5.2.1 Twin span

tackles are to include:

-

Two separate span tackles

each attached to the head of the boom, directly or via outriggers,

and operated by independent winches.

-

Two span tackles led

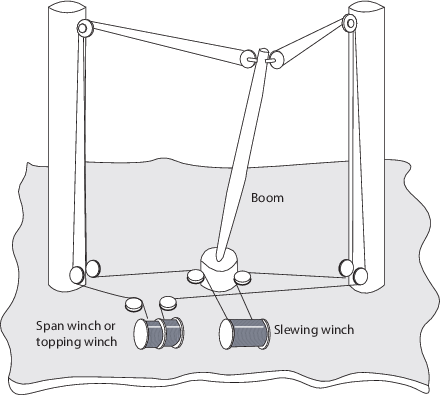

to a topping winch and a slewing winch. The topping winch shortens

equally on both spans and the slewing winch shortens one span while

paying out the other, see

Figure 2.5.1 Span tackles with winch.

The two sections of the tackles may be attached to the cross

trees of a mast or they may be fitted to two separate derrick posts.

Where two separate posts are used, the boom is sometimes arranged

so that it can pass through the vertical position between the posts

and so be available to work hatches both forward and aft of the posts.

Figure 2.5.1 Span tackles with winch

5.2.2 Where twin

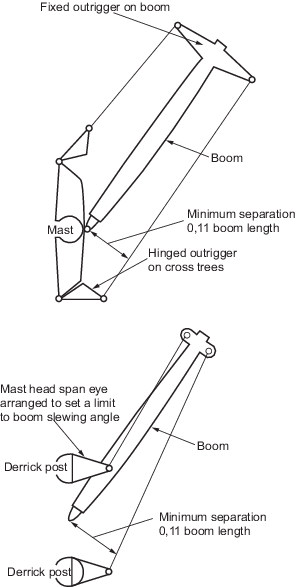

span tackles are fitted, they are to be so arranged that the minimum

distance of the span tackle from the vertical through the boom gooseneck

is not less than one ninth of the boom length. This distance is to

be measured horizontally at right angles to the line of action of

the span tackle, or to the section of the span tackle under consideration, see

Figure 2.5.2 Minimum separation. This minimum

separation can be achieved by one or more of the following means:

-

by limiting the slewing

angle of the boom; or

-

by fitting outriggers

to the boom head; or

-

by fitting hinged or

fixed outriggers, or their equivalent to the derrick posts, mast house

or cross tree; or

-

by a combination of

one or more of the above.

Figure 2.5.2 Minimum separation

5.2.3 Alternatively,

the stability of the system may be demonstrated by calculation or

by model tests.

5.2.4 Where the

slewing angle of the boom is to be restricted, this may be done by

moving the position of the mast head span eyeplate away from the transverse

plane through the gooseneck into a position that will be vertically

above the derrick boom when the boom is in its limiting position.

Alternatively, limit switches may be installed to provide automatic

cut-out of the slewing system. Limiting the slewing angle of the boom

by means of a stop fitted to the boom heel or by allowing the boom

to come up against a shroud or other obstruction cannot normally be

recommended as these methods tend to induce large transverse bending

moments in the boom or to cause local indentations and consequential

failure of the boom tube.

5.2.5 In general,

where twin span tackles are fitted, the strength of each is to be

sufficient to support the boom plus the safe working load in the boom’s

fully outboard position. Where, however, it can be shown that it is

not possible for either span tackle to become slack in service, the

strength of each tackle may be based on the maximum calculated span

tension but is to be taken as not less than two thirds of the total

span tension. Calculations in this respect are to be submitted by

the manufacturer of the derrick crane.

5.2.6 Where the

derrick boom is fitted with a cross-head and the span tackles are

each connected by strops to both ends of the cross-head, then the

required breaking load of each of the strops may be based upon 80

per cent of the maximum load in the span tackle.