Section

8 Double bottom structure

8.1 General

8.1.1 The

double bottom is, in general, to be longitudinally framed, but special

consideration will be given to proposals for a transverse framing

system.

8.1.4 The

requirements given in Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition are

to be applied to bulk carriers which satisfy the following criteria:

- Single skin construction, or double skin construction where any

part of the longitudinal bulkhead is located within B/5 or 11,5 m,

whichever is less, inboard from the ship’s side at right angles

to the centreline at the assigned summer load line.

- Length, L, of 150 m or above.

- Intended for the carriage of cargoes having bulk densities of

1,0 tonne/m3 or above.

8.1.5 For

all bulk carriers where bulk cargoes are discharged by grabs the maximum

recommended unladen weight of the grab corresponding to the approved

inner bottom plating thickness is to be calculated using the following

formulae:

where:

|

d

|

= |

|

|

P

|

= |

unladen

grab weight, in tonnes |

|

s

|

= |

spacing

of inner bottom longitudinal, in mm |

|

k

|

= |

higher

tensile steel factor as defined in Pt 4, Ch 7, 1.8 Symbols and definitions 1.8.1

|

|

t

|

= |

thickness

of inner bottom plating, in mm |

The maximum recommended unladen weight of the grab rounded up

to the next tonne above, is to be recorded in the Loading Manual (see

also

Pt 3, Ch 4, 8.2 Loading Manual 8.2.4.(e)),

and does not preclude the use of heavier grabs. It is intended as

an indication to the Builders, Owners and operators of the increased

risk of local damage and the possibility of accelerated diminution

of the plating thickness if grabs heavier than this are used regularly

to discharge cargo.

8.1.6 Detail

design guidelines for stiffeners connecting inner bottom and bottom

longitudinals are shown in the ShipRight FDA Procedure, Structural

Detail Design Guide (SDDG).

Table 7.8.1 Strengthening for heavy cargo

requirements

| Symbols

|

Item

|

Requirement

|

L, l

e, D, T, s, S, k, Z and t as defined in Pt 4, Ch 7, 1.8 Symbols and definitions 1.8.1

|

C

1

|

= |

a factor varying from 1,0 at  to to  at base line of ship at base line of ship |

|

C

|

= |

stowage rate, in m3/tonne, and is defined

as the volume of the hold excluding the volume contained within the

depth of the cargo hatchway divided by the weight of cargo stowed

in the hold. The value is not to be taken greater than 0,865 |

F

B as defined in Pt 3, Ch 4, 5.7 Local reduction factors

R and θ as

defined in Pt 4, Ch 7, 1.8 Symbols and definitions 1.8.1

|

H

|

= |

height from tank top, at position under

consideration, to deck at side amidships, in metres |

|

Y

1

|

= |

distance from to tank top, in metres to tank top, in metres |

|

h

0

|

= |

for plating and stiffeners the vertical distance, in

metres, from the inner bottom to the highest point of the tank

excluding hatchway |

|

b

1

|

= |

the larger horizontal distance, in metres, from the

tank corner at top of tank either side to the point of plate or

stiffener under consideration |

|

(1) Double bottom floors

|

The spacing of floors, generally, is

not to exceed 2,5 m. Scantlings are to comply with the requirements of Pt 4, Ch 1, 8.5 Floors

|

|

(2) Double bottom side girders

|

The spacing of side girders,

generally, is not to exceed 3,7 m. Scantlings are to comply with the

requirements of Pt 4, Ch 1, 8.3 Girders

|

|

(3) Inner bottom plating,

see Note 3

|

The thickness of the inner bottom plating in the holds is to

be not less than required by the greatest of the following:

(a)

or or

(b) t = 0,00455s

mm, or mm, or

(c) Where the double bottom tanks are interconnected with

double skin side tanks or combined hopper and topside tanks the

scantlings are also to satisfy the requirements for deep tanks in Table 1.9.1 Watertight and deep tank bulkhead

scantlings in Chapter 1,

with the load head h

4, = h

0 cos θ + Rb

1 m

(d) In way of ballast holds the scantlings are also to

satisfy the requirements for deep tanks in Table 1.9.1 Watertight and deep tank bulkhead

scantlings in Pt 4, Ch 1 General Cargo Ships, with the load head h

4, in metres, measured to the deck at centre, but see

also

Pt 3, Ch 9, 7 Bottom strengthening for loading and unloading aground if protection against heavy

grabs is desired.

