Section

5 Loose gear

5.1 Shackles

5.1.1 The safe working

load of any shackle securing a block is to be not less than the SWL

marked on the block, except in the case of single sheave blocks where

the SWL is to be not less than twice that marked on the block.

5.1.2 The safe working

load of any shackle used in another location is to be not less than

the resultant load on the shackle.

5.1.3 Mild steel

shackles are to be normalised after forging and before tapping and

screwing. Higher tensile and alloy steel shackles are to be subjected

to a suitable heat treatment.

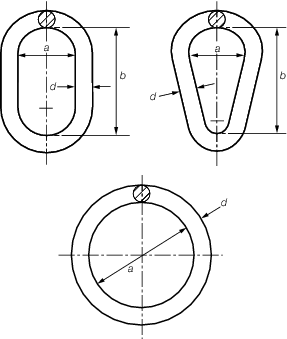

5.1.4 Standard dimensions

of Dee and Bow shackles are given for reference in Table 8.5.1 Dimensions of Dee shackles and Table 8.5.2 Dimensions of Bow shackles for the arrangements illustrated in Figure 8.5.1 Shackles.

Table 8.5.1 Dimensions of Dee shackles

| Safe working load, in tonnes

|

|

|

Mild steel

|

Higher tensile steel

|

|

a

|

b

|

d

1

|

d

2

|

d

1

|

d

2

|

| 1,0

|

20

|

44

|

13

|

15

|

11

|

12

|

| 1,6

|

25

|

55

|

17

|

19

|

13

|

15

|

| 2,0

|

28

|

62

|

19

|

21

|

15

|

17

|

| 2,5

|

31

|

69

|

21

|

24

|

17

|

19

|

| 3,2

|

35

|

78

|

24

|

27

|

19

|

21

|

| 4,0

|

40

|

87

|

26

|

30

|

21

|

23

|

| 5,0

|

44

|

97

|

29

|

33

|

23

|

26

|

| 6,3

|

50

|

109

|

33

|

37

|

26

|

29

|

| 8,0

|

56

|

123

|

37

|

42

|

29

|

33

|

| 10,0

|

63

|

138

|

41

|

47

|

33

|

37

|

| 12,5

|

70

|

154

|

46

|

53

|

36

|

42

|

| 16,0

|

79

|

174

|

52

|

60

|

41

|

47

|

| 20,0

|

89

|

195

|

59

|

67

|

46

|

52

|

| 25,0

|

99

|

218

|

65

|

75

|

51

|

59

|

| 32,0

|

112

|

247

|

74

|

84

|

58

|

66

|

| 40,0

|

125

|

275

|

83

|

94

|

65

|

74

|

| 50,0

|

140

|

308

|

92

|

106

|

72

|

83

|

| 63,0

|

157

|

346

|

104

|

119

|

81

|

93

|

| 80,0

|

177

|

390

|

117

|

134

|

91

|

105

|

Note

2. Higher tensile steel is defined as

steel having a tensile strength not less than 540 N/mm2.

Note

3. Diameter d

3 is to be not less than 2d

2.

