Section

8 Fittings for masts and derrick booms

8.1 General

8.1.1 The application

of fixed fittings, ropes and loose gear in derrick systems is to comply

with the requirements of this Section. The items themselves are to

be manufactured in accordance with the requirements given in Ch 8 Fittings, Loose Gear and Ropes.

8.1.2 Effective

continuity of materials is to be maintained in the bearing brackets

for fittings and abrupt changes of plate thickness are to be avoided.

Care is to be taken to avoid pockets in which water may collect. The

connection to the mast or derrick boom is to provide an easy transfer

of load into the surrounding structure and to minimise hard spots

and sources of stress concentration.

8.1.3 All welds

are to be sound, uniform and free from undercutting or other defects.

Care is to be taken to ensure adequate weld penetration. Effective

arrangements are to be made for the inspection of finished welds.

The extent of examination by non-destructive methods is to be to the

Surveyor’s satisfaction.

8.1.4 All bearing

surfaces are to be machined to ensure a smooth finish and a good fit.

Adequate and accessible means of lubrication are to be provided.

8.2 Goosenecks and derrick heel assemblies

8.2.1 The gooseneck

bearing assembly is to be such that:

-

The gooseneck pin is

secured in position to prevent displacement under normal operating

conditions.

-

Brackets and supporting

structure are adequate to support the forces from the derrick boom

operating at the maximum and minimum angles. Edges of brackets are

to be stiffened as necessary to resist distortion.

-

Where the gooseneck

is supported by a mast, a diaphragm or equivalent stiffening is fitted,

or the width of brackets or other attachments is not less than two

thirds of the diameter of the mast at that level.

8.2.2 Derrick heel

fittings are to be such that:

-

The axis of the derrick

heel crosspin cuts the axis of the derrick boom. Design incorporating

a small offset will be specially considered.

-

The derrick heel crosspin

is secured to prevent displacement under normal operating conditions.

8.2.3 Trunnions

and other alternatives to goosenecks will be specially considered.

8.2.4 Adequate means

are to be provided for the lubrication of all bearing surfaces and

their protection from contamination by dirt or excessive water. Such

protection is not to make inspection of the assembly unreasonably

difficult.

8.3 Cargo runner and span tackle

8.3.1 The cargo

runner is to be of sufficient length to ensure that with the derrick

rigged for lifting, the maximum safe working load is to be that at

least two turns remain on the winch barrel when the derrick is at

either:

-

its highest working

position and lifting from the tank top or lowest level from which

it can be operated;

-

its maximum overside

position and lifting from a lighter with the ship at its light waterline.

The cargo runner is to be securely attached to the winch barrel.

8.3.2 The length

of the span tackles is to be such that at least two turns remain on

the winch barrel when the derrick is at its position of maximum outreach,

or one turn when the derrick is in its stowed position. Where single

rope spans are fitted, the span rope may be led to a topping winch

or be fitted with a span chain securely attached to the deck eyeplates

by a shackle or screw pin. Where span chains are fitted, the links

are to be of sufficient size that the eye of a shackle can be passed

through. Where the span rope is more than one part, it is to be led

to a winch barrel or topping winch and securely attached to it.

8.4 Slewing and preventer guys

8.4.1 In general,

each derrick boom is to be provided with two slewing guys where the

SWL of the derrick does not exceed 20 tonnes or three guys for derricks

with higher safe working loads. The safe working load of each guy

is to be not less than that required by Table 2.8.1 SWL of derrick boom slewing

guys. Where three guys are required, deck fittings are to

be provided so that two guys can be used on each side of the ship.

For slewing guys used with derrick cranes, see

Ch 2, 5.3 Slewing guys 5.3.3.

Table 2.8.1 SWL of derrick boom slewing

guys

SWL of derrick rig

not

exceeding, tonnes

|

SWL of each slewing guy,

tonnes

|

| 1

|

1

|

| 2

|

1,5

|

| 3

|

2

|

| 4

|

2,5

|

| 5

|

3

|

| 6

|

3,25

|

| 9,5

|

3,5

|

| 12,5

|

3,75

|

| 15

|

4

|

| 60

|

25% of derrick SWL

|

| 75

|

15

|

| over 75

|

20% of derrick SWL

|

8.4.2 Where the

angle of the heel or trim in the operating condition exceeds 5°

or 2° respectively, the requirements for slewing guys will be

considered.

8.4.3 Alternative

arrangements of slewing guys and proposals for reduced slewing guys

where cargo slewing guys are fitted will be specially considered.

Such arrangements are to be capable of operating at 5° heel and

2° trim or at greater angles where specified.

8.4.4 Natural or

man-made fibre ropes may be used in the guy tackle (but not the guy

pendant) provided the SWL of the guy does not exceed 4 t.

