Section

6 Derrick booms

6.1 General

6.1.1 The requirements

of this Section are applicable to the following types of tubular derrick

boom:

-

Parallel boom.

A boom which is of uniform diameter and thickness over its full length.

-

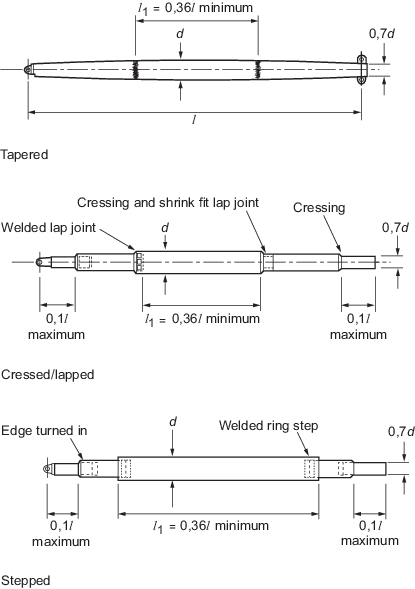

Tapered boom.

A boom which has a mid-section of uniform diameter and thickness welded

to tapered end sections.

-

Stepped boom.

A boom which has a mid-section of uniform diameter and thickness reducing

towards the ends in one or more steps. The change of section may be

obtained by cressed, lapped or stepped construction.

6.1.2 Proportions

for tapered and stepped derricks booms are illustrated in Figure 2.6.1 Forms of booms. Alternative arrangements will,

however, be accepted where it may be shown that the resulting strength

of the boom is adequate. Derricks of unusual design or incorporating

special features will be considered on the general basis of these

requirements.

Figure 2.6.1 Forms of booms

6.1.3 The scantlings

of derrick booms are to be determined on the basis of the axial thrust

and the maximum combination of bending moments applied to the boom,

as derived from the force diagrams and calculations for the derrick

system.

6.1.4 Steel for

derrick booms is to comply with the requirements of Ch 2, 1.5 Materials 1.5.3. Derrick booms intended for a SWL

of 60t or more are to be suitably heat-treated after welding where

considered necessary. For mild steel booms, this may normally be confined

to the region of highly loaded welded connections. The requirements

for higher tensile steel booms will depend on the materials specification.

6.2 Determination of forces

6.2.2 The bending

moments acting on the boom are to be calculated for conditions with

the boom in its lowest and its highest working positions.

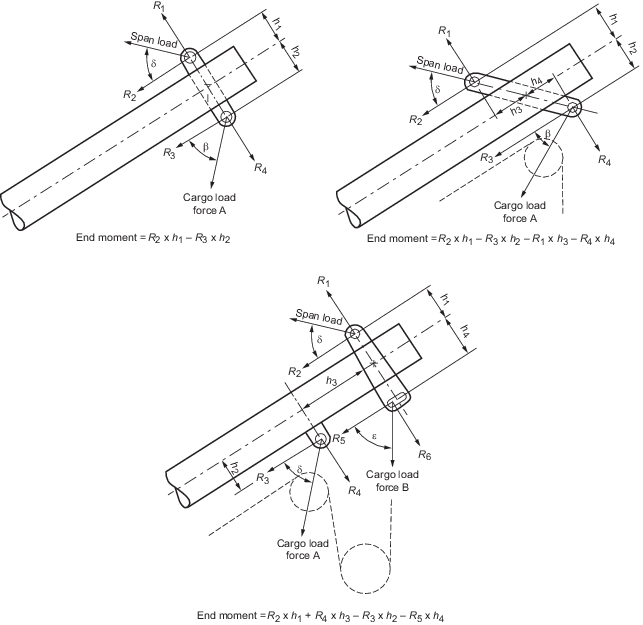

6.2.3 The determination

of vertical end bending moments for typical derrick head arrangements

is illustrated in Figure 2.6.2 Determination of end bending

moment. The

bending moment is to be calculated approximately at the point of intersection

of the axis of the boom with the line joining the points of action

of the cargo and span loads and this may be taken as reducing linearly

from this point to zero at the derrick heel.

Figure 2.6.2 Determination of end bending

moment

6.2.4 For built-in

sheaves, where the sheave pin intersects the axis of the boom, the

value of h is to be taken as zero.