|

Table 8.5.2 Dimensions of Bow shackles

| Safe working load,

in tonnes

|

|

|

|

Mild steel

|

Higher tensile steel

|

|

a

|

b

|

2r

|

d

1

|

d

2

|

d

1

|

d

2

|

| 1,0

|

20

|

50

|

34

|

14

|

16

|

12

|

13

|

| 1,6

|

25

|

63

|

43

|

18

|

20

|

15

|

16

|

| 2,0

|

28

|

70

|

48

|

20

|

22

|

17

|

18

|

| 2,5

|

31

|

78

|

53

|

23

|

25

|

18

|

20

|

| 3,2

|

35

|

89

|

60

|

25

|

28

|

21

|

22

|

| 4,0

|

40

|

99

|

67

|

28

|

31

|

23

|

25

|

| 5,0

|

44

|

111

|

75

|

32

|

35

|

26

|

28

|

| 6,3

|

50

|

124

|

84

|

36

|

39

|

29

|

32

|

| 8,0

|

56

|

140

|

95

|

40

|

44

|

33

|

36

|

| 10,0

|

63

|

157

|

106

|

45

|

49

|

36

|

40

|

| 12,5

|

70

|

175

|

119

|

50

|

55

|

41

|

44

|

| 16,0

|

79

|

198

|

135

|

56

|

62

|

46

|

50

|

| 20,0

|

89

|

221

|

150

|

63

|

69

|

51

|

56

|

| 25,0

|

99

|

248

|

168

|

70

|

77

|

57

|

63

|

| 32,0

|

112

|

280

|

190

|

80

|

87

|

65

|

71

|

| 40,0

|

125

|

313

|

213

|

89

|

98

|

72

|

79

|

| 50,0

|

140

|

350

|

248

|

99

|

109

|

81

|

89

|

| 63,0

|

157

|

394

|

267

|

112

|

123

|

91

|

100

|

| 80,0

|

177

|

444

|

301

|

126

|

138

|

102

|

112

|

Note

2. Higher tensile steel is defined as

steel having a tensile strength not less than 540 N/mm2.

Note

3. Diameter d

3 is to be not less than 2d

2.

|

Figure 8.5.1 Shackles

5.1.5 Where the

shackle is not manufactured in accordance with a recognised Standard,

the safe working load may be taken as the lowest of the values derived

from the following formulae:

Side of body:

Crown of body:

Shackle pin:

where all dimensions are in millimetres and are illustrated

in Figure 8.5.1 Shackles. The value of c is

given in Table 8.5.3 Values of c for

shackles.

Table 8.5.3 Values of c for

shackles

Minimum

tensile

strength of steel, in

N/mm2

|

c

|

| Side

|

Crown

|

Pin

|

| 330

|

0,0076

|

0,0082

|

0,0072

|

| 430

|

0,0105

|

0,0113

|

0,0099

|

| 540

|

0,0140

|

0,0151

|

0,0132

|

5.2 Hooks

5.2.1 The safe working

load of a hook is the maximum load that the hook is certified to lift

in service.

5.2.2 Hooks may

be of the C or Liverpool type or of the double armed

Ramshorn type, as indicated in Figure 8.5.2 Hooks.

In general, C type hooks are not to be used for safe

working loads exceeding 25t. Hooks manufactured to recognised

National or International Standards could be accepted based on manufacturers

certification confirming the SWL and proof load as per Ch 12 Testing, Marking and Surveys of the Code. Hooks with a SWL beyond

those given in Table 8.5.4 Dimensions of higher tensile steel

C hooks or Table 8.5.5 Dimensions of higher tensile steel

Ramshorn hooks and/or hooks which do not comply

with a recognised National or International Standard will be specially

considered.

Figure 8.5.2 Hooks

Table 8.5.4 Dimensions of higher tensile steel

C hooks

Safe working load,

in tonnes

|

a

|

b

|

c

|

D

|

H

|

M

|

G

|

| 1,0

|

124

|

78

|

6

|

31

|

26

|

17

|

17

|

| 1,6

|

156

|

98

|

8

|

39

|

33

|

21

|

20

|

| 2,0

|

176

|

110

|

8

|

44

|

37

|

24

|

25

|

| 2,5

|

196

|

123

|

10

|

49

|

41

|

27

|

25

|

| 3,2

|

219

|

138

|

12

|

55

|

46

|

30

|

30

|

| 4,0

|

247

|

156

|

12

|

62

|

52

|

34

|

30

|

| 5,0

|

279

|

176

|

14

|

70

|

59

|

38

|

35

|

| 6,3

|

311

|

196

|

16

|

78

|

66

|

43

|

40

|

| 8,0

|

351

|

221

|

18

|

88

|

74

|

48

|

45

|

| 10,0

|

391

|

246

|

20

|

98

|

82

|

54

|

50

|

| 12,5

|

439

|

276

|

22

|

110

|

92

|

60

|

55

|

| 16,0

|

495

|

311

|

24

|

124

|

104

|

68

|

60

|

| 20,0

|

555

|

349

|

28

|

139

|

117

|

76

|

70

|

| 25,0

|

622

|

392

|

32

|

156

|

131

|

86

|

80

|

Note

1. All dimensions are given in

millimetres and are illustrated in Figure 8.5.2 Hooks.