8.4.5 Where derricks

are rigged for use in union purchase, preventer guys are to be fitted

in addition to slewing guys. Preventer guys are to have a safe working

load not less than the maximum guy tension derived from Ch 2, 4.3 Calculation of forces. Fibre rope is not to be used for preventer

guys.

8.4.6 Boom head

or schooner guys used for crossconnecting the heads of derricks in

union purchase are to have a safe working load not less than 20 per

cent of the SWL of the union purchase system, and not less than 1,0

t. These guys may be of steel wire or of fibre rope.

8.4.7 The hauling

end of wire rope slewing guys is to be securely attached to a winch

barrel when the derrick is being slewed under load.

8.4.8 Slewing guys

are to be attached to the derrick boom and the deck eyeplate by a

link, shackle or similar device so designed as to permit the guy to

take up its varying positions while maintaining a straight lead. Leads

are to be such that the guys will not foul rails, bulwarks or other

obstructions when under load. Fairleads may be used.

8.4.9 Preventer

guys are to be shackled on, or looped over the derrick head and shackled,

or equivalent, to eyeplates on the deck or bulwark.

8.5 Swivelling and fixed eyeplates

8.5.1 Swivelling

eyeplates are to be used for the attachment of span tackle and cargo

runner lead blocks to the mast for all derricks where the safe working

load is 3,0 t or more or where the load in the span tackle exceeds

5,0 t. They may also be used elsewhere.

8.5.2 Fixed eyeplates

at the derrick head may be of the ’sword-fitting’ type,

providing a pair of eyeplates on opposite sides of the derrick tube,

or the fitting may penetrate one side of the tube and be securely

attached to internal structure.

8.6 Blocks

8.6.1 Swivels are

to be arranged, as necessary, to ensure that blocks maintain their

correct alignment.

8.6.2 The cargo

runner lead block at the derrick heel is to have a duckbill or similar

head fitting which prevents the block falling when the cargo runner

is slack. This is to be arranged so as to allow the heel block to

clear the derrick tube when the derrick tube is in its stowed position.

8.6.3 Snatch blocks

may only be used as deck lead blocks.

8.6.4 Wood blocks

may only be used with fibre ropes.

8.7 Cargo hooks

8.7.1 Cargo hooks

are to be of such construction or shape, or are to be provided with

an efficient device, so as to prevent displacement of the sling or

load from the hook.

8.7.2 In general,

‘C’, (or Liverpool) type hooks may be used where the SWL

of the derrick rig does not exceed 25 t. Cargo hooks of the Ramshorn

type may be used in rigs of any SWL. Proposals to use other designs

of hook will be considered.

8.8 Miscellaneous fittings

8.8.1 Where built-in

sheaves are fitted to the derrick boom, the design of the sheave slot

is to be such as to maintain continuity of strength of the boom tube.

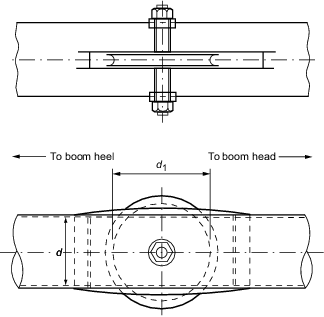

A typical arrangement is shown in Figure 2.8.1 Built-in sheaves but alternative arrangements will be considered.

Figure 2.8.1 Built-in sheaves

8.8.2 Where cargo

runner roller guides are fitted to the derrick boom, they are to be

such that:

-

They are of adequate

strength to resist distortion.

-

Any tendency for the

runner to chafe or jam in or between the rollers and their supports

is minimised.

-

There is adequate means

of lubrication.

8.8.3 Where it is

intended to loop preventer guys over the end of a derrick boom, a

preventer safety catch is to be securely welded or otherwise fixed

to the boom. This safety catch can take the form of the boom end sealing

plate being extended, over part of its circumference, beyond the outer

surface of the boom tube, or alternatively, a separate fitting can

be used. Edges are to be smoothed.

8.9 Deck eyeplates

8.9.1 Sufficient

eyeplates or equivalent attachments are to be provided for the safe

operation of the derrick system and they are to be of suitable design

and safe working load.

8.9.2 Eyeplates

are not to be welded to the upper edge of the sheerstrake nor, in

general, are they to penetrate the strength deck plating. Deck, bulwark

or other plating is to be of sufficient thickness to withstand any

shear forces that may be incurred in way of eyeplates due to asymmetrical

loading of the eyeplate, and such plating is to be stiffened as necessary

to prevent deformation under direct eyeplate loadings. The attachment

of eyeplates and the adequacy of the supporting structure are to be

to the Surveyor’s satisfaction.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|