6.2.5 Horizontal

bending moments arising from slewing or preventer guys attached to

the derrick boom head may generally be neglected.

6.2.6 Where the

derrick is fitted with a cross-head or outrigger, consideration is

to be given to the bending and torsional moments which may arise where

the span force is not equally distributed between the span tackles.

In general, the boom is to be designed to resist the bending moments

induced when supported by one span tackle only.

6.3 Boom scantlings

6.3.1 The following

symbols are used in this sub-Section:

|

d

|

= |

external

diameter of the boom in the mid length region, in mm |

|

l |

= |

overall

length of the derrick boom, in mm |

|

l1

|

= |

length

of the parallel part of the boom, in mm |

|

r

|

= |

effective

radius of gyration of the boom, in mm |

|

t

|

= |

wall

thickness of the boom in the mid length region, in mm |

|

A

|

= |

cross-sectional

area of material of the boom in the mid length region, in mm2

|

|

Ae

|

= |

cross-sectional area of material of the boom at the boom head,

in mm2

|

|

= |

moment of inertia of the

boom in the mid length region, in mm4

|

|

= |

moment of inertia of the

boom at the head, in mm4

|

|

Z

|

= |

section

modulus of the boom in the mid length region, in mm3

|

|

Ze

|

= |

section modulus of the boom at the boom head, in mm3.

|

6.3.2 The slenderness

ratio  of the boom is not to exceed 180. It is recommended that

the slenderness ratio be less than 150. of the boom is not to exceed 180. It is recommended that

the slenderness ratio be less than 150.

6.3.3 The wall thickness

of the boom at mid length is to be not less than:

The wall thickness at ends is to be such that the

cross-sectional area of material is not less than 0,75A.

6.3.4 The moment of inertia at the derrick head,  , is to be not less than 0,40 , is to be not less than 0,40 . .

6.3.5 Where the

derrick boom is tapered or stepped, an effective radius of gyration, r, is to be determined from:

where

|

c

|

= |

|

|

u

|

= |

|

Where l1 is greater than 0,5l the value

of c is to be obtained by interpolation between c calculated

for l1 = 0,5l and c = 1 at l1 = 0,8l.

6.3.7 Where significant

horizontal bending moments are likely to be applied to the boom, they

are to be taken into account in the calculation.

6.3.8 The critical

stress, σ, in N/mm2 for the derrick boom is to be determined

from:

6.3.9 The maximum

allowable thrust, T, in the boom is to be determined

from the critical stress and a factor of safety, F, such

that:

where

|

A

x

|

= |

the cross-sectional area of material at the section under

consideration, in mm2

|

|

F |

= |

(i) at mid length but 2,333 ≤ F ≤ 3,85 but 2,333 ≤ F ≤ 3,85 |

| = |

(ii) at ends 1,85 |

| = |

(iii) at intermediate positions:

by parabolic interpolation

between the values at mid-length and at the boom head. |

6.3.10 Where T lies

between 10 and 160 tonnes, the value T for the mid length

region may be determined from:

6.3.11 For the

purpose of making a first approximation to the required scantlings

for a boom, thrust coefficients are tabulated in Table 2.6.1 Boom thrust coefficients (mild

steel σy = 235 N/mm2) and Table 2.6.2 Boom thrust coefficients (high

tensile steel σy = 355 N/mm2) . The maximum allowable thrust, before making allowance

for applied bending moments, is approximately:

Having selected a suitable boom diameter and wall

thickness, the allowable thrust, taking into account the applied bending

moment, is to be determined in accordance with the method given above.

Table 2.6.1 Boom thrust coefficients (mild

steel σy = 235 N/mm2)

