Section

4 Union purchase arrangements

4.1 General

4.1.1 Where the

derricks are arranged for operation in union purchase, the maximum

resultant loads in the system are to be determined, in accordance

with the requirements of this Section.

4.1.2 The scantlings

and arrangements of the derrick system are to be determined for union

purchase operation and for operation as single slewing derricks. Each

part of the rig is to be suitable for the most severe loading to which

it may be subjected.

4.1.3 The union

purchase rig is generally to be designed so that the operation is

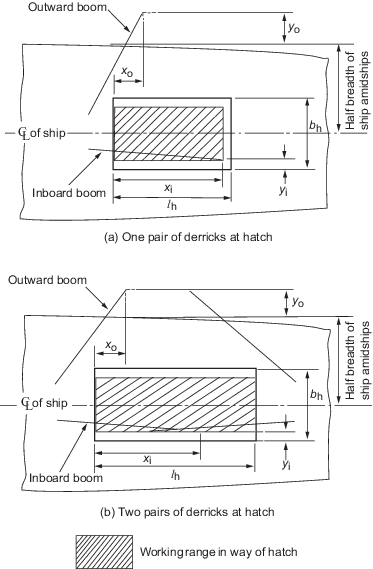

possible on either side of the ship. A typical rig is shown in Figure 2.4.1 Typical union purchase rig.

Figure 2.4.1 Typical union purchase rig

4.1.4 Union purchase

rigs may be designed on the basis of either:

-

minimum headroom below

the triangle plate; or

-

maximum included angle

between the cargo runners.

4.1.5 The following

criteria are to be complied with at all times:

-

Minimum operating angle

of either derrick is to be not less than 15° to the horizontal,

and it is recommended this angle is not less than 30°.

-

Minimum headroom to

the triangle plate is to be not less than 4,0 m where the SWL(U) of

the rig does not exceed 2,0 t, or 5,0 m for higher values of SWL(U).

-

The maximum included

angle between the cargo runners is not to exceed 120°.

-

The outreach beyond

the midship breadth of the ship is to be not less than 4,0 m.

4.1.6 The minimum

headroom is defined as the least vertical in distance at any stage

in the operating cycle of the rig, from the highest point of the ship’s

deck structure (usually the top of the hatch coaming or the ship side

bulwark or rails) to the centre of the triangle plate.

4.2 Working range of the rig

4.2.1 The derrick

booms are to be of sufficient length and to be so positioned as to

cover the required working area of the hatch while complying with

the criteria given in Ch 2, 4.1 General 4.1.5.

4.2.2 For this purpose,

the booms are to be such that the boom heads may be located at the

positions listed in Table 2.4.1 Boom head positions for union

purchase calculations.

These arrangements are illustrated in Figure 2.4.2 Positions of derricks for union

purchase and Figure 2.4.2 Positions of derricks for union

purchase for hatches

with one pair and two pairs of derricks respectively.

Table 2.4.1 Boom head positions for union

purchase calculations

| Boom and direction

|

Symbol

|

Number of pairs of booms at the hatch

|

| One

|

Two

|

| Dimension, in metres

|

| Outboard

boom

|

|

|

|

|

|

Transverse

|

y

o

|

4

|

4

|

|

|

Longitudinal

|

x

o

|

0,25lh

|

0,20lh

|

|

|

|

|

|

|

| Inboard

boom:

|

|

|

|

|

|

Case

1

|

Transverse

|

y

j

|

1

|

1

|

|

|

|

Longitudinal

|

xj

|

0,75lh

|

0,67lh

|

|

|

Case

2

|

Transverse

|

y

j

|

0,25b

h

|

0,25b

h

|

|

|

|

Longitudinal

|

x

j

|

0,375lh

|

0,33lh

|

Note

2. Case 2 is applicable to operation in

the maximum included angle mode only.

Note

3. lh and b

h are defined as the length and breadth respectively of the

hatch openings, in metres.

|

Figure 2.4.2 Positions of derricks for union

purchase

4.2.4 Calculations

of the forces and resultant loads in the system are to be made as

follows:

-

Based on maximum headroom:

-

Based on maximum included

runner angle:

4.2.5 Where, at

the request of the Owner, the rig is to operate over a working range

different from that given in Ch 2, 4.2 Working range of the rig 4.2.2,

including instances where the rig is designed for use in one fixed

position only, calculations are to be made for the extreme positions

of the specified range. The boom positions are to be clearly defined

in the Register of Ship’s Lifting Appliances and Cargo

Handling Gear. In all instances, the arrangement is to comply

with the limiting criteria given in Ch 2, 4.1 General 4.1.5.

4.2.6 It may be

assumed that the maximum forces will be associated with the extreme

positions of the rig. Intermediate positions within the working range

need not, in general, be examined.

4.2.7 The derrick

booms are to be restrained by the use of preventer guys which are

to be attached to eyeplates at the boom head or looped over the boom.