Note

2. Minimum material tensile strength

σu 540 N/mm2.

|

Table 8.5.5 Dimensions of higher tensile steel

Ramshorn hooks

Safe working load,

in tonnes

|

a

|

b

|

c

|

D

|

H

|

M

|

G

|

| 20

|

238

|

457

|

30

|

121

|

113

|

76

|

89

|

| 25

|

267

|

511

|

33

|

133

|

126

|

86

|

102

|

| 32

|

299

|

567

|

37

|

146

|

143

|

97

|

114

|

| 40

|

329

|

616

|

41

|

162

|

155

|

108

|

127

|

| 50

|

365

|

683

|

46

|

178

|

174

|

117

|

140

|

| 63

|

408

|

745

|

51

|

194

|

195

|

132

|

144

|

| 80

|

452

|

813

|

57

|

213

|

216

|

146

|

152

|

| 100

|

498

|

883

|

64

|

229

|

241

|

162

|

165

|

Note

1. All dimensions are given in

millimetres and are illustrated in Figure 8.5.2 Hooks.

Note

2. Minimum material tensile strength

σu 540 N/mm2.

|

5.2.3 Hooks are to be forged from killed steel with suitable mechanical

properties and heat treatment conditions. Cast hooks are not generally permitted but

special consideration will be given on a case-by-case basis to proposals for cast hooks

that are manufactured in accordance with recognised National or International Standards.

The following information is to be included in the proposal:

- proposed material specification including the applicable

National or International Standard, material grade, chemical composition, and

mechanical properties and heat treatment conditions;

- stress and fatigue calculations supporting the proposal;

and

- proposed surface and volumetric NDE specification, procedure

and acceptance criteria including the technical justification of the criteria,

i.e. casting simulations showing the potential casting defect area and/or

calculated tolerable defect size based on engineering assessment.

Other manufacturing methods, such as additive manufacturing, will require special

consideration.

5.2.4 C

type hooks are to be so designed as to reduce as far as possible the

risk of the hook catching on an obstruction when hoisting and also

the risk of the displacement of the load. An adequate safety catch

is to be fitted across the jaw on all C hooks.

5.2.6 Where the

hook is not manufactured in accordance with a recognised Standard,

the safe working load may be taken as:

where

the dimensions are measured in millimetres and are illustrated in Figure 8.5.2 Hooks. The values of c and kare to be

obtained from Table 8.5.6 Values of c for hooks and Table 8.5.7 Values of k for hooks .

Table 8.5.6 Values of c for hooks

Minimum

tensile

strength of steel, in

N/mm2

|

c

|

| C hooks

|

Ramshorn hooks

|

| 430

|

0,0011

|

0,0016

|

| 540

|

0,0015

|

0,0021

|

Table 8.5.7 Values of k for hooks

|

|

θ

|

| M/H

|

40°

|

30°

|

25°

|

20°

|

15°

|

10°

|

5°

|

0°

|

| 0,55

|

0,48

|

0,75

|

0,85

|

0,92

|

0,98

|

1,03

|

1,06

|

1,10

|

| 0,65

|

0,82

|

1,01

|

1,08

|

1,12

|

1,16

|

1,20

|

1,23

|

1,27

|

| 0,75

|

1,07

|

1,18

|

1,22

|

1,27

|

1,30

|

1,34

|

1,37

|

1,40

|

| 0,85

|

1,16

|

1,30

|

1,33

|

1,36

|

1,40

|

|

|

|

5.2.7 The hook shank is to be such that the direct tensile stress complies with

Table 8.3.3 Allowable stresses in

blocks. Alternatively, the allowable stresses for the

hook shank may be calculated using the approach as defined in Ch 8, 3.5 Hook blocks.

Detailed design is to be such as to minimise stress concentrations and in particular at

the end of the threaded section. Shanks are to be forged from killed steel with suitable

mechanical properties and heat treatment conditions. Cast shanks are not generally

permitted but special consideration will be given on a case-by-case basis to proposals

for cast shanks (reference is made to Ch 8, 5.2 Hooks 5.2.3.(a) to Ch 8, 5.2 Hooks 5.2.3.(c)). Other manufacturing methods, such as

additive manufacturing, will require special consideration.

5.2.8 The safe working

load for Ramshorn hooks, derived in accordance with this Section,

is appropriate for sling legs at an included angle not exceeding 90°.

No increase in SWL is permitted for lesser included angles.

5.2.9 Hooks for

special purposes, such as for lifting freight containers, are to comply

with appropriate recognised National or International Standards.

5.3 Swivels and lifting eyes

5.3.1 The safe working

load of the swivel or lifting eye is to be equal to the maximum load

for which the item is certified.

5.3.2 Lifting eyes

and lug fittings as detailed in this Section may be used in association

with swivel bow pieces or with another item of loose gear such as

a cargo block.