| Boom diameter, in

mm

|

Boom length, in metres

|

|

|

| 6,0

|

7,5

|

9,0

|

10,5

|

12,0

|

13,5

|

15,0

|

16,5

|

18,0

|

19,5

|

21,0

|

| 152,4

|

1,36

|

0,94

|

0,68

|

|

|

|

|

|

|

|

|

| 159,0

|

1,55

|

1,06

|

0,77

|

|

|

|

|

|

|

|

|

| 165,1

|

1,73

|

1,18

|

0,86

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 168,3

|

1,83

|

1,25

|

0,91

|

0,70

|

|

|

|

|

|

|

|

| 177,8

|

2,14

|

1,48

|

1,07

|

0,82

|

|

|

|

|

|

|

|

| 193,7

|

2,71

|

1,93

|

1,39

|

1,05

|

0,83

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 219,1

|

3,71

|

2,78

|

2,05

|

1,53

|

1,19

|

0,96

|

|

|

|

|

|

| 244,5

|

4,78

|

3,77

|

2,87

|

2,19

|

1,70

|

1,34

|

1,10

|

|

|

|

|

| 267,0

|

5,75

|

4,72

|

3,72

|

2,88

|

2,25

|

1,79

|

1,45

|

1,20

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 273,0

|

6,02

|

4,99

|

3,96

|

3,09

|

2,42

|

1,93

|

1,56

|

1,29

|

|

|

|

| 298,5

|

7,14

|

6,14

|

5,05

|

4,05

|

3,22

|

2,58

|

2,10

|

1,73

|

1,45

|

|

|

| 323,9

|

8,27

|

7,30

|

6,21

|

5,12

|

4,15

|

3,36

|

2,74

|

2,27

|

1,90

|

1,61

|

1,38

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 355,6

|

9,69

|

8,77

|

7,71

|

6,57

|

5,47

|

4,51

|

3,72

|

3,09

|

2,60

|

2,20

|

1,89

|

| 368,0

|

10,25

|

9,35

|

8,30

|

7,16

|

6,03

|

5,01

|

4,16

|

3,47

|

2,91

|

2,47

|

2,18

|

| 406,4

|

11,99

|

11,14

|

10,15

|

9,03

|

7,85

|

6,71

|

5,67

|

4,79

|

4,05

|

3,45

|

2,96

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 419,0

|

12,57

|

11,73

|

10,76

|

9,65

|

8,47

|

7,30

|

6,22

|

5,27

|

4,48

|

3,82

|

3,29

|

| 457,2

|

14,31

|

13,52

|

12,60

|

11,55

|

10,39

|

9,18

|

7,99

|

6,90

|

5,93

|

5,11

|

4,41

|

| 508,0

|

16,65

|

15,89

|

15,03

|

14,06

|

12,96

|

11,77

|

10,53

|

9,32

|

8,18

|

7,15

|

6,24

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 558,8

|

18,80

|

18,19

|

17,46

|

16,55

|

15,52

|

14,39

|

13,18

|

11,92

|

10,67

|

9,50

|

8,41

|

| 609,6

|

20,75

|

20,17

|

19,53

|

18,81

|

18,02

|

16,99

|

15,83

|

14,59

|

13,32

|

12,06

|

10,85

|

Note Intermediate values may be obtained by interpolation but

extrapolation is not permitted.

|

Table 2.6.2 Boom thrust coefficients (high

tensile steel σy = 355 N/mm2)