The slewing guys are to be slackened off once the rig is set up and

only the preventer guys are to be taken into account with regard to

the calculation of forces in the rig.

4.2.8 It is recommended

that the deck eyeplate for the preventer to the inboard derrick should

be approximately abreast the derrick head. The eyeplate for the preventer

to the outboard derrick is to be positioned so as to obviate the risk

of jack-knifing, see

Figure 2.4.5 Form of diagram when beam is in

danger of jack-knifing, and to avoid excessive guy tension.

4.2.9 The boom heads

are to be connected by a boom head or schooner guy, the safe working

load of which is to be as required by Ch 2, 8.4 Slewing and preventer guys 8.4.6.

Alternative arrangements will be considered.

4.3 Calculation of forces

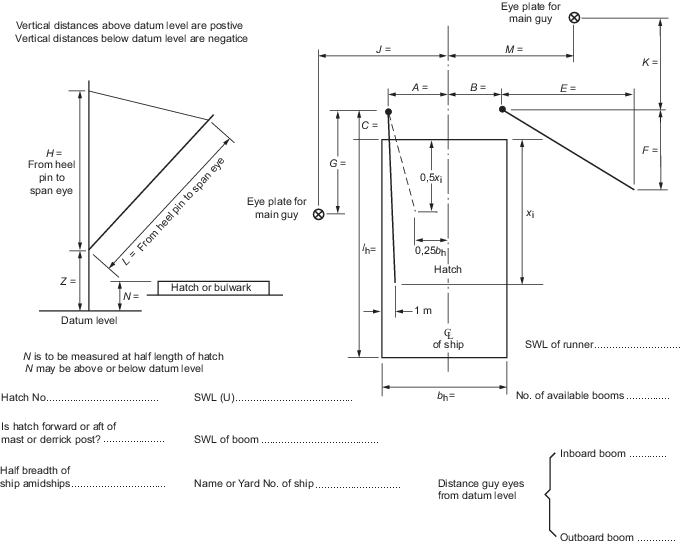

4.3.1 The dimensions

and other particulars required for the calculation of forces in the

rig are indicated in Figure 2.4.3 Typical data sheet.

Figure 2.4.3 Typical data sheet

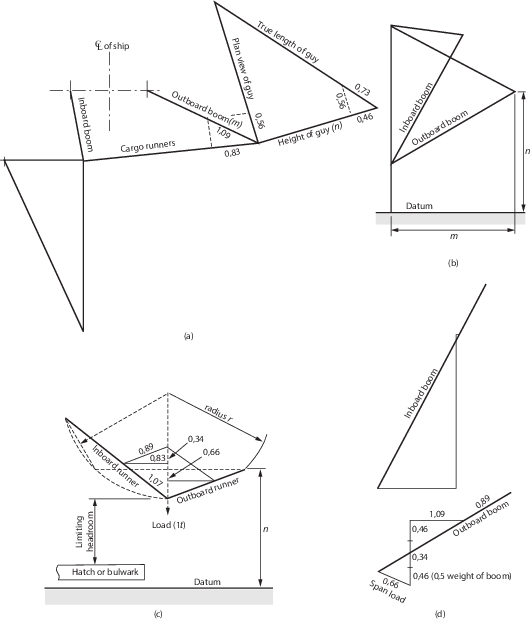

4.3.2 Where the

forces are to be determined by the construction of force diagrams,

it is recommended that the following procedure be adopted, corresponding

to the parts of the typical diagrams as labelled in Figure 2.4.4 Typical union purchase

calculations:

-

Projected plan of the

rig.

-

True side elevations

of the derrick booms.

-

Lines of the cargo runners

at the minimum headroom position.

Figure 2.4.4 Typical union purchase

calculations

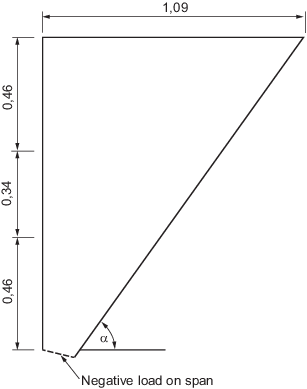

4.3.4 Where a diagram

of the character shown in Figure 2.4.5 Form of diagram when beam is in

danger of jack-knifing is

obtained (this is where the diagram does not ‘close’),

the boom is in danger of jack-knifing. The boom will be in danger

of jack-knifing if the total vertical load is less than the span tension

x tan α, where α is the angle of the boom to the horizontal.

Where this situation arises, the eyeplates for the preventer guys

are to be repositioned. In general, it is recommended that the position

of the guy eyeplate for the outboard boom is such that the load due

to the vertical components of the runner and guy forces (but not the

boom weight) is at least equal to span tension x tan α.

Figure 2.4.5 Form of diagram when beam is in

danger of jack-knifing

4.3.5 As an alternative

to the graphical procedure, the forces in the rig may be determined

by direct calculation.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|