Section

3 Blocks

3.1 General

3.1.1 A typical

cargo block is shown diagrammatically in Figure 8.3.1 Typical cargo block with the component items labelled for reference.

Figure 8.3.1 Typical cargo block

3.1.2 The ultimate

strength of the block as an assembled unit is in no case to be less

than five times the resultant load for which the block is designed.

For blocks that are used in situations where the hoisting factor, F

h, for the lifting appliance is greater than 1,6,

a block of larger nominal capacity is to be used such that the normal

test load meets the requirements of Note 4 in Table 12.1.1 Proof loads for loose gear.

3.1.3 The safe working

load of each block is to be appropriate to its particular position

in the rig and is to be not less than the resultant load determined

in accordance with the appropriate Chapter of this Code. Blocks are

not to be used in positions other than those for which they were approved

without first confirming that their safe working load is at least

that required for the proposed location.

3.1.4 The required

safe working load of the block is to be determined by reference to

the resultant load, R, imposed on the block at its particular

position in the rig.

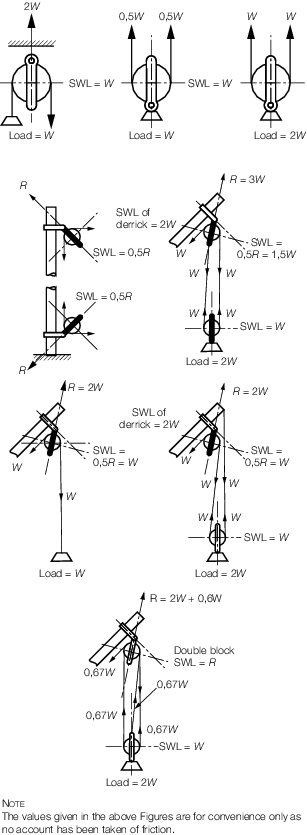

3.1.5 The safe working

load of a single sheave block is assessed on one particular condition

of loading, namely where the block is suspended by its head fitting

and where the cargo load is attached to a wire passing around the

sheave such that the hauling part is parallel to the part to which

the load is attached, see

Figure 8.3.2 Safe working load of single sheave

blocks. The SWL marked on the block is the weight, W in tonnes,

that can safely be lifted by the block, when rigged in this way. The

resultant load, R, on the head fitting (neglecting friction)

is, however, twice the SWL marked on the block, i.e. 2W tonnes.

The block and head fitting must, therefore, be designed to take a

resultant force of 2W tonnes and the proof-load applied

to the head fitting must be based on this resultant force. That is,

the proof-load will be 4W tonnes.

Figure 8.3.2 Safe working load of single sheave

blocks

3.1.6 When the same

block is rigged as a lower cargo block (the load being attached to

the head fitting), the SWL marked on the block is unchanged, but the

resultant force on the head fitting is only W tonnes.

As the block has been designed to withstand a resultant load on the

head fitting of 2W tonnes, the block is safe to support

a cargo load of 2W tonnes.

3.1.7 For single

sheave blocks with beckets, the SWL marked on the block is to be not

less than one half the resultant load on the head fitting.

3.1.8

Figure 8.3.2 Safe working load of single sheave

blocks gives examples of the use of

single sheave blocks and the method of obtaining their SWLs. In all

cases with single sheave blocks, the shackle or link securing the

block is to be marked with an SWL which is twice the SWL marked on

the block.

3.1.9 The safe working

load marked on any multiple sheave block is to correspond to the maximum

resultant load on the head fitting of that block.

3.2 Design loads and stresses

3.2.1 The percentage

of the resultant load on the head fitting which is transmitted by

a sheave is to be taken as not less than the value given in Table 8.3.1 Percentage load transmitted by a

sheave

Table 8.3.1 Percentage load transmitted by a

sheave

| Type of block

|

Number of sheaves

|

Bushed or plain bearings

|

Roller or ball bearings

|

| Without becket

|

With

becket

|

Without

becket

|

With becket

|

| Double

|

2

|

52

|

43

|

51

|

42

|

| Treble

|

3

|

37

|

32

|

35

|

30

|

| Fourfold

|

4

|

29

|

26

|

27

|

24

|

| Fivefold

|

5

|

24

|

22

|

22

|

20

|

| Sixfold

|

6

|

21

|

20

|

19

|

18

|

| Sevenfold

|

7

|

19

|

18

|

17

|

16

|

| Eightfold

|

8

|

17

|

16

|

15

|

14

|

Note Friction allowance taken as 5% for bushed or plain

bearings and 2% for roller or ball bearings.