5.3.3 Swivels are

to be fitted with plain bearings or with ball or roller thrust bearings.

5.3.4 Triangular

lifting eyes are to be designed for an included angle between the

sling legs not exceeding 90° and they are not to be used for single

point loading. Ball or roller thrust bearings are to be incorporated

in the swivel arrangements.

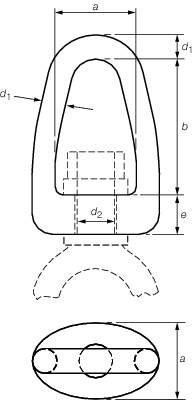

5.3.5 Standard dimensions for mild steel, swivel bow pieces, round, oval and

triangular eyes and lug fittings are given in Table 8.5.8 Dimensions of bow pieces for

swivels to Ch 8, 5.3 Swivels and lifting eyes 5.3.5 for the arrangements illustrated in Figure 8.5.3 Bow piece for swivel to Ch 8, 5.3 Swivels and lifting eyes 5.3.5.

Table 8.5.8 Dimensions of bow pieces for

swivels

Safe working load,

in tonnes

|

a

|

b

|

d

1

|

d

2

|

e

|

| 1,0

|

37

|

64

|

13

|

20

|

20

|

| 1,6

|

46

|

80

|

16

|

25

|

25

|

| 2,0

|

53

|

92

|

18

|

25

|

29

|

| 2,5

|

60

|

104

|

21

|

30

|

32

|

| 3,2

|

67

|

116

|

23

|

30

|

36

|

| 4,0

|

74

|

128

|

26

|

35

|

40

|

| 5,0

|

83

|

144

|

29

|

40

|

45

|

| 6,3

|

92

|

160

|

32

|

40

|

50

|

| 8,0

|

104

|

180

|

36

|

45

|

56

|

| 10,0

|

117

|

204

|

41

|

55

|

64

|

| 12,5

|

131

|

228

|

46

|

60

|

71

|

|

|

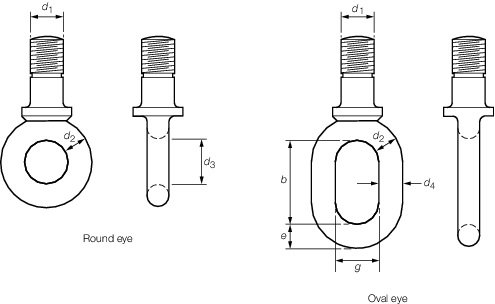

Table 8.5.9 Dimensions of round and oval

eyes

Safe working

load, in

tonnes

|

Shank

|

Round

|

Oval

|

|

d

1

|

d

2

|

d

3

|

b

|

g

|

d

4

|

e

|

| 1,0

|

M18

|

11

|

24

|

48

|

21

|

12

|

14

|

| 1,6

|

M22

|

14

|

30

|

58

|

26

|

16

|

18

|

| 2,0

|

M24

|

16

|

34

|

58

|

26

|

16

|

18

|

| 2,5

|

M27

|

18

|

39

|

72

|

32

|

21

|

23

|

| 3,2

|

M30

|

20

|

44

|

72

|

32

|

21

|

23

|

| 4,0

|

M33

|

22

|

48

|

94

|

40

|

26

|

28

|

| 5,0

|

M36

|

25

|

54

|

94

|

40

|

26

|

28

|

| 6,3

|

M42

|

27

|

60

|

108

|

45

|

29

|

32

|

| 8,0

|

M45

|

31

|

68

|

115

|

49

|

32

|

35

|

| 10,0

|

M52

|

35

|

76

|

125

|

54

|

36

|

39

|

| 12,5

|

M56

|

39

|

86

|

144

|

60

|

41

|

44

|

| 16,0

|

M64

|

|

|

163

|

66

|

46

|

49

|

| 20,0

|

M72 × 6

|

|

|

173

|

72

|

56

|

54

|

| 25,0

|

M76 × 6

|

|

|

192

|

80

|

56

|

59

|

| 32,0

|

M80 × 6

|

|

|

216

|

90

|

60

|

64

|

| 40,0

|

