Section

9 Consumables for welding aluminium alloys

9.1 General

9.1.2 Approval

will be indicated by the grade shown in Table 11.9.1 Requirements for butt weld

tests. Plate of the corresponding type of aluminium alloy

and of appropriate thickness is to be used for the preparation of

the weld test assemblies, and may be of any temper listed in LR Rules.

Table 11.9.1 Requirements for butt weld

tests

| Consumable Approval Grade

(see Note 1)

|

Base material used for the

test

|

Tensile strength N/mm2

minimum

|

Bend test ratio

|

| LR RA/LR WA

|

5754

|

190

|

3

|

| LR RB/LR WB

|

5086

|

240

|

6

|

| LR RC1/LR WC1

|

5083

|

275

|

6

|

LR RC2/LR WC2

(see Note 2)

|

5383 or 5456

|

290

|

6

|

LR RC3/LR

WC3

(see Note 2)

|

5059

|

330

|

6

|

LR RD/LR

WD

(see Note 4)

|

6005A

|

170

|

6

|

|

|

6061

|

170

|

6

|

|

|

6082

|

170

|

6

|

Note

1. The prefixes ‘R’ and ‘W’ indicate

‘rod’ form (for Gas Tungsten Arc Welding (GTAW)) or ‘wire’ form (for

Gas Metal Arc Welding (GMAW) and GTAW).

|

Note

2. Approval of grade LR RC2/LR WC2

confers approval of 5383, 5456 and 5083 base material grade.

|

Note

3. Approval of grade LR RC3/LR WC3

confers approval of 5059, 5383, 5456 and 5083 base material

grades.

|

Note

4. Approval of grade LR RD/LR WD confers

approval of 6005A, 6061 and 6082 base material grades.

|

9.1.3 The welding

technique will be indicated in the approval grading by a letter:

|

m

|

= |

manual multi-run

welding (GTAW), |

|

S

|

= |

semi-automatic

multi-run welding (GMAW), |

|

M

|

= |

automatic multi-run

welding (GTAW or GMAW), |

|

T

|

= |

automatic two-run

welding (GMAW). |

9.1.4 The compositions

of the shielding gas and the filler/electrode wire are to be reported.

9.1.5 Approval

granted using the multi-run technique for a specific filler/electrode

wire with a gas in one of the groups listed in Table 11.9.2 Shielding gas compositions will extend to any other

gas compositions within that same group, provided that the gas composition

is within the range recommended by the consumable manufacturer, subject

to agreement with LR.

Table 11.9.2 Shielding gas compositions

| Group

|

Gas composition (Vol. %)

(see Note)

|

| Helium

|

Argon

|

| I-1

|

—

|

100

|

| I-2

|

100

|

—

|

| I-3

|

>0

≤33

|

Remainder

|

| I-4

|

>33

≤66

|

Remainder

|

| I-5

|

>66

≤95

|

Remainder

|

| S

|

Special gas

|

Note Gases of other composition (mixed gases) or special purity

may be considered as special gases and will require separate approval

tests.

|

9.1.6 Approval

granted for the two-run technique will be for a specific shielding

gas composition; additional tests may be required if a change in shielding

gas composition is sought.

9.1.7 On completion

of welding, assemblies are to be allowed to cool naturally to ambient

temperature. Welded test assemblies and test specimens are not to

be subjected to any heat treatment after welding except for the alloy

Grades 6005A, 6061 and 6082. These are to be allowed to naturally

age at ambient temperature for a period of 72 hours from the completion

of welding, before testing is carried out. A second solution heat

treatment is not permitted.

9.1.8 All butt

test assemblies are to be subjected to both radiographic and visual

examination and imperfections such as lack of fusion, lack of penetration,

cavities, inclusions, pores and cracks assessed in accordance with

Intermediate Level C of ISO 10042, aided where necessary by dye penetrant

and ultrasonic examination.

9.1.9 Fillet weld

test assemblies and macro-sections are to be visually examined for

imperfections, such as lack of fusion, lack of penetration, cavities,

inclusions, pores and cracks, in accordance with Intermediate Level

C of ISO 10042, aided where necessary by radiographic and dye penetrant

examination.

9.2 Approval tests for manual, semi-automatic and automatic multi-run

techniques

9.2.1 Plate of

the corresponding type of aluminium alloy and of appropriate thickness

is to be used for the preparation of the weld test assemblies.

9.2.2 The welding

parameters are to be within the range recommended by the manufacturer

and are to be reported.

9.3 Deposited metal test assembly

9.3.2 The chemical

composition of the plate used for the assembly is to be compatible

with the weld metal.

9.3.3 The thickness

of the plate used, and the length of the assembly, are to be appropriate

to the welding process. The plate thickness is to be not less than

12 mm.

9.3.4 For the

approval of filler wire/gas and electrode wire/gas combinations for

manual or semi-automatic welding by GTAW or GMAW, one test assembly

is to be welded using any size of wire within the range for which

approval is sought.

9.3.5 For automatic

multi-run approval, one test assembly is to be welded by the respective

process using the recommended diameter of wire.

9.3.6 The weld

metal is to be deposited in multi-run layers in accordance with normal

practice. The direction of deposition of each layer is to alternate

from each end of the plate.

9.3.7 The deposited

weld metal in the assembly is to be analysed and reported including

the contents of all significant elements. The elements reported will

be dependent on the type of aluminium alloy for which approval of

the consumables is requested. The results of the analysis are not

to exceed the limit values specified in the standards or by the manufacturer,

the narrower tolerances being applicable in each case.