|

3.2.2 The percentage

of the resultant load on the head fitting which is transmitted to

the side straps and partition plates of the sheave is to be taken

as not less than the value given in Table 8.3.2 Percentage load on side plates or

supporting straps

Table 8.3.2 Percentage load on side plates or

supporting straps

| Type of block

|

Number of sheaves

|

Number of supports

|

Bushed or plain bearings

|

Roller or ball bearings

|

| Inner

|

Outer

|

Partition

|

Side strap

|

Partition

|

Side

strap

|

| Double

|

2

|

1

|

2

|

63

|

20

|

63

|

19

|

| Treble

|

3

|

2

|

2

|

40

|

15

|

38

|

14

|

| Fourfold

|

4

|

3

|

2

|

32

|

12

|

30

|

11

|

| Fivefold

|

5

|

4

|

2

|

26

|

10

|

24

|

9

|

| Sixfold

|

6

|

5

|

2

|

23

|

9

|

21

|

8

|

| Sevenfold

|

7

|

6

|

2

|

21

|

8

|

18

|

7

|

| Eightfold

|

8

|

7

|

2

|

19

|

7

|

16

|

6

|

Note

1. Friction allowance taken as 5% for

bushed or plain bearings and 2% for roller or ball bearings.

Note

2. Where a becket is fitted, the

partitions and straps are to be designed to take account of the loads

imposed on the block.

|

3.2.3 The load on

a becket, where fitted, is to be taken as the maximum load to which

it may be subjected in service.

3.2.4 The stresses

in the component parts of the block are to be determined from the

unfactored loads transmitted from the sheaves and straps and are not

to exceed the values given in Table 8.3.3 Allowable stresses in

blocks

Table 8.3.3 Allowable stresses in

blocks

| Item

|

Allowable stress

|

| Sheave bush to axle

pin

|

Bearing pressure:

|

|

|

|

Single sheave 39

N/mm2

|

|

|

|

Multiple sheaves 31 N/mm2

|

|

|

|

|

| Axle pin to supporting straps and

partitions

|

Bearing

pressure:

|

|

|

|

154 N/mm2

|

|

|

|

|

| Axle pin and through bolts

|

Shear

stress:

|

|

|

|

Mild steel 62 N/mm2

|

|

|

|

Higher tensile steel 77

N/mm2

|

|

|

Bending

stress:

|

|

|

|

0,35σy N/mm2

|

|

|

|

|

| Becket to through bolt

|

Bearing

pressure:

|

|

|

|

39 N/mm2

|

|

|

|

|

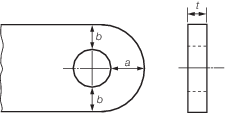

| Straps and beckets,

|

Shear

pullout at end:

|

|

see

Figure 8.3.3 Dimensions of straps

|

|

54 N/mm2 on area 2 x

(a x t)

|

|

|

Tensile

stress at side:

|

|

|

|

Mild steel 77 N/mm2

|

|

|

|

Higher tensile steel 85

N/mm2

|

|

|

|

on area 2 x (b x t)

|

|

|

|

|

| Tensile stress in shanks

|

Mild

steel:

|

| of head fittings (based

|

|

R ≤ 50: σt = 62 N/mm2

|

| on core area)

|

|

50< R ≤ 75: σt =

(9,6R + 32) N/mm2

|

|

|

|

75 < R: σt = 77

N/mm2

|

|

|

Higher

tensile steel:

|

|

|

|

85 N/mm2

|

|

|

|

|

| Collars and nuts of shanks

|

Bearing

stress:

|

|

|

|

10 N/mm2

|

|

|

Minimum

diameter:

|

|

|

|

(1,5d + 3) mm

|

|

Note 1. Higher

tensile steel is defined as steel having a tensile strength not less than

540 N/mm2.

Note 2.

|

R |

= |

resultant load on the head fitting, in tonnes |

|

d |

= |

diameter of shank of head fitting, in mm. |

|

Figure 8.3.3 Dimensions of straps

3.3 Materials and construction

3.3.1 Sheaves may be forged or fabricated from steel plate. In general, castings

in steel or spheroidal graphite iron may be accepted, but grey cast iron or malleable

cast iron is not to be used for sheaves unless specially agreed.

3.3.2 Cast nylon

sheaves may also be used for general cargo handling applications when

the manufacturer indicates satisfactory service experience. However,

attention is drawn to the fact that whilst tests have indicated longer

service life for ropes used with cast nylon sheaves, the ropes do

not exhibit the normal warning signs of broken wires and may break

without external warning due to internal rope fatigue. Consequently,

it is recommended that one steel sheave be included in the reeving

arrangement, in addition to the steel winch drum.

