Section

2 Design criteria

2.1 Operating range for derricks

2.1.1 Calculations

are to be made for derrick systems with the derrick booms at the maximum

and minimum angles for which the system is to be certified. These

angles are to be taken as follows:

-

Maximum angle to the

horizontal:

70° generally, but a greater angle may be specified.

-

Minimum angle to the

horizontal:

-

SWL not exceeding

15 t:

30° generally, but a lesser angle may be specified.

In no case is the angle to be less than 15°.

-

SWL exceeding 15

t:

30° generally, but a greater angle may be specified.

In no case is the angle to be greater than 45°.

2.1.2 The length

of the derrick boom is to be such as to give adequate coverage of

the cargo hatch and sufficient outreach beyond the ships side,

within the limiting angles given in Ch 2, 2.1 Operating range for derricks 2.1.1.

2.2 Inclination of the ship

2.2.1 For swinging

derrick and union purchase systems, a basic angle of heel of 5°

and a trim of 2° are assumed for the ship. Provided these angles

are not exceeded, they may generally be ignored in the calculation

of forces and tensions in the derrick system and in the masts and

derrick posts.

2.2.2 The angles

of heel and trim of the ship with its largest loaded derrick (or derricks

if more than one can be used at one time) swung fully outboard are

to be calculated. Where the calculation shows that the ship would

have a greater angle of heel or trim than 5° or 2° respectively,

the actual angles are to be taken into consideration. This calculation

is NOT to be taken to mean that LR accepts responsibility for the

stability of the ship. Stability is a matter to be agreed between

the Builder, designer and Owner and may be subject to National Regulations.

2.2.3 For derrick

cranes, a basic angle of heel of 5° and a trim of 2° is generally

to be included in the calculations. Greater or lesser angles may be

specified provided these angles are clearly stated in the certificates.

2.3 Weight of boom and tackle

2.3.1 The weight

of the derrick boom and tackle is to be included in the calculations

for all union purchase rigs and for swinging derricks and derrick

cranes where the SWL exceeds 15t. Where available, the

actual weight of the derrick boom and tackle is to be used. Alternatively,

an estimated value equal to 10 per cent of the SWL of the system when

rigged as a swinging derrick or derrick crane is to be applied at

the derrick boom head.

2.4 Friction allowance

2.4.1 For calculation

purposes, a combined allowance for sheave friction and wire stiffness

is to be made as follows:

|

|

Blocks with plain or bushed

sheaves:

|

|

5 per cent

|

|

|

Blocks with ball or roller

sheaves:

|

|

2 per cent

|

| Allowances for sheaves with low friction bearings will

be specially considered.

|

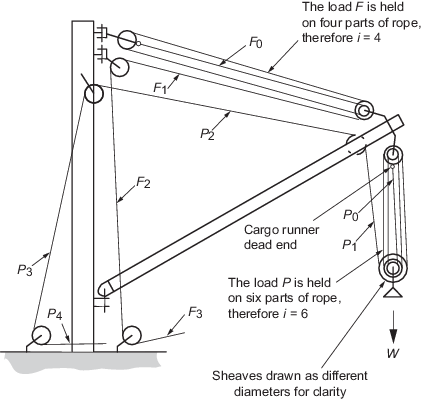

2.4.2 The appropriate

percentage is to be applied cumulatively to the parts of the rope

supporting the load. Coefficients for estimating the rope tension

are given in Table 2.2.1 Coefficients of rope

tension and in

association with Figure 2.2.1 Coefficients of rope

tension.

