7.2.1 Hopper

side structure is typically arranged in self-unloading bulk carriers.

7.2.2 The sloped

hopper structure, clear of the hopper side tank structure, on self-unloading

bulk carriers, is not normally included in the longitudinal strength

calculations. Where it is included in the longitudinal or transverse

strength calculations, the structure is to be specially considered.

7.2.3 Where the

structure is longitudinally framed, transverses are to be arranged

in the hopper side structure in alignment with the double bottom floors

to ensure continuity of transverse strength.

7.2.4 The scantlings

of hopper structures are to be determined to satisfy the following:

-

Deep tank requirements

if applicable.

-

Cargo loading requirements.

The deep tank requirements are given in Rules for Ships, Table 1.9.1 Watertight and deep tank bulkhead

scantlings. The cargo loading

requirements are to be specially considered.

7.2.5 The scantlings

of the sloped hopper bulkhead transverses are to comply with the requirements

of Table 7.9.1 Hopper tank primary

structure of

the Rules for Ships, with a maximum stowage rate of 1,00 m3/tonne.

Alternative scantlings may be considered based on direct calculations.

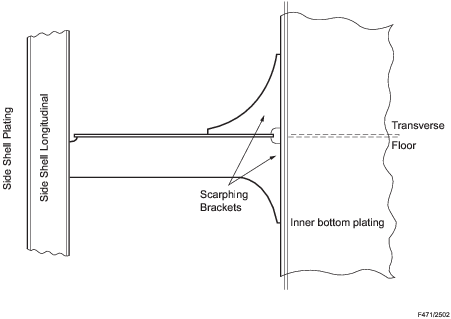

7.2.6 Where the

breadth of the double bottom structure exceeds the breadth of the

hopper tank structure over the breadth of the ship, suitable scarphing

of the inner bottom plating is to be arranged into the wing bottom

structure by horizontal scarphing brackets, fitted in line with the

inner bottom plating at each transverse. These brackets are to be

arranged on each side of the transverse, see

Figure 4.7.1 Scarphing of inner bottom plating into the wing/hopper side structure.

7.2.7 Where the

bottom and side shell structure and the sloped longitudinal bulkhead

are transversely framed, the transverse web frames are to be in line

with the double bottom floors and the single bottom floors integrated

into the double bottom structure, see

Figure 4.8.1 Floor.

Figure 4.7.1 Scarphing of inner bottom plating into the wing/hopper side structure