3.3.3 The diameter

of the sheave is to be measured to the base of the rope groove and

is to be not less than what is given in Table 8.3.4 Diameter of sheaves for wire

rope

Table 8.3.4 Diameter of sheaves for wire

rope

| Rope use

|

Sheave diameter, in mm

|

| Running ropes

|

Fixed span ropes

|

| SOLAS LSA systems

|

12d

|

8d

|

Derrick systems

Vehicle

ramps

|

14d

|

10d

|

Cranes

Derrick cranes

Vehicle lifts

Cargo lifts

Mechanical lift docks

Diving systems

(excluding umbilicals)

Other lifting appliances

|

19d

|

10d

|

| Passenger lifts

|

39d

|

10d

|

Note

d is the diameter of the rope.

|

3.3.4 The depth

of the groove in the sheave is to be not less than three quarters

of the rope diameter. A depth equal to the rope diameter is recommended.

The contour at the bottom of the groove is to be circular over an

angle between 120° and 135° with the corresponding opening

angle to be between 60° and 45°. The radius of the groove

is to be as recommended by the rope manufacturer for the size and

application. The usual range of the radius of the groove is between

0,525d and 0,550d of the nominal rope diameter.

In no case shall the radius be smaller than 50 per cent of the actual

rope diameter.

3.3.5 Side and partition plates and straps are to be steel castings or fabricated

from steel plate. The plates are to project beyond the sheaves to provide ample

protection for the rope. Means are to be provided to prevent the rope from jamming

between the sheave and the side or partition plates by minimising the clearance or by

fitting suitable guards.

3.3.6 Snatch blocks

are to be well designed and arrangements are to be provided to ensure

that the block remains closed at all times when it is in use.

3.3.7 Crossheads and beckets may be steel cast, forged or machined from

plate.

3.3.8 Axle pins

are to be positively secured against rotation and lateral movement.

The surface finish of the pin is to be suitable for the type of bearing

to be used.

3.3.9 Provision

is to be made for lubricating all bearings and swivel head fittings

without dismantling the block and for withdrawing the axle pin for

inspection.

3.4 Blocks for fibre ropes

3.4.1 Blocks intended

for use with fibre ropes are not to be fitted with more than three

sheaves and a becket or with four sheaves and no becket.

3.4.2 The diameter

of the sheave measured to the base of the rope groove is generally

to be not less than five times the nominal diameter of the rope. The

depth of the groove is to be not less than one third the diameter

of the rope. The contour at the bottom of the groove is to be of a

radius in accordance with Ch 8, 3.3 Materials and construction 3.3.4 However,

for synthetic ropes, the manufacturer’s recommendations are

to be followed as this may vary with the type of construction and

material used.

3.4.3 Proposals

to use materials other than steel or iron castings for the sheaves

and body of the block will be considered. Bearing pressures and stresses

are to be appropriate to the materials used.

3.5 Hook blocks

3.5.1 Blocks that

are integrated with a hook are known as hook blocks. As an alternative

to the allowable stresses given in Table 8.3.3 Allowable stresses in

blocks, the hook blocks are to comply with all the requirements

below:

-

The hook blocks are to be designed with a safety factor against the

ultimate tensile strength as given below:

For hook blocks with SWL ≤ 25 t, SF = 5,0

and SWL ≥ 160 t, SF = 3,0.

For hook blocks with a SWL between 25 t and 160 t, the safety factor

should be based on the equation below:

where

|

SF

|

= |

minimum safety factor required

The minimum

safety factor (SF) shall be increased by the ratio of

Fh/1,6.

|

|

SWL |

= |

safe working load of hook block, in tonnes. |

The minimum safety factor (SF) shall be increased by the ratio

of Fh/1,6.

-

The hook block is to be designed by applying the hoist factor and duty

factor appropriate for the situation of operation and for the SWL of the hook and

using the allowable stress criteria given in Ch 4, 2.17 Allowable stress – Elastic failure, for cases 1 and 2.

-

The hook block is to be designed for the applicable test load for the

hook and using the allowable stress criteria given in Ch 4, 2.17 Allowable stress – Elastic failure, for case 3.

Large hook blocks, well in excess of 160 t SWL, will be specially

considered.

|

| Copyright 2022 Clasifications Register Group Limited, International Maritime Organization, International Labour Organization or Maritime

and Coastguard Agency. All rights reserved. Clasifications Register Group Limited, its affiliates and subsidiaries and their respective

officers, employees or agents are, individually and collectively, referred to in this clause as 'Clasifications Register'. Clasifications

Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance

on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant

Clasifications Register entity for the provision of this information or advice and in that case any responsibility or liability is

exclusively on the terms and conditions set out in that contract.

|

|

|