|

|

(4) Inner bottom longitudinals

see Notes 1 and 2

|

The section modulus of inner bottom longitudinals is to be

not less than the greatest of the following:

(a) Z = 85 per cent of the Rule value for bottom

longitudinals as given in Table 1.6.2 Shell framing (longitudinal)

Pt 4, Ch 1 General Cargo Ships , or

(b)  cm3 or cm3 or

(c) Where the double bottom tanks are interconnected with

double skin side tanks or combined hopper and topside tanks Z =

0,0073skh

4

l

e

2 cm3 where h

4 = h

0 cos θ + Rb

1 m. Z is not to be less than the requirements for deep

tanks in Table 1.9.1 Watertight and deep tank bulkhead

scantlings in Pt 4, Ch 1 General Cargo Ships, with the load head h

4, in metres, measured to the highest point of the topside

tank, or side tank, or

(d) In way of ballast holds the section modulus of the

longitudinals is to be not less than required for deep tanks in Table 1.9.1 Watertight and deep tank bulkhead

scantlings in Pt 4, Ch 1 General Cargo Ships, with the load head h

4, in metres, measured to the deck at centre

|

Note

1. If plate girders are fitted

alternatively with built or rolled sections, the section modulus as

given in (4)(b) may be reduced by 10 per cent.

|

Note

2. Consideration will be given to the

fitting of struts in way of double bottom tanks in ships with

homogeneous loading. The arrangement and scantlings are, in general,

to be confirmed by direct calculation.

|

Note

3.

See also

Pt 4, Ch 7, 8.1 General 8.1.5 for the maximum recommended

unladen weight of the grab corresponding to the approved inner bottom

plating thickness.

|

8.2 Carriage of heavy cargoes

8.3 Carriage of heavy cargoes with specified or alternate holds empty

8.4 Ships to be classed '100A1 bulk carrier, strengthened for heavy

cargoes, any hold may be empty, ESP'

8.4.1 For

ships to be classed ‘100A1 bulk carrier, strengthened

for heavy cargoes, any hold may be empty, ESP’, the requirements

of Pt 4, Ch 7, 8.2 Carriage of heavy cargoes 8.2.1 and Pt 4, Ch 7, 8.3 Carriage of heavy cargoes with specified or alternate holds empty 8.3.1 are to be complied with. In

addition the value for C, the stowage rate in m3/tonne,

as defined in Table 7.8.1 Strengthening for heavy cargo

requirements,

is not be taken greater than 0,60 for each hold.

8.5 Ballast ducts

8.5.1 Where

ballast ducts are arranged in lieu of suction and/or filling pipes,

the scantlings will be approved as suitable for a specified equivalent

static head of water. This head must not be exceeded in service, and

details of methods to ensure this are to be submitted. The continuity

of the floors is to be maintained in way of the ducts.

8.6 Structural details in way of double bottom tank and hopper tank

knuckle

8.6.1 In all

dry holds where the double bottom tank and hopper tank knuckle is

of radiused construction and the floor spacing is 2,5 m or greater

brackets shown as in Figure 7.8.1 Intermediate brackets at knuckle are

to be arranged mid-length between floors in way of the intersection.

The brackets are to be attached to the adjacent inner bottom and hopper

longitudinals. The thickness of the brackets is to be in accordance

with Pt 4, Ch 1, 8.5 Floors 8.5.3 but need not

exceed 15 mm. This requirement does not apply where the double bottom

tank and hopper tank knuckle is of welded construction.