9.4 Butt weld test assemblies

9.4.1 Plate of

the corresponding type of aluminium alloy and of an appropriate thickness

is to be used for the preparation of the test assemblies.

9.4.2 In order

to ensure sound and representative welds, it is essential that test

assemblies are cleaned and degreased prior to welding. Assemblies

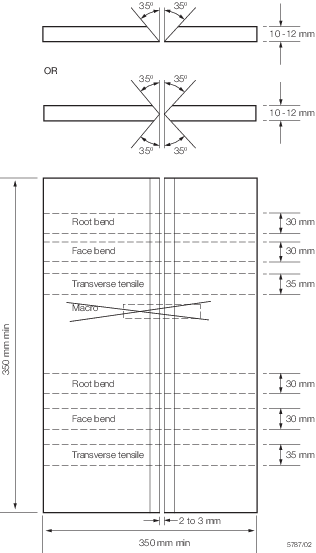

as shown in Figure 11.9.2 Butt weld test assembly (positional, multi-run technique) are to

be prepared for each welding position (downhand, horizontal-vertical,

vertical-upward, vertical-downward, and overhead) for which the consumable

is recommended by the manufacturer; except that consumables satisfying

the requirements for downhand and vertical-upward positions will be

considered as also complying with the requirements for the horizontal-vertical

position. Any wire diameter(s) to be approved may be used.

Figure 11.9.2 Butt weld test assembly (positional, multi-run technique)

9.4.3 One assembly,

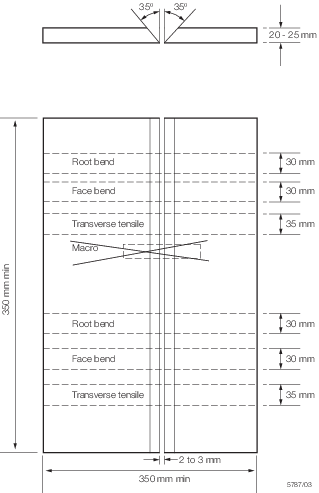

as shown in Figure 11.9.3 Butt weld test assembly (downhand, multi-run technique), is to

be prepared for welding in the downhand position. The assembly is

to be welded using, for the first run, wire of the smallest diameter

recommended by the manufacturer and, for the remaining runs, wire

of the largest diameter to be approved.

Figure 11.9.3 Butt weld test assembly (downhand, multi-run technique)

9.4.4 The welding

conditions are to be in accordance with the recommendations of the

manufacturer and are to be reported in detail.

9.4.5 The welded

assemblies are to be subjected to NDE. Imperfections are to be assessed

in accordance with Ch 11, 9.1 General 9.1.8.

9.4.8 The bend

test specimens are to be bent around a former having a diameter not

more than the number of times the thickness of the test specimen,

as shown in Table 11.9.1 Requirements for butt weld

tests, and

can be considered as complying with the requirements if, after bending

to an angle of not less than 180°, no crack or other open defect

exceeding 3 mm in length can be seen on the outer surface. Flaws appearing

at the corners of a test specimen may be ignored.

9.4.9 In order

to obtain uniform bending of the bend test specimens, it is recommended

that the wrap-around or guided bend test using a roller method is

employed.

9.5 Fillet weld test assembly

9.5.1 When approval

is being sought for both butt and fillet welding, one assembly is

to be prepared and welded in the horizontal-vertical position and

tested in accordance with the appropriate requirements of Ch 11, 3.5 Fillet weld test assemblies, except that the plates are to be

of an aluminium alloy compatible with the weld metal, that no hardness

tests are required and that for automatic multi-run approval only

one fillet weld bead is to be made using the recommended wire diameter.

In this case, the bead size is to be as large as the maximum single

bead size recommended by the manufacturer for fillet welding.

9.5.2 When approval

is being sought for fillet welding only, one assembly is to be prepared

and welded in each position for which approval is sought, and tested

as detailed in Ch 11, 9.5 Fillet weld test assembly 9.5.1.

9.6 Approval tests for two-run technique

9.6.1 Two butt

weld test assemblies are to be prepared using the following plate

thicknesses:

-

one with the maximum

thickness for which approval is requested,

-

one with a thickness

approximately one half to two thirds that of the maximum thickness.

9.7 Butt weld test assemblies (two-run technique)

9.7.2 The wire

diameter, edge preparation, welding current, arc voltage and travel

speed are to be in accordance with the manufacturer's recommendations

and are to be reported.

9.7.3 Each butt

weld is to be made in two runs, one from each side. After completion

of the first run the assembly is to be left in still air until it

has cooled to less than 50°C.

9.7.4 The welded

assemblies are to be subjected to NDE. Imperfections are to be assessed

in accordance with Ch 11, 9.1 General 9.1.8.

9.7.5 The test

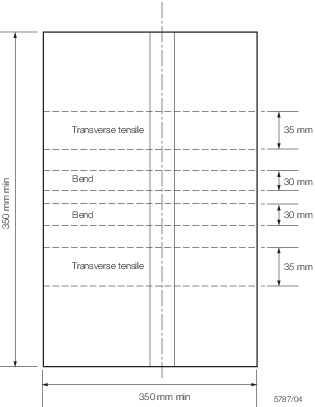

specimens as shown in Figure 11.9.4 Butt weld test assembly (two-run technique) are

to be prepared from each test assembly. The edges of the discards

are to be polished and etched, and must show complete fusion and inter-run

penetration of the welds. Each cut in the assembly is also to be examined

to confirm that complete fusion and penetration have been achieved.

Figure 11.9.4 Butt weld test assembly (two-run technique)

9.8 Annual tests

|