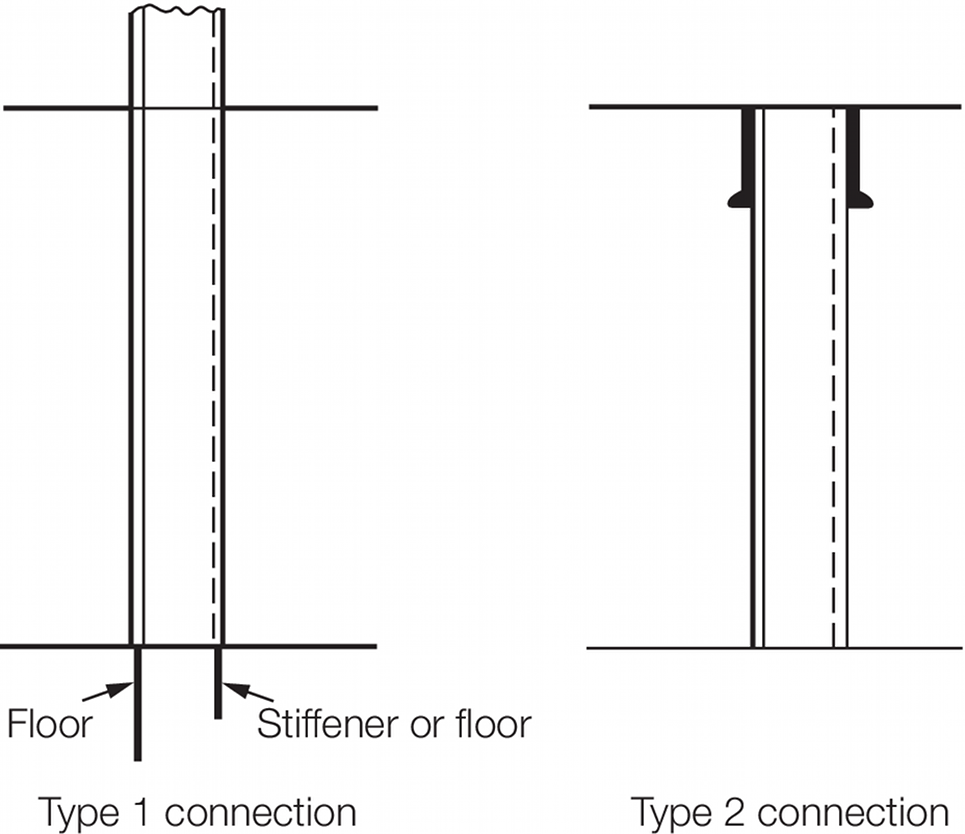

3.6 Bracketless connections

3.6.1 For the

purpose of these Rules, bracketless connections are divided into two

types as follows:

3.6.2 Type 2 connections may only be adopted at watertight bulkhead stiffeners,

wash bulkhead stiffeners and at stiffeners on centreline division bulkheads (non-tight)

in tanks. Type 2 connections are not allowed for the secondary member end connections in

way of the deep tank boundary or the shell boundary.

Figure 10.3.2 Types of bracketless end connections

3.7 Correction of stiffening member modulus in relation to end connections

3.7.2 The modulus

of bracketless stiffeners is to be increased as follows:

| Type 1 connection:

|

increase 10 per cent per end

connection.

|

| Type 2 connection:

|

increase 25 per cent per end

connection.

|

3.8 End connections of corrugated bulkheads

3.8.1 The constraint

of the end connection is to be assured by the positioning of floors

and/or carlings or a corrugated bulkhead in line with the corrugated

bulkhead under consideration. This type of connection is considered

as a bracketless Type 1 connection, see also

Figure 10.3.3 End connections of corrugated bulkheads. Where the bulkhead corrugations

are not supported, the connection is considered as a Type 2 connection, see also

Figure 10.3.3 End connections of corrugated bulkheads.

Figure 10.3.3 End connections of corrugated bulkheads

3.8.2 The yield stress of floors and/or carlings in line with the corrugated bulkhead is not

to be less than the yield stress of the corrugated bulkhead.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|