M90 × 6

|

|

|

240

|

100

|

66

|

70

|

| 50,0

|

M100 × 6

|

|

|

264

|

110

|

74

|

78

|

| 63,0

|

M110 × 6

|

|

|

290

|

120

|

84

|

89

|

| 80,0

|

M120 × 6

|

|

|

325

|

135

|

94

|

99

|

| 100,0

|

M130 × 6

|

|

|

360

|

150

|

105

|

111

|

|

|

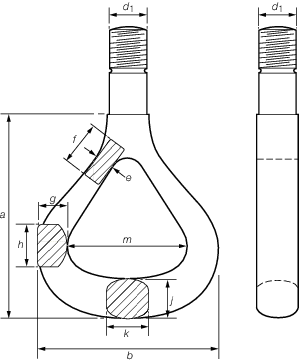

Table 8.5.10 Dimensions of triangular lifting

eyes

Safe working

load, in

tonnes

|

Shank

|

|

Top

|

Side

|

Bottom

|

|

d

1

|

a

|

b

|

e

|

f

|

g

|

h

|

j

|

k

|

| 20

|

M72 x

6

|

475

|

400

|

48

|

95

|

66

|

95

|

94

|

95

|

| 25

|

M76 x

6

|

515

|

445

|

51

|

108

|

72

|

108

|

100

|

108

|

| 32

|

M80 x

6

|

565

|

500

|

55

|

120

|

79

|

120

|

108

|

120

|

| 40

|

M90 x

6

|

630

|

550

|

59

|

133

|

86

|

133

|

117

|

133

|

| 50

|

M100 x

6

|

675

|

600

|

64

|

146

|

94

|

146

|

127

|

146

|

| 63

|

M110 x

6

|

740

|

660

|

71

|

150

|

104

|

150

|

139

|

150

|

| 80

|

M120 x

6

|

815

|

725

|

78

|

158

|

115

|

158

|

153

|

158

|

| 100

|

M130 x

6

|

880

|

795

|

86

|

178

|

127

|

178

|

168

|

178

|

|

|

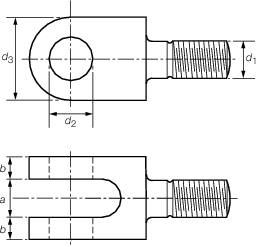

Table 8.5.11 Dimensions of lug fittings

Safe working

load, in

tonnes

|

Shank

|

|

|

d

1

|

a

|

b

|

d

2

|

d

3

|

| 1,0

|

M18

|

19

|

8

|

17

|

35

|

| 1,6

|

M22

|

23

|

11

|

21

|

45

|

| 2,0

|

M24

|

26

|

12

|

23

|

50

|

| 2,5

|

M27

|

29

|

13

|

25

|

55

|

| 3,2

|

M30

|

32

|

14

|

28

|

60

|

| 4,0

|

M33

|

35

|

15

|

31

|

65

|

| 5,0

|

M36

|

39

|

18

|

37

|

75

|

| 6,3

|

M42

|

45

|

20

|

40

|

85

|

| 8,0

|

M45

|

49

|

23

|

46

|

95

|

| 10,0

|

M52

|

58

|

26

|

50

|

110

|

| 12,5

|

M56

|

64

|

28

|

54

|

120

|

| 16,0

|

M64

|

70

|

30

|

62

|

130

|

| 20,0

|

M72 × 6

|

74

|

33

|

70

|

140

|

| 25,0

|

M76 × 6

|

80

|

35

|

74

|

150

|

| 32,0

|

M80 × 6

|

90

|

40

|

82

|

170

|

|

|

Figure 8.5.3 Bow piece for swivel

Figure 8.5.4 Round the oval eyes

Figure 8.5.5 Triangular lifting eye

Figure 8.5.6 Lug fitting

5.3.6 Items whose

dimensions differ from those given in Table 8.5.4 Dimensions of higher tensile steel

C hooks may be designed in accordance with the requirements

given in Table 8.5.12 Swivels and eyes and Table 8.5.14 Form factors, K

.