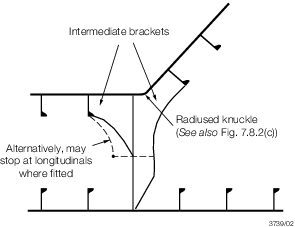

Figure 7.8.1 Intermediate brackets at knuckle

8.6.2 In way

of floodable holds, two intermediate bracket arrangements, as shown

in Figure 7.8.1 Intermediate brackets at knuckle, are to be provided

in all cases where the hopper to double bottom knuckle is radiused

and are, in general, to be located at each frame space. Where the

double bottom tank and hopper tank knuckle is of welded construction,

a single intermediate bracket arrangement, as shown in Figure 7.8.1 Intermediate brackets at knuckle, is to be provided only

when the floor spacing is greater than 2,5 m.

8.6.4 Detail

design guidelines for the connection of hopper tank sloping plating

to inner bottom plating are shown in the ShipRight FDA Procedure,

Structural Detail Design Guide (SDDG).

8.7 Combined double bottom/hopper tank and topside tank

8.7.1 Where

a double bottom/hopper tank is interconnected with a topside tank

the dimensions of the connecting trunks or pipes, and the air/overflow

pipe(s) and the type of closing appliance are to comply with the requirements

of Pt 5, Ch 13, 12 Air, overflow and sounding pipes.

8.8 Allowable hold loading in the flooded condition

8.8.2 The

maximum load which may be carried in each cargo hold in combination

with flood water is to be determined for the most severe homogeneous,

non-homogeneous and packed cargo conditions contained in the Loading

Manual. The maximum density of cargo intended to be carried in each

condition is to be used.

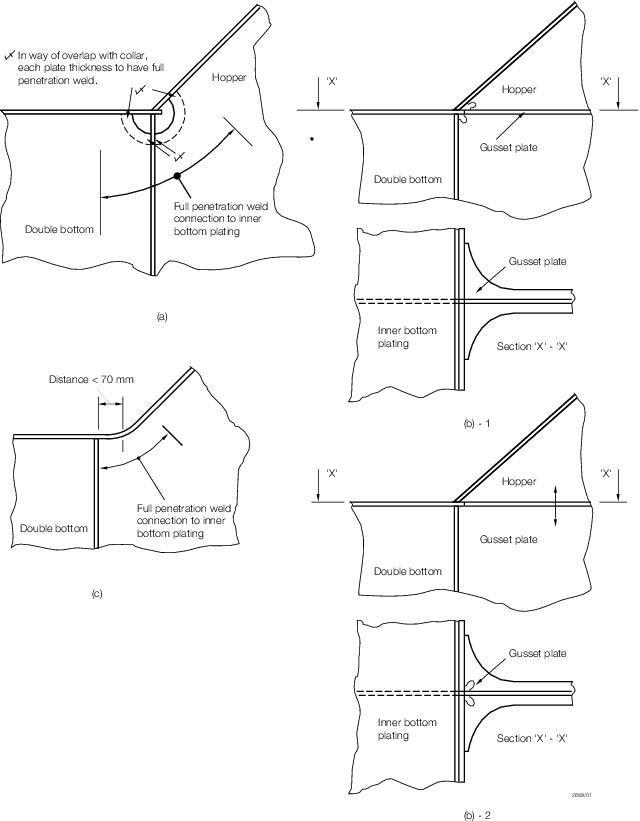

Figure 7.8.2 Connection at intersection of double bottom and hopper

8.8.3 The

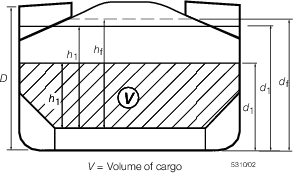

ship is to be assumed immersed to the draught, TF, in metres,

in way of the flooded cargo hold under consideration. The flooding

head, hf, see

Figure 7.8.3 Loading, is to be taken as the distance, in metres, measured

vertically with the ship in the upright position, from the inner bottom

to position, df, in metres, from the baseline given by:

-

In general:

-

d

f = D for the foremost hold

-

d

f = 0,9D for other holds

-

For ships less

than 50 000 tonnes deadweight with Type B freeboard:

-

d

f = 0,95D for the foremost hold

-

d

f = 0,85D for other holds

where

|

D

|

= |

distance,

in metres, from the baseline to the freeboard deck at side amidships. |

Figure 7.8.3 Loading

8.8.4 For

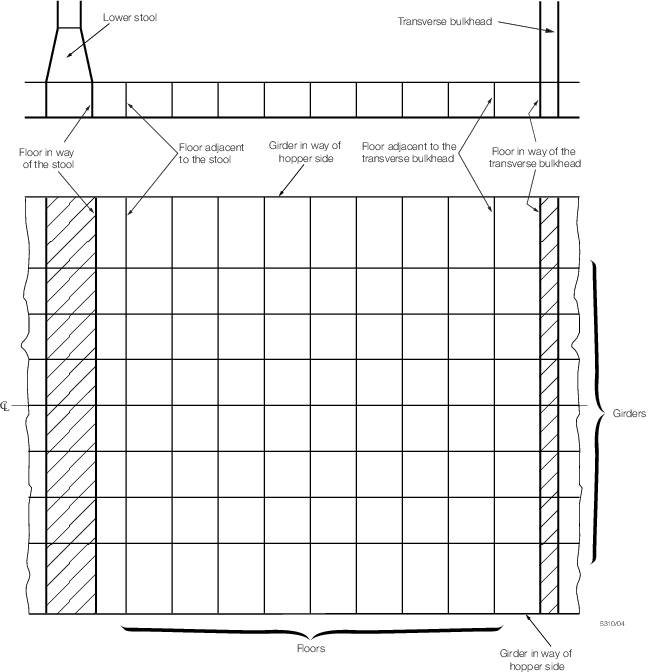

this application, the double bottom is defined as the structure bounded

by the transverse bulkhead lower stools (or bulkhead plating if no

lower stools are fitted) and the hopper sides. The floors and girders

immediately in way of these structures are excluded.

8.8.5 The

determination of shear strength required for the permissible load

assessment in Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.9, is to

be performed using the net plate thickness, tnet, for the

floors and girders:

where

|

t |

= |

as built thickness,

in mm |

|

tc

|

= |

thickness

deduction for corrosion, in mm, generally to be taken as 2,5 mm. |

8.8.6 Shear

capacity of the double bottom is defined as the sum of the shear strengths

for:

-

all the floors

adjacent to both hoppers, less one half the strength of the floors

adjacent to each lower stool (or transverse bulkhead if no lower stool

is fitted), see

Figure 7.8.4 Double bottom structure, and

-

all the girders

adjacent to the lower stools (or transverse bulkheads if no lower

stool is fitted).

Where a girder or floor terminates without direct attachment

to the boundary stool or hopper side girder, its shear capacity is

to include only that for the effectively connected end.

8.8.7 The

shear strengths, S

f1, of floors adjacent to

hoppers, and S

f2, of floors in way of openings

in bays nearest to the hoppers, are as follows:

|

Sf2

|

= |

0,001 Af,h τp/η2 kN |

where

|

A

f

|

= |

net sectional area, in mm2, of floor panel adjacent

to hopper

|

|

A

f,h

|

= |

net sectional area, in mm2, of floor panel in way

of opening in the bay closest to hopper

|

|

η1

|

= |

1,10 |

|

η2

|

= |

1,20

generally |

|

|

= |

1,10 where appropriate

reinforcement is fitted in way of the opening |

|

σ0

|

= |

specified minimum yield stress, in N/mm2

|

|

τp

|

= |

permissible

shear stress, to be taken equal to the lesser of: |

|

τ0

|

= |

|

|

τc

|

= |

|

where

|

s1

|

= |

spacing

of stiffening members, in mm, for the panel under consideration |

|

tnet

|

= |

net

thickness, in mm, of the panel under consideration. |

For floors adjacent to the stools (or bulkhead plating if no lower stools

are fitted), τp may be taken as  N/mm2. N/mm2.

8.8.8 The

shear strengths S

g1, of girders adjacent to

transverse bulkhead lower stools (or transverse bulkheads if no lower

stools are fitted), and S

g2, of girders in

way of the largest openings in bays nearest to the lower stools (or

transverse bulkheads if no lower stools are fitted), are as follows:

|

S

g2

|

= |

0,001 Ag,h τp/η2 kN |

where

|

A

g

|

= |

net sectional area, in mm2, of the girder adjacent

to transverse bulkhead lower stool (or transverse bulkhead, if no

lower stool is fitted)

|

|

A

g,h

|

= |

net sectional area, in mm2, of the girder in way

of the largest openings in the bays closest to the transverse bulkhead

lower stool (or transverse bulkhead if no lower stool is fitted)

|

|

η1

|

= |

1,10 |

|

η2

|

= |

1,15

generally |

|

|

= |

1,10 where appropriate

reinforcement is fitted in way of the opening. |

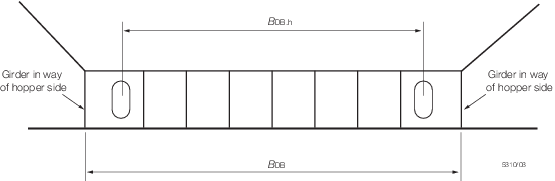

Figure 7.8.4 Double bottom structure

8.8.9 The

permissible cargo hold loading, W

p, is given

by:

where

|

d

f, D

|

= |

as defined in Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.3

|

|

g

|

= |

gravitational

constant, 9,81 m/sec2

|

|

h

f

|

= |

flooding head, in metres, as defined in Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.3

|

|

h

1

|

= |

where Y is in kN/m2 where Y is in kN/m2

|

|

n |

= |

number of floors

between transverse bulkhead lower stools or transverse bulkheads,

if no lower stools are fitted |

|

s

|

= |

spacing,

in metres, of double bottom longitudinals adjacent to hoppers |

|

A

DB,e

|

= |

|

|

A

DB,h

|

= |

|

|

B

DB

|

= |

breadth of double bottom, in metres, between hoppers see

Figure 7.8.5 Double bottom breadth

|

|

B

DB,h

|

= |

distance, in metres, between openings see

Figure 7.8.5 Double bottom breadth

|

|

B

DB,i

|

= |

(B

DB-s) for floors where

shear strength is given by Sf1

|

|

|

= |

B

DB,h for floors where shear strength is given by Sf2

|

|

C

e

|

= |

shear capacity of the double bottom, in kN (tonne- f), as defined

in Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.6, considering for

each floor, the shear strength S

f1, see

Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.7, and for each girder, the

lesser of the shear strengths S

g1 and S

g2, see

Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.8

|

|

C

h

|

= |

shear capacity of the double bottom, in kN (tonne- f), as defined

in Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.6, considering for

each floor, the lesser of the shear strengths S

f1 and S

f2, see

Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.7, and for each girder, the lesser of the shear strengths S

g1 and Sg2, see

Pt 4, Ch 7, 8.8 Allowable hold loading in the flooded condition 8.8.8

|

|

F

c

|

= |

1,1 in general |

|

|

= |

1,05 for steel

mill products |

|

S

i

|

= |

spacing of ith floor, in metres

|

|

T

F

|

= |

d

f - 0,1D

|

|

V

|

= |

volume,

in m3, occupied by cargo at a level h

1

|

|

X

|

= |

the

lesser of X

1 and X

2 for

bulk cargoes and

|

|

X

|

= |

X

1 for steel mill products

|

where

|

X

1

|

= |

where Y is in kN/m2 where Y is in kN/m2

|

|

X

2

|

= |

Y + ρ g (TF - h

f μ) where Y is in kN/m2

|

|

Y

|

= |

the

lesser of Y

1 and Y

2 given

by:

|

|

Y

1

|

= |

|

|

Y

2

|

= |

|

|

μ |

= |

permeability

of cargo but need not exceed 0,3 |

|

|

= |

0,0 for steel mill

products |

|

ρ |

= |

density of

sea water, 1,025 tonne/m3

|

|

ρc

|

= |

cargo

density, in tonne/m3 (bulk density for bulk cargoes and

actual cargo density for steel mill products).

|

Figure 7.8.5 Double bottom breadth

|