Table 2.2.1 Coefficients of rope

tension

Number

of

parts

supporting

the load

|

Friction

allowance

per

sheave %

|

Static

rope pull

|

Hoisting

|

Lowering

|

|

P

0

|

P

1

|

P

2

|

P

3

|

P

4

|

P

5

|

P

0

|

P

1

|

P

2

|

P

3

|

P

4

|

P

5

|

|

F

0

|

F

1

|

F

2

|

F

3

|

F

4

|

F

5

|

F

0

|

F

1

|

F

2

|

F

3

|

F

4

|

F

5

|

| 1

|

2

|

1,00

|

|

|

1,02

|

1,04

|

1,06

|

1,08

|

|

|

0,98

|

0,96

|

0,94

|

0,92

|

|

|

5

|

|

|

1,05

|

1,10

|

1,16

|

1,22

|

|

|

0,95

|

0,91

|

0,86

|

0,82

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2

|

2

|

0,500

|

0,495

|

0,505

|

0,515

|

0,525

|

0,536

|

0,547

|

0,505

|

0,495

|

0,485

|

0,476

|

0,467

|

0,457

|

|

|

5

|

0,488

|

0,512

|

0,538

|

0,565

|

0,593

|

0,623

|

0,512

|

0,488

|

0,465

|

0,443

|

0,421

|

0,401

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3

|

2

|

0,333

|

0,327

|

0,340

|

0,347

|

0,354

|

0,361

|

0,368

|

0,340

|

0,327

|

0,320

|

0,314

|

0,308

|

0,302

|

|

|

5

|

0,317

|

0,350

|

0,357

|

0,386

|

0,405

|

0,425

|

0,350

|

0,317

|

0,302

|

0,288

|

0,274

|

0,261

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4

|

2

|

0,250

|

0,243

|

0,258

|

0,263

|

0,268

|

0,273

|

0,279

|

0,258

|

0,243

|

0,238

|

0,233

|

0,229

|

0,224

|

|

|

5

|

0,232

|

0,269

|

0,282

|

0,296

|

0,311

|

0,327

|

0,259

|

0,232

|

0,221

|

0,210

|

0,200

|

0,191

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5

|

2

|

0,200

|

0,192

|

0,208

|

0,212

|

0,216

|

0,221

|

0,225

|

0,208

|

0,192

|

0,188

|

0,185

|

0,181

|

0,178

|

|

|

5

|

0,181

|

0,220

|

0,231

|

0,243

|

0,255

|

0,267

|

0,220

|

0,181

|

0,172

|

0,164

|

0,156

|

0,149

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6

|

2

|

0,167

|

0,159

|

0,175

|

0,179

|

0,182

|

0,186

|

0,189

|

0,175

|

0,159

|

0,155

|

0,152

|

0,149

|

0,146

|

|

|

5

|

0,147

|

0,188

|

0,197

|

0,207

|

0,217

|

0,228

|

0,188

|

0,147

|

0,140

|

0,133

|

0,127

|

0,121

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 7

|

2

|

0,143

|

0,135

|

0,152

|

0,155

|

0,158

|

0,160

|

0,164

|

0,152

|

0,135

|

0,132

|

0,129

|

0,127

|

0,124

|

|

|

5

|

0,123

|

0,165

|

0,173

|

0,181

|

0,191

|

0,200

|

0,155

|

0,123

|

0,117

|

0,111

|

0,106

|

0,101

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 8

|

2

|

0,125

|

0,117

|

0,134

|

0,137

|

0,139

|

0,142

|

0,145

|

0,134

|

0,117

|

0,114

|

0,112

|

0,110

|

0,108

|

|

|

5

|

0,105

|

0,147

|

0,155

|

0,162

|

0,171

|

0,179

|

0,147

|

0,105

|

0,100

|

0,095

|

0,090

|

0,086

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 9

|

2

|

0,111

|

0,103

|

0,120

|

0,123

|

0,125

|

0,128

|

0,130

|

0,120

|

0,103

|

0,101

|

0,099

|

0,097

|

0,095

|

|

|

5

|

0,091

|

0,134

|

0,141

|

0,148

|

0,155

|

0,163

|

0,134

|

0,091

|

0,086

|

0,082

|

0,078

|

0,075

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10

|

2

|

0,100

|

0,091

|

0,109

|

0,111

|

0,114

|

0,116

|

0,118

|

0,109

|

0,091

|

0,090

|

0,088

|

0,086

|

0,084

|

|

|

5

|

0,080

|

0,123

|

0,130

|

0,136

|

0,143

|

0,150

|

0,123

|

0,080

|

0,076

|

0,072

|

0,069

|

0,065

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 11

|

2

|

0,091

|

0,082

|

0,100

|

0,102

|

0,104

|

0,106

|

0,108

|

0,100

|

0,082

|

0,081

|

0,079

|

0,077

|

0,076

|

|

|

5

|

0,070

|

0,115

|

0,120

|

0,126

|

0,133

|

0,139

|

0,115

|

0,070

|

0,067

|

0,064

|

0,061

|

0,058

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 12

|

2

|

0,083

|

0,075

|

0,093

|

0,095

|

0,097

|

0,099

|

0,100

|

0,093

|

0,076

|

0,073

|

0,072

|

0,070

|

0,069

|

|

|

5

|

0,063

|

0,108

|

0,113

|

0,118

|

0,124

|

0,131

|

0,108

|

0,063

|

0,060

|

0,057

|

0,054

|

0,052

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 13

|

2

|

0,077

|

0,068

|

0,086

|

0,088

|

0,090

|

0,092

|

0,094

|

0,086

|

0,068

|

0,067

|

0,066

|

0,064

|

0,063

|

|

|

5

|

0,057

|

0,101

|

0,107

|

0,112

|

0,117

|

0,123

|

0,101

|

0,057

|

0,054

|

0,051

|

0,049

|

0,046

|

Figure 2.2.1 Coefficients of rope

tension

2.4.3 As an alternative, the coefficients of rope tensions may be determined as

follows:

where

|

μ |

= |

percentage of friction (e.g. 2 per cent for roller bearings) |

|

= |

number of parts supporting the load |

2.5 Factor of safety for ropes

2.5.1 Wire ropes

are to have a breaking load not less than the maximum tension in the

rope multiplied by a factor obtained from Table 2.2.2 Factors for wire ropes.

Table 2.2.2 Factors for wire ropes

| Item

|

Factor

|

| (1)

|

Running rigging:

Cargo

runner

Span tackle

Slewing

guys

Preventer guys

Schooner guys

|

but not greater than 5 or less than 3

|

| (2)

|

Standing rigging:

Mast

stays

|

As for running rigging but need not

exceed 3,5

|

|

Note SWL is the safe working

load of the derrick or derrick crane with which the rope is to be used.

For standing rigging, SWL is the highest safe working load of any derrick

or derrick crane supported by the mast.

|

2.5.2 Natural fibre

ropes used in derrick systems, where permitted, are to have a breaking

load not less than the maximum tension in the rope multiplied by 8.

2.5.3 Man-made fibre

ropes, where permitted for standing rigging, are to have a breaking

load not less than the value obtained from Table 2.2.2 Factors for wire ropes multiplied by 1,25.

|