Table 8.5.12 Swivels and eyes

| Item

|

Safe working load, in tonnes

|

| Swivel bow piece

|

|

| where

b < 2,55d

1, this value is to be multiplied

|

by 0,22

|

| Round eye

|

|

| where

d

3 < 2,55d

2, this value is to be multiplied

|

by 0,22

|

| Oval eye

|

|

| where

b < 2,55d

4, this value is to be multiplied

|

by 0,22

|

| Triangular eye

|

Top

|

0,0069e

f

|

| Side

|

|

| Bottom

|

|

| Lugs

|

0,0125b (d

3 d

2)

|

| Shank

|

c

d

1

2

|

|

|

Table 8.5.13 Values of c for swivel and

eyes

| Item

|

c

|

| Mild steel

|

Higher tensile

steel

|

| Swivel bow piece

|

0,0066

|

0,0088

|

| Round eye

|

0,0176

|

0,0236

|

| Oval eye

|

0,0057

|

0,0076

|

| Shank

|

0,00493

|

0,00625

|

Note Higher tensile steel is defined as steel having a tensile

strength not less than 540 N/mm2.

|

Table 8.5.14 Form factors, K

| Shape of

section

|

|

|

K

|

| Square

|

H = B

|

|

1,00

|

| Circular

|

H = B

|

|

0,66

|

| Rectangular

|

H = 0,75B

|

|

0,95

|

|

H = 0,50B

|

0,90

|

Radius at intrados

and extrados

|

H = 0,90B

|

|

0,80

|

Radius at intrados

only

|

H = 0,70B

|

|

0,75

|

| Ellipse

|

H = 1,25B

|

|

0,66

|

|

H = 0,75B

|

0,65

|

|

H = 0,50B

|

0,64

|

| Semi-circle

|

H = 0,50B

|

|

0,64

|

Note Values for intermediate shapes may be obtained by

interpolation.

|

5.4 Chains, links and rings

5.4.1 The overall

dimensions of the links of chain are to be within the limits in Table 8.5.15 Link chain limits.

Table 8.5.15 Link chain limits

|

|

Length

|

Breadth

|

| Short link

|

4,5d

5,0d

|

3,25d

3,5d

|

| Long link

|

7,0d

9,0d

|

3,25d

3,5d

|

| Symbols

|

|

d =nominal diameter of the chain

|

5.4.2 The certified

safe working load of short or long link chain is not to exceed the

values derived from Table 8.5.16 Safe working load of chain.

Proposals for the use of alloy steel chains will be specially considered.

Table 8.5.16 Safe working load of chain

| Item and material

|

Safe working load, in

tonnes

|

| Short

link

|

|

|

|

Mild steel

|

0,0094d

2

|

|

|

Higher tensile

steel

|

0,0125d

2

|

|

|

ISO Grade 40

|

0,0161d

2

|

|

|

|

|

| Long

link

|

|

|

|

Mild steel

|

0,0063d

2

|

|

|

Higher tensile steel

|

0,00825d

2

|

Note

1. Where d is the nominal diameter

of the chain, in mm.

Note

2. ISO Grade 40 chain is to comply with

the requirements of ISO/R 1834, 1835 and 1836 as appropriate.

|

5.4.3 The safe working

load for links or rings is to be not greater than the value obtained

from Table 8.5.17 Safe working load of links and

rings.

Table 8.5.17 Safe working load of links and

rings

| Item

|

Safe working load, in

tonnes

|

| Swivel bow piece

|

|

| where b < 2,55d,

this value is to be multiplied

|

by 0,22

|

| Rings

|

|

| where a < 2,55d,

this value is to be multiplied

|

by 0,22

|

|

|

Figure 8.5.7 Chain link and ring

Table 8.5.18 Values of c for links and

rings

Minimum tensile

strength of

material, in N/mm2

|

Value

of c

|

| Links

|

Rings

|

| 430

|

0,0053

|

0,0116

|

| 540

|

0,0071

|

0,0155

|

5.5 Miscellaneous items

5.5.1 The triangle

plate for use with a span chain or with union purchase cargo runners

is to be provided with three holes of diameter not less than 1,25

times the diameter of the associated shackle pin. One of the holes

may be extended as a slot to facilitate reeving of the shackle.

5.5.2 The corners

of the plate are to be radiused. The corner radius, measured from

the centre of each hole is to be not less than the diameter of the

hole. The thickness of the plate is to be not less than one half the

width of the jaw of the associated shackle. The radius of the corners

and thickness of the plate are to be such that, when subjected to

the safe working load, the mean tensile stress in the material around

the hole does not exceed (25 + SWL) N/mm2, where the SWL

is measured in tonnes.

5.5.4 Tubular bodies

and end fittings of rigging screws are to be of steel having a tensile

strength not less than 350 N/mm2. The tensile stress in

the body and in the shanks of the end fittings is not to exceed (25

+ SWL) N/mm2, where SWL is the safe working load, in tonnes,

of the rigging screw.

|