| Boom diameter, in

mm

|

Boom length, in metres

|

|

|

| 6,0

|

7,5

|

9,0

|

10,5

|

12,0

|

13,5

|

15,0

|

16,5

|

18,0

|

19,5

|

21,0

|

| 152,4

|

1,56

|

1,01

|

0,72

|

|

|

|

|

|

|

|

|

| 159,0

|

1,80

|

1,15

|

0,82

|

|

|

|

|

|

|

|

|

| 165,1

|

2,04

|

1,30

|

0,92

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 168,3

|

2,17

|

1,39

|

0,98

|

0,73

|

|

|

|

|

|

|

|

| 177,8

|

2,61

|

1,67

|

1,15

|

0,87

|

|

|

|

|

|

|

|

| 193,7

|

3,45

|

2,24

|

1,54

|

1,12

|

0,88

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 219,1

|

5,05

|

3,40

|

2,35

|

1,70

|

1,28

|

1,02

|

|

|

|

|

|

| 244,5

|

6,88

|

4,86

|

3,42

|

2,48

|

1,87

|

1,45

|

1,16

|

|

|

|

|

| 267,0

|

8,60

|

6,39

|

4,61

|

3,37

|

2,53

|

1,97

|

1,57

|

1,28

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 273,0

|

9,07

|

6,83

|

4,96

|

3,64

|

2,74

|

2,12

|

1,69

|

1,38

|

|

|

|

| 298,5

|

11,05

|

8,77

|

6,13

|

4,94

|

3,74

|

2,90

|

2,31

|

1,87

|

1,55

|

|

|

| 323,9

|

13,00

|

10,79

|

8,47

|

6,48

|

4,97

|

3,87

|

3,08

|

2,49

|

2,06

|

1,73

|

1,47

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 355,6

|

15,41

|

13,35

|

10,98

|

8,70

|

6,82

|

5,37

|

4,28

|

3,47

|

2,86

|

2,39

|

2,03

|

| 368,0

|

16,34

|

14,34

|

11,99

|

9,65

|

7,63

|

6,04

|

4,83

|

3,92

|

3,23

|

2,70

|

2,29

|

| 406,4

|

18,96

|

17,39

|

15,16

|

12,73

|

10,41

|

8,42

|

6,83

|

5,58

|

4,61

|

3,85

|

3,26

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 419,0

|

19,73

|

18,28

|

16,20

|

13,77

|

11,39

|

9,29

|

7,57

|

6,21

|

5,14

|

4,30

|

3,64

|

| 457,2

|

22,03

|

20,71

|

19,07

|

16,99

|

14,51

|

12,15

|

10,09

|

8,38

|

6,99

|

5,87

|

4,98

|

| 508,0

|

25,04

|

23,85

|

22,40

|

20,64

|

18,64

|

16,31

|

13,93

|

11,81

|

10,00

|

8,49

|

7,25

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 558,8

|

28,02

|

26,92

|

25,61

|

24,04

|

22,20

|

20,16

|

18,08

|

15,73

|

13,56

|

11,68

|

10,07

|

| 609,6

|

30,97

|

29,95

|

28,74

|

27,32

|

25,64

|

23,74

|

21,68

|

19,59

|

17,55

|

15,35

|

13,40

|

Note Intermediate values may be obtained by interpolation but

extrapolation is not permitted.

|

6.4 Construction details

6.4.1 In way of

head and heel fittings, the wall thickness is to be not less than

5,0 mm or 0,025 x tube diameter at that point, whichever is the greater.

Proposals to fit stiffening in lieu of increased plate thickness to

meet this requirement will be considered.

6.4.2 Where internal

access for welding of the derrick tube is impracticable, means of

obtaining full penetration welds are to be agreed.

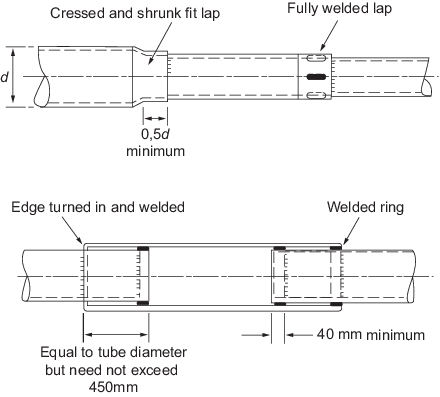

6.4.3 Lap joints

are to be not less than half the boom diameter at that point in extent.

Where the lap is welded, this is to be achieved by slot welds of at

least 75 mm length and twice the boom wall thickness (but not less

than 25 mm) in breadth. Where step joints are adopted, the inner tube

is to extend into the outer tube a distance of not less than the diameter

of the outer tube or 450 mm, whichever is the lesser. The end of the

inner tube is to be stiffened by a steel ring not less than 40 mm

in width and of thickness sufficient to give a sliding fit within

the outer tube, see

Figure 2.6.3 Steps and joints in booms.

Figure 2.6.3 Steps and joints in booms

6.4.4 Welds are

to be sound, uniform and substantially free from defects. The throat

thickness of fillet welds on lapped joints is to be not less than

0,7 times the thickness of the inner plate forming the joint.

6.4.5 Derrick booms

are to be sealed to minimise corrosion to their internal surfaces.

Where practicable, derrick booms are to be painted internally or otherwise

treated to reduce corrosion, after the completion of all welding.

6.4.6 Derrick boom

cross-heads, brackets for cargo runner and span tackle blocks and

similar structures are to be of such a design that the combined stress

does not exceed 0